Celotex® & Dow® Polyisocyanurate Insulating Foam Board

Celotex® & Dow® Polyisocyanurate Insulating Foam Board

PIB Foam board properties, housewrap, history, asbestos, facings

- POST a QUESTION or COMMENT about this article topic.

Celotex & Dow polyisocyanurate foam board insulation:

Here we describe the history & asbestos content of certain Celotex® & Dow polyisocyanurate foam board insulation products and we clarify the asbestos content in contemporary polyisocyanurate foam board insulation.

This article gives the history and properties of Celotex® Thermax and other foam board insulating products. Celotex® foam board insulation was later purchased by Dow Chemical who continues to market polyisocyanurate foam insulating board. Page top photo: Celotex® Tuff-R polyisocyanurate foam board insulation.

This article series assists building buyers, owners or inspectors who need to identify foam board insulation and to address possible presence of asbestos in buildings.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Celotex™ Foam Board Insulation: History, Properties, Asbestos Content

Typical Polyisocyanurate insulation R-Values

Polyisocyanurate insulation products have an R-value of about R 7.04 to R 7.20 per inch. Shown in the photo, Celotex Thermax solid foam insulating board with aluminum foil facing.

With a stabilized 3/4" air space on one side of this insulating board its R-value at 1" increases to R10.

1/2" Celotex Thermax was rated at R 3.8, increasing to R 6.4 with the air space we specified above.

4" Celotex Thermax was rated at R 28.8, increasing to R 31.6 with the air space we specified above.

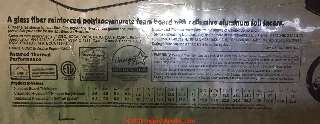

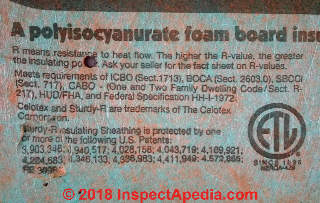

Celotex Thermax Polyisocyanurate Foam Certifications

According to product markings we show below, modern Celotex or more recently Dow polyisocyanurate insulation complies with requirements of ICBO, BOCA, SBCCI, CABO, ICC, HUD/FHA, Federal Specification HH-I-1972/1, Class 2, ASTM C 1289, Type 1, Class 2. The product is described in ICBO Report #3223, SBCCI #9574A, and BOCA #89-45.

In Canada see CCMC Evaluation Report #08433-L. The product shown below also is stamped with logos of NAHB, ETL, Good Housekeeping, and Energy Star.

Readers may also want to review IAQ and health questions discussed at POLYISOCYANURATE FOAM and IAQ.

Watch out: for safety also see FIRE PROTECTION FOR FOAM BOARD INSULATION

Question: was asbestos used in Celotex Thermax foam core insulating board sheathing?

Hi, can you tell me if this ceiling foam contains asbestos? I think it is from 1981. Thank you!

Photo: Celotex® Thermax foam core insulating board, courtesy of reader Jaclyn.

2017/05/05 Jason Wojnowiak said:

I have a picture of some Celotex. [Shown above - Ed. ] [Click to enlarge any image]

Would you know if this has asbestos?

This question was posted originally

Reply: some Celotex Thermax™ laminate insulating board products contained asbestos at least in patent disclosures

Jason and Jaclyn,

Celotex Thermax™ as illustrated by your first photo above was (and is currently as a Dow Thermax™ product) a foil-faced insulating board comprised chiefly of foam insulation, laminated with aluminum foil or possibly kraft paper.

Asbestos appeared in some, probably not all, foam insulating boards made up to the early to mid 1980's, particularly or more likely in fire-resistant products that incorporated a layer of asbestos paper.

In the photos just above and below, provided by Jason [above], the Celotex Thermax board has been cut-open.

Enlarging the photo (enlarged view above) I don't see any sign of an asbestos paper, though of course a closer look in the field would be in order.

[Click to enlarge any image]

Above and then below we show your images of the labeling and text on this Celotex Thermax insulating board. Readers will want to click to enlarge each image to read the details of the Celotex insulation specifications.

This insulation meets several standards and specifications including Energy Star ratings - a rating that well post-dates asbestos-based insulation for in-home use. The company's stamping describes this product as a "Glass fiber reinforced polyisocyanurate foam board with reflective aluminum foil facers."

Question: does this Dow polyisocyanurate foam board contain asbestos?

Is it possible this product contains asbestos? It’s an insulation board in my pull behind camper.

Exact year unknown but between 1975 & 1985. Manufactured by the Dow Chemical Co. some other legible words include: STURDY-R, Dow, nominal board

[Click to enlarge any image]

This Q&A were posted originally

Reply: possibly

From the text, that's a polyisocyanurate foam product. You can see details about that product

at POLYISOCYANURATE FOAM BOARD

Some of those products included asbestos.

If you can attach a photo of the rest of the text on your board and of any patent numbers that would be most helpful.

Also, what are the brand and model of your camper and where is it located (Country, city)?

Patents Establishing Use of Asbestos in Some isocyanurate foam products

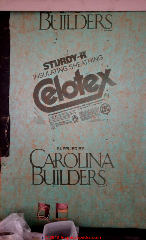

Photo: Celotex Sturdy-R installed in a U.S. home in Gloucester County Virginia between 1996 and 1998, courtesy of reader Sirrena.

Photo: Celotex Sturdy-R installed in a U.S. home in Gloucester County Virginia between 1996 and 1998, courtesy of reader Sirrena.

Foil faced and structural laminate type insulating boards using foam and aluminum or other facings have patents that help identify the product contents.

- Hipchen, Donald E., Michael J. Skowronski, and Joseph R. Hagan. "Structural laminate and method for making same." U.S. Patent 4,118,533, issued October 3, 1978.

Description:

A structural laminate comprises at least one planar facing sheet with a rigid foam attached to one surface of the facing sheet. The rigid foam is characterized in that the major recurring chemical linkage therein is the isocyanurate moiety.

Distributed substantially evenly throughout the foam is a mat of long straight glass fibers arranged in layers substantially parallel to the facing sheet.

The process for producing this structural laminate comprises the steps of contacting a thin, substantially incompressible yet expansible mat of long straight glass fibers with a foam-forming mixture of an organic Polyisocyanurate and a diol, positioning a facing sheet on each face of the mat, and passing the facing sheets having the mat and the foam-forming mixture there between through the nip of two rotating rolls.

