Well Pump Types

Well Pump Types

Types of Jet Pumps, Submersible Pumps, Hand Pumps, Solar Pumps, Wind Operated Pumps

- POST a QUESTION or COMMENT about things that impact the life of a well pump or water pump

Well pump definitions, types.

Page top photo: this old Myers well pump, installed in a home renovated by the author (DF) is easily identified as a two-line jet pump by the two black water lines connected to the pump's pumping impeller assembly at left in the photo.

This article series describes the different types of water pumps or well pumps, and we list the factors affecting the life expectancy of water pumps and we include a list of steps to take to maximize the life of a well or water pump and its motor.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Types of Water Pumps

In this article we describe and give specifics of different types of water pumps.

Article Series Contents

- HAND PUMP for WELLS - separate article, Hand pumps / pitcher pumps on shallow wells

- KINETIC WATER RAM - flowing stream-water can provide pumping power

- SOLAR WELL PUMPS - sun / solar power operated pumps

- PISTON WATER PUMPS - an antique pump design

- VARIABLE FREQUENCY / VARIABLE SPEED DRIVE WELL PUMPS (VFDs)

- WATER PRESSURE BOOSTER PUMP - separate article

- WATER PUMP, ONE LINE JET - separate article

- WATER PUMP VARIABLE FREQUENCY / VARIABLE SPEED DRIVE (VFDs) - separate article, includes tankless pumps such as the Scala 2 from Grundfos.

- WATER PUMP, SUBMERSIBLE - separate article

- WATER PUMP, TWO LINE JET - separate article

- WINDMILL OPERATED WELL PUMPS - wind powered water pumps

Kinetic water ram water pumps, or Ram Pumps for water delivery

A kinetic water ram pump or hydraulic ram pump uses the force of running water in a stream combined with the principles of hydraulics to lift water as much as 50 meters from the pump location.

A kinetic water ram pump or hydraulic ram pump uses the force of running water in a stream combined with the principles of hydraulics to lift water as much as 50 meters from the pump location.

The water ram was invented in 1780 by Frenchman Joseph Michael Montgolfier. Cox's hydraulic ram type water pump (1990) is shown below.

Since surface or stream water is unlikely to be sanitary in most locations, water ram pumps are used mostly in agriculture to move stream water to fields for irrigation.

- Allison, Jesse H. "Pumping-engine." U.S. Patent 1,229,009, issued June 5, 1917.

- Carlson, Edward P. "Hydraulic pump." U.S. Patent 1,353,216, issued September 21, 1920.

- Cox, Larry A. "Hydraulic ram-type water pump." U.S. Patent 4,911,613, issued March 27, 1990.

- Folk, James E. "Water powered ram pump." U.S. Patent D338,891, issued August 31, 1993.

- Jeffery, T. D., T. H. Thomas, A. V. Smith, P. B. Glover, and P. D. Fountain. Hydraulic ram pumps: a guide to ram pump water supply systems. Intermediate Technology Publications, 1992.

- Merten, Eugen. "Hydraulic ram system." U.S. Patent 2,424,108, issued July 15, 1947.

- Mohammed, Shuaibu Ndache. "Design and construction of a hydraulic ram pump." Leonardo Electronic Journal of Practices and Technologies 6, no. 11 (2007): 59-70.

- Young, B. W. "Design of hydraulic ram pump systems." Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy 209, no. 4 (1995): 313-322.

A very different water ram, a "Kinetic water ram" pump using compressed air to clear clogged building drains is available and is discussed

at CLOGGED DRAIN DIAGNOSIS & REPAIR.

That kinetic water ram, discussed in detail

at KINETIC WATER RAM, is a drain clearing tool not a water pump.

Hand Pumps (Pitcher Pumps) & Mechanical Pumps for Pumping Water

A variety of systems to lift water out of a well, including human carriers, rope and bucket, or mechanical pumps operated by hand, wind, or other means has been in use for thousands of years.

While simple pitcher pumps are still used to draw water from a shallow well, an engineered hand pump can lift water from depths around 300 ft. .

A leather valve on the end of the suction rod seals against the inner surface of the pipe to create water-lifting suction as the pump handle moves the suction rod up and down.

