Light-Weight Concrete Wall Insulation for buildings

Light-Weight Concrete Wall Insulation for buildings

- POST a QUESTION or COMMENT about how light weight concrete insulation

This article discusses the use of light-weight concrete building insulation (such as Thermal Krete™ in building wall-stud cavities.

Accompanying text reprinted/adapted/excerpted with permission from Solar Age Magazine - editor Steven Bliss.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Properties of Light-Weight Concrete Building Insulation

Quoting energy.gov's definition of cementious foam insulation material

Quoting energy.gov's definition of cementious foam insulation material

Cementitious insulation material is a cement-based foam used as sprayed-foam or foamed-in-placed insulation.

One type of cementitious spray foam insulation known as aircrete® contains magnesium silicate and has an initial consistency similar to shaving cream.

Air krete® is pumped into closed cavities.

Cementitious foam costs about as much as polyurethane foam, is nontoxic and nonflammable, and is made from minerals (like magnesium oxide) extracted from seawater. - 2023/09/08 original source energy.gov/energysaver/insulation-materials#cementitious

Below on this page we provide a table of R-values and other properties for lightweight concrete, cementious insulation, including Air krete® and other products.

In a related approach to using light-weight concrete, "lightweight concrete construction" often uses pre-fabricated lightweight concrete panels, lightweight concrete blocks, or light-weight concrete placed on-site.