Watch out: you are absolutely right to ask if asbestos ever was used in insulating foam boards. Indeed the patent I cite above as well as at least one other patent describe possible use of asbestos in these insulating board products.

Excerpt from Hipchen: The structural laminate of the present invention has at least one but preferably has two facing sheets, one on either side of the foam core. These facing sheets can be constructed of a wide variety of non-flammable materials such as asbestos, glass fibers, or metals.

In the broadest aspects of the invention, any metal can be employed such as copper, brass, iron, steel, or aluminum. Aluminum is the preferred metal because of its ductility and ease with which it can be manufactured into a material of suitable thickness.

Celotex is the original assignee of this patent. That does NOT tell us what Celotex products actually contain when marketed.

Here is a later patent citing asbestos in foam insulating boards:

- Ohashi, Takashi, Toru Okuyama, Akira Suzuki, and Katsuhiko Arai. "Asbestos-metal surfaced urethane modified polyisocyanurate foam." U.S. Patent 4,292,361, issued September 29, 1981.

Description:

A fireproof laminate passing Grade 2 incombustibility according to Japanese Industrial Standard (JIS) A-1321 combustion test is disclosed.

The laminate comprises a urethane modified polyisocyanurate foam as a core material and particular surface materials piled on both sides of the foam through self-adhesion of the foam and has a density of the core material of 0.02-0.04 g/cm3 and a total thickness of not more than 30 mm.

Notice that where fireproof or fire resistant products were being marketed asbestos was more likely to appear.

Excerpt from Ohashi:

This invention relates to novel fireproof laminates using a urethane modified polyisocyanurate foam as a core material.

More particularly, it relates to fireproof laminates having excellent fireproof property and low-smoke development, which are obtained by using the above core material having a defined density and an asbestos paper lined with a metal foil as a surface material for at least one side of the core material and piling them one upon another at a total thickness of a defined range through self-adhesion of the urethane modified polyisocyanurate foam.

In the U.S. in the 1980's Celotex Thermax insulating board was described by the Celotex Company (Jim Walters corporation, Tampa) as an insulating sheathing board with an R-value of 5.4 for a 3/4" thick board: higher R than its competitors at the time as it was compared with foam insulating board sold by Dow, WR Grade and Simplex. (Popular Mechanics, October 1984, advertisement p. 139)

In July 2001 Celotex's rigid foam insulation business was purchased by Dow Chemical which explains why most web searches for Celotex Thermax insulating board will turn up Dow Chemical company listings for Thermax products.

I have not found reports of use of asbestos in foam currently-marketed (2016) insulating foam board products. But laminated foam insulating board products sold in North America up to about the mid 1980's might indeed contain asbestos, particularly in special fire-resistant applications.

At FOAM BOARD INSULATION TYPES you can see more photos of Celotex-branded foam insulating board, principally a polyisocyanurate foam product.

Question: does 1990 Celotex foam insulating board contain asbestos?

[Click to enlarge any image]

We are replacing our siding on a home, built in 1990. It is Celotex Tuff-R. We are concerned with the possibility of Asbestos, but are coming up blank with searching online. Here are pictures of the information we did see on it

. Any information would be really appreciated. - Anonymous by private email 2018/03/22

Reply: in 1990 Celotex foam board would not be expected to include asbestos

A home built in the U.S. (where is yours?) in 1990 would not be expected to have used asbestos-containing materials.

Celotex Tuff-R sold in the 1990's is a polyisocyanurate foam insulation product. That's not asbestos.

Review also this EPA ASBESTOS MATERIALS BAN: CLARIFICATION 1999 [PDF]

Is Housewrap needed Over Celotex Polyisocyanurate Foam Sheathing?

Foil-faced or water-resistant-faced polyiso foam sheathing board approved for use without a weather resistive barrier (WRB) or housewrap will generally be named as having that advantage by its manufacturer - after all it's a selling point. The insulating sheathing board seams, particularly horizontal seams, must be properly taped - sealed to avoid leakage.

But some other polyiso sheathing and insulating board products are NOT listed as approved for use without a WRB.

The home was built between 1996 and 1998 in Gloucester County, Virginia.

Question: is this Celotex Sturdy-R supposed to be directly under siding an no wrapping?

2018/07/23 Sirrena said:

Found this under my siding, is this suppose to be directly under siding an no wrapping?

[Click to enlarge any image]

Reply: without an explicit statement from the manufacturer, use housewrap

Thank you for asking about the need for a housewrap over Celotex Sturdy-R insulating sheathing.

Bottom line: We could find NO company statement from Celotex nor an independent statement that a housewrap or weather barrier can be omitted under Celotex Sturdy-R.

Therefore unless you can find such a statement from Celotex about their Sturdy-R sheathing permitting its use without a housewrap it would make sense to install a housewrap over the walls before installing siding.

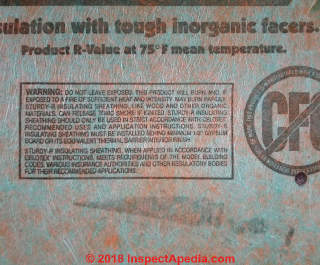

From what I can read on the imprint on your U.S.-sold Celotex Sturdy-R

1. The insulation can not be left exposed - (that would be a fire and smoke hazard) - used indoors it would be covered by drywall. Outdoors by siding - leaving some fire rating questions a bit unclear.

2. The certifications, such as ICBO Chapter 17 STRUCTURAL TESTS and SPECIAL INSPECTIONS - Section 1713 [PDF] marked on this PIB have to do with approving use of the board as structural sheathing (not requiring cross-bracing, for example) and say nothing about the omission of a housewrap weather resistive barrier.

3. The facing looks like a synthetic fabric, but we don't have more of its properties.

4. However I am not arguing that existing siding on the home must be stripped just to add a WRB.

IF all siding was removed for another reason (like re-siding) you should install housewrap.

IF there is evidence of leaks into the building walls those areas deserve further exploration for hidden damage and we'd decide based on diagnosis of the leak if what was needed was a spot-repair or something more extensive.

Product labeling details about this Celotex Sturdy-R U.S. product are provided in photographs from Sirrena.

Research on the Need for Housewrap Over Polyisocyanurate Insulating Sheathing Board PIB

Some brands and types of foam-based insulating wall sheathing are code-approved for use without a weather resistive barrier (WRB), typically closed-cell waterproof styrofoam but also some polyisocyanurate foam sheathings as well as other types of foam-based wall sheathing boards.