This simple but effective pump design could be operated by hand or by another power source such as a windmill.

See details about all types of hand-pumps for lifting water, now

We discuss windmills for lifting water separately

at WINDMILL OPERATED WELL PUMPS

Solar powered water pumps

Solar powered pumps run on direct current (DC) supplied by a solar panel. The panel

contains photovoltaic (PV) cells that convert light into electricity.

Solar powered pumps run on direct current (DC) supplied by a solar panel. The panel

contains photovoltaic (PV) cells that convert light into electricity.

These cells are arranged into modules that form the panels.

The electricity is transmitted to either a floating pump or a submerged pump. Floating pumps are used to pump water while they float over a stream, pond, etc. The submersible pumps are used to pump water from a deep water source such as a well.

Since the PV cells are expensive and solar power is limited to the day hours manufacturers strive to produce very efficient pumps. Panels must be install and oriented to maximize the capture of the sun light.

A solar tracker may be used to automatically move the panels to face

the sun as it moves during the day/season. For night time or cloudy days the system can be equipped with battery backup or a storage tank provided with capacity to supply the water demand for a few days.

-USDA, "Renewable Energy Sources to

Power Grazing Watering

Systems

A CSP On-Farm Pilot Project ", retrieved 2022/05/30 original source: https://www.nrcs.usda.gov/Internet/FSE_DOCUMENTS/nrcs142p2_017476.pdf

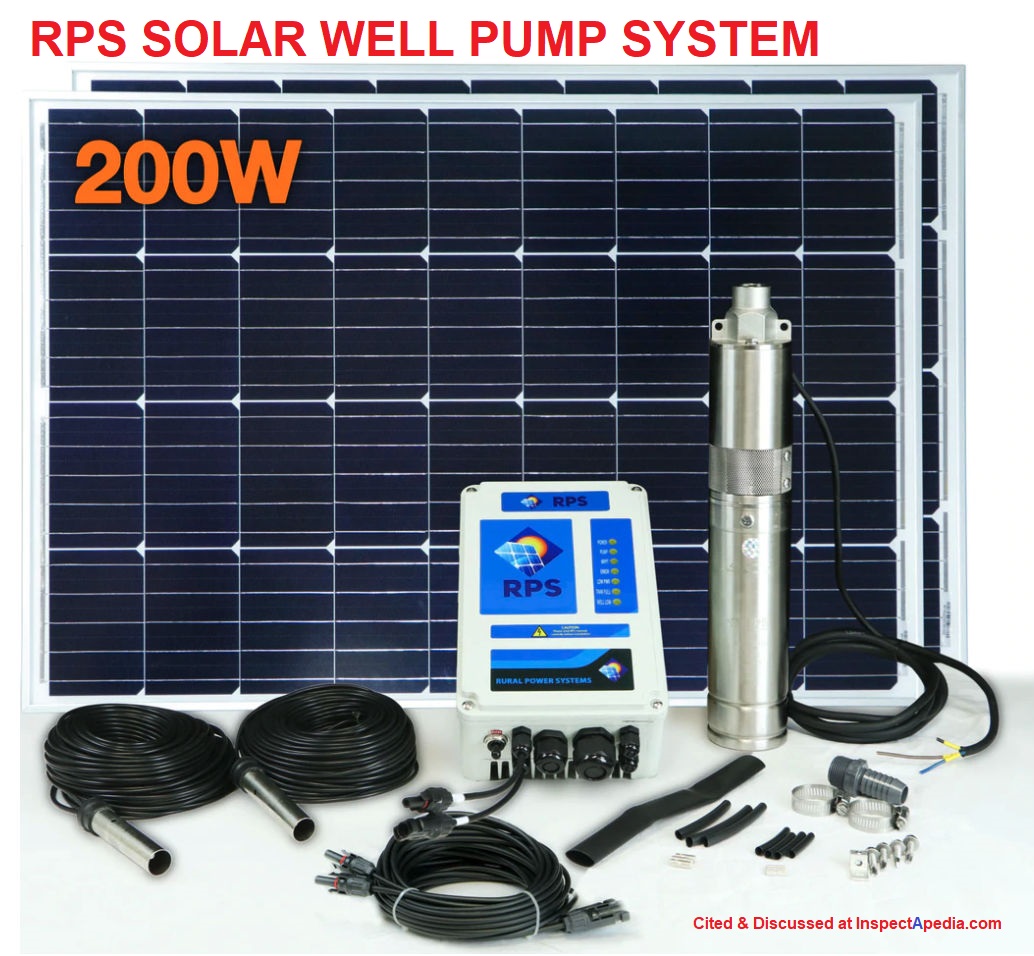

Shown above: a 200-Watt solar powerd well pump provided by RPS Solar Pumps, cited below.

