How to Maximize Water Pump

Life

How to Maximize Water Pump

Life

- POST a QUESTION or COMMENT about things that impact the life of a well pump or water pump

Water pump life extension or how to maximize the life of a well pump:

This article provides a list of steps to take to maximize the life of a well or water pump and its motor.

Well pump definitions, types, & water pump life: this article series describes the different types of water pumps or well pumps, and we list the factors affecting the life expectancy of water pumps and we include a list of steps to take to maximize the life of a well or water pump and its motor.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Water Pump Life Maximization

How Can We Maximize the Life Expectancy of a Well Water Pump?

Article Series Contents

- WATER PUMP LIFE MAXIMIZATION

- Check valves: install check valves where they will protect the water pump from loss of prime and having to work as hard to restore prime. Consult the pump manufacturere's recommendations for the type and placement of check valves to protect the system. Typically we need a check valve on deep wells at a rate of one for every 250 feet of lift. Even on a shallow well we need a foot valve or check valve.

For example, while most submersible pumps contain their own integrated check valve, installing a second check valve at the top of the well or further in the well piping reduces the load on the water pump's internal valve, protects against loss of prime in the well piping, and extends the life of the water pump itself. - Low water cutoff: Install a low water cutoff to protect the pump motor from overheating should water level drop in the well.

See PUMP LOW WATER CUTOFF

Use a well drawdown low water cutoff device or well tailpipe: Install

a WELL PIPING TAIL PIECE (or well low water cutoff) or a well drawdown pump protection tailpiece in the well itself if the pump is likely to encounter seasonal low water table conditions that drop the well safe yield point, install a drawdown cutoff device or low-water cutoff device (also called drawdown protection device) in the well to protect the pump.

Install a Smart Tank or other water pressure regulation device that regulates water flow in the building to reduce the water pump cycling rate - Pump Amperage Draw & Pump operating temperature: P if the pump motor feels very hot to the touch compare its operating temperature to the rated operating temperature on the pump motor data plate. (You may need to borrow an infra red scanner and make a black dot on the motor surface to get an accurate temperature reading.)

If the water pump motor is running hot or is otherwise acting oddly check the actual motor current draw (amperage) when the motor is running under load. If the amps draw is significantly above the rated run amperage stated on the data tag there is most likely a mechanical or wiring problem with the equipment and further investigation is needed. - Pump Capacity or Horsepower: Select a pump motor horsepower or size which is appropriate for the anticipated usage

or WATER PUMP DUTY CYCLE for the well and pump installation.

In general a larger motor will outlast a smaller pump motor. Match the pump output rate to the safe well yield. See WELL YIELD DEFINITION.

This avoids

WATER PUMP CAVITATION that can damage the pump. - Pump Circuit Voltage: check available voltages on the pump motor circuit. We speculate that some electric motors will fail sooner if they are required to frequently operate at voltages lower than their design voltage range. Typically pump manufacturers state that the voltage must be within 10% of the specified or nominal pump operating voltage. [1]

- Pump installation:

- Submersible pump debris protection for submersible pumps, mount the pump far enough from the well bottom to avoid picking up dirt or debris;

- Pump mounting: the pump and related piping need to be protected from twisting movements caused by pump motor start-up and also for above-ground pumps, from vibration.

- Pump wiring: electrical grounding must be provided as specified by the manufacturer for shock protection and where required, GFCI protection as well. Include electrical surge protection and lightning protection for the pump motor, well, wiring, and controls.

- Pump Maintenance: Perform necessary pump maintenance: some water pumps require inspection and replacement of internal parts such as bearings or impellers as often as after just four or five years of use. While it may be possible to ignore this maintenance for a while, the effect may be to so wear the pump or pump motor parts that complete pump or pump motor replacement are necessary.

- Pump Lubrication: a few above-ground pump motors and other electric motors require periodic lubrication. Check your pump's installation manual specifications for motor lubrication; if the motor requires a lubricant, use the type recommended by the manufacturer. Select an oil specifically rated for use on electric motors. Don't use other oils (such as spray WD 40™ or you may damage the electric motor windings.

Watch out: do not try to lubricate an electric motor that is not specifically designed to be lubricated. - Pump Noises: listen to the water pump when it is operating.