Some brands and types of foam-based insulating wall sheathing are code-approved for use without a weather resistive barrier (WRB), typically closed-cell waterproof styrofoam but also some polyisocyanurate foam sheathings as well as other types of foam-based wall sheathing boards.

But other foam based insulating sheathing products are not approved for use without a WRB or housewrap. When companies are not explicit on the requirement for a WRB you may find an answer implied in the fine print in product publications - as I’ll show below.

Otherwise we’re left guessing and having to assume that if a company is silent on the WRB requirement there’s a reason for that that might leave us at, at best, nervous.

Even where an insulating sheathing is rated for use without housewrap, the sheathing seams should be sealed or taped the same way they were to pass (in the U.S.) the AC71 tests. Otherwise your wall may leak, inviting rot and insect damage.

Dow’s polyisocyanurate sheathing (Thermax and Tuff-R) as well as their extruded polystyrene products such as Styrofoam can be used as wall sheathing without requiring a housewrap or WRB.

Celotex, a U.K. company under Saint-Gobain, website www.celotex.co.uk/- has this to say about Celotex Sturdy-R insulating sheathing:

“…”

That’s right. Nothing.

At least a search of the company’s website and a Google search for Celotex Sturdy-R produces not a shred of information. In 2017 Celotex suspended the supply of some other Celotex “PIR” insulation board products due to compliance issues and pending further testing. I can’t say if Celotex Sturdy-R met a similar fate but I can tell you that the suspended products were all polyisocyanurate or PIR foam products. The company is (in July 2018) silent on the Tuff-R product in your photo.

It seems likely that Celotex Sturdy-R, an inorganic-covered polyisocyanurate foam insulating sheathing board, is not supported and not marketed currently.

So if your building is sheathed in this material it would make sense and seem safer to me to install a water-shedding housewrap on the walls before adding siding.

Celotex Sturdy-R PIB & Other PIB Sheathing Installation Instructions & Specifications

- ACCEPTANCE CRITERIA FOR FOAM PLASTIC SHEATHING PANELS USED AS WATER-RESISTIVE BARRIERS AC71 [PDF] (2003) ICC Evaluation Service, Website: www.icc-es.org, tel: 800-423-6587, subsidiary of the ICC International Code Council

- Celotex: Basements, High performance PIR insulation board suspension announcement, retrieved 2018/07/23 original source:

https://www.celotex.co.uk/applications/conversions/basements

(this is not an exterior sheathing product)

Excerpt:

IMPORTANT: On 1 September 2017, Celotex took the precautionary measure to temporarily suspend the supply of Celotex FR5000, Celotex CG5000, Celotex CF5000 and Celotex SL5000 while we investigate the results of recent tests (Parts 6 and 7 of British Standard 476).

In addition, we have recently identified a compliance issue relating to our calculation and testing of the declared lambda value of products in the 4000 and 5000 ranges and the Crown-Bond and Crown-Fix products within the Crown Flat Roofing range. Due to this issue, the suspension of the 5000 range will continue and now includes the FI5000 and GD5000 products.

Materials relating to the 5000 range products are for information only. Please note that all products in the TB4000, GA4000 below 100mm, PL4000 and CW4000 ranges manufactured after 15 December 2017 will be marketed from January as Celotex 3000 with a declared lambda value of 0.023 W/mK.

- Celotex SL 5000 Product Suspension announcement: 5000 Class 0 testing 1 Sept 2017, Celotex Saint-Gobain, UK, Email: info@celotex.co.uk Tel: 01 473 822 093 Retrieved 2018/08/23, original source:

https://www.celotex.co.uk/5000-test

Excerpts:

After careful consideration, we have taken the decision to temporarily suspend supply of some of our 5000 product range in light of a recent and unexpected test result. This relates to Celotex FR5000, Celotex CG5000, Celotex CF5000 and Celotex SL5000 which share the same insulation core and facer. 1

We recognise that this decision could have some practical implications for some of our customers for which we apologise. We hope in the present circumstances which are explained in further detail below, that customers will understand the reasons behind our decision.

A sample of our 5000 product was tested under Parts 6 and 7 of British Standard 476 (“BS 476”) in 2011 and achieved a Class 0 fire rating 2. In April 2017, we sent a sample of RS5000 for independent testing under both Parts 6 and 7 of BS 476.

We were surprised when we learned, in August 2017, that whilst this sample continues to meet the standard for Class 1, the sample did not achieve a Class 0 rating. A sample of this product was used in a full system test for a rainscreen cladding system in 2014, where the system passed. We understand that in August 2017 a sample of the same product passed 3 the DCLG test 5 4 for a full rainscreen cladding system.

All the products in the 5000 range share a core which is made of the same material (Polyisocyanurate or “PIR”). They are marketed under different names according to their intended application (CG5000, FR5000, RS5000 etc.). The sample tested in 2011 was of the product marketed as FR5000. We applied the 2011 test results in relation to Celotex RS5000, Celotex CG5000, Celotex CF5000 and Celotex SL5000.

We do not currently know why the RS5000 sample did not achieve a Class 0 rating in these later tests, given the results from 2011 and we are investigating this. In light of this test result and the desire to act responsibly, we believe it is right to temporarily suspend supply of these 5000 ranges.

We would like to reassure all of our customers that we will provide additional information once we are in a position to do so in respect of both the results and the applications of these 5000 ranges, and following engagement with the relevant third parties.

We appreciate that many uses to which a product from these ranges is put will not require it to have the Class 0 rating. However, in the current circumstances, we believe it is important that there should be clarity as to the applications the product can be used for with its revised rating.

A temporary suspension of supply is the right thing to do in the circumstances and will, we anticipate, also help to achieve that clarity. We shall be making appropriate amendments to our marketing materials. We are recommending to our distributors that they do not sell existing stock in this period and we shall collect any relevant 5000 series products in its original packaging and will credit customers seeking to return such product with the purchase price with no restocking charge, regardless of when the product was supplied to the customer.