See our SOLAR ENERGY SYSTEMS home page at InspectApedia as well as the solar pumps listed below.

In addition to solar-powered jet pumps or submersible well pumps, the engineered deep well lift-pumps described above for hand pumping can also be adapted to use a solar-operated motor provided by the same company. The solar water pump uses a single 200W solar panel and can pump from depths to 350 ft. (Castle, op. cit.)

- AbleSolar, New Zealand well bore pumps, Able Solar Ltd 40 Spartan Rd Takanini Auckland 2105 NZ, Email: info@ablesolar.co.nz Tel: 09 267 7065 Web: https://www.ablesolar.co.nz/solar-water-pump.html

- American Solar Energy Society, 2525 Arapahoe Ave, Ste E4-253 Boulder, Colorado 80302 Email: info@ases.orgWeb: https://ases.org/ Tel: (303) 443-3130 (MWF 10-Noon)

- Australian Bore Pumps Co., 6/2, Taminga Street, Regency Park, SA 5010 AU, Tel: 0412 211 221 Emaill:info@australianborepumps.com Web: https://australianborepumps.com/

- Das, Debashis, and M. Ram Gopal. "Studies on a metal hydride based solar water pump." International journal of hydrogen energy 29, no. 1 (2004): 103-112.

- Daud, Abdel-Karim, and Marwan M. Mahmoud. "Solar powered induction motor-driven water pump operating on a desert well, simulation and field tests." Renewable energy 30, no. 5 (2005): 701-714.

- Eco-Worthy Solar pump kit with battery backup, includes 100W solar panel and 1.6 GPM deep well pump (96W) and 10Ah waterproof power box with switch. Email: info@eco-worthy.com Tel: +1-866-939-8222 Web: www.eco-worthy.com/

The company offers a wide range of solar pump systems and kits of varying capacity. - Eker, Bülent. "Solar powered water pumping systems." Trakia Journal of Sciences 3, no. 7 (2005): 7-11.

- Harishankar, S., R. Sathish Kumar, K. P. Sudharsan, U. Vignesh, and T. Viveknath. SOLAR POWERED SMART IRRIGATION SYSTEM [PDF] Advance in electronic and electric engineering 4, no. 4 (2014): 341-346.

Abstract excerpts:

... This system consists of solar powered water pump along with an automatic water flow control using a moisture sensor. It is the proposed solution for the present energy crisis for the Indian farmers.

This system conserves electricity by reducing the usage of grid power and conserves water by reducing water losses. Keywords: Smart irrigation; solar power; solar pump; moisture sensor;energy crisis. - Halcrow, S.W. and Partners. 1981. Small-scale solar powered irrigation pumping systems: technical and economic review. UNDP Project GLO/78/004.Intermediate Technology Power, London, UK. A. Harmim et al., “Mathematical modeling of a box-type solar cooker employing an asymmetric compound parabolic concentrator,” Solar Energy, vol.86, pp. 1673–1682, 2012.

