Warm Air Furnace Heat Inspection Steps

Warm Air Furnace Heat Inspection Steps

Additional Inspection Steps for Heating Systems & Heating System Controls

- POST a QUESTION or COMMENT about heating system inspections

How to inspect warm air furnace heating systems & additional heating system inspection points - heating controls.

This document presents alternative sequences & methods inspecting residential heating systems with focus on heating boilers and furnaces, on assuring completeness, accuracy, and on maximum heating system defect detection.

The heating system inspection methodology involved is intended to be generalized to the forensic diagnostic inspection of any complex system in order to have the highest probability of detecting important safety or operating defects.

Our object is to use an organized procedure for inspecting for defects, without losing the ability to discover unexpected problems as well. The methodology discussed includes both details specific to heating boilers (the full outline at "Contents") and more general complex-system inspection methods (listed immediately below).

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Furnaces - Hot Air Heating System Inspection & Sequence of Operation

Working Definition of a Heating Furnace

Working Definition of a Heating Furnace

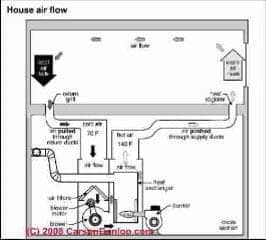

A warm air heating furnace (some call it hot air heat) is a steel or cast iron "box" connected to a series of duct work which runs through the house bringing hot air to grilles (registers).

A fan, usually at the furnace, circulates air from cold-air return grilles through duct work to the furnace where the air is heated and then returned through "supply ducts" to the living area

Sketch at left courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

An Outline of Inspecting a Warm Air Heating Furnace System by Understanding its Sequence of Operation

Details of how a furnace works are at FURNACE OPERATION DETAILS.

Here we summarize that process and name some inspection topics and concerns. If the furnace is already known to be not working at all or not working properly, start at DIAGNOSE & FIX FURNACE.

Furnaces have a simpler, operating sequence than heating boilers that were discussed in earlier articles of this series

- Heating furnace controls: Different heating system controls are used on furnaces than on hot water heating systems. To turn the furnace on and off on a call for heat: basically we use a control that operates the furnace blower - the fan/limit switch

see FAN LIMIT SWITCH

and FAN LIMIT SWITCH TROUBLESHOOTING

Other furnace controls depend on the type of fuel being used. See:- ELECTRIC MOTOR OVERLOAD RESET SWITCH

- ELECTRICAL POWER SWITCH FOR HEAT

- FURNACE CONTROLS & SWITCHES

- CAD CELL RELAY SWITCH (oil fired equipment)

- FIRE SAFETY CONTROLS (oil fired equipment)

- FLUE GAS SPILL SWITCH TRIPPING & RESET (gas fired equipment)

- STACK RELAY SWITCH (oil fired equipment)

- Thermostat calls for heat: When the occupied space or room cools, the thermostat switch closes(callingfor heat), oil burner or gas burner is turned on, oil is pumped from tank to burner or gas is delivered from piped in natural gas or LP gas, the fuel is ignited, burned.

See THERMOSTATS, HEATING / COOLING- Oil burner start-up noises, smoke or odors are signs of trouble that could risk a dangerous puffback or loss of heat.

See OIL BURNER NOISE SMOKE ODORS

- Oil burner start-up noises, smoke or odors are signs of trouble that could risk a dangerous puffback or loss of heat.

- Gas burner start up flame aberrations (wrong color, movement, patterns that lift flame off of the burner, yellow flames) are signs of trouble.

See GAS BURNER FLAME & NOISE DEFECTS

Watch Out: for sooty gas burners: If you see soot on or around gas burners such as shown in our photo (above) you should shut off the equipment (it is unsafe) and call a heating service technician promptly.

If this is the problem, cleaning rust and debris off of the pilot and igniter, or rust and debris off of the burners and checking their adjustment might fix the trouble. If the gas burner tubes include flame crossover slots, those are intended to assist the spread of flame from the first ignited gas burner tube over to the other tubes. Be sure those slots are cleaned as well.

- Combustion products are vented: Hot gases pass through a fire chamber (steel can) and via the interior of a multi-passage or serpentine steel heat exchanger, gases pass out an exhaust flue, past a barometric damper to a chimney to outdoors.

- ASHI 9.2.C. The inspector shall open readily open-able access panels provided by the manufacturer or installer for routine homeowner maintenance

- Blower fan turns on: when temperatures inside the suppy plenum reach the ON temperature set on the fan limit control switch the switch turns on the blower - a fan (usually located inside the return plenum) - that circulates air through the building.

See FURNACE OPERATING TEMPERATURES

When the fan is running it draws cool air into the duct system at the return registers and return ducts, passes it through the return plenum, through the heat exchanger, through the supply plenum, and pushes it onwards through supply ducts to supply registers in the occupied space. - Air circulation ductwork: Building air is circulated from one or more return duct inlets (accepting cool air from the building occupied space), through a return air plenum at the furnace, around the exterior of the heat exchanger mentioned above, where the air is warmed. The building air, having been heated by the heat exchanger, passes into a supply plenum (chamber) on the outlet end of the furnace.