- [1] Celotex 1973 Celotex Acoustical Systems catalog, January 1973

- [2] Celotex Home Building Materials, 1947 catalog, lists: Cane fiber products: Celotex sheathing, Celotex insulating lath (board), Celotex interior finish, Celo-Siding, Celo-Rok Gypsum products [may contain asbestos]: Celo-Rok anchor lath, Celo-Rock wallboards, Celo-Rok plasters, and Other Products: Celotex rock wool, Celotex roofing, Celotex hard boards, Celotex Cemesta, Celotex Corporation, Chicago IL

- [3] Celotex Insulating Cane Board, product catalog

- [4] Celotex Building Insulating Materials, 1948 Catalog, listing: Cemesto insulation, Cemesto roof decks, Cemesto exterior wall coverings, Cemesto interior wall coverings [we believe the Cemesto lines refer to cement-asbestos products - ed. ]

- [5] Celotex Sound Conditioning, 1948 Catalog, including perforated asbestos board sheets

- Celotex ceiling products division was purchased by Ceiling Products & Gypsum Wallboard (BPB) of the U.K. beginning in 1999

- Celotex roofing products division was purchased by Certainteed Corporation (Valley Forge PA) beginning in 1999

- [6] Certainteed Ceilings, Adagio fiberglass/mineral fiber composite acoustical ceiling product MSDS, web search 11/22/2011, original source: certainteed.com/resources/Adagio_MSDS_2010.pdf

- [7] "Board of Education for the School District of the City of Detroit v. Celotex, et al., Circuit Court of Wayne County, Michigan, No. 84-429634-ND"

- [11] Celotex [UK] History, Celotex Insulation Specialists, web search 6/30/12, original source: http://www.celotex.co.uk/celotex-history [Copy on file as Celotex_History_UK.pdf ]

- Dow Sturdy-R POLYISOCYANURATE INSULATION PRODUCT INFORMATION [PDF] retrieved 2018/07/23, original source: http://www.fabricationspecialties.com/pdf/sturdy-r.pdf - Dow Building & Construction, Tel -technical information: 1-866-583-BLUE (2583)

Website: www.insulateyourhome.com

Excerpts:

STURDY-R* polyisocyanurate insulation is one of the strongest, most damage-resistant foam sheathings available. STURDY-R insulation consists of a closed-cell polyisocyanurate foam core sandwiched between two highly durable exterior facers.

The proprietary fiberglass facers are bonded with a superior resin to the core for exceptional strength. STURDY-R insulation is designed to resist the rigors of shipping and handling and severe weather conditions. Install STURDY-R insulation as exterior sheathing in residential applications wherever you would use more traditional sheathings. STURDY-R insulation can be used as the substrate for nearly any type of siding.

NOTICE: Changes to the International Residential Code (IRC) require the installation of a weather-resistive barrier within most exterior wall assemblies in residential construction. The following Dow insulated sheathing products qualify as a weather-resistive barrier (WRB) when installed according to the installation instructions developed for “installation of foam sheathing as a weather-resistive barrier”:

STYROFOAM* DURAMATE* Plus, STYROFOAM Residential Sheathing, STYROFOAM Tongue & Groove, STYROFOAM Square Edge, STYROFOAM Residing Board, THERMAX*, TUFF-R*, Super TUFF-R and therefore do not require the use of a building paper or a housewrap as a WRB. When a WRB is not needed, these Dow foam sheathings may be installed according to standard installation instructions for foam sheathing from Dow. Be sure products and installation procedures meet code requirements for your particular location.

[NOTE: the product list above that does NOT require a weather resistive barrier does NOT include the product named Dow Sturdy-R - Ed.] - Dow Sturdy-R POLYISOCYANURATE FOAM SHEATHING SPECIFICATIONS [PDF] retrieved 2018/07/23, original source: http://www.fabricationspecialties.com/pdf/sturdyr.pdf

Excerpts:

These proprietary fiberglass facers are bonded to the foam core with a superior resin, making STURDY-R insulation the best choice when durability is the primary consideration. Recommended for wall sheathing in residential applications, …

NOTICE: Changes to the International Residential Code (IRC) require the installation of a weather-resistive barrier within most exterior wall assemblies in residential construction. The following Dow insulated sheathing products qualify as a weather-resistive barrier (WRB) when installed according to the installation instructions developed for “installation of foam sheathing as a weather-resistive barrier”:

STYROFOAM* DURAMATE* Plus, STYROFOAM Residential Sheathing, STYROFOAM Tongue & Groove, STYROFOAM Square Edge, STYROFOAM Residing Board, THERMAX*, TUFF-R*, and Super TUFF-R and therefore do not require the use of a building paper or a housewrap as a WRB.

When a WRB is not needed, these Dow foam sheathings may be installed according to standard installation instructions for foam sheathing from Dow.

Be sure products and installation procedures meet code requirements for your particular location.

[NOTE: the product list above that does NOT require a weather resistive barrier does NOT include the product named Dow Sturdy-R - Ed.] - Dow STYROFOAM SIS STRUCTURAL INSULATING SHEATHING INSTALLATION AND USAGE GUIDE [PDF] Dow Chemical, Op. Cit.

Excerpt:

Housewrap can be installed over STYROFOAM SIS™ Sheathing; however, it is not required to meet WRB requirements if all joints are taped (visit www.insulateyourhome.com for WEATHERMATE™ Housewrap installation instructions) - Young, Scott, SHEATHING as a HIGH PERFORMANCE BARRIER [PDF], Dow Building & Construction, Blueprints Services, Continuing Education for Code Officials, Vol. 1, August 2006, retrieved 20178.07.23, original source: http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_007b/0901b8038007b3ab.pdf?filepath=styrofoam/pdfs/noreg/179-07370.pdffromPage=GetDoc

Excerpt:

Section R703.2 of the International Residential Code (IRC) discusses the requirements for a weather-resistive barrier. In recent tests, several extruded polystyrene and polyisocyanurate insulated sheathing products qualified as “weather-resistive barriers” for residential construction. - Owens Corning, AIR LEAKAGE and WATER RESISTSANCE ENCLOSURE SOLUTIONS [PDF] Technical Bulletin SS-02 l ASTM E2357, AC71, and AATC Test Method 127 Test results for FOAMULAR 250XPS as an air and water resistive barrier system. www.owenscorning.com/NetworkShare/EIS/Owens-Corning-Enclosure-Solutions-Steel-Stud-Air-Leakage-and-Water-Resistance-ASTM-E2357-E331-Tech-Bulletin.pdf

SS02 Enclosure Solutions that includes a discussion of taping requirements. - Styrofoam SIS Structural Insulated Sheathing Installation and Usage Guide, Dow, 2018/07/23

http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_07a1/0901b803807a15b3.pdf?filepath=styrofoam/pdfs/noreg/179-07585.pd&fromPage=GetDoc

Excerpt:

To ensure a water-resistive barrier, tape all joints with 2 7/8" WEATHERMATE™ Construction Tape (Fasteners in the field of the board do NOT need to be taped to achieve WRB)

Note that this product is styrofoam - that is a different material, it is NOT a polyisocyanurate foam board. - MOISTURE SORPTION of BUILDING MATERIALS, [PDF] PMIA technical bulletin 404, (2016) PIMA, Polyisocyanurate Insulation Manufacturers Association, 529 14th St.NW Suite 750, Washington dDC 20045 USA, Tel: 202-595-2473, Website: www.polyiso.org Email: pima@pima.org - retrieved 2018/07/23 original source https://www.hunterpanels.com/xci-polyiso-wall-products/leed-documents/246-pima-technical-bulletin-404/file

Constituents & Properties of Modern Insulating Foam Board from Dow Chemical

Modern foam insulating board products like the Dow Chemical SuperTuf and Thermax may use fiberglass or other reinforcing fibers however. Shown above: Dow Super Tuff R foil faced insulating foam board at a Home Depot store in Poughkeepsie, NY. This product is rated by the Dow Chemical company as R 3.3 in 1/2" board and R 6.5 in 1" thickness board.