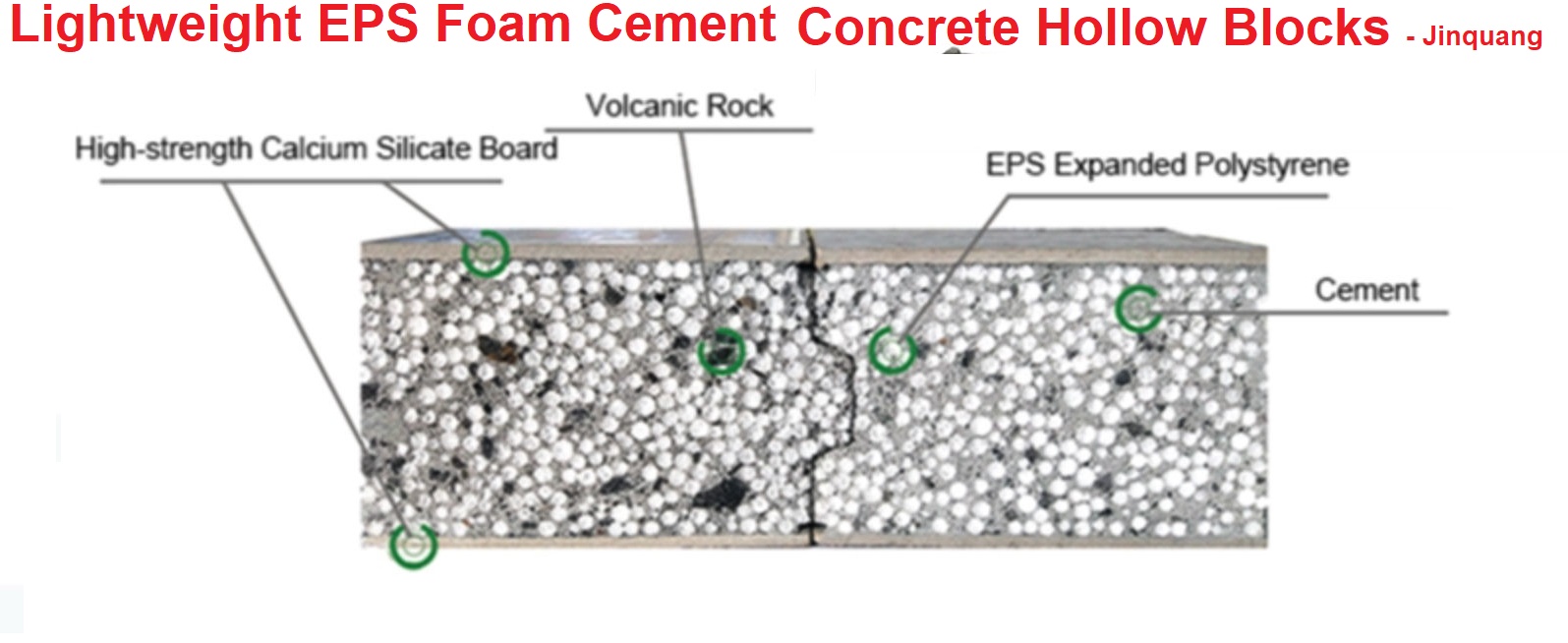

Polystyrene concrete block, panels, or EPS (expanded polystyrene) foam concrete is a composite material made of a mix of any of several versions of Portland cement to which additional ingredients are added to produce lightweight concrete.

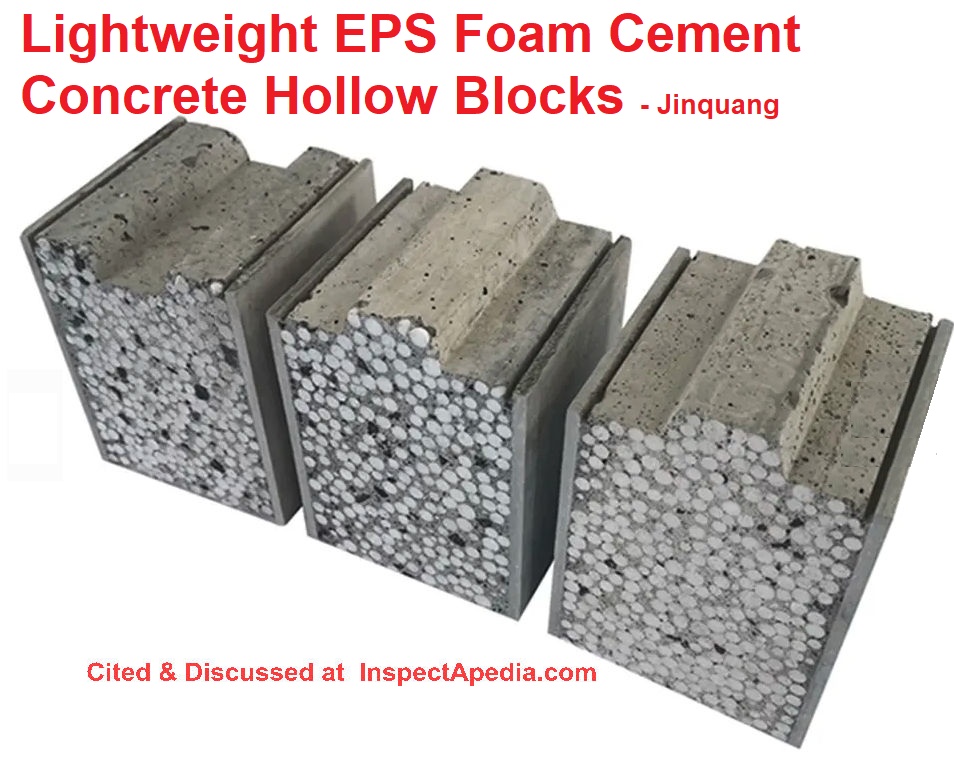

Above at the top of this page and just above this text are examples cross-section of a lightweight panel distributed by Jinquang and building construction using those panels, cited in more detail below.

The additional lightweight concrete ingredients typically include silica aggregate (silica sand or fly ash often collected as waste from an electrical power generating utility), EPS / polystyrene granules or similar porous filler, concrete modifying agents (a set accelerator or a plasticizer and in some applications, a concrete foaming agent).

Depending on how these ingredients are combined and in what ratios, concrete products of varying density between D150 to D600 are produced for use as a construction material that has greater insulating R-value than traditional concrete or other solid masonry materials.

