VFD Variable Frequency Drive Pumps

VFD Variable Frequency Drive Pumps

Constant

Pressure Water Pumps

Control omits pressure tank & delivers water to meet varying needs

- POST a QUESTION or COMMENT about pressure sensitive water pumps for rainwater harvesting or water pressure boosting; using an inline pump controller, omitting a water pressure tank.

Constant pressure or pressure-sensitive water pump systems & inline water pump controllers are explained here where we define and list the common applications of and advantages of VFD water pumps.

This article explains how pressure sensitive pumps and inline pump controllers provide water pressure boosting, rainwater harvesting, or similar functions without requiring a water pressure tank. We explain pressure sensitive pumps and for similar as well as for higher water volume or pressure applications we describe inline pump controls, how they work and where are they most often used.

Our page top photo shows a model set-up for a Rowa brand pressure sensitive pump and control system suitable for water pressure boosting, cistern or rooftop water storage tank water delivery, or rainwater harvesting systems. This system can operate without requiring a separate hydropneumatic or water pressure tank.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

VFD, Pressure Sensitive Water Pumps

![Water pump control that avoids needing a pressure tank (C) Daniel Friedman]](Water_Pump_Pressure_Control_No_Tank_023ss.jpg) Pressure sensitive or "constant pressure" water pumps and inline VFD (Variable Frequency Drive) pump controllers can provide water pressure boosting, rainwater harvesting, or similar functions without requiring a water pressure tank.

Pressure sensitive or "constant pressure" water pumps and inline VFD (Variable Frequency Drive) pump controllers can provide water pressure boosting, rainwater harvesting, or similar functions without requiring a water pressure tank.

What are pressure sensitive pumps and what are inline pump controls, how do they work and where are they most often used?

At WATER PUMP TYPES we explain that

VFDs constant-pressure or variable frequency drive pumps maintain constant water pressure on its output side by varying the motor speed or rpm according to the demand. A check-valve on the pump's output side prevents back-flow from the pressurized side of the pump when the pump stops.

Manufacturers of VFD pumps such as Grundfos and DAB produce variable frequency drive pumps, also known as constant-pressure pumps, that use a motor controller to vary pump speed and thus output in order to maintain a constant pressure in the water system, increasing pump speed as water usage rate increase, and vice versa.

Article Contents

- VFD PUMP APPLICATIONS & BENEFITS

- VFD PUMP INSTALLATION NOTES

- VFD PUMP PRESSURE TANK AIR CHARGE SETTING

- VFD PUMP MANUALS & SOURCES

- VFD PUMP RESEARCH

Applications & Benefits of VFD Constant Pressure Pumps & Motors

There is a wide range of applications in which VFD pumps are most-suitable, particularly where variable torque is useful such as in centrifugal pumps used in handling wastewater or in supplying varying needs of potable water.

- Economy of operation & water use,

by matching the load on a water pump's motor to the amount of electrical energy it needs to support that load. - Reduced water tank storage:

domestic water supply applications where tap water is provided by pumping directly from the water well without an intermediate pressure tank, reducing the requirement to store a quantity of water that may become stagnant or non-potable if demand is intermittent or where the water usage rate requirement varies widely over time or season. - Fountains

using pressure change for decorative purposes ("dancing fountains") - Geothermal wells

used to provide constant temperature control in buildings, achieved by varying the water flow rate through the heat exchanger - Groundwater control

in mines or construction projects - Hydraulic shock and water hammer

in the plumbing system are reduced. Hydraulic shock can cause of annoying water hammer or even of leaks that in turn can cause water damage or may compromise a TPR relief valve - Increased pump component life:

because the VFD pump ramps up to necessary speed gradually and because during most of its use the pump doesn't run at full speed, the life of its wear-components such as pump and motor bearings, seals, and the impeller assembly are increased. - Increased pump motor life:

also, because a VFD pump motor is brought up to necessary speed gradually it is subjected to considerably less starting torque and wear than a conventional pump motor that is turned on by an instant supply of full voltage. The VFD pump motor life is increased and its maintenance costs are reduced. - Water usage rate control

where the supplying aquifer is of limited capacity, limiting the water withdrawal rate to match the aquifer's delivery capacity, thus avoiding over-pumping that can damage the water source; we add that by avoiding over-pumping you also avoid the damage that occurs to a conventional pump if it is run dry after exhausting the water supply.

- Adapted from

Grundfos, "The Advantages of frequency drive operation in submersible pumps", Grundfos Pump Co., retrieved 2022/05/30 original source: https://www.grundfos.com/solutions/learn/ecademy/all-courses/the-sp-submersible-pump/the-advantages-of-frequency-drive-operation-in-submersible-pumps

MPT, "The Benefits of Variable Speed Pumping" Modern Pumping Today Magazine, (2016) retrieved 2022/05/30 original source: https://modernpumpingtoday.com/benefits-of-variable-speed-pumping/

Really? Well in opinion, yes, the above applications and our own use experience with VFD pumps provides ample and economical justification for their use.

But we were stunned to find, in researching this topic, that Cycle Stop Valves, a company producing a device intended to protect pumps from damage from short-cycling, has written what is in our view a highly-opinionated, self-serving Cyclestop article [PDF] claiming that VFD pumps are unnecessary, a scam, and supported by lies and false claims.

It's fair to say that not all plumbers are fans of VFD pumps and some dislike specific brands and models that in their experience were troublesome. However we should not confuse opinion with more-reliable unbiased research.

Our review of that Cyclestop Valve article found it to be factually incorrect. Which in our OPINION is too bad since other than shooting themselves in their own foot by those claims, Cycle Stop valves are a perfectly-legitimate, functional product.

We're disappointed in Cycle Stop whose product we've described in detail

at WATER PUMP SHORT CYCLE STOP VALVE

Watch out: a cycle stop valve is not a proper repair for a well pump that is short cycling - turning on and off rapidly, perhaps every few seconds or four or more times a minute when water is being run. If your well pump is cycling rapidly in that manner, before installing a cycle stop valve, check for a water-logged pressure tank.

Some Pressure Sensitive Water Pumps Omit Water Pressure Tank

Water pressure booster pumps including models that omit the need for a separate water pressure tank are used as building water pressure boosting systems, irrigation system water pressure improvements, agricultural and horticultural applications, and in industrial processes requiring a constant water pressure and flow rate.

Other VFD and pressure booster pumps are designed to work with a small pressure tank (municipal water pressure boosting) or a much larger one (well water systems).

Above is the Simer Water Pressure Booster pump illustrated by the manufacturer.