- Johnson, Jason, SOLAR-POWERED PUMP COMBATS LIVESTOCK WATERING ISSUES [PDF] (2008) USDA, NRCS, Public Affairs Specialist, retrieved 2022/05/30, original source: https://www.nrcs.usda.gov/wps/portal/nrcs/ia/newsroom/stories/nrcs142p2_008609/

- RPS Solar, RPS 200 SOLAR WELL PUMP KIT SPECIFICATIONS [PDF], Real Power Systems, RPS, Rural Power Systems, 40250 County Rd 27, Woodland CA 95776 USA, Website: rpssolarpumps.com Tel: 888-637-4493

Excerpt:

Solar pumps come in many makes, models, and sizes. A typical solar pump installation will have three components: solar panels, an electronic pump controller, and the pump itself. It is important that these components are compatible with each other. Most reputable solar pump suppliers provide the complete system that will work as intended. - Klausmeyer, Kelly J., SOLAR PUMPS [PDF] USDA, Kansas, retrieved 2022/05/30 original source: https://www.nrcs.usda.gov/wps/portal/nrcs/detail/ks/newsroom/features/?cid=nrcs142p2_033495

Excerpt:

The extended drought across Kansas this year has cattle operations scrambling to find and secure water resources.

Ponds and creeks across the state have been drying up and are being replaced with groundwater sources such as springs and wells. Windmills have been the traditional method for developing groundwater for many years now, but a relatively new technology is becoming more and more popular.

That technology is solar. Solar pumps come in many makes, models, and sizes.

A typical solar pump installation will have three components: solar panels, an electronic pump controller, and the pump itself. It is important that these components are compatible with each other.

Most reputable solar pump suppliers provide the complete system that will work as intended. Solar panels (also called Photovoltaic panels) harness the sun’s energy to create a voltage that can be used to operate the pump.

Panels will produce at least some energy anytime the sun hits them. However, it is important to note that the solar panel will generate its peak energy rating only for part of the day. This peak sun energy is roughly six hours per day in the summer, but reduced to about four hours per day in the winter for northwest Kansas.

- Morales, Teresa D., John Busch, DESIGN OF SMALL PHOTOVOLTAIC (PV)

SOLAR-POWERED WATER PUMP SYSTEMS [PDF] (2012)

(Watt Estimator for Solar Powered Pump System Spreadsheet), Technical Note 29 (Portland, OR as revised for New Mexico) USDA, NRCS, New Mexico, retrieved 2022/05/30 original source: https://efotg.sc.egov.usda.gov/references/public/NM/eng4a2-Design_Of_Small_Photovoltaic(Pv)Solar-Powered_Water_Pump_Systems.pdf

(Watt Estimator for Solar Powered Pump System Spreadsheet)

Excerpts:

New Mexico NRCS is adopting Oregon’s Technical Note No. 28, “Design of Small Photovoltaic (PV) Solar Powered Water Pump Systems,” (October 2010). Technical Note 28 is pages 2-65 of this document. It was developed for NRCS in Oregon with assistance from the WNTSC.

The intent of this technical publication is to provide general guidance on the design of small solar-powered water pump systems for use with livestock operations or irrigation systems.

This document provides a review of the basic elements of electricity, a description of the different components of solar-powered water pump systems, important planning considerations, and general guidance on designing a solar-powered water pump system.

This publication also provides design examples for typical design scenarios and standard drawings for use by the reader. However, this technical note is not intended to be used as a standalone document. Instead, users are encouraged to consult the NRCS National Engineering Manual (NEH 210) on hydraulics and irrigation engineering for additional assistance in the design of water delivery systems.

All sources used in the development of this technical note are provided in the References section at the back of the document. - UK Solar Borehole & Well Pumps, Tel: +44 (0) 1502 589407 Email: info@solar-wind.co.uk Web: https://www.solar-wind.co.uk/solar-borehole-well-pumps-lorentz

- Yousuf, Nafisa Binte, Khosru M. Salim, Rafid Haider, Md Rajin Alam, and Fatima Binte Zia. "Development of a three phase induction motor controller for solar powered water pump." In 2nd International Conference on the Developments in Renewable Energy Technology (ICDRET 2012), pp. 1-5. IEEE, 2012.

VFD Well Pumps: Variable Frequency Drive, Variable Speed Pumps

A more-sophisticated type of water pump than others described in this article series, VFDs constant-pressure or variable frequency drive pumps, as described here, maintain constant pressure by varing the pump's motor-speed. These pumps are designed to start and stop repeatedly without suffering damage.

A more-sophisticated type of water pump than others described in this article series, VFDs constant-pressure or variable frequency drive pumps, as described here, maintain constant pressure by varing the pump's motor-speed. These pumps are designed to start and stop repeatedly without suffering damage.