Shown in our second photo above in which some shopper (not me) peeled back part of the foam board facing, you may see that some insulating board products use aluminum foil only on one side, facing the other side with paper or plastic.

The Dow Chemical company notes that the installer can obtain an additional R 2.8 if the insulation is installed with an air space on the reflective side - the side without printing.

Contemporary Thermax branded insulating board or sheathing board, a Dow Chemicals product, is described by DOW as follows:

THERMAX™ Heavy Duty Insulation consists of a glass-fiber-reinforced polyisocyanurate foam core faced with nominal 4 mil embossed white thermoset-coated aluminum on one side and 1.25 mil embossed aluminum on the other. It can be installed exposed to the interior without a thermal barrier.

Dow Chemical currently markets several versions of Thermax™ to meet different needs such as building insulating sheathing, heavier duty insulating sheathing or insulating board for metal buildings, etc.

Here is a copy of one of the current Thermax™ Sheathing products now produced and sold by the Dow Chemical Company and an example Dow Chemical MSDS for a typical Thermax insulating sheathing product.

- Dow Thermax™ Sheathing[PDF] product literature, retrieved 2016/11/13, original source: http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_0940/0901b80380940471.pdf?filepath=styrofoam/pdfs/noreg/179-04015.pdf&fromPage=GetDoc

Excerpt:

THERMAX™ Sheathing is a non-structural, rigid board insulation consisting of a glass-fiber-infused polyisocyanurate foam core laminated between 1.0 mil smooth, reflective aluminum facers on both sides. The glass-fiber reinforcement contributes to improved fire performance and dimensional stability. THERMAX™ Sheathing can be installed exposed to the interior without a thermal barrier. - Thermax 0.75 inch Insulating Sheathing Safety Data Sheet, MSDS, Dow Chemical Company (2015), retrieved 2016/11/13, original source: http://www.dow.com/webapps/msds/ShowPDF.aspx?id=090003e8806f23d2

- 2012: Celotex Corporation continues operations in the U.K. selling foam board (polyisocyanurate foam) insulation.

- Also see theReferences or Citations of this article for more citations

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-05-26 by Kevin - how to dispose of waste foam-core Polyurethane & EPS insulating board waste

I have a bunch of this from a jacuzzi dismantle. How do I get rid of it?

On 2020-05-26 - by (mod) -

Kevin,

Regulations for disposal of waste insulation products including foam board will vary depending on where you live (country, city, province, state etc). But in general, a very small amount, a few scraps can usually be bagged as household waste while a larger amount such as from a demolition are disposed-of as construction debris.

Some foam products are recyclable according to many sources I reviewed for this response, but those offering that comment may not have run into the practical difficulty of actually recycling foam insulation. For example in some Minnesota communities the recycling contractors will accept only a very limited number of types of foam, often only #1 and #2.

Polyurethane is recycled in two primary ways: mechanical recycling, in which the material is reused in its polymer form, and chemical recycling that takes the material back to its various chemical constituents. - American Chemistry

Regulations for disposal of foam insulation board may also vary by the type or kind of foam. Some states have banned all use of some common foam products such as EPS, Expanded Polystyrene. Examples of foam waste disposal or recycling regulations and methods are below,

- American Chemistry Council, "Polyurethane Recycling" [web article] American Chemistry Council 700 Second St., NE Washington, DC 20002 [directions] Phone: (202) 249-7000 retrieved 2020/06/17 original source: https://polyurethane.americanchemistry.com/Polyurethane-Recycling/

[The American Chemistry Council (ACC) represents a diverse set of companies engaged in the business of chemistry. ... Our mission is to deliver value to our members through advocacy, using best-in-class member engagement, political advocacy, communications and scientific research. We are committed to fostering progress in our economy, environment and society.]- ISOPA, RECYCLING & RECOVERY OF POLYURETHANE FOAM FROM CONSTRUCTION AND DEMOLITION [PDF] (2012) European Diisocyanate and Polyol Producers Association Avenue E. van Nieuwenhuyse Laan 4, 1160 Brussels Belgium Tel: +32 2 676 7475 Fax: +32 2 676 7479 Email: main@isopa.org

Excerpt:

EoL PU waste may be reused when panels or boards have been not glued to other materials such as gypsum, concrete or bitumen.

In most cases this option is not available, due to demolition and rebuilding creating a mixture of PU and other organic C&D waste or its separation into a foam mostly containing different materials. In these two cases municipal solid waste incineration is the most eco-efficient route.- Lucas, Donald, Sara M. Petty, Olya Keen, Bob Luedeka, Martin Schlummer, Roland Weber, Morton Barlaz et al. "Methods of responsibly managing end-of-life foams and plastics containing flame retardants: Part I." Environmental engineering science 35, no. 6 (2018): 573-587.

Abstract

Flame retardants (FRs) are added to foams and plastics to comply with flammability standards and test requirements in products for household and industrial uses. When these regulations were implemented, potential health and environmental impacts of FR use were not fully recognized or understood. Extensive research in the past decades reveal that exposure to halogenated FRs, such as those used widely in furniture foam, is associated with and/or causally related to numerous health effects in animals and humans.

While many of the toxic FRs have been eliminated and replaced by other FRs, existing products containing toxic or potentially toxic chemical FRs will remain in use for decades, and new products containing these and similar chemicals will permeate the environment. When such products reach the end of their useful life, proper disposal methods are needed to avoid health and ecological risks.