Shown above are two water pressure booster pumps that use a pressure-sensitive control and omit the requirement for a water pressure tank

. At above left is a 1 1/2 horsepower pressure booster pump suitable for a whole-house water system pressure boost, while at right in that illustration is the Simer 3/4 HP inline "on demand" pressure booster pump.

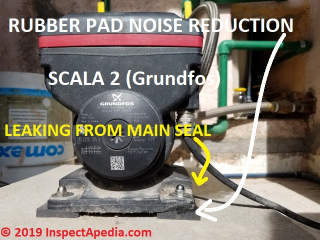

Shown above: a Grundfos SCALA2 (aka ScalaII or Scala II or Scala-II) tankless water pressrue pump in process of being installed atop a home in San Miguel de Allende, Mexico in March 2017.

- Grundfos Domestic Water Pressure Boosting Pumps, Grundfos CME Plus, BMQE system, and MQ series pumps are designed for pressure boosting systems, Grundfos Pumps Corporation

2001

Butterfield Road, Suite 1700 Downers Grove, IL 60515, Website: https://us.grundfos.com

Grundfos Indianapolis – Peerless Brand: 1-800-879-0182

Grundfos Chicago – Yeomans, Morris, Chicago Brands & Grundfos Wastewater Products: 1-800-921-7867

Grundfos Kansas City – Grundfos Brand: 1-888-237-1960

Grundfos Brookshire – PACO Brand: 1-800-955-5847

The Grundfos SCALA2 pressure pump was installed the property shown in the photograph above in March 2017.

Some important features that we found were that the pump is extremely quiet, and when running at its low speeds is unlikely to be heard outside of a utility or mechanical room at most installations.

Though the pump is very quiet we also mounted it on rubber pads (white arrow) to reduce noise transmission through the concrete roof that also forms the ceiling of an office located immediately-below.

I'm still a fan of this sophisticated pump, though by December 2018 this unit had a main seal leak (yellow arrow) about 20 months after original installation (March 2017).

See its performance discussed at

- WATER PUMP NOISE DIAGNOSIS - noisy Scala 2 improved by mounting on rubber padding

- - noisy Scala 2 pump due to seized, failed motor bearing

- Grundfos Scala 2 PUMP MANUALS [web article] provides details about this pump & a full set of installation & operation manuals, features, service history, warranty replacement information as free PDF downloads.

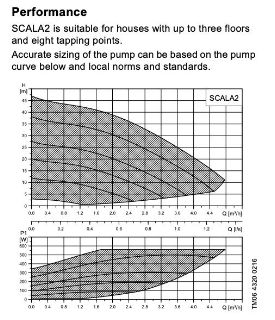

- GRUNDFOS SCALA2 DATA SHEET [PDF] retrieved 2017/03/26, original source: http://us.grundfos.com/content/dam/GPU/Literature/SCALA2/SCALA2-DATASHEET.pdf

Other VFD pumps and their suppliers are given below on this page.

Water Pressure Booster Pump Installation Notes & Warnings

Generally your pump should be installed in a dry area, protected from the weather and from freezing. Some units like the Scala 2 are also rated for outdoor use.

Check the pump manufacturer's installation instructions for the proper location of check valves in the piping system. Some pressure boosting pump models include a built-in check valve while others require an external valve or if pumping from a well, a foot valve.

Watch out: Check the pump manufacturer's advice about the maximum allowable input water pressure. If you are using the pump to boost building water pressure, for safety you may be required to install a pressure reducer/regulator on the municipal water supply line to limit the water pressure into the pump to a maximum of 20 psi (or other pressure specified by the pump manufacturer.

Watch out: warnings in the installation instructions for some of the pressure booster pumps we examined advise that you should never allow the pump to run "dry" as the pump will be damaged.

The pump body and suction line must be filled with water before the pump is turned on.

Watch out: sand and debris, such as from water obtained from a driven point well can damage the pump.

If there is sand, sediment or debris in the water supply protect the pump with an appropriate filter on the suction side of the pump.

Watch out: for leaks in the plumbing system that can damage the booster pump or that may show up in response to new, higher water pressure levels in the building or due to banging pipes that may occur due to increased water velocity when the tankless water pressure booster pump is installed.

VFD Water Pump Pressure Tank Settings

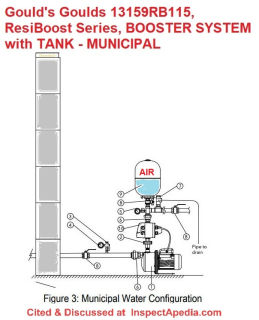

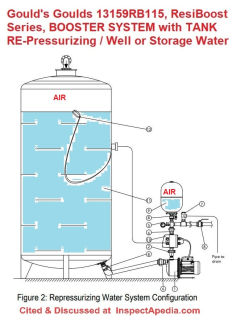

On constant pressure or VFD water pump systems, some designs use a pressure tank, either a small 2-gallon tank or a larger one.

The small pressure tank smooths out the VFD pump's water deliver at low flow rates and in the factory or default 2-gallon size, is used when the VFD pump system is functioning in an individual home or building as a pressure booster for a municipal water supply system.

Where a VFD pump system is used with a large water storage tank as a re-pressurizing system or with well water supply, often a larger water pressure tank will be installed as well, configured as shown below.

Our examples here make use of Gould's Goulds 13159RB115, ResiBoost Series, BOOSTER SYSTEM with TANK for which the IO manual is given from Xylem below on this page.

On 2023-05-08 by Larry Grotenhuis - what's the correct pressure tank setting for use with a VFD water pump / controller?

what pressure should I set my expansion tank bladder at on a Constant Pressure Well System? My VFD is set at 60 PSI on the controller.

I have a 2 gallon Well-X-Trol expansion tank.

This Q&A were posted originally

at WATER TANK PRESSURE SELF-INCREASE

On 2023-05-08 by InspectApedia Editor (mod) - pressure tank is set to 20 psi below the VFD pump pressure setpoint

@Larry Grotenhuis,

Thanks, that's a really helpful constant pressure pump + pressure tank settings question.

Why is there a little pressure tank at all on a VFD constant pressure water pump system?

The answer is that at very low flow rates, such as a single toilet flush tank re-filling, the pressure tank can let the VFD pump rest - at use rates that are so low that they're below the low-end of the pump's intended/expected delivery rate.

This is avoiding what can be more of a problem than one might think. For example, at the variable flow Scala 2 pump we use for lots of examples in this article series,

see

https://inspectapedia.com/water/Water_Pump_Pressure_Sensitive.php VARIABLE FREQUENCY / VARIABLE SPEED DRIVE WELL PUMPS (VFDs)

we found that when the water softener system is running in regeneration mode the flow rate can be so long and so slow that the VFD pump thinks that there is a water leak somewhere. That can cause the VFD pump's protection circuit to actually shut the pump off entirely, fouling up the softener's regeneration process.

