Hand Pumps for Water Wells

Hand Pumps for Water Wells

History & Types of hand pumps: wood, cast iron pitcher pumps, deep well engineered

- POST a QUESTION or COMMENT about things that impact the life of a well pump or water pump

Well hand pump types include antique pumps made almost entirely of wood, more-modern cast iron pitcher pumps, and engineered hand-operated well pumps that can pump from greater depth.

This article series describes the different types of water pumps or well pumps, and we list the factors affecting the life expectancy of water pumps and we include a list of steps to take to maximize the life of a well or water pump and its motor.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Hand Pumps (Pitcher Pumps) & Mechanical Pumps for Pumping Water

A variety of systems to lift water out of a well, including human carriers, rope and bucket, or mechanical pumps operated by hand, wind, or other means has been in use for thousands of years.

A variety of systems to lift water out of a well, including human carriers, rope and bucket, or mechanical pumps operated by hand, wind, or other means has been in use for thousands of years.

Water lifting techniques include human or animal-rotated water wheels to lift water from a river or stream and more recently piston-type pumps that combine a vertical rod and handle to lower and then lift a piston in a pipe or tube, "sucking" water from as deep as 18-25 feet to the surface for traditional hand pump.

Photo: a traditional hand-operated well pump installed on a cistern in Guanajuato, in central Mexico.

[Click to enlarge any image]

Before the design of modern high-capacity hand pumps for lifting water, deeper wells were traditionally accessed by the simple bucket and rope method.

In the simplest of wells, the rope and bucket and winch system of the 1700's dug well is still in operation at Las Trancas in Guanajuato, Mexico.

Alternatively, bringing well water up to ground level from a shallow well by pumping permitted a more-continuous flow of water, replacing rope, bucket, and crank with a vertical pipe into which a suction rod assembly could be placed.

Lifting water from a well depth of 18 - 20 feet was the limit of the suction rod and hand pump until development of a more highly-engineered hand pump available from specialty sources.

While simple pitcher pumps are still used to draw water from a shallow well, an engineered hand pump can lift water from depths around 300 ft. .

A leather valve on the end of the suction rod seals against the inner surface of the pipe to create water-lifting suction as the pump handle moves the suction rod up and down. This simple but effective pump design could be operated by hand or by another power source such as a windmill.

We discuss windmills for lifting water separately

at WINDMILL OPERATED WELL PUMPS

Traditional hand operated water pumps or pitcher pumps like the ones shown here are able to lift water from a dug well or driven point well from depths of about twenty-five feet.

Earlier hand pump assemblies that drew water from a shallow well were constructed principally of wood and pipe extending into a shallow well.

Photos above: a wooden water pump in Washington, D.C., published 23 December 1888, and early Kodak print from the U.S. Library of Congress catalog. (Call Number: LOT 3860-1-C-2) and the Poplar Grove wooden pump, Matthews county Virginia, photographed by Frances Benjamin Johnston in 1935, also from the US Library of Congress Reproduction Number: LC-DIG-csas-05153, from Carnegie Survey of the Architecture of the South, Library of Congress, Prints and Photographs Division.

Shallow well pumps constructed entirely of wood like those we show above can still be seen working at museum sites such as the Peter Wentz farmstead, a Pennsylvania Dutch farm in Worcester, Pennsylvania.

A wooden tower, set atop a wooden well cover, supported a vertical wooden pipe made of a hardwood log, plunger-rod or suction rod using a leather end-valve, and a handle to permit hand pumping water from the well.

The first cast iron pitcher pump, funded by Seabury S. Gould, (Gould's Pumps) was made in Seneca Falls, New York in 1848, as a sand-cast cast-iron pump assembly.

More-sophisticated hand pump systems, described below, are able to lift water from greater depths.

A traditional cast-iron hand pump on a well will have trouble lifting from depth greater than about 25 feet.

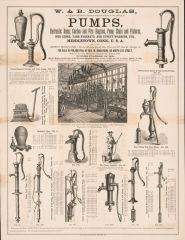

Below: From the U.S. Library of Congress photo catalog, is this image of a catalog of W&B Douglas Pumps, Middletown Connecticut, published ca 1876.