In our illustrations just below, polystyrene and concrete have been mixed to form concrete construction panels. In other forms the same material may be used to produce individual concrete blocks or CMUs (Concrete Masonry Units).

Both lightweight concrete block and panels may also be manufactured as lightweight cellular concrete shown below, without the concrete "skin" on the lightweigh concrete blocks shown above. (Illustration below adapted from Alibaba's oniste store, September 2023).

Above: lightweight concrete blocks with a concrete "skin".

Below: lightweight cellular concrete blocks - no skin.

- Jinquang Lightweight EPS FOAM CEMENT CONCRETE Hollow Blocks & Lightweight Insulating Concrete Panels - source: alibaba in 2023, produced by Golden Power Building Material Technology Co., Ltd. in Fujian, China and sold in the Phillipines and othe rlocations.

This is an "eps styrofoam sandwich board" using as raw material rock wool, cellulose fiber, quartz sand and portland cement.

Opinion: using light-weight concrete insulation such as Thermal Krete™ in Walls?

This question-and-answer series on lightweight concrete use paraphrases, quotes-from, updates, and comments an original article from Solar Age Magazine and written by Steven Bliss.

This question-and-answer series on lightweight concrete use paraphrases, quotes-from, updates, and comments an original article from Solar Age Magazine and written by Steven Bliss.

Question: What is the Effectiveness of using Cementious Foam Insulation in a Super-Insulated Building Using Double-Wall Construction

What do you think of using light-weight concrete insulation such as Thermal Krete™ as an insulating filler for double 2x4 walls?

Would use of lightweight concrete insulation eliminate the need for a moisture and/or air barrier? - Lane Felker, Jefferson MD

Answer:

Thermal Krete™ (discussed at "Product Update," Solar Age 11/83) is a special magnesite concrete that is pumped into wall cavities in a way that traps air bubbles. It insulates to about R-4 per inch.

Can I install light-weight concrete insulation in a super-insulated double-framed building wall?

According to Thermal Krete™ company president Fred Moer, the thickest cavity in which Thermal Krete™ has been installed is a 2x8 framed (rafter depth nominal size 2" x 8" is actually about 1.5" x 7.5") cathedral ceiling. The company should be consulted regarding lightweight concrete installations in cavities beyond 8-inches thick.

The weight of the material (4-5 pounds per cubic foot) could bow out drywall in a double-framed super-insulated building wall design, or the water from the larger volume of concrete could damage building materials.

See our discussion of super-insulated buildings and double-framed wall studs

at INSULATION CHOICES & PROPERTIES.

Do I need a moisture barrier on a light-weight concrete-insulated wall?

Thermal Krete is fairly permeable to water vapor, so a vapor retarder is recommended.

Do I need an air barrier on a light-weight concrete-insulated wall?

As for air leakage, you should be primarily concerned about places where the concrete does not penetrate, e.g. under soleplates (sill plates), through ceiling penetrations, and out through interior partitions. Thermal Krete's manufacturer, Omni Tech Energy Products, welcomes inquiries.

Specifications for Wall Insulation for Superinsulated Homes

As we discuss at INSULATION CHOICES , for superinsulated buildings the article concludes that a double-stud wall with fiberglass batts provided the greatest insulating value per dollar. However other insulating products may be a better choice depending on other construction details and space limitations.

Our photograph (left) shows an insulation retrofit in a crawl space where icynene foam spray was applied to the crawl space wall and between the floor joists overhead.

The article also discusses the question of air permeability of fiberglass insulation and its impact on the actual insulating value of the material compared with impermeable (to air) foam insulation products.

The impact of moisture on the R-value of fiberglass insulation is also discussed (it's low). Fiberglass both gains and loses moisture more rapidly than some other insulating products.