What is the proper pressure tank setting for a VFD water pump system?

- an example answer, using the Xylem Goulds 13159RB115, ResiBoost Series, Booster System with Tank IO MANUAL

the company says

Set the air pressure (pre-charge) in the tank with the tank empty of water.

Pre-charge must be adjusted to be 20 psi below the Pressure Setpoint (SP) based on 5 psi pressure drop.

Notice that this is significantly-different than the "2 psi below pressure switch cut-in" for conventional pump and tank systems.

So you set the required operating pressure of your water system (that's the SP given above) using the pump's set-up instructions, then set the tank pre-charge as we just indicated, to 20 psi below the setpoint.

I think that for your system running at 60 psi that means your little 2 gallon expansion tank air pre-charge, set with the system EMPTY of water and pressure - would be set to

40 psi.

Thanks for really helpful question, let me know what you think.

- the "right" answer depends on the brand and model of VFD pump and tank that you have installed, so please give us that information so that together we can see what the IO manual wants us to do

Pressure sensitive water pump sources & IO Manuals

- AMTROL Inc.

Corporate Office

1400 Division Road

West Warwick, R.I. 02893

Phone: (401) 884-6300

Email: info@amtrol.com, Website: http://www.amtrol.com/, Amtrol RP-HP

Pressureiser water pressure booster systems include a pressure boosting pump integrated with an Amtrol water pressure tank. The system is designed to boost building water pressure 50-50 psi above the incoming municipal-supplied water.

Amtrol has offices world wide including Canada, Central America, Europe, Puerto Rico, Mexico, South America, United States - AQUASUB ENGINEERING (Corporate Office) Thudiyalur (post) Coimbatore - 641 034. Tamilnadu, India Phone: 0422-2642484 Fax : 0422-2642128 Email : aquasub@vsnl.com

- Aquatec 8800 Series Booster Pumps, Aquatec International, 17422 Pullman St., Irvine CA 92614, Tel: 800-975-9995, Website: www.aquatec.com

- Bell & Gossett: commercial grade and sized inline pumps, http://bellgossett.com/pumps-circulators/in-line-pumps/

- B&G / XYLEM ECOCIRC XL PUMP INSTALLATION & OPERATION MANUAL [PDF] (2018) Xylem / Bell & Gossett - retrieved 2022/11/17 original source: https://www.nationalpumpsupply.com/content/pdf/bell-&-gossett-ecocirc-xl-installation-guide.pdf

- BurCam Pressure Booster pumps, e.g. Burcam Model 506532SS dual application pressure booster pump can be used as a water pressure booster pump or as a shallow well single-line jet pump; Bur-Cam Company, 2190 Boul, Dagenais West, Laval, Quebec, Canada H7L 5X9, Tel: 514-337-4415, Website: www.burcam.com, also sold through re-sellers such as Northern Tool, Sears, Walmart

- Dayton 4HFA8 booster Pumps sold through Grainger, Zoro, other retailers

- e-LNE in-line pumps, capable of higher flow rates than the small systems we discussed in the article above,Xylem Water Solutions UK Limited Main Office Millwey Rise Industrial Estate Axminster Devon EX13 5HU – UK Tel: (+44) 01297 630210 Fax: (+44) 01297 630295 E-mail: lowaraukservice@xyleminc.com http://www.lowara.co.uk/

- ESYBOX AC VFD PUMP INSTRUCTION MANUAL [PDF] DAB PUMPS S.p.A.

Via M. Polo, 14 - 35035 Mestrino (PD) - Italy

Tel. +39 049 5125000 - Fax +39 049 5125950

www.dabpumps.com

Excerpt:

The product is an integrated system composed of a vertical multi-stage centrifugal electric pump, an electronic circuit that controls it and an expansion vessel.

The pump also has WiFi and Bluetooth connection systems for remote control via DConnect Cloud and for a better user experience with mobile devices via the dedicated app, see chapter 12.

The APP and DConnect Cloud also allow the use of additional features not present directly on the display (e.g. energy and flow meters).

DAB Pumps and Grundfos both distribute VFD pumps world-wide. - Flexcon, SMART TANK INSTALLATION INSTRUCTIONS [PDF], Flexcon Industries, 300 Pond St., Randolph MA 02368, www.flexconind.com, Tel: 800-527-0030 - web search 07/24/2010, original source: http://www.flexconind.com/pdf/st_install.pdf

Excerpt:

The Smart Tank pressure system provides constant pressure over a broad range of flows, and the storage that every water system needs.

The unique Smart Tee valve is connected to the Online tank with a union.

Every Smart Tank system includes a relief valve and a manifold that provides ports for the system’s pressure switch, pressure gauge, drain valve and relief valve.

This puts the controls right where they belong - at the tank. The Smart Tee valve and Online tank have been engineered to work together for optimum system performance. - FRANKLIN ELECTRIC INLINE SYSTEM CONSTANT PRESSURE SYSTEM OWNERS MANUAL [PDF] link as above, retrieved 2018/10/30, original source: http://littlegiant.com/media/130617/225883101.pdf

- Grundfos Pumps Corporation 2001 Butterfield Road, Suite 1700 Downers Grove, IL 60515 USA, E.g. the Grundfos CU 301 control and communication unit developed for SQE well pumps used in constant-pressure applications and the

- Grundfos Scala 2 PUMP MANUALS [web article] provides details about this pump & a full set of installation & operation manuals, features, service history, warranty replacement information.

- GRUNDFOS SCALA2 DATA SHEET [PDF] example of a Variable Freque3ncy VFD pressure sensitive water pump - retrieved 2017/03/26, original source: us.grundfos.com/content/dam/GPU/Literature/SCALA2/SCALA2-DATASHEET.pdf

- Grundfos CU331SP VFD PUMP CONTROLLER MANUAL [ PDF] is a constant pressure, variable frequency drive controller programmed with parameter settings optimized for submersible pump applications, and the

This switch is also discussed

at WATER PUMP PROTECTION SWITCH - LITTLE GIANT INLINE SYSTEM CONSTANT PRESSURE SYSTEM OWNERS MANUAL [PDF] link as above, retrieved 2018/10/30, original source: http://littlegiant.com/media/130617/225883101.pdf

- Pacific Hydrostar pressure boosting pump, sold by Harbor Freight and at Amazon.com, a brand trademarked by Harbor Freight, is shown just below. 90 day warranty. Pacific Hydrostar also makes pressure washers, sewage pumps, fountain pumps and utility pumps. We haven't found the actual manufacturer of this pump.