Below, snow-covered, is a similar antique hand pump drawing from a dug well in Poughkeepsie, New York.

Water Well Hand Pump / Pitcher Pump Parts & Repairs

- Vevor Co., an equipment and tool supplier, Tel: 855-385-1880, Email: support@vevor.com Web: https://www.vevor.com/ operations, world-wide.

Shown above, Vevor hand water pumps (Cast Iron), are sold in both modern and "antique" versions, and can pump from a maximum depth of 6 meters (19.6 ft.) - Water Source, Water Source, LLC 330 Milan Ave Norwalk, OH 44857 USA, Web: watersourceusa.com P: 800-346-7611

Pitcher Pumps and replacement pitcher pump leathers, sold at building supply stores such as Menards, illustrated below. A traditional pitcher pump can lift water from about 25 ft.

Below: this illustration, also from Water Source Co., shows the pitcher pump plunger assembly (sucker rod) that, by moving up and down vertically in the well pump drop pipe, provides sufficient suction to lift water from a shallow well.

Engineered hand pumps for water wells pump from greater depth

Illustration: this hand pump from the SimplePump company can pump from depths to 300 ft. according to the vendor.

Illustration: this hand pump from the SimplePump company can pump from depths to 300 ft. according to the vendor.

- Simple Pump Company 2516 Business Parkway, Unit B / Minden, NV 89423 Phone: 1.877.492.8711 (toll free) or 1.775.229.8175 Mon-Fri: 8am-5pm PST (GMT/UTC – 8 hours) Fax: 1.888.826.1444 (toll-free) info@simplepump.com * www.simplepump.com

- Sunshine works, SIMPLE PUMP INSTALATION INSTRUCTIONS [PDF] (2019) Op. Cit., retrieved 2022/05/29, original source: https://sunshineworks.com/downloads/SimplePump-HandPump-Install.pdf

- Castle, Ron, Castle, Pam, "Hand Water Well Pump Stainless Steel Simple Pump Works with Shallow Wells, Deep Wells and Solar', [Web Article] Sunshine Works, Ron and Pam Castle, 401 Lynchburg Road Winchester, TN 37398-1621 USA sales[@]sunshineworks.com +1.931.962.8665 Phone

+1.888.878.6014, retrieved 2016/04/13, original source: sunshineworks.com/pumps/hand-pumps

With a 24-inch handle a modern hand pump sold by Sunshine Works in the U.S. can provide water from a 125 foot deep well at 5 gpm at 60 pump handle strokes per minute. Increasing the pump level length to 36-inches and pumping at the same rate permits lifting water from 250 feet of depth.

Other pump models from the same company, combined with a long lever arm and a strong individual who can keep up the pumping rate without having a heart attack can deliver water from a 350-foot head. (Castle 2016)Watch out: pumping water from greater depth requires more force, and increasing the head or lift height of the water can also reduce the flow rate of gallons of water per minute that you can achieve.

Typically if your (modern, engineered) hand pump is lifting water from 150 to 350 feet of head depth and you use a 24" to 36" pump handle, and you can pump at 60 pump strokes per minute, you can obtain between 2.5 gpm and 5.0 gpm using about 18 pounds of down force on the pump handle. - Sunshine Works (2016)

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: Is this open pipe next to our hand pump a vent? How should I screen it?

I saw your article " Well Caps, Covers and Vents" at WELL CAPS & COVERS and had a quick question.

I saw your article " Well Caps, Covers and Vents" at WELL CAPS & COVERS and had a quick question.

We have a shallow well with a hand pump that has been used at our cabin for generations.

It has what appears to be a vent pipe at the base that has no cap or other means of keeping out rodents or insects or bird droppings. (See photo above).

We recently tested the water in the well and it came back positive for coliform bacteria so we are trying to determine the source of the contamination before we disinfect the water with bleach. It would appear that the most likely source is that pipe since it is open to the air.

Is that pipe in fact a vent or is that something that could be sealed with a rubber cap?

If it is a vent that needs to provide airflow, is there any other type of cap solution we could put on there that would allow for necessary airflow that would also seal it from rodents and insects and bird droppings.

If not would some simple fine screening material or cheese cloth do the trick? Thanks for your thoughts!

