How to Diagnose Oil Burner Noise, Smoke, Odors

How to Diagnose Oil Burner Noise, Smoke, Odors

- POST a QUESTION or COMMENT about how to diagnose and fix the causes of oil burner noises, smoke, soot, or odors & smells

Oil burner noise, odor, performance or smoke troubleshooting:

Some oil burner noises are normal, others indicate trouble - we explain the difference.

We also explain how to recognize & diagnose the cause of oil fired heating boiler noises, leaks, odors, or soot and smoke.

We describe just about any noise that you might hear at or near an oil burner, where it comes from, what it means, and what needs to be done about it.

We discuss: What oil fired heating system noises are abnormal and may indicate an operating problem or an unsafe condition? What can we do to reduce heating system operating noises? Diagnose & repair oil burner soot, puffback, rumbling, hard-starting.

Oil burner noise: rattling oil burner motor sounds - "combustion ventilator"? Flue gas exposure hazards, smells, odor. How to diagnose loss of heat, heating boiler noises, leaks, odors, or smoke. Cause & cure for heating boiler "snap, crackle, & popping" noises: antifreeze acidified & debris in the system: flush out needed.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Diagnose Noises During Oil Burner Operation

This article series answers most questions about central hot water heating system troubleshooting, inspection, diagnosis, and repairs.

This article series answers most questions about central hot water heating system troubleshooting, inspection, diagnosis, and repairs.

What Oil Fired Heating System Noises are Normal and What are the Noise Sources?

Some heating system and heating oil burner noises are considered normal. These include noises coming from the following items:

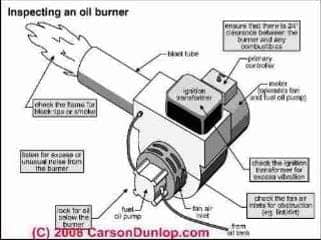

The sketch above is provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

- Electric motor noise: The electric motor which operates the oil unit and blower unit on the oil burner, or an electric motor which may operate a furnace

blower fan or a flue-vent draft inducer fan.

However some electric motor noises are "normal" while others indicate trouble, as we will elaborate below.

Details about electric motor troubleshooting are

at ELECTRIC MOTOR NOISE DIAGNOSIS. - Combustion air fan noise: The combustion air blower, usually a squirrel cage fan on oil burners is spun by a shaft extending out of the

oil burner's electric motor.

The blower itself produces noise as it spins and moves air into the combustion chamber. Unless the oil burner blower is damaged you probably won't hear it over the other noises produced at the burner. - Warm air furnace blower noise: Furnace blower fan units:

A bad furnace fan blower motor or assembly may produce noise you would indeed hear above the noises coming from the oil burner itself. - Heating oil pump noises: The oil burner's heating oil pump or "fuel unit" is usually driven by a shaft (and couplings) which begin at the electric

motor on the oil burner, extend through the combustion air blower, and connect to a drive shaft protruding from the oil pump.

Unless there is an internal problem with the pump, these units are pretty quiet compared with other normal oil burner noises.

But a pump may whine, rattle, buzz, or make other funny noises when something is wrong.

See HEATING SYSTEM BUZZING NOISE

See OIL BURNER FUEL UNIT for details on diagnosing and fixing noisy troublesome oil burner fuel unit pumps.

also

see OIL BURNER RATTLING NOISE - Draft inducer fan noises: A flue vent connector-mounted or chimney-mounted combustion gas vent draft inducer fan if one is used, is usually audible, and in a typical installation you'll hear this fan turn on up 15 seconds or so before the oil burner itself begins to operate.

- Oil burner combustion noise: Oil burner flame or combustion noise is usually the loudest "normal" noise coming from an oil burner.

The fuel unit pumps heating oil to 100 psi or higher, then sprays it through an oil burner nozzle where the oil is ignited by electrodes mounted in the oil burner's tube at the entry to the combustion chamber. The "roar" that you hear at a normally operating heating system oil burner is usually produced mostly by this combustion process.

Watch out: if you hear a "bang!" sound when the oil burner is starting that may indicate the ignition of accumulated unburned fuel in the combustion chamber.

If you have not already had a messy and destructive puffback one is quite possibly imminent. The need for oil burner service is urgent and the system may be unsafe.

Watch out: if you see soot or smoke or smell combustion gases, possibly accompanied by an increase in oil burner or heater noise, the system is not operating properly and may be unsafe.

See OIL BURNER SOOT & PUFFBACKS

Also see BANGING BOOMING NOISE DIAGNOSIS & CURE - home - High speed oil burner noise compared with low speed oil burner noise: High speed oil burners noises: older traditional oil burners used on heating boilers and furnaces were driven by an electric

motor spinning at 1725 rpm.

Modern "high speed" heating system oil burners usually run at 3450 rpm. The higher speed permits more air flow and greater oil burner efficiency.

But in buildings where an older low-speed oil burner is swapped out for a new "high speed" oil burner unit, the occupants are often surprised to hear that the new equipment is noticeably noisier than the old unit.

This is normal, and your heating installer would have been smart to tell you to expect this change so you don't think something's wrong with the new heating system. You're tolerating more noise for lower heating system operating costs.