- Pentair INTELLIFLO VARIABLE SPEED PUMP INSTALLATION & USERS GUIDE [PDF] (2020) Pentair, retrieved 2022/11/17, original source: https://www.pentair.com/content/dam/extranet/nam/pentair-pool/residential/manuals/pool-pumps/intelliflo-vs/intelliflo-vs-pump-manual-english.pdf

- PENTEK INTELLIKIT HOME WATER MANAGEMENT SYSTEM CHOICES [PDF] (2012) Pentair, 293 Wright Street, Delavan, Wi 53115 USA Website: www.pentair.com Tel: 866-9 PenteK retrieved 2020/10/19, original source: https://www.pentair.com/content/dam/extranet/pentek/sell-sheets/intellikit-choices-well-system-sell-sheet.pdf#page=1

Described further at

WATER PRESSURE BOOSTER PUMP [web article]

- Rowa water pumps - Bombas Rowa, http://www.bombasrowa.com/ are distributed throughout Latin America and provide instructions in English, Spanish, or Portugese. Rua Benedito Campos de Moraes, 177 - Vila Anastácio - São Paulo – SP – CEP: 05094-010 - Tel: 55(11) 3648-9294 www.bombasrowa.com / diretoria@bombasrowa.com.br

- Simer Water Pressure Booster Pumps, Simer Pump 293 Wright Street Delavan, WI 53115, Tel: (800)468-7867, Website: http://www.simerpumps.com/

- ShurFlo industrial pumps, Pentair Food Service, 1040 MUIRFIELD DRIVE HANOVER PARK, IL 60133 USA T 630.307.3000 / 800.942.1153 (US ONLY) Website: http://foodservice.pentair.com/

- TQ Booster Pumps, Walrus Corporation, e.g. TQ400, TQ800, or TQ1500 electronic control water pressure boosting pumps

- Xylem HYDROVAR PUMP CONTROL INSTALLATION, OPERATION, MAINTENANCE MANUAL [PDF] (2015) Hydrovar variable speed drive pump control from Xylem

- Xylem Goulds 13159RB115, ResiBoost Series, BOOSTER SYSTEM with TANK IO MANUAL [PDF] (2022) Xylem Inc.

1 Goulds Drive

Auburn, NY 13021

USA

Tel: +1 (866) 325-4210

Web:

www.xylem.com/goulds - Retrieved 2023/05/08, original source: xylem.com /siteassets/brand/g oulds-water-technology/resources/manual/r esiboost-installation-manual---im325.pdf

This is the Variable Frequency Controller for VFD Goulds/Xylem water pump systems.

Overview:

ResiBoost™ is a variable frequency drive (controller) intended to be used with an electric pump for constant pressure systems. Not suitable for drainage systems with/without level control.

A water system is only occasionally required to run at maximum capacity and the amount of water withdrawn varies over time.

ResiBoost™ automatically controls the speed of the electric pump while keeping the pressure in the system constant in relation to the signal of the pressure transducer (sensor) which is integral to the drive.

InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information provided free to the public - we have no business nor financial connection with any manufacturer or service provider discussed at our website. We do not sell products nor services.

Pressure Sensitive Pump & VFD Variable Frequency Drive Pumps Research

A look at some relevant patents, books and other documents can help us understand how pressure sensitive water pump controls work.

A look at some relevant patents, books and other documents can help us understand how pressure sensitive water pump controls work.

- Arnette, Henry K. "System for protecting a liquid pump." U.S. Patent 5,244,351, issued September 14, 1993.

- Bynum, J. "Pressure sensitive control for pump regulator." U.S. Patent 3,794,789, issued February 26, 1974. Abstract:

The specification discloses a water pumping system including an electric motor driven pump coupled to an underground water reservoir by way of conduits and to an uphold storage tank for storing water

and having a pressure regulator for completing an electrical circuit to the pump motor from an electrical energy source when the water pressure falls below a preset low pressure level and for disconnecting the electrical circuit when the water pressure rises above a preset upper pressure level.

Coupled between the source and the pump motor is a pressure switch sensitive to the water pressure of the system for disconnecting the electrical circuit in the event that the water pressure falls to a given lower pressure level below the preset low pressure level of the pressure regulator. - Gray, John. "Pressure control for water systems." U.S. Patent 3,135,282, issued June 2, 1964.

Excerpt: This invention relates to a pressure control for water systems, and is particularly concerned with apparatus for delivering water or other liquid at a constant pressure when the system demand and the supply source are both variable. - Grundfos, THE ADVANTAGES OF FREQUENCY DRIVE OPERATION IN SUBMERSIBLE PUMPS [PDF] Grundfos Pump Co., retrieved 2022/05/30 original source: https://www.grundfos.com/solutions/learn/ecademy/all-courses/the-sp-submersible-pump/the-advantages-of-frequency-drive-operation-in-submersible-pumps

- Grundfos Pumps, Australia, vGrundfos Pumps Pty. Ltd

Mail: P. O. Box 2040, Regency Park, South Australia 5942

Delivery: 515 South Road, Regency Park, South Australia 5010 Web: http://au.grundfos.com/

- Herrmann, Thilo, and Uwe Schmida. "Rainwater utilisation in Germany: efficiency, dimensioning, hydraulic and environmental aspects." Urban water 1, no. 4 (2000): 307-316.

- Hollinshead, William H., "Pump control." U.S. Patent 2,765,743, issued October 9, 1956. Earlier and more traditional pump pressure control switch design for rotary pumps.

- Jones, Matthew P., and William F. Hunt. "Performance of rainwater harvesting systems in the southeastern United States." Resources, Conservation and Recycling 54, no. 10 (2010): 623-629.

- Kulkarni, Sunil Jayant. FACTORS AFFECTING PUMP PERFORMANCE-AN INSIGHT INTO RESEARCH AND INVESTIGATION [PDF] International Journal of Research & Review 4, no. 8 (2017).

Abstract:

Different geometrical parameters such as slot radial position (Rs), slot height (hs) and slot inclination angle (θs) affects pump performance.

Many investigators have carried out experiments and simulation studies to optimize the parameters affecting pump performance. Current review summarizes research and investigation on pumps and factors affecting pump performance.

Studies by various researchers confirm that with increasing the slot height, the impeller head decreased. For proper selection of a pump, it is important to have proper understanding of design restrictions, operating conditions of the irrigation system, and required flexibility in system operation.

Series configurations are used for very high heads and parallel are used in high flow rate applications.