A VFD pump maintains a constant water pressure on its output side by varying the motor speed or rpm according to the demand. A check-valve on the pump's output side prevents back-flow from the pressurized side of the pump when the pump stops.

Manufacturers of VFD pumps such as Grundfos and DAB produce variable frequency drive pumps, also known as constant-pressure pumps, that use a motor controller to vary pump speed and thus output in order to maintain a constant pressure in the water system, increasing pump speed as water usage rate increase, and vice versa.

The Grundfos Scala2 whose control panel is shown above, increases its speed as it senses a pressure drop associated with increased water-use rate (flow in gpm or lpm( in the building.

If you're watching the pump as water usage rate increases in the bilding it serves, you'll hear the pump pick up speed and you'll see the green lights creep up the power scale on the pump's display.

At the center-right of our photo I've marked the up and down arrows that give pressure control.

The control allows the user or building occupants to set up or down the water pressure to be maintaind by the pump as water usage rate varies.

In the photos above and just below is the Grundfos VFD Scala 2 pump Model A (120VAC) that we installed in a home in San Miguel de Allende, Guanajuato, Mexico.

This pump, with a lift capacity of 148 ft., and a nominal maximum flow rate of 13 gpm, was manufactured in Serbia.

We describe this Grudnfos VFD pump in detail along with other VFDs (Variable Frequency Drive Pumps)

at WATER PUMP VARIABLE FREQUENCY / VARIABLE SPEED DRIVE (VFDs) where we describe these pumps in more-detail and we list sources for constant pressure VFD water pumps pumps such as the Simer VFD, and the Scala 2 from Grundfos. Details are also in

GRUNDFOS SCALA2 DATA SHEET [PDF] retrieved 2017/03/26, original source: http://us.grundfos.com/content/dam/GPU/Literature/SCALA2/SCALA2-DATASHEET.pdf

Below is the DAB ESYBOX MAX - Integrated Water Booster Pumping System (230V) as marketed by rainwaterequipment.com T: 877-331-7008.

This pump is capable of delivering functional water pressure to medium and large buildings at least as tall as 14 stories. These 230VAC pumps can also be installed in a ganged or cascaded system and can pump to a head of 370 ft.

Note that the pump's output capacity in gpm or lpm will, of course, decrease as the lift height is increased.

- ESYBOX AC VFD PUMP INSTRUCTION MANUAL [PDF] DAB PUMPS S.p.A.

Via M. Polo, 14 - 35035 Mestrino (PD) - Italy

Tel. +39 049 5125000 - Fax +39 049 5125950

www.dabpumps.com

Excerpt:

The product is an integrated system composed of a vertical multi-stage centrifugal electric pump, an electronic circuit that controls it and an expansion vessel.

The pump also has WiFi and Bluetooth connection systems for remote control via DConnect Cloud and for a better user experience with mobile devices via the dedicated app, see chapter 12.

The APP and DConnect Cloud also allow the use of additional features not present directly on the display (e.g. energy and flow meters).

DAP and Grundfs both distribute and operate providing VFD pumps world-wide.

At SHORT CYCLING WATER PUMP we explain that rapid on-off cycling of a typical jet pump or submersible pump ultimately damages the motor or can even destroy it. Short cycling, as described there, refers to rapid water pump switching that occurs due, usually, to a water-logged pressure tank (easily fixed).

Wind-operated water pumps: Windmills

Above: an antique windmill in Holland and below, the Eli Windmill in Iowa, a wind operated well pump system manufactured by the Kregel Windmill Co.

The windmill Dutch windmill is also discussed

[Click to enlarge any image]

From the Library of Congress catalog: 57. Detail of head and wheel of eli windmill on the ground at the Stoll residence, about 1-1/2 miles west of Nebraska City on Steam Wagon Road. - Kregel Windmill Company factory, 1416 central Avenue, Nebraska City, Otoe county, NE. - Library of Congress Prints and Photographs Division Washington, D.C. 20540 USA http://hdl.loc.gov/loc.pnp/pp.print

Above: details of the Kreger Co. windmill head from the same Library of Congress collection (Reproduction Number: HAER NEB,66-NEBCI,6--57).