Foil-faced polyisocyanurate insulation

such as the Thermax® and Hi-R® brands are discussed - these products give the highest R-value per inch among insulating materials. Also, as we tested in the 1970's, the use of these products combined with a 3/4" air space permits achieving an additional R 2.7 provided that the foil is clean and the gap or air space is uniform.

Structural Properties of Air-Entrained or "Foamed in Place" Concrete Insulation such as AirKrete® Insulation

The question-and-answer article below paraphrases, quotes-from, updates, and comments an original article from Solar Age Magazine and written by Steven Bliss.

Will insulation retrofit using AirKrete Cause Problems with the Structure of the Building?

I am renovating a 100-year-old house that is a mix of timber frame and stick frame construction, with massive diagonals at the corners. At some point a second story was added, and later a balloon-framed addition.

I had planned to cut fiberglass batts to fit the stud spaces but I'm beginning to think that foam-in-place insulation might save enough on labor to offset the higher material cost.

Would a foam such as Air Krete® cause any problems with the structural integrity of the house due to pressure during application, or will it actually strengthen the framework? - Stephen Ortado, contractor, White Stone, VA.

Answer:

AirKrete® is a cementious foam with the consistency of shaving cream and an R-value of about 4 per inch. (See our table just below, and see INSULATION R-VALUES & PROPERTIES to compare various insulation products.).

When foamed in place, AirKrete® (and similar products such as discussed above), has finished expanding and flows around obstacles. So it places little stress on the structure of a building. After it sets, the foam is dimensionally stable, and there is no shrinkage problem.

Because it has no structural strength, AirKrete or other cementious foam insulating products will not make the building frame any stiffer.

A vapor barrier is recommended according to the product specifications and also according to Jay Savery, an East Coast manufacturer of the material, because the foam is very porous to moisture flow.

The table below summarizes the properties of various types of cementious building insulation and was excerpted from the more extensive table of insulation properties found

| Insulation Material 9 |

R-Value1 | Density2 | Perm3 | Absorption4 | Flame Spread 5 |

Smoke6 | Toxicity7 | Aging Effects |

| Concrete, uninsulated | 0.0818 - 0.312517 | Typical residential weight concrete 8" wall = R 2.5 | ||||||

| Concrete-insulated | 0.85 - 1.2 | 12-88 | Varies | Varies | 0 | 0 | 0 | Insulated forms available |

| Concrete, air entrained | 3.9021 | |||||||

Air Krete®26

|

3.9026 | 2.07 lbs/cuFt26 | 0.1457 in/sec coefficient, or 0.3407 in/sec flow rate at 68 degF H2O27 | 026 | 026 | no | Cementious foam insulation, fireproof, non-toxic, non-shrinking, also used for acoustical sound proofing; MgO cement (Magnesium Oxide); 6 mil poly vapor barrier required |

Notes to the Table of Building Insulation Properties

- R-Value is expressed as rate of heat loss per hour per square foot per inch of thickness of material per deg. F - see "R" value definition at Definitions of R K U values

- Insulation density is expressed in pounds per cubic foot of material

- Permeability is expressed as the water vapor permeability of the material per inch of thickness. These numbers are most useful to compare one insulating material to another.

- Absorption is the tendency of the insulation to absorb water in percent by weight. This is important for assessing the risk of mold in some materials

- Flame Spread is a measure of fire resistance of the material. Use these numbers to compare one insulating material to another.

- Smoke is a measure of fire safety - that is, the relative amount of smoke produced if the insulation is exposed to flame or combustion

- Toxicity is a measure of fire safety - that is, toxins given off if the insulation is exposed to flame or combustion.

- Polystyrene may be in molded or extruded forms and like some other plastic or foam insulations may be in open or closed cell form. (Closed cell foams are more moisture resistant). Polystyrene also is referred to as molded expanded polystyrene (MEPS), expanded polystyrene (EPS), and extruded polystyrene (XPS) - the most common foam board insulation product. MEPS & XPS are used in insulated structural panels and in insulating concrete forms (ICFs).