Also studies indicated that that the friction effect on centrifugal pump can be reduced by properly studying the impeller friction losses, volute friction losses and disk friction losses. - LaValley Sr, Ronnie L. "Pressure responsive fluid pump shut off and alarm system." U.S. Patent 5,064,347, issued November 12, 1991. Abstract:

A pump supply system for furnishing well water or the like which is sensitive to and operates within a range defined by a pressure switch to supply water when pressure in the system falls below a preset minimum pressure and shut off the pump when the pressure reaches a predetermined value.

Timing means is employed in the system and preset to time out after a predesignated interval of operation of the pump.

The system will retime the next pumping cycle, if that interval of operation is not exceeded. If the pump seeks to operate beyond the predesingated time period, the timing circuit is disabled, the pump is shut down, and an alarm is activated. - Lancaster, Brad, and Joe Marshall. Rainwater harvesting for drylands and beyond. Vol. 1. Rainsource Press, 2008.

- Merritt, Herbert E. Hydraulic control systems. John Wiley & Sons, 1967.

- McIntosh, Todd. "Gray-water reclamation and reuse system." U.S. Patent 5,106,493, issued April 21, 1992.

- MPD & SWPA, THE BENEFITS OF VARIABLE SPEED PUMPING [PDF] (2016) Modern Pumping Today Magazine, Web: modernpumpingtoday.com - retrieved 2022/05/30 original source: https://modernpumpingtoday.com/benefits-of-variable-speed-pumping/

This article was written by authors at the SWPA, Submersible Pump Wastewater Association, Tel: 847.681.1868 Email: swpaexdir@sbcglobal.net Website: www.swpa.org

Excerpts:

Combining the strength of submersible pumps with the efficiency of variable frequency drives (VFDs) creates a tremendous opportunity for pump users to reduce energy costs, improve performance, and extend equipment life.

VFDs work on “Affinity Laws” where BHP of the pump is related to the cube of operating speed, with reduction in speed leads to lower resultant pressure on the fluid and hence less consumption of centrifugal energy. - Rahman, Ataur, Joseph Keane, and Monzur Alam Imteaz. "Rainwater harvesting in Greater Sydney: Water savings, reliability and economic benefits." Resources, Conservation and Recycling 61 (2012): 16-21.

- Rainwater harvesting pumps: HydroForce™ Pumps Ltd Contact Details HydroForce Pumps Ltd Unit A Harrier Park, Southgate Way Peterborough Cambridgeshire PE2 6YQ +44(0) 1733 405 107 info@hydroforcepumps.co.uk

- Rainwater Harvesting Ltd Unit A Harrier Park Southgate Way Peterborough Cambridgeshire PE2 6YQ General enquiries call +44 (0) 1733 405 111 Fax: 01733 230 996 info@rainwaterharvesting.co.uk

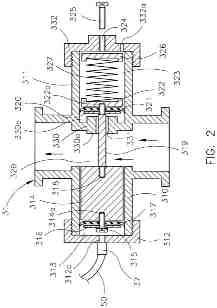

- Schaub, Robert F., "Tankless water pressure system." U.S. Patent 3,198,121, issued August 3, 1965. Abstract excerpts:

This invention relates to a tankless water pressure system and more particularly to a system for boosting water supply pressure for multi-story buildings and the like. ... One system heretofore used is a hydro-pneumatic tank system

. Such systems have the disadvantage of requiring large expensive tanks occupying a large amount of space, normally require a separate air compressor, involve substantial fluctuations in the pressure of the water supplied, and increase the air content in the water thereby increasing its corrosive action on the plumbing.

Tankless systems have also been proposed utilizing one or more continuously operating pumps driven through variable speed driving mechanisms which are controlled in response to the demand to vary the pump speed.

While such systems maintain the pressure within closer limits than a tank system and eliminate the need for the tank and air compressor, they are expensive to install and are difficult and expensive to maintain, due to the complexities of the variable speed driving mechanisms and the controls therefor.

Systems of this type, however, occupy a substantial amount of space.

It is accordingly an object of the present invention to provide a tankless Water pressure system which is simple and inexpensive to install and maintain, which occupies a minimum amount of space and which maintains the pressure within very close limits.

- Shen, Der-Fan. "Flow regulator for water pump." U.S. Patent 6,564,826, issued May 20, 2003.

Abstract:

A flow regulator for a water pump, comprising a valve body, a piston block, a spring, a connecting pipe, and a rod.

The valve body is roughly shaped like a cross, having a passageway in a vertical direction and a first tube and a second tube in a horizontal direction. The piston block is glidingly movable in the horizontal direction in the first tube.

The spring is disposed in the second tube, having ends that are fastened to inner and outer holding plates.

The connecting pipe is connected with the first tube, transmitting water pressure from a supply pipe to the first tube.

The rod connects the inner holding plate and the piston block to allow the water pressure and the elastic force to balance each other.

The piston block is pushed inward by the water pressure, narrowing the passageway, while being pressed outward by the elastic force, so that controlled water flow and pressure in the supply pipe are achieved....

The present invention relates to a flow regulator for a water pump, particularly to a flow regulator for a water pump, which controls water outflow of a water pump by a differential pressure method, achieving smooth delivery of water by the water pump. - Shen, Der-Fan. "Flow regulator for water pump." U.S. Patent 6,309,185, issued October 30, 2001.

- Smith, Dresden G. "Air and water volume control apparatus for hydropneumatic tanks." U.S. Patent 4,576,552, issued March 18, 1986.

- Speed, Russell H. "Water well pump control assembly." U.S. Patent 4,462,758, issued July 31, 1984.

This patent describes a more traditional pump pressure control switch design. Abstract Excerpt:

The control assembly includes a mounting plate, a pressure switch that responds to the pressure of the liquid in the tank, the pressure switch being mounted on the plate, a terminal board and a printed circuit board. - Triezenberg, David M. "Variable-speed motor drive controller for a pump-motor assembly." U.S. Patent 6,264,431, issued July 24, 2001. Abstract:

A liquid pump system for providing liquid to a tank includes a variable-speed motor drive and a control circuit coupling the variable-speed motor drive to a power source.

The control circuit has a switch that may be disposed in a state according to the amount of liquid in the tank.

The control circuit provides for supplying power to the variable-speed motor drive from the power source regardless of the state of the switch.

The control circuit may include a transmitter that generates a high frequency signal representative of the state of the switch. In that embodiment, a detector coupled to the variable-speed motor drive receives the high frequency signal to control operation of the liquid pump system. - Triezenberg, David M. "Motor drive circuit for pressure control of a pumping system." U.S. Patent 5,580,221, issued December 3, 1996.