Below: a water well sucker rod workbench and wooden sucker rod sucker rod storage racks inside of of the Kregel Windmill Company Factory, 1416 Central Avenue, Nebraska City, Otoe County, NE, USA

The Kregel Windmill Company factory is the last preserved intact windmill factory in the United States.

The company was founded in 1879, and began to manufacture wooden windmills known as the "Kregel." By the last decade of the nineteenth century, the company was producing steel windmills sold under the name "Eli."

Company founder George F. Kregel moved the factory to its present location in 1903, where he manufactured windmills through World War II when materials rationing forced him to stop production.

After the war George's son Arthur took over the business and focused on water well and pump services. - U.S. Library of Congress, retrieved 2022/05/30, original source: https://www.loc.gov/pictures/collection/hh/item/ne0071/

Below: a wind-operated water pump, using a vertical axis barrel wind rotor but no longer in operation, in San Miguel de Allende, Guanajuato, Mexico.

Photo & Description of Piston Type Well Pumps

A mechanical version of the hand pump on wells (shown just above) was able to lift from somewhat greater depth, perhaps as much as 20 feet.

The well pump motor and its vertically-operated piston was set directly over the well casing as we show in the photo of an old, discontinued piston well pump.

In our photo at left you can see the large pulley wheel on the right side of the vertical piston pump, but the drive belt and motor that drove the pump have been removed.

What is Well Pump Cavitation?

Well pump cavitation describes the entry of air or gases into the mechanical parts that are trying to move water through a water pump.

The presence of air or other gases in the actual pump chambers or around the water pump impellers leads to overheating of these parts and mechanical damage to the pump moving parts.

Cavitation can also cause the pump to have to work longer to satisfy the water demand and thus its electric motor to overheat, also reducing motor life.

Cavitation inside of a water pump can be caused by several problems including:

- Inadequate well yield:

if the yield of a well drops for any reason, trying to pump water beyond the safe yield of a well pump can introduce air into the well pump and water piping.

See WELL YIELD DEFINITION where we define safe well yield.

Also see AIR DISCHARGE at FAUCETS, FIXTURES. - Oversized pumps

that mismatch the well flow rate to the pump's output rate can also cause the pump to form a strong vacuum inside the pumping chamber around the pump impeller. The vacuum, in turn, causes dissolved gases in the water itself to leave solution and return to bubble form.

Low Water Cutoff Devices and Well Tailpieces for Well Pump Protection on a Low-Flow-Rate Well

For details about well pipe tailpieces, tail pipes, or other low water cutoff devices that protect the well pump from damage when the well flow is too limited, please see our compete article

For details about well pipe tailpieces, tail pipes, or other low water cutoff devices that protect the well pump from damage when the well flow is too limited, please see our compete article

at WELL PIPING TAIL PIECE. Excerpts are just below.

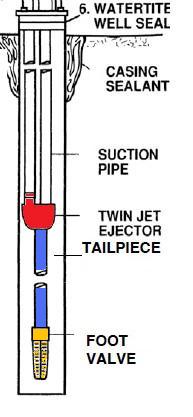

When the well pump's capacity is known to exceed the flow rate of the well, a tail pipe, tail piece, or low water cutoff control is installed to protect the pump from damage.

The well piping tailpiece (also shown in this SKETCH [image file]) permits the in-well water pump to continue to run by recirculating well water within the pump but by halting delivery of water or slowing delivery of water to the building.

Many sources, including the Penn State School of Forest Resources recommend installing a low water cutoff device to protect a well pump that has to operate in an inadequate or low-yield well.

A still different approach that may provide some water pump protection by reducing the well pump cycling rate is the installation of a Smart Tank that regulates water flow in the building.

Pressure Sensitive Water Pumps & Inline Control Water Pumps: Variable Speed, Variable Frequency VFD Pumps

Pressure sensitive pumps and inline pump controllers provide water pressure boosting, rainwater harvesting, or similar functions without requiring a water pressure tank.

See WATER PUMP VARIABLE FREQUENCY / VARIABLE SPEED DRIVE (VFDs)

What are Artesian Wells & How do They Work?