- Anonymous by private email, Monson, Maine 2023-09-14

Moderator reply: Use a slip-on screened vent cap to Protect a Water Well Hand Pump Vent

Thank you for a helpful hand pumped well sanitation and vent pipe cap question.

Yes I think that vertical standpipe next to your hand pump (or "pitcher pump") is probably a vent. One would need a vent if the well diameter is small and has no other easy air inlet, otherwise pumping water out of the well could be difficult.

At the InspectApedia article that you cited about WELL CAPS & COVERS (live link just above) you may have read this excerpt from California's Chapter 10 on well construction codes:

Openings.

Openings into the top of the well which are designed to provide access to the well, i.e., for measuring, chlorinating, adding gravel, etc., shall be protected against entrance of surface waters or foreign matter by installation of watertight caps or plugs.

Access openings designed to permit the entrance or egress of air or gas (air or casing vents) shall terminate above the ground and above known flood levels and shall be protected against the entrance of foreign material by installation of down-turned and screened "U" bends (see Figures 6 and 7). All other openings (holes, crevices, cracks, etc.) shall be sealed. - op. cit.

So you could install an inverted "U" bend atop that vent, but as your standpipe isn't threaded, I'll offer a couple of other suggestions.

The ideal cap for the vent pipe in your photo might be a slip-on version of the same cap that's used atop oil tank vent pipes, shown below

These caps have a built-in insect screen and a dome shaped rain cap.

Since the standpipe in your photo isn't threaded, you you'll want to buy a slip-on type vent cap like the one shown in our photo.

These screened oil tank vent pipe caps, such as the one shown here manufactured by Beckett, # OEM 4037 are sold by your local plumbing suppliers, some big box building supply stores, and of course by online vendors.

Typically these are sold to fit a 1 1/4" pipe so if your pipe is a different outside diameter, you'll either need to use a rubber coupling to connect to a short length of 1 1/4" pipe or find a similar slip-on vent cap that fits your pipe diameter. You can find these vent cap sin sizes from 1" up to 2".

More about these vents and vent caps, discussed in their application on oil storage tanks, are

at OIL TANK FILL & VENT PIPING OUTDOOR TERMINATION & CLEARANCES

An alternative might also be an air admittance valve - a one-way vent that will let air into that vertical pipe but also would screen against unwanted guests.

You can see those at AIR ADMITTANCE VALVES AAVs - home

Temporarily you might start with a simple insect screen, fitted over the top of that pipe and held in place with a stainless steel hose clamp. Don't use cheese cloth - that won't hold up where exposed to the weather. I like copper screening material for this job.

But

Watch out: where you're seeing bacterial contamination of your well water, I am not sure I agree with you that that the most likely source of shallow well water contamination is coming from the bird droppings hitting a bullseye into the top of that open vent pipe.

More-often unsanitary groundwater is leaking into the well, particularly if your well is shallow - as hand-pumped wells usually are, it's also possible that the supplying aquifer itself could be contaminated.

So if shocking the well doesn't cure the problem, and if you can't see and fix some other source of surface runoff entering the well, you may need to install a well water disinfection system.

I don't know if your well pump is over a dug well or over a shallow well protected by a well casing, but in either case you'll want to see these articles:

- DUG WELL SANITATION PROTECTION

- WATER TESTS for CONTAMINANTS - home

- WATER TREATMENT EQUIPMENT DISINFECTION - disinfection systems for water wells

- WELL CHLORINATION SHOCKING PROCEDURE - how to sanitize a well

...

Continue reading at WATER PUMP TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- HAND DUG WELLS

- HAND PUMP for WELLS

- WATER PRESSURE BOOSTER PUMP

- WATER PUMP CAPACITIES TYPES RATES GPM - general pump capacities and operating ranges

- WATER PUMP LIFE EXPECTANCY

- WATER PUMP LIFE MAXIMIZATION - how to get the longest life out of your well pump

- WATER PUMP TYPES

- WATER PUMP WONT STOP RUNNING

- WATER PUMP & TANK I&O & REPAIR MANUALS

- WELL LIFE EXPECTANCY

Suggested citation for this web page

HAND PUMP for WELLS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about things that impact the life of a well pump or water pump.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.