- US DOE WHEN SHOULD INVERTER-DUTY MOTORS BE SPECIFIED? [PDF] U.S. Department of Energy, Advanced Manufacturing Office, Motor Systems Tip Sheet #14, retrieved 2017/11/17, original source: http://energy.gov/sites/prod/files/2014/04/f15/motor_tip_sheet14.pdf

Excerpt: Electronic adjustable speed drives, known as variable frequency drives (VFD), used to be marketed as “usable with any standard motor.” However, premature failures of motor insulation systems began to occur as fast-switching, pulse-width-modulated (PWM) VFDs were introduced.

The switching rates of modern power semiconductors can lead to voltage overshoots. These voltage spikes can rapidly damage a motor’s insulation system, resulting in premature motor failure. - Vishwanath, S. "Domestic Rainwater Harvesting–Some applications in Bangalore, India." In Rain Water Harvesting Conference. H2-1, p. 5. 2001.

- Walski, Thomas, Kyle Zimmerman, Mark Dudinyak, and Preethy Dileepkumar. "Some surprises in estimating the efficiency of variable-speed pumps with the pump affinity laws." In World Water & Environmental Resources Congress 2003, pp. 1-10. 2003.

Abstract:

The pump affinity laws are widely used in adjusting pump performance curves from one pump or speed to another.

In most cases, they work fairly well and can be reliably used in modeling studies. This paper describes an experiment undertaken to determine how well these laws apply to a variable speed pump, in which the speed is controlled by a variable-frequency drive, the most common technology used today.

The pump speed was varied from full speed to roughly 30 percent of full speed. Over that range, the affinity laws worked quite well for adjusting the pump head characteristic curves.

However, the pump efficiency curves fell significantly lower than those predicted by the affinity laws.

The explanation for this is most likely the loss of efficiency in the variable-frequency drive itself.

Since energy costs are the largest component of pump life-cycle costs, the implications for pump selection are significant.

With variable-speed drives costing almost as much as the pumps themselves, it becomes essential for life-cycle cost estimates, whether done manually or with models, to accurately account for the loss of efficiency. - Walters, William. "Pump protector apparatus." U.S. Patent 4,329,120, issued May 11, 1982.

- Ward, S., F. A. Memon, and D. Butler. "Performance of a large building rainwater harvesting system." Water research 46, no. 16 (2012): 5127-5134.

- Ward, Sarah. "Rainwater harvesting in the UK: a strategic framework to enable transition from novel to mainstream." (2010).

- Whitesides, Randall W. BASIC PUMP PARAMETERS AND THE AFFINITY LAWS [PDF] PDH Center, Fairfax, VA (2012). Contact: 5272 Meadow

Estates Drive

Fairfax, VA 22030-

6658 USA, Phone & Fax:

703-988-0088

www.PDHonline.org

www.PDHcenter.com

Excerpt: A brief discussion of the mathematics of variables and constants is undertaken to support the introduction and understanding of the Affinity Laws. The Affinity Laws allow Engineers to estimate the resulting changes to certain hydraulic parameters caused by the manipulation of a single centrifugal pump variable. - Worm, Janette. AD43E Rainwater harvesting for domestic use. Agromisa Foundation, 2006.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-01-21 by (mod) - what is the cut-in pressure for a VFD pump? Performance curve for VFD or Variable Output Pumps like the Scala2

Forgive me anon I"m not sure what's meant by "running through VFD"

Forgive me anon I"m not sure what's meant by "running through VFD"

I make "VFD" pumps to be a variable frequency drive centrifugal pump.

There are two similar approaches: an external control box that operates the pump (or another machine) providing variable speed control by varying the electrical frequency (VFD) or a VFD pump that includes that control built into the pump assembly itself.

Those pumps have (at least mine, a Scala-2 does) their own pressure sensor and on-pump settings that allow the user to select levels of delivery pressure or flow; then the pump will speed up to keep up as more fixtures are opened in the building.

The pump's rated cut-in and maximum rates are given in the pump specs, but that's not going to be a fixed set of numbers, rather it's ar range.

You can of course put a pressure gauge on the system and monitor line pressure as water is being used to see the dynamic pressure. Static pressure won't mean a thing.

I describe this type of VFD pump

at WATER PUMP VARIABLE FREQUENCY / VARIABLE SPEED DRIVE (VFDs) [web article] - pressure-sensitive, tankless water or "mini-tank" pressure booster pumps

Operating instructions and performance details & specifications for the Scala II variable speed (variable output pressure & flow) are

at Grundfos Scala 2 PUMP MANUALS [Web article]

About the pump running continuously, that sounds as if you have one of the following problems:

Check this first: debris clogging the non-return valve or check-valve on the pump outlet

there's a loss of water supply and the pump can't reach its (low) internal shutoff

there's a leak somewhere

the pump's pressure sensor is debris clogged or has failed

there is a failed control

More things to check in general (not specific to your pump type) are found by using the on page search box for

WATER PUMP WON'T STOP RUNNING

On 2020-01-20 by Abdul Rehman

How can we know about the cutt-in pressure of booster pump that is running through VFD.

My booster pump is controlling through hydrovar VFC. It is running continuously. Their is no water leakage, NRV is ok.

No leakage in pressure vessel. It's cutt-off pressure is 2.5 bar but I don't know about cutt-in pressure.

This Q&A were posted originally

at WATER PUMP INTERMITTENT CYCLING

On 2018-10-30 by (mod) - why does the constant pressure pump cycle on and off rapidly?

Brett

Brett

re your question about why during demand, your water pressure pump cycles on for 3-4 seconds and stops for 3-4 seconds,

That sounds as if you may be missing a pressure tank - on the system or there could be an obstruction in the outlet piping.

Here is what the pump manual tells us:

The Inline System needs a small pressure tank placed on the pump outlet to maintain constant pressure.

The tank supplies water while the pump ramps up to speed and in circumstances where only a small amount of water is required for a short period of time. In addition, the tank prevents water hammer by acting as a system buffer.

This buffer also helps to prevent pressure spikes when there is a sudden change in demand. For 12 gpm (45 lpm) flow or greater, minimum pressure tank size is 4 gallons (15 L); for 12 gpm (45 lpm) flow, minimum pressure tank size is 2 gallons (7.5 L).

Pressure Tank Pre-charge (PSI)

The pressure tank pre-charge setting should be 70% of the system

pressure sensor setting as indicated in the preceeding table. - see the IO Manual table on page 3.

If you don't have the IO manual for your pump you can obtain one from

- Franklin Electric 9255 Coverdale Road, Fort Wayne, IN 46809 Tel: 260.824.2900 Fax: 260.824.2909 www.franklinwater.com

- LITTLE GIANT INLINE SYSTEM CONSTANT PRESSURE SYSTEM OWNERS MANUAL [PDF] link as above, retrieved 2018/10/30, original source: http://littlegiant.com/media/130617/225883101.pdf

On 2018-10-30 by Brett

Brett said:

Thank you for responding... I don't see the reply I posted earlier today so will try again...