Water flows naturally to the ground surface of an artesian well, pushed there by higher pressure groundwater deeper in the earth. "Artesian" refers to Artois, the region in France that gave this type of water source its name. The Latin form of Artois is Artesia.

The level of groundwater is not "flat" under the surface of the earth. Rather underground water tends to follow the contours of the ground surface.

When the underground water reservoir is actually higher than the well that taps into it, water is forced from the higher level to the surface of the artesian well.

See details at

At SINKHOLES in Estonia-The Witches' Well we describe a non-artesian well that also pushes groundwater to the surface when a nearby underground river floods.

Research on Life Expectancy of Various Types of Water Well Pumps

- Gordon, Peter M., Matt C. Johnson, and Dylan A. Smith. DEEP WELL PUMP SEAL [PDF] (2017). [Class assignment] Mechanical Engineering Department,

California Polytechnic State University, San Luis Obispo

Abstract:

Lifewater International, a Christian non-profit, trains locals to repair water well hand pumps in various third world countries. It would be beneficial to retrofit difficult-to-repair hand pumps with a locally-made pump cylinder such as HydroMission's "SlapShot".

The majority of the components in the "SlapShot" can be easily obtained in rural third world villages.

However, the thick leather gaskets required to seal the water cylinder during the pumping operation are imported. These thick leather gaskets are expensive, and when they fail, this results in pumps being out of commission for extended periods of time.

Lifewater has presented this problem to a team of three undergraduate mechanical engineering students at California Polytechnic State University, San Luis Obispo with the goal of being able to locally source and manufacture an adequate seal to replace the current thick leather seal.

Excerpts:

The life cycle and leak rates cannot be determined without testing, so these … pump seals. The users would continue using the pump until absolutely no water was coming out, making life … - Iskenderli, I. N., I. S. Kuliev, V. A. Narimanov, and F. M. Kel’biev. "Analysis of efficiency of methods for improving sucker-rod deep-well pump plungers and choice of an alternative method." Chemical and Petroleum Engineering 49, no. 7 (2013): 536-538.

- McCarter, A. B., S. V. Os Jr, and R. E. Blount. Well pump for fluids and vapors. No. US 3884299. 1975.

- Muth, G. M., and T. M. Walker. "Extending Downhole Pump Life Using New Technology." In SPE Western Regional Meeting. OnePetro, 2001.

- Ondrey, Gerald. "Analyzing pump life-cycle costs." Chemical Engineering 107, no. 12 (2000): 33.

- Truslove, Jonathan P., Andrea B. Coulson, Emma Mbalame, and Robert M. Kalin. "Barriers to handpump serviceability in Malawi: Life-cycle costing for sustainable service delivery." Environmental Science: Water Research & Technology 6, no. 8 (2020): 2138-2152.

Includes a discussion of the life expectancy of hand pumps or pitcher pumps on water wells.

Abstract excerpt:

The implementation of handpumps has contributed to increased improved water access.

However,'universal access' as the metric for success within Sustainable Development Goal (SDG) 6, potentially conceals fundamental barriers for sustainable services and hinders SDG 6 target success.

Tariffs, in the form of household contributions, are the most common form of financial provision for the maintenance of rural water supplies. ... The findings highlight the burden placed on rural communities of maintaining inherently unsustainable assets that inevitably hinders lasting service delivery and benefits for rural communities in the SDG period and beyond. - Ylaya, Vrian Jay V., and Ruel T. Buba. PERFORMANCE ANALYSIS OF SOLAR POWERED WATER WELL PUMP [PDF]” International Research Journal of

Advanced Engineering and Science, Volume 7, Issue 2, pp. 85-89, 2022.

Abstract

The Philippines is abundant in water. In remote areas, sources of water are from wells. The collection of water needs effort and is laborious. Mechanical pumps are available to collect water from the well automatically, but this is impossible in remote areas deprived of electricity.

This research addresses the later issue: water pumps are powered with solar. The performance of the solar-powered water well pump is analyzed from their series and parallel connections based on the provided flow rate—data analysis using a two-tailed ttest implemented in Python.

The Ho is that there is no significant difference in the flow rate of series and parallel connections of the solar-powered water well pump. The p-value solve is 1.346, which rejects the null hypothesis. Thus, there is a significant difference in the performance of series and parallel connections of the solar-powered water well pump.