To minimize continued human and environmental exposures to hazardous FR chemicals from discarded products, waste management technologies and processes must be improved. This review discusses a wide range of issues associated with all aspects of the use and responsible disposal of wastes containing FRs, and identifies basic and applied research needs in the areas of responsible collection, pretreatment, processing, and management of these wastes.- Lucas, Donald, Sara M. Petty, Olya Keen, Bob Luedeka, Martin Schlummer, Roland Weber, Ramin Yazdani et al. "Methods of responsibly managing end-of-life foams and plastics containing flame retardants: Part II." Environmental engineering science 35, no. 6 (2018): 588-602.

Abstract

This is Part II of a review covering the wide range of issues associated with all aspects of the use and responsible disposal of foam and plastic wastes containing toxic or potentially toxic flame retardants. We identify basic and applied research needs in the areas of responsible collection, pretreatment, processing, and management of these wastes.

In Part II, we explore alternative technologies for the management of halogenated flame retardant (HFR) containing wastes, including chemical, mechanical, and thermal processes for recycling, treatment, and disposal.- New York City, FOAM BAN [PDF] City of New York, retrieved 2020/06/17 original source: https://www1.nyc.gov/assets/dsny/site/resources/recycling-and-garbage-laws/collection-setout-laws-for-business/foam-ban

Excerpt:

In accordance with Local Law 142 of 2013, the NYC Department of Sanitation determined that dirty, post-consumer, single-service foam food and beverage containers cannot be recycled in a manner that is economically feasible, environmentally effective, and safe for employees as part of the City’s curbside recycling program.

These items continue to be collected as trash. For more information, please review Local Law 142 of 2013 and the DSNY Determination on the Recyclability of Food-Service Foam.- Yang, Wenqing, Qingyin Dong, Shili Liu, Henghua Xie, Lili Liu, and Jinhui Li. RECYCLING AND DISPOSAL METHODS FOR POLYURETHANE FOAM WASTES [PDF] Procedia Environmental Sciences 16 (2012): 167-175. Retrieved 2020/06/17, original source: https://core.ac.uk/download/pdf/81928123.pdf

Abstract

With the wide application of polyurethane foam materials, a large number of polyurethane foam wastes need to be disposed.

There are mainly three types of disposal technology, landfill, incineration and recycling in the world.

In this paper, through comprehensive comparison, recycling is the most desirable way. Physical recycling method, due to the simple operation and relatively active application, in the short term is an effective means.

Chemical recycling method, due to its higher technical difficulty, is difficult to realize large-scale industrialized production in the short term. And in the future, recovery utilization is the ultimate method.- Zevenhoven, Ron. TREATMENT AND DISPOSAL OF POLYURETHANE WASTES: OPTIONS FOR RECOVERY AND RECYCLING [PDF] (2004) Helsinki University of Technology, 2004. Retrieved 2020/06/17 original source: http://users.abo.fi/rzevenho/tkk-eny-19.pdf

On 2020-02-14 by bucky - avoid trapping moisture in walls

I have a walk out basement 2x4 wall at my home in central N.E. ,so a heating climate, that I want to reinsulate and finish with sheet rock.

The current insulation is old /damaged kraft faced R-11. I was planning on using R-15 fiberglass batts to reinsulate. On the exterior is 1/2 plywood sheathing and cedar clapboards which is in good shape and not in need of replacement.

I was considering adding polyisocyanurate foam board, probably 1/2" , to add additional R value and to reduce thermal bridging through the studs. A few questions. The R-15 fiberglass that I have has a kraft facing on it.

Is it ok to install the DOW SUPER TUFF-R over the kraft facing or does the TUFF-R provide an adequate vapor retarder itself? I would prefer not to remove the kraft facing but don't want to cause a double vapor barrier.

The foam board would be in direct contact with the kraft paper [any less of double vapor barrier issue?] Finally do the seams /penetrations in the foam board need to be taped or sealed ? Suggestions? Thanks

On 2020-02-14 - by (mod) - avoid trapping moisture in walls

I appreciate the concern for trapping moisture in walls where we inadvertently install multiple moisture barriers.

At inspectapedia.com/interiors/Perm-Ratings-for-Materials.php PERM RATINGS of BUILDING MATERIALS we give perm ratings of various building materials.

There you'll see that Insulation, Kraft-Faced has a perm of about 1.0 and foil faced Kraft of about 0.5

1-inch polyisocyanurate foam board has about the same permeability or about 1.0 while thicker foam boards will have less permeability. (2-inch polyisocyanurate foam board has a perm of about 0.5)

If your polyisocyanurate foam board is a product like Dow Tuff-R, that has a permeability of much less, about 0.03. That's because it's a foil-faced foam board.

I would leave the lower-perm kraft faced insulation - (not to mention that as edges are only stapled the permeability of the whole wall surface is far greater than just that of the kraft paper)

Taping the Tuff-R boards is always a nice additional measure to keep moist warm air from pushing moisture into the wall cavity.

For fire safety you're not going to leave foam board exposed anyway; you're going to install drywall over it, right?

But the critical step in avoiding sending moisture into any wall is to

- minimize the penetratrations into the wall

- to seal any penetrations you cannot avoid

since most of the source of moisture that gets into wall cavities is not by penetrating the field of the wall materials but rather air leaks at penetrations.

On 2020-02-15 by bucky

Thanks for the quick reply. Yes I will be installing drywall over the DOW TUFF- R. So just to confirm you suggest leaving the Kraft Facing in place?

As far as stapling goes, is it better to staple the tabs on the face of the studs creating a somewhat tighter barrier or as I think your suggesting to staple the tabs on the inside edge?

Or might it be better to only staple the tabs on the inside edge only at the very top of the wall to prevent the batt from potentially sagging over time but leave the rest unstapled /unfolded to prevent air space. Or is that slight air space created on the edges by stapling the tabs inside a potential benefit by increasing R-value against the foam board? ??

On 2020-02-15 - by (mod) -

Stapling to the stud face, overlapping adjacent facings is standard and is what I usually do. Stapling to the inside edge is much more work, risks tearing the kraft with the stapler, but adds an air space and might slightly improve overall R-value.

We do not normally staple the bat at the top and bottom of the stud Bay. Stapling at the sides is the proper way to support the insulation batt and it will certainly prevent any sagging if you staple up and down both sides. I've never found sagging fiberglass Staples in place be a problem.

On 2020-02-15 by Bucky

thanks for your help

On 2018-07-23 by Sirrena

Found this under my siding, is this suppose to be directly under siding an no wrapping?

IMAGE LOST by older version of Clark Van Oyen’s useful Comments code - now fixed. Please re-post the image if you can. Sorry. Mod.