I have the Little Giant In-Line CP, Model # 25LGIL1100N4.

- link deleted by moderator, see image above.

Little Giant pumps (Franklin Electric) website is littlegiant.com -

With that info, it's pretty easy to find the install diagram. Plumber's design matched the diagram pretty closely. He added a bypass to be able to go back to a non-pump-assisted flow.

First, thank you for the reply. I appreciate your time and willingness to help.

The pump is a Little Giant CP. http://littlegiant.com/products/water-systems/constant-pressureboosting-systems/inline-cp/

Model # : 25LGIL1100N4

Above is a picture of the Install instructions which the plumber followed pretty well from what I can tell...

<<i'm having trouble getting a menu to appear after choosing "add image" >>

...but you can find the installation PDF pretty easily by Googling "little giant constant pressure" and looking for the PDF, "Constant Pressure System -- Little Giant Pump"

These questions were posted originally

at WATER PRESSURE BOOSTER PUMP - the home page for this topic. You will want to check the advice given there.

On 2018-10-29 by (mod) - review the pump manufacturer's instructions about pressure tanks, pressure settings, pump cycling con trols

Brett

Let's start with a careful review of the specific pump brand and model and thence its installation instructions.

If you installed a pump that is designed specifically to work *without* a pressure tank, and as you have a pressure tank installed, that could be causing the trouble you describe.

On 2018-10-29 by Brett - constant pressure inline water pump cycling issue

I had a constant pressure inline water pump professionally installed in the basement of my single story home. Incoming pressure is around 30psi; the pump is set-up to supply the outgoing water to the house around 60psi. During demand, the pump cycles on for 3-4 seconds and stops for 3-4 seconds, etc.

When the pump stops, a single 'clunk/thud' type noise can be heard behind the basement wall where the water pipe enters the house.

Currently the water pressure TANK shows 54psi. I recall my plumber telling the tank should be around 42psi (+/- 2).

Question is: could the noise I'm hearing be caused by the pressure tank having too high pressure?

Also worth noting, the demand from my irrigation system has the pump running steady for the duration of an irrigation zone -- the pressure maintains a constant 60psi. But there is no 'clunk/thud' when the system cycles to the next zone.

Reader Question: I got rid of my pressure tank and now am having trouble with short cycling.

(July 5, 2015) Mike Lambadarios said:

Have had problems with water supply ended up doing away with the header tank and pressurised the system directly to the house.

Ran fine for quite a while but is now constantly short cycling,I removed the bladder tank and blocked off the fitting again ran fine for a while but now back to short cycling again.

Was it a mistake to pressurise directly to the house and should I reinstate the header tank?

Reply: either install a water pressure tank (header tank) or install a pressure-sensitive water pump system.

MIke

Pressure-sensitive water pumps

You need either a pressure tank installed to prevent short cycling of the pump, or you need a special hydropneumatic pump control that combines the pump with a pressure switch - shown at left. This is essentially is a switch that can turn a pump on and off when needed without short cycling.

While there is a variety of tankless pressure boosting water pumps available, typically an electronic control built into or attached directly to the pump senses either a pressure drop or the flow of water when a faucet or fixture is opened in the building. The control turns on the pump and in addition the controller maintains constant water pressure until the fixture is closed.

While there is a variety of tankless pressure boosting water pumps available, typically an electronic control built into or attached directly to the pump senses either a pressure drop or the flow of water when a faucet or fixture is opened in the building. The control turns on the pump and in addition the controller maintains constant water pressure until the fixture is closed.

The pump will then stop after a brief interval of a few seconds.

A tiny built-in or attached pressure tank is factory pressurized at the "cut-in" pressure for the pump and forms part of the control that prevents rapid on-off pump short cycling.

For details about the Scala2 pressure sensitive booster pump see details

at GRUNDFOS SCALA 2 PUMP GUIDE

For short cycling pump diagnosis and repair

Water pressure booster pumps are widely used with rooftop water tank systems, in buildings where municipal water supply pressure is low, on shallow well systems and driven point wells, in irrigation systems and in similar applications.

Both tankless designs using an electronic pressure sensor and flow sensor and perhaps a tiny built-in pressure tank, and pressure booster systems designed to work with a separate water pressure tank (Amtrol) are available and are listed later in this article.

Pressure booster pump models, including the Walrus TQ series, include controls specifically designed to prevent the pump motor from cycling on and off (short cycling) when water is being run, enhancing the pump's ability to deliver water at a constant pressure.

The pressure operating range varies by pump design, brand, and model but pump pressure boost capacities are typically between 30 and 75 psi (supporting a water piping height of up to 170 feet) and deliver water at flow rates ranging from 17 to 70 gallons per minute depending on variables such as incoming pressure, pipe diameter, piping length and rise, etc.

In our photo at above left that silver domed gadget above the red pressure-sensitive water pump works with the silver micro-pressure tank to provide a boost to water delivered (typically) from a rooftop water tank. No water pressure tank is used with this system.

These systems are typically used as water pressure boosters and not as the primary water source pump. The little silver dome dome is a miniature pressure tank itself, pre-charged to 7 psi and the whole system is calibrated to avoid short cycling of the water pump.

This equipment is distributed by bombasrowa.com and is widely distributed in Mexico where often we want simply to boost the pressure delivered by a rooftop water storage tank. Keep in mind that the total flow rate and building water service from this sort of system is of limited capacity.

This equipment is distributed by bombasrowa.com and is widely distributed in Mexico where often we want simply to boost the pressure delivered by a rooftop water storage tank. Keep in mind that the total flow rate and building water service from this sort of system is of limited capacity.

Often we see pressure sensitive water pumps or inline pump controllers used with rainwater harvesting systems and cisterns or rooftop water tank systems serving small buildings. Submersible models of these pumps are also available for installation in the water tank.

Similar devices are sold by Aqua Group in India: the Aquatex APS hydropneumatic system. This approach floats a very small internal-bladder type pressure tank atop the water pump. Other models are used in marine applications such as the Shurflo and the Jabsco.

Typically a check valve is also required with pressure-controlled water pressure booster or rainwater harvesting pump systems.

Inline pump controllers to avoid using a pressure tank

A third option might be to use an in-line pump controller. An inline pump controller can be added to an existing system and works with most water pumps.

The inline pump controller senses pressure changes similarly to the pressure-sensitive water pump system we described above, and turns the pump on or off as needed. Some inline pump controllers include an additional sensor to shut off the pump if the water supply is lost, thus protecting the pump from damage.