- Links to details: Insulation product names in the first table column include links to articles that help identify and provide the properties of each insulating material listed.

- Open vs. closed cell: Foam insulation densities vary among closed-cell vs open cell forms. Open cell foams are typically about 1/2 lb/cubic foot; Closed cell foams are more dense and rigid, typically about 2 lb/cu. ft.

- C or Thermal conductance of these materials is the reciprocal of the R-value. C is known only when the k, the thermal conductivity of a material is known. k is the heat transmitted through a 1-inch thickness of homogenous material per square foot per hour when there is 1 degree of temperature change. k= (BTU * inch) / sq.ft. * hour * degF.

- Air film: This table of R-values does not consider the insulating characteristic of the air film on each side of a surface nor the effects of wind on the air film or on the material itself. Some of these materials are more resistant to wind-caused heat transmission than others.

- Moisture: Closed cell foams resist moisture uptake (good) but if construction is improper they can trap moisture (bad) leading to rot or mold problems in other building materials.

- Insects: Exterior foam board on foundations can ease attack by wood destroying insects.

- Fire & smoke: Foam insulation products present fire-smoke hazards and usually they must be protected with a fire barrier (usually 1/2" drywall).

- R-Values for wooden log walls

given by the U.S. DOE are in error except for square log walls. D-logs and round logs that are given a nominal log thickness, say 6" logs are calculated by DOE as having an R-value of just over 8.

This is incorrect for non-square logs because the cross section of the log is 6" only at the log's widest point. A correct assessment of the R-value of a wooden log wall needs to be calculated based on the average wall thickness, considering the variation in thicknesses over the curvature of the logs. Therefore the DOE's value is on the "high" end of the R-value of a log wall. - R-Values of uninsulated concrete:

Concrete Homes Magazine web search 5/18/2010 - R-Value for concrete, glass, other materials, Wikipedia web search 5/18/2010 citing Ristinen, Robert A., and Jack J. Kraushaar. Energy and the Environment. 2nd ed. Hoboken, NJ: John Wiley & Sons, Inc., 2006.

- E-Star Colorado. Energy Saving Calculations. Energy Living Alliance, 2008. Web 05/18/2010

- U.S. Department of Energy, DOE Handbook, see http://buildingsdatabook.eren.doe.gov/TableView.aspx?table=5.1.3 18 May 2010. The DOE in turn cited these sources

- ASHRAE, 1997 ASHRAE Handbook: Fundamentals, p. 24-4, 22-5

- DOE, Insulation Fact Sheet, Jan. 1988, p. 6

- Journal of Thermal Insulation, 1987, p. 81-95

- ORNL, ORNL/SUB/88-SA835/1, 1990

- ORNL, Science and Technology for a Sustainable Energy Future, Mar. 1995, p. 17

- ORNL for vacuum insulation panel

- Wikipedia, web search 5/18/2010 R-Values per Inch

- EcoHaus UltraTouch cotton insulation batts batts http://www.ecohaus.com/C-121/ultratouch+batts Web search 5/18/2010

- Icynene product information see http://www.icynene.com/icynene-insulation/ - Web search 5/18/2010

- ICC Legacy Report ER-2833 - Cocoon Thermal and Sound Insulation Products, ICC Evaluation Services, Inc., http://www.icc-es.org - Web search 5/18/2010

- HomeFoam®, Home Insulation Corp. - see http://www.homefoam.ca/articles/Why_HF.htm - Web search 5/18/2010

Home Foam® does not contain formaldehyde, fibrous particulate, HFCs1, CFCs2 or HCFCs3 and is a zero-ODP4 product. The Saskatchewan Research Council (SRC) advises that even sensitive individuals may take occupancy just 24 hours after application is complete. - Air Krete®, Air Krete Inc., P.O. Box 380, Weedsport NY 13166-0380 –Keene Christopher, Principal Telephone: (315) 834-