While the noise level varies quite a bit among well pumps by type and quality of manufacturing, if you hear a significant increase in the motor noise or screeching, grinding, whining, the motor or the mechanical parts it is driving may be in trouble and further investigation is in order. Other sources of pump noise include air leaks into the well and water piping system

and WATER PUMP CAVITATION. - Pump Voltage: wire the pump for 240V: If your pump motor and control are labeled indicating that it is permitted to run the pump at either 120V or 240V, and if you are installing the pump new, there are some advantages to wiring the pump to operate

on 240V rather than 120V. The motor will start more easily and you might improve the pump motor life.

Most well pumps, except the very smallest models, can be wired to run at either voltage level. The higher voltage will make it easier for the pump to start. The efficiency of the water pump and its operating cost will be about the same regardless of the voltage used.

See EFFICIENCY of 120V vs 240V EQUIPMENT for an answer to the question of whether or not changing a well pump from 120V to 240V will save in operating cost. (Basically, no.) Also

see DEFINITIONS of ELECTRICAL TERMS for definitions of Amps, Volts, Watts, Ohms, etc. - Sediment filter: Install a sediment filter ahead of the water pump in above ground water pump installations. Most well equipment installers place a filter after

the water pump, or even after the water pressure tank rather than ahead of these components.

If the well water has a high sediment level placing a sediment filter upstream or before the water passes through the water pump will extend the pump life significantly. - Short cycling: rapid on-off cycling of the pump motor is hard on both the pump motor itself and the pressure control switch as well. Maintain the water pressure tank: a water pressure tank which has lost its air charge and is short cycling is very hard on and

shortens the life of a water pump.

See SHORT CYCLING WATER PUMPS - Water chemistry: aggressive or corrosive water may impact pump impeller and other parts life. A water treatment system may be needed. In addition to other pump motor properties such as voltage and horsepower discussed in this list, add a motor that includes internal thermal protection to protect the pump from overheating due to mineral deposits accumulating from the water supply

- Water flow rate: some pumps such as submersibles depend on an adequate water flow rate through the pump for adequate cooling. If the well flow rate is inadequate or if water flow controls slow the flow rate below the manufacturer's specifications, the pump will suffer and may have a reduced life.

- Water temperature: most well water is cool enough for this not to be an issue. But for pumps handling hot water such as from a thermal spring or natural geyser, the water temperature may exceed the pumps rating, cause it to operate too hot, and shorten its life.

- Water Pump Control & Switch life:

See WELL PUMP PRESSURE CONTROL ADJUSTMENT and its companion articles which include a discussion of the life expectancy and common modes of failure of water pump and tank pressure controls. - Water pump protection switch: install a pump control that protects the pump from running dry or cavitating.

See WATER PUMP PROTECTION SWITCH - Water piping leaks: leaks anywhere in the well or water piping system not only waste water they cause extra operation of the pump, adding to its workload and perhaps shortening its life. Leaks in the well or water piping may allow water out or air into the system.

See WELL PIPING LEAK DIAGNOSIS

and

see AIR DISCHARGE at FAUCETS, FIXTURES.

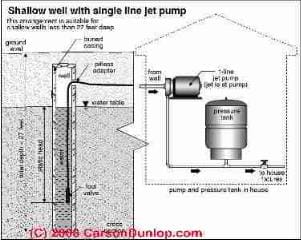

Page top schematic of a shallow well jet pump installation is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

[Click to enlarge any image]

...

Continue reading at WATER PUMP LIFE EXPECTANCY or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Suggested citation for this web page

WATER PUMP LIFE MAXIMIZATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about things that impact the life of a well pump or water pump.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Air in Drinking Water, Environmental Fact Sheet, New Hampshire Department of Environmental Services, 29 Hazen Drive, Concord NH 03301 - web search 07/14/2010 original source: http://des.nh.gov/organization/commissioner/pip/factsheets

/dwgb/documents/dwgb-3-18.pdf, original author Kenneth D. George Manager of Submersible Engineering, Franklin Electric, Bluffton, IN. - Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Kinetic water rams are described and demonstrated at waterram.com/faq.php

- Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Water Ace Jet Pump Installation Manual, instructions from Water Ace Pump Co., web search 08/28/2010, original source: http://www.waterace.com/pdf/R510%20R520%20and%20R100%20Jet%20Pumps%20Manual.pdf

Consumer hotline: 800-942-3343 - instructions for the installation and maintenance of

Water Ace shallow well pump Model R510 1/2 HP

Water Ace deep well pump Model R100 convertible 1HP and

Water Ace deep well jet pump Model R250 convertible 1/2 hp.

Water Supply & Drain Piping, Wells, Pumps, Water Supply Equipment

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.