On 2018-08-08 - by (mod) - what type/brand tank less booster pump would you recommend ?

Dan, take a look at the Scala2 pump:

GRUNDFOS SCALA2 DATA SHEET [PDF] retrieved 2017/03/26, original source: http://us.grundfos.com/content/dam/GPU/Literature/SCALA2/SCALA2-DATASHEET.pdf

On 2018-08-08 by Dan P

Low water pressure, what type/brand tank less booster pump would you recommend ?

Existing conditions: private 2" well w/ jet pump/tank primed with artesian well. pumps up hill approx. 40' to cabin. low pressure .

will install booster pump indoors in heated walk-in crawl space @ inline filter location. should pump be installed before or after filter ? Thank You, Dan.

On 2017-08-20 by Kay

Thanks for your answer, I appreciate your help.

On 2017-08-19 - by (mod) - the pressure control is put close as possible to the pressure tank - livestock watering system

Kay,

Normally the pressure control is put close as possible to the pressure tank, and they decide when to turn on the pump.

Your Tee is probably way ahead of the tank and pressure control and probably also way ahead of a check valve near the tank.

So the pump won't come on to feed your livestock waterer until pressure on the house side falls enough to turn on the pump.

The livestock won't appreciate such a setup as they'd have to let you know to run water just to give them a drink.

If you don't want to feed the livestock waterer from a water line originating at the house, you'll probably need to install a second pressure tank and pressure control switch at the livestock watering equipment and wire the second system to turn on the pump as a logical-inclusive "OR" circuit - that is, either or both switches can turn on the pump.

On 2017-08-19 by Kay

We installed a self waterer for our livestock by putting a T in the line from the submersible pump to the house that has a pressure tank in it.

The self waterer will only work if the water in the house is running and has run for about five minutes. Would an inline controller be a solution and if so where would it be placed? Would it work with any submersible pump?

On 2017-07-02 by Roland Schmid, Thailand

Booster pumps in series possible?

Hello,

I need your help to verify if this installation will work.

We need to increase todays water pressure in our the 1-storage building from 2,2-2,8 bars (31,9-40,6 PSI) up to ,5-5,5 bar (65-80 PSI).

Today the Mitsubishi booster pump model WP-255QS delivers this 2,2-2,8 bars but we cannot increase the water pressure by installing a pressure tank as the Mitsubishi pump won’t work anymore (checked with Mitsubishi already).

To simply replace the Mitsubishi pump by the Grundfos SCALA2 won’t work either as SCALA2 requires a minimal inlet water pressure of 1 bar (14,5 PSI) if the SCALA2 pump operates at 4,5-5 bars (65-80 PSI). The natural water pressure from the water tank exit is only 0,15 bar (2,2 PSI).

Our installation idea is the following:

Today’s on-ground basement 1’000L tank (unchanged), followed by the Mitsubishi pump as today (unchanged) plus an additional installation of the SCALA2 (series booster pump installation).

The inlet pressure and amount of water supplied from the Mitsubishi pump to SCALA2 would match the specifications of SCALA2.

Does something speak against this idea?

I appreciate your help. Thank you.

On 2016-01-24 - by (mod) - tankless booster pump system as an adjunct to water systems using a rooftop tank

Usually I see the tankless booster pump system as an adjunct to water systems that deliver water to the building from a rooftop tank or from a municipal system with low water pressure; generally a pressure tank system is easier on the pump and thus gives a long pump life as the pump has to cycle on and off less often.

On 2016-01-23 by krisna

which is best type for home application, is it inline pressure one or with tank model. can you clarify and compare?

Question: water pump is cycling on and off,every 2-3 sec. when a tap is opened

10 Aug 2015 Dave said:

My water pump is cycling on and off,every 2-3 sec. when a tap is opened. I have replaced the switch with a 20-40 psi switch and checked that the pressure tank ( bladder type ) has 18 psi in it.. any ideas would be helpful. Tks

Reply: rock the water pressure tank gently to see if it's waterlogged

Dave:

Watch the pressure switch. It's possible that water is not entering the tank or that your tank is waterlogged and includes a pressure gauge that's stuck, giving a false reading.

Gently rock the tank (don't break any connections) and you can usually tell if it's empty (it'll be light), and similarly, if no water is entering the tank its pressure and temperature and weight wont' change.

If you are dead certain the pressure tank accepts water and is being pumped up I cannot imagine why you'd have sort cycling every 2-3 seconds. I'd be looking for an obstruction that lets water into the tank such as a bladder stuck on itself or a nearly closed or blocked valve.

...

Continue reading at WATER PRESSURE BOOSTER PUMP - tank type water pressure boosting systems, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CISTERN & RAINWATER COLLECTION SYSTEMS

- ELECTRIC MOTOR OVERHEATS - includes overheating in variable-speed electric motors & drives

- MUNICIPAL WATER PRESSURE IMPROVEMENTS

- WATER PUMP PROTECTION SWITCH - protect pumps from short-cycling, solutions include external VFD pump controllers

- VARIABLE FREQUENCY / VARIABLE SPEED DRIVE WELL PUMPS (VFDs)

- WATER PRESSURE BOOSTER PUMP

- WATER PUMP CONTROLS & SWITCHES

- WATER PUMP LIFE EXPECTANCY

- WATER PUMP VARIABLE FREQUENCY / VARIABLE SPEED DRIVE (VFDs) - pressure-sensitive tankless water pressure booster pumps

- WATER PUMP SHORT CYCLING - home

- WATER PUMP SHORT CYCLE STOP VALVE

- WATER PUMP TYPES

- WATER PUMP & TANK I&O & REPAIR MANUALS

- WELL YIELD, SAFE LIMITS - safe total well yield, causes of flow rate change

- WELL WATER PRESSURE IMPROVEMENT

Suggested citation for this web page

VARIABLE FREQUENCY / VARIABLE SPEED DRIVE WELL PUMPS (VFDs) at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Pumptrol® Pressure Switch Adjustment, Square D, Schneider Electric Corporation, 8001 Knightdale Blvd., Knightdale< NC 27545 1-888-778-2733 - Square D Technical Library, web search 07/24/2010 original source: http://ecatalog.squared.com/techlib/docdetail.cfm?oid=09008926800a93be

- 9013 Pumptrol® Commercial Pressure Switches Type F and 9013 Commercial Pressure Switches Type G, Catalog, SquareD, Schneider Electric Industries SAS, Schneider Electric Industries SAS, web search 02/23/2011, original source:

http://ecatalog.squared.com/pubs/Machine Control/

Pressure-Float-Vacuum Switches/Pressure Switches-Water and Air/9013CT9701.pdf

Square D is a brand of Schneider Electric. - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.