6609, Retrieved 05 Dec 2010,

AirKrete® GREEN INSULATION SPECIFICSTIONS, original source: airkrete.com/ Specifications for AirKrete® can be found at airkrete.com/pdf/072101specification.pdf - AirKrete® WATER PERMEABILITY COEFFICIENT [PDF] 03/02/2005, letter provided by AirKrete, retrieved 05 Dec 2010, original source: airkrete.com/testResults_files/PermRating.pdf

Specifications for Wall Insulation for Superinsulated Homes

As we discuss at INSULATION CHOICES & PROPERTIES , for superinsulated buildings the article concludes that a double-stud wall with fiberglass batts provided the greatest insulating value per dollar.

However other insulating products may be a better choice depending on other construction details and space limitations.

Our photograph (left) shows an insulation retrofit in a crawl space where icynene foam spray was applied to the crawl space wall and between the floor joists overhead.

The article also discusses the question of air permeability of fiberglass insulation and its impact on the actual insulating value of the material compared with impermeable (to air) foam insulation products.

The impact of moisture on the R-value of fiberglass insulation is also discussed (it's low). Fiberglass both gains and loses moisture more rapidly than some other insulating products.

Foil-faced polyisocyanurate insulation

such as the Thermax® and Hi-R® brands are discussed - these products give the highest R-value per inch among insulating materials.

Also, as we tested in the 1970's, the use of these products combined with a 3/4" air space permits achieving an additional R 2.7 provided that the foil is clean and the gap or air space is uniform.

The link to the original Q&A article in PDF form immediately above was preceded by the expanded/updated online version of this article found above.

- Q&A on Wall-Cavity Concrete Building Insulation - PDF form, use your browser's back button to return to this page. Original article, Solar Age Magazine, Nov. 1983, , adapted and updated for InspectAPedia.com December 2010.

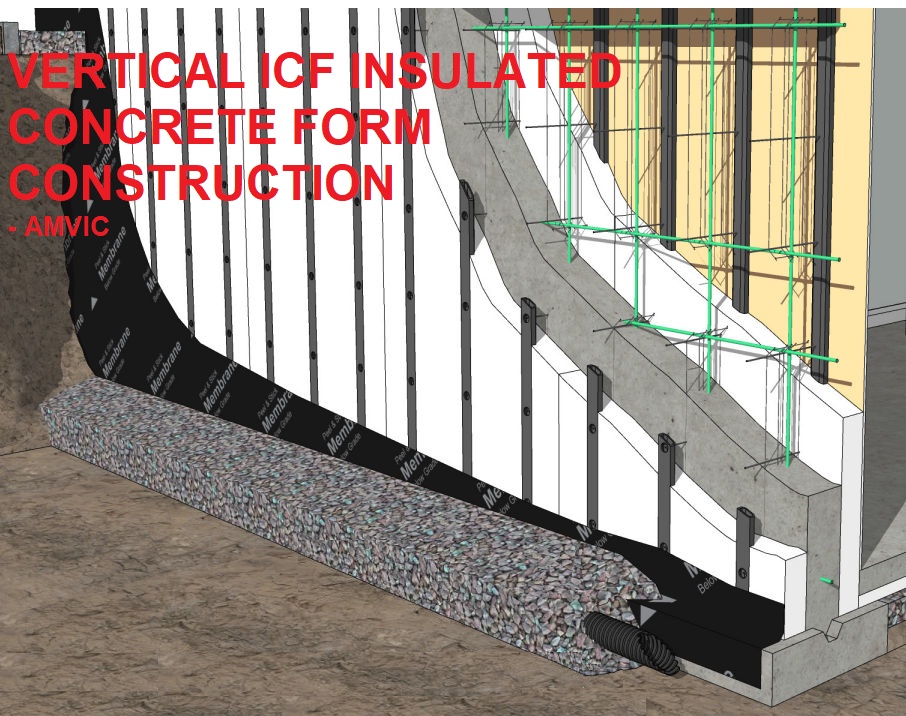

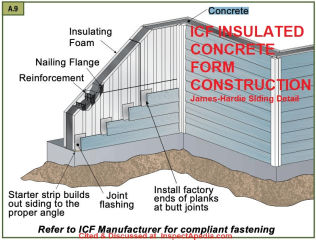

Lightweight Concrete Walls & ICF Insulated Concrete Form Construction Research & Product Sources