I also want to clarify that the two square holes were pre-exsisting when we removed the siding. I also want to thank you for your help, it was greatly appreciated.

IMAGE LOST by older version of Clark Van Oyen’s useful Comments code - now fixed. Please re-post the image if you can. Sorry. Mod.

On 2018-07-24 - by (mod) -

Sirrena

I'd add that the holes cut into the sheathing, if it was immediately behind siding without a housewrap, invite leaks into the wall.

'

Also I note what looks like felt or building paper around the window in the bottom (or left if the photo is upright) of your image shows that detailing around the windows is incomplete - adding risks of leaks into the wall in such locations. Where such spots are revealed by siding removal it's worth a close inspection for water entry, leaks, rot, insect attack - that might need further steps - before adding housewrap and restoring siding.

On 2018-07-23 by Sirena

the home was built between 1996 and 1998 in Gloucester County, Virginia.

IMAGE LOST by older version of Clark Van Oyen’s useful Comments code - now fixed. Please re-post the image if you can. Sorry. Mod.

On 2018-07-23 - by (mod) -

From what I can read on the imprint on your U.S.-sold Celotex Sturdy-R

To have space to provide a detailed answer including research I have repeated your question and our reply in the article above.

1. The insulation can not be left exposed - (that would be a fire and smoke hazard) - used indoors it's covered by drywall, outdoors by exterior siding.

2. The certifications, such as ICBO Section 1713 have to do with approving use of the board as structural sheathing (not requiring cross-bracing, for example) and say nothing about the omission of a housewrap weather resistive barrier.

3. The facing looks like a synthetic fabric, but we don't have more of its properties.

4. However I am not arguing that existing siding on the home must be stripped just to add a WRB.

IF all siding was removed for another reason (like re-siding) you should install housewrap.

IF there is evidence of leaks into the building walls those areas deserve further exploration for hidden damage and we'd decide based on diagnosis of the leak if what was needed was a spot-repair or something more extensive.

The detailed photos are helpful, I have added them to the article to invite further comment from other readers.

Please take a look, and send along additional photos and information I ask for there - if you can.

Editor

Question: Do some Celotex® ceiling tiles contain asbestos?

We bought a house that was built in the 50's - it has what I THINK is a Celotex ceiling (or some copy of Celotex) - it's in horrible shape and needs to be taken down - what are your thoughts on it containing asbestos, considering the age? - Saundra

Reply: Yes. In the article above we provide a list of Celotex® fiber-board, ceiling covering, acoustical, sound control & other products that may contain asbestos

Saundra,

Keep in mind that Celotex and other insulating board panel and ceiling tile and panel manufacturers produced a range of products, many of which may contain asbestos, but others made of organic fibers, wood fibers, cane fibers may not contain asbestos.

The Celotex ceiling products division was sold to Certainteed Saint-Gobain beginning in 1999. Certainteed continues to produce and sell both fiberglass and mineral-fiber ceiling products, as well as gypsum based ceiling materials. You may find look-alike products by searching that company's product catalogs.

Modern ceiling products do not contain asbestos.

Using Certainteed as an example, [www.certainteed.com] you can obtain an MSDS (Material Data Safety Sheet) for each of the company's products. Common modern ceiling product ingredients include fibrous glass wool, urea formaldehyde resin, and fiberboard products contain slag wool, starch, cellulose [wood fibers], perlite, crystalline silica, and clay. It's worth noting that even modern building products can present health hazards if they are not handled properly.

For example crystalline silica can cause nose, throat, and lung irritation. [6]

If you are not sure of the product brand and age of the ceiling covering, and are not sure whether or not the product contains asbestos, and if we accept as a "given" that your ceiling covering needs to be removed, there are two reasonable ways to proceed:

- Dampen and remove a small sample of the material (about 1 sq.in.) and send it to a certified asbestos testing lab for identification. Typically the test is inexpensive (less than $100), and the result can close any argument about how to proceed with handling the material.

or

- Assume based on age (for example an acoustical ceiling installed before 1973) that the material may contain asbestos and handle its removal accordingly. To be safe, I'd assume that an acoustical ceiling product made before 1981 contains asbestos, and I'd keep in mind that a ceiling installed even in the few years after 1981 could have made use of old stock made before that date.

Follow recommended procedures for wetting, dust control, bagging, personal protection of workers, and disposal. See ASBESTOS REMOVAL, WETTING GUIDELINES.

For most projects and certainly any area as large as a basement ceiling, we recommend hiring a professional company who knows proper demolition and cleaning procedures. An amateur job of asbestos removal, even if it is legally permitted in your area, risks not only health hazards to the workers, but also the creation of a still more costly cleanup job if proper dust and debris control procedures are not followed.To elaborate your question about asbestos-containing products made by Celotex, the company produced a wide range of fiber-based insulation products such as insulating boards and panels and the company continues to produce modern (non-asbestos-containing) versions of those products today.

At FIBERBOARD SHEATHING, Celotex Homasote & Other we include identifying photographs of some Celotex products.

Question: is it safe to clean Celotex board ceilings in our 1935 church?

Is it safe to clean the ceiling of our Church which has celotex boards and believed to have been installed in 1935? - Len Taylor 10/25/12

Reply:

"Safe" depends - the greatest hazard of cleaning a church ceiling is falling off of a ladder. I don't know what kind of cleaning you are talking about, nor what the concern was; But if you avoid aggressive cleaning that damages the material and creates fibers and dust, you should be ok. Celotex fiberboard insulating panels are not an asbestos product - as you can read at SHEATHING, FIBERBOARD

Question: Asbestos in paper HVAC duct wrap

(May 24, 2015) Anonymous said:

What kind of asbestos was used in paper duct wrap in 1908? Was it chrysotile or another form?

Reply:

Please see ASBESTOS PAPER DUCT INSULATION and also see ASBESTOS DUCTS, HVAC - where we cite research on these materials as well as advice on action plans when they're present in a building.

Question: asbestos in Louisiana-Made Ceiling Tiles from 1971?

(Aug 5, 2015) Melanie said:

I need to find out if our ceiling tile contains asbestos. They were manufactured in Marrero, LA in 1971. Numbers found on the box are: 32286 and 270. Can you help? Thank you.

Reply:

Check with Louisiana Acoustical & Drywall Materials is a subsidiary of GMS, 2601 Samford Ave Shreveport, LA 71103 318-459-2944 louisianamaterials.com

See details at ASBESTOS CEILING TILES

Question: need to know if Celotex mineral wool contains asbestos

(Nov 9, 2015) homeowner said:

I need to know if Celotex mineral wool contains asbestos.