George Lanthier (Fuel Oil News) reported on customer complaints about the increase in noise when new, more energy efficient but noisier oil burners are installed.

In a 2006 article in that publication he offered several suggestions of which his first is that oil companies should "scare the dickens out of the customer" meaning that the vendor should prepare the client for an increase in heating system noise level.- Oil burner mechanical noise: Break the noise levels down by area in the equipment: is the noise from the burner itself?

He argues that the burner mechanical parts are pretty quiet (barring a bad bearing or motor-DF); - Oil burner flame noise: draft conditions can affect flame noise, but Lanthier skirted the basic fact that doubling the burner speed along with concomitant higher oil and combustion chamber pressures increase noise levels. Careful selection of oil burner nozzle, flame retention head and head settings may reduce this noise a bit.

- Switching to intermittent oil burner ignition (most residential burners run the igniter all during burner operation) may reduce burner flame noise and also reduce NOX emissions. A service tech can test for this benefit by installing a jumper to permit temporary turn-off of the ignition circuit once flame is established. (Appropriate safety controls must also be installed).

- Hollow-cone oil burner nozzles may reduce flame noise. Indeed we (DF) recall from oil burner service days that changing the oil burner nozzle to a flame type and pattern that better matched the burner and combustion chamber could make a large difference in how the burner and flame behaved and sounded.

We had good success at reducing rumbling noises at older oil burners by changing to a Monarch AR oil burner nozzle of the proper size.

See OIL BURNER ELECTRODES for details.

Also see OIL BURNER RUMBLING NOISE - Measure the system standard heating tuneup parameters including smoke and CO2 to verify that your adjustments have improved, not hurt, system performance. We often found better combustion efficiency using hollow-cone oil burner nozzles -DF.

- Oil burner mechanical noise: Break the noise levels down by area in the equipment: is the noise from the burner itself?

- Chimney noise: In Lanthier's opinion this is the most serious noise problem from heating systems. Certainly we'd agree that many chimneys act as sound amplifiers and transmitters through a building. But

Watch out for chimney fires: a roaring freight train sound that means a deadly dangerous fire is occurring (more likely with a wood-stove).

More on chimneys is

at CHIMNEYS & CHIMNEY FIRES. Steps to reduce chimney noise, assuming we don't have a dangerous condition, include:- Install a chimney liner (have this done by a professional, certified chimney service company) to reduce noise, condensation problems, and oversized flues that may create venting and even safety problems.

See NFPA31-2001, National Fire Protection Association and read all of Appendix E, “Relining Masonry Chimneys” . - Litman chimney elbow: Lanthier describes an idea from Roger Litman (North Shore Fuel) who adds an elbow at the end of a flue pipe run in the base of a chimney to reduce chimney noise.

The elbow both reduced noise and improved chimney draft, perhaps because the elbow adds length and thus velocity to incoming chimney vent products.

Add a drainage hole in the low point of the elbow, and "get the outlet of the elbow to angle about 15 degrees to the base".

- Install a chimney liner (have this done by a professional, certified chimney service company) to reduce noise, condensation problems, and oversized flues that may create venting and even safety problems.

- Watch out: Too-Quiet Chimneys can mean big trouble: Lanthier explained that a blocked chimney flue can reduce heating system noise below normal levels, but of course a blocked chimney is dangerous, risking a fatal carbon monoxide poisoning condition as well as improper and unsafe heating boiler or furnace operation and damaging the burner itself (backpressure-burning off the burner end).

What oil fired heating system noises are abnormal and may indicate an operating problem or an unsafe condition?

Noises & soot buildup can lead to a potentially dangerous puffback which can damage the heating equipment and blow soot and smoke throughout the building. An experienced heating service technician may recognize the following diagnostic list of heating system or oil burner noises as well as perhaps other signs of trouble:

- Chimney fires: Watch Out: DANGEROUS, IMMEDIATE ACTION NEEDED: Very loud noise like a roaring freight train coming from a chimney is likely to be a

chimney fire- extremely dangerous, risking a house fire: turn off heat as you run out of the house: call the fire department from your cell phone or from a neighbor's house.

A chimney fire moves fast, loud, and produces lots of smoke. In fact a quick look at the chimney serving a heater at any time can tell you how the heating system is operating. If the chimney top shows smoke or soot (without the freight train noise of a chimney fire) the burner is not operating properly.

Watch out: If you have a chimney fire (or any kind of fire) stop reading this Internet article, leave the building immediately, and call your fire department.

Later See CHIMNEY INSPECTION DIAGNOSIS REPAIR for details of chimney inspection, diagnosis, and repair, including- BLOCKED CHIMNEY FLUES - article on flue vent connectors

- BACKDRAFTING HEATING EQUIPMENT, leaks, and odors from flues.

Separately we discuss CARBON MONOXIDE hazards in buildings.

- Banging Noises during oil burner startup - a "bang" or puffback which blows soot into the room through the barometric damper or through other equipment openings: the oil pump may not be shutting down properly at the end of

an oil burn cycle, leaking incompletely burned oil into the combustion chamber. That oil ignites at startup causing a potentially dangerous puffback. Immediate service and repair are needed.

Watch out: an oil burner puffback not only creates a horrible mess, it is dangerous.

The puffback can cause the flue vent connection between oil fired appliance and chimney to separate, sending