- Warm air heating zone control: Some warm air heating systems divide heat into different heating zones by providing multiple thermostats in various areas; warm air heat delivery to each individual area is controled by a motor-operated damper in the ductwork.

See ZONE DAMPER CONTROLS.

Just about all warm air supply registers have operable levers that permit partial closing of the supply air flow to aid in balancing heat delivery in the building. (Return air registers do not include closable register louvers). - When the room thermostat is satisfied, the thermostat stops calling for heat - turning off the heating source - an oil or gas burner or in an electric furnace, electric heaters. The blower will continue to operate for a few minutes until the supply plenum temperature has fallen to a safe level.

How to Understand the Implications of Inspection Observations when Inspecting Warm Air Heating Systems

Understanding the heating furnace functions and sequence operation leads to an understanding of the implications of what might be observed during a heating system inspection, including important factors outside of the heating equipment itself.

Examples of important heating system site observations where a furnace is installed

- A common heating system observation is a problem with the air filter: no filter installed, or a crumpled leaky filter (that can be drawn into the blower assembly, jamming the fan, even causing a fire), or most common, a dirty air filter (AIR FILTERS for HVAC SYSTEMS) meaning reduced warm air output, cool rooms, increased heating costs, even increased maintenance cost when the blower fan itself has to be cleaned, or when dirt and dust collect on an A/C cooling coil.

- We might observe the combination of a wet basement and a steel furnace that combined suggest that there are high, potentially fatal carbon monoxide CO risks from rusted heat exchanger.

See CARBON MONOXIDE - CO - We might observe burn marks around the openings to a gas burner, soot or odors spilling out of a draft hood

See DRAFT REGULATORS / HOODS GAS HEATERS) or a barometric damper

See DRAFT REGULATOR, DAMPER, BOOSTER

or simply the presence of a whole house exhaust fan where a gas fired furnace is installed - clues that would warn us to look

for BACKDRAFTING HEATING EQUIPMENT - We might observe that the system is a combined air conditioner and warm air heater, with the cooling coil above the heat exchanger in the place of the supply air plenum; we might observe signs of A/C condensate leaks that could have dripped into the furnace, risking serious damage to the heat exchanger -

See FURNACE HEAT EXCHANGER LEAKS - We might observe soot stains around warm air supply registers in the occupied space but take note that often those dark stains are house dust, not mold and not soot - deposited because the system is dirty

See FURNACE HEAT EXCHANGER LEAKS - We might observe that on a call for heat the blower motor seems to stumble or have trouble starting up

See FAN MOTOR START CAPACITORS

Alternative Heating System Operating & Inspection Sequences - check the controls

Eg: immediate burner on when the thermostat is turned-on from the living area.

How to recognize different types of heating systems & controls - these are not found on forced air furnaces

- Air vents at radiators, RADIATORS

and Air-bound radiators, baseboards, boilers - Pressure switch at boiler, typically set to .2 to .5 psi

- Lower-pressure relief valve

- Water feeder, manual or automatic. (Don't mess with either, they may open and be hard to shut off.)

- Low Water Cutoff on some systems. (Also found on some hydronic boilers.)

- Different piping on some systems - one-pipe vs two-pipe, easy to identify and very different implications for retrofit/conversion to other heating methods such as hot water.

- Immediately recognized from the living area by presence of steam valves on radiators. Don't confuse steam valve with air bleeder valves found on hot water radiators.

- Steam rises--hence no circulator pump - if you see a pump is it a separate HW zone? is it a condensate return pump?

Example of understanding function=understanding implications

A pressure control set to 10 PSI indicates some operating problem with system, addressed by a service person who's trying to "force" steam into the house rather than debugging a problem, probably with piping or steam valves. Service has been by someone unfamiliar with steam systems.Absence of any sign that the occupants ever drain and clean the automatic water feeder suggests risk of inoperative key safety device. Needs attention even if you see absolutely no problems. Modified piping? improperly sloped radiators?

© Copyright Daniel Friedman 2014-2015 all rights reserved -- Tri-State ASHI Seminar -- Last update 08/03/2014 - first presentation November 6-7, 1993

...

Continue reading at FINAL BOILER/FURNACE ROOM INSPECTION CHECKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- HEATING SYSTEM INSPECTION - home

- HEATING INSPECTION CONCEPTS - home

- CONDENSING GAS FURNACE INSPECTION & TESTS

- FINAL BOILER/FURNACE ROOM INSPECTION CHECKS

- GAS BURNER FLAME & NOISE DEFECTS

- GAS BURNER SOOT CAUSE & CURE

- GAS BURNER PILOT LIGHT PROCEDURE

- HEAT EXCHANGER CORROSION

- HEAT EXCHANGER LEAK TEST

- HEATING INSPECTION PROCEDURE-GENERAL

- HEATING SYSTEM INSPECTION DETAILS

- HEATING BOILER INSPECTION GUIDE

- HEATING FURNACE INSPECTION GUIDE

- HEATING SYSTEM SAFETY INSPECTION

- INDOOR INSPECTION of HEATING SYSTEM

- OIL BURNER INSPECTION & REPAIR

- SAFETY RECALLS CHIMNEYS VENTS HEATERS

Suggested citation for this web page

HEATING FURNACE INSPECTION GUIDE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about how to inspect heating furnaces & heating system controls. .

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.