This is loose fiber insulation in walls and attic found in home that was renovated with this product in 1959. There is a package that says "Celotex Mineral Wool,fire retardant" in the home.

Reply:

Mineral wool is not an asbestos product. Only if yours was cross-contaminated might we expect to find asbestos in it.

See inspectapedia.com/insulation/Rock_Wool_Insulation.php for details.

Question: 1940's Celotex ceiling tile board asbestos?

(Jan 30, 2016) jane said:

We are rehabbing a house that has Celotex tile board as the ceiling in the upstairs. I'm guessing it was put up in the early 1940's. I have a box with a label and wondered if you could tell me if they contain asbestos. Type No.91 Joint Es Size 1/2x16"x16" sq. Ft.88.89 No.Pieces 50

Reply:

Jane, please use the page bottom CONTACT link to send some pictures of the box labeling on all sides and the tile bith sides and we can comment further as well as researching further.

Question: Realtor says ceiling panels are made of sugar cane not asbestos

(May 28, 2016) tclark said:

I'm looking at purchasing a home built in 1929. All of the walls and ceilings are finished with panels that our realtor is calling Celotex panels.

She states that they are a by product of sugar cane which would not be surprising as the town in which it is located produces sugar cane. I see on this site that this product does not contain asbestos.

How can I be sure that this is actually the product that was used vs one of the others that do contain asbestos? Also, how is this material repaired when needed? I can post photos if it will help

Reply:

TClark

Your realtor may or may not be correct as cellulose-based (wood-based) insulating board panels were made from a variety of products, not just sugar cane.

But as you may read in the article above, she is right that some Celotex was made of that material. Or perhaps she was sugar coating the sale for you. Did you ask the realtor how she knew for sure what the material was, who made it and what were its constituents and how she knew that it was made at a plant that was not at risk of asbestos cross-contamination.

To know for certain if a product contains no asbestos, with no more data than your question, you'd have to have a sample tested by a certified asbestos test lab (about $50.) though it may not be justified in this case.

You can use our page top or page bottom CONTACT link to send me photos. The Comment Box software does not yet let readers post photos, though many of us have asked for that feature.

...

Continue reading at POLYISOCYANURATE FOAM and IAQ possible health hazards?, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CELOTEX ASBESTOS PRODUCTS includes a history of key dates for the Celotex corporation.

- CELOTEX DRYWALL ASBESTOS

- FOAM BOARD INSULATION TYPES

- ICYNENE FOAM SPRAY INSULATION

- POLYISOCYANURATE FOAM and IAQ

- POLYISOCYANURATE FOAM BOARD

- POLYISOCYANURATE FOAM BELOW SLABS

- RIGID FOAM USE INDOORS

Suggested citation for this web page

POLYISOCYANURATE FOAM BOARD at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [16] Steven Mlynarek, Morton Corn, Charles Blake, "Asbestos Exposure of Building Maintenance Personnel", Regulatory Toxicology and Pharmacology, 23, 213–224 (1996) ARTICLE NO. 0045, http://library.certh.gr/libfiles/PDF/GEN-PAPYR-4810-ASBESTOS-by-MLYNAREK

-in-RTAP-VOL-23-ISS-3-PP-213-224-Y-1996.pdf - [17] National Institute of Occupational Safety and Health (NIOSH) (1989). In NIOSH Manual of Analytical Methods (P. M. Eller, Ed.), Method 7400. NIOSH, Washington, DC.

- [18] U.S. Environmental Protection Agency (USEPA—Green Book) (1990). In Managing Asbestos in Place: A Building Owners Guide to Operations and Maintenance Programs for Asbestos-Containing

- [19] U.S. Department of Labor, Occupational Safety and Health Administration (USDOL) (1994). In Occupational Exposure to Asbestos: Final Rule, FR Vol. 59, No. 153:40964–41162. Materials, Report 2OT-2003. USEPA, Washington, DC.

- [20] U.S. Department of Labor, Occupational Safety and Health Administration

(USDOL) (1986). In Occupational Exposure to Asbestos: Tremolite, Anthophyllite, and Actinolite: Final Rule, FR Vol. 51, No. 119:22631–22644. - [21] U.S. Environmental Protection Agency (USEPA) (1990). In Environmental Asbestos Assessment Manual, Superfund Method for the Determination of Asbestos in Ambient Air, Part 2, Technical Background Document, Report EPA/540/2-90/005 b. USEPA, Washington, DC

- [22] Ceiling - Frequently Asked Questions, Armstrong Corporation, web search 6/30/12, original source: https://www.armstrongflooring.com/resclgam/na/ceilings/en/us/article17697.html

- [23] BPB America Inc., 5301 West Cypress St., Suite 300, Tampa, FL 33607, Tel: 866-427-2872 E-mail: crc@bpb-na.com Web: www.bpb-na.com. Acoustic ceiling tile & accessories.

- [24] Affa Tile Company No. 1116/8, Poonamalee High Road, Opposite Hotel Shan Royal, Koyambedu Chennai, Tamil Nadu - 600 107, India, E-Mail: affatiles@gmail.com website: http://www.affatiles.com Tel:044-24757498, 044 - 24757497

- [26] "Directive 2003/18/EC of the European Parliament and of the Council of 27 March 2003 amending Council Directive 83/477/EEC on the protection of workers from the risks related to exposure to asbestos at work". Publications Office of the European Union. 27 March 2003 Web search 6/30/12, original source: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=CELEX:32003L0018:EN:NOT,

- [27] H. M. Murray, testimony before the Departmental Committee on Compensation for Industrial Diseases "Minutes of Evidence, Appendices and Index", 1907. p. 127

- [28] D. Auribault, "Note sur l'Hygiène et la Sécurité des Ouvriers dans les Filatures et Tissages d'Amianté (On hygiene and security of the workers in the spinning and weaving of asbestos)" in Le Bulletin de l'Inspection du Travail, 1906, pp 120–132.

- [29] Wikipedia entry on Asbestos and various citations from that article, web search 6/30/12, original source: en.wikipedia.org "Asbestos"

- EPA ASBESTOS MATERIALS BAN: CLARIFICATION 1999

- EPA Guidance for Controlling Asbestos-Containing Materials in buildings, NIAST, National Institute on Abatement Sciences & Technology, [republishing EPA public documents] 1985 ed., Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.