- VERTICAL CONCRETE FORMS (ICF) Product Data Sheet [PDF] AMVIC, 501 McNicoll Avenue Toronto, ON, CA, M2H 2E2 Tel: 1 (877) 470-9991 Web: amvicsystem.com -retrieved 2023-09-07, original source: amvicsystem.com/wp-content/uploads/2020/02/Amvic-ICF-Vertical-Product-Data-Sheet.pdf

Excerpts:

Amvic Insulated Concrete Forms (ICF) are stay in place formwork manufactured using Type 3/Type IX closed cell, Expanded Polystyrene (EPS) panels connected by metal webs placed at 16” (406mm) on center.

The forms offer a 6-in-1 system that provides structure, insulation, vapor barrier, air barrier, sound attenuation and attachments for interior finishes and exterior cladding.

Illustrated above, James Hardie provides a general example of how the company's siding products should be attached to ICF or Insulated Concrete Form constructed buildings.

- James Hardie FIBER CEMENT BEST PRACTICES, Appendix A, (2014) [PDF] available from James Hardie Corporation, 231 S. LaSalle St., Suite 2000

Chicago, Illinois 60604, USA, Website: https://www.jameshardie.com or in Canada: http://www.jameshardie.ca

...

Continue reading at FOAM BOARD INSULATION TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CONCRETE BLOCK INSULATION - foam core & similar products

- CONCRETE INSULATION & ICFs Insulated Concrete Form construction - what's the difference?

- ENERGY SAVINGS RETROFIT OPTIONS - ultra lightweight concrete insulation, insulating forms for concrete foundations

- FOAM BOARD INSULATION TYPES

- HEAT LOSS in BUILDINGS - home

- INSULATION INSPECTION & IMPROVEMENT - home

- INSULATION LOCATION - WHERE TO PUT IT - home

- INSULATION R-VALUES & PROPERTIES

- STRESS SKIN / STRUCTURAL INSULATED PANELS (SIPs)

Suggested citation for this web page

CONCRETE INSULATION, LIGHT WEIGHT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INSULATION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Solar Age Magazine was the official publication of the American Solar Energy Society. The contemporary solar energy magazine associated with the Society is Solar Today. "Established in 1954, the nonprofit American Solar Energy Society (ASES) is the nation's leading association of solar professionals & advocates. Our mission is to inspire an era of energy innovation and speed the transition to a sustainable energy economy. We advance education, research and policy. Leading for more than 50 years. ASES leads national efforts to increase the use of solar energy, energy efficiency and other sustainable technologies in the U.S. We publish the award-winning SOLAR TODAY magazine, organize and present the ASES National Solar Conference and lead the ASES National Solar Tour – the largest grassroots solar event in the world."

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - Air Krete®, Air Krete Inc., P.O. Box 380, Weedsport NY 13166-0380 –Keene Christopher, Principal Telephone: (315) 834- 6609, Retrieved 05 Dec 2010, AirKrete® Green Insulation Specifications, original source: http://www.airkrete.com/ Specifications for AirKrete® can be found at http://www.airkrete.com/pdf/072101specification.pdf

- AirKrete® Water Permeability Coefficient, 03/02/2005, letter provided by AirKrete, retrieved 05 Dec 2010, original source: http://www.airkrete.com/testResults_files/PermRating.pdf

- Omni Tech Energy Products can be contacted at 616-458-5894.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.