Efficiently, a parallel connection performed well in implementing a solar-powered water well pump. - Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Flexcon, SMART TANK INSTALLATION INSTRUCTIONS [PDF], Flexcon Industries, 300 Pond St., Randolph MA 02368, www.flexconind.com, Tel: 800-527-0030 - web search 07/24/2010, original source: http://www.flexconind.com/pdf/st_install.pdf

Smart tank tee gives constant water flow and pressure - Grove Electric, Typical Shallow Well ONE LINE JET PUMP INSTALLATION [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

This page has illustrations and description of a typical shallow well one line jet pump installation. - Grove Electric, Typical Deep Well TWO LINE JET PUMP INSTALLATION [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

This page has illustrations and description of a typical two line jet pump installation for deep wells. - Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- See additional citations at the page bottomReferences or Citations

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: does pressure control switch setting level affect well pump life?

2019/03/31 Gary said:

Are low (20/40) or high (40/60) switch settings better or worse for pump life, and why?

This Q&A were posted originally

at WATER PUMP DRAWDOWN VOLUME & TIME

Reply:

Gary

I offer two apparently but not really contradictory answers:

1. A pump that is required to reach a higher cut-off pressure before it turns off - all else being equal - has to work a bit harder so might run a bit longer or a bit hotter, factors that *could* affect pump life.

2. However, As long as you are operating a water pump within the pressure range for which it is designed and more-important the duty cycle for which it's designed, the cut-off pressure range should not measurably affect the pump life.

Starting at WATER PUMP LIFE EXPECTANCY (at the top of this very page) you'll see that there are factors that affect well pump life, among which the pressure control switch does, indirectly play a part.

In my opinion the most harmful problems affecting pump life are rapid on-off short-cycling. (see SHORT CYCLING at the end of this page)

...

Continue reading at WATER PUMP LIFE MAXIMIZATION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see WATER PUMP LIFE EXPECTANCY FAQs - questions and answers posted originally at the end of this article.

Or see these

Recommended Articles

- WATER PRESSURE BOOSTER PUMP

- WATER PUMP CAPACITIES TYPES RATES GPM - general pump capacities and operating ranges

- WATER PUMP CONTROLS & SWITCHES

- WATER PUMP DUTY CYCLE

- WATER PUMP LIFE EXPECTANCY

- WATER PUMP LIFE MAXIMIZATION - how to get the longest life out of your well pump

- WATER PUMP VARIABLE FREQUENCY / VARIABLE SPEED DRIVE (VFDs)

- WATER PUMP SHORT CYCLING

- WATER PUMP TYPES

- WATER PUMP WONT STOP RUNNING

- WATER PUMP & TANK I&O & REPAIR MANUALS

- WATER TANK LIFE EXPECTANCY

- WELL LIFE EXPECTANCY

Suggested citation for this web page

WATER PUMP TYPES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about things that impact the life of a well pump or water pump.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Air in Drinking Water, Environmental Fact Sheet, New Hampshire Department of Environmental Services, 29 Hazen Drive, Concord NH 03301 - web search 07/14/2010 original source: http://des.nh.gov/organization/commissioner/pip/factsheets

/dwgb/documents/dwgb-3-18.pdf - Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Kinetic water rams are described and demonstrated at waterram.com/faq.php

- Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- Flexcon, SMART TANK INSTALLATION INSTRUCTIONS [PDF], Flexcon Industries, 300 Pond St., Randolph MA 02368, www.flexconind.com, Tel: 800-527-0030 - web search 07/24/2010, original source: http://www.flexconind.com/pdf/st_install.pdf

- Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Water Ace Jet Pump Installation Manual, instructions from Water Ace Pump Co., web search 08/28/2010, original source: http://www.waterace.com/pdf/R510%20R520%20and%20R100%20Jet%20Pumps%20Manual.pdf

Consumer hotline: 800-942-3343 - instructions for the installation and maintenance of

Water Ace shallow well pump Model R510 1/2 HP

Water Ace deep well pump Model R100 convertible 1HP and

Water Ace deep well jet pump Model R250 convertible 1/2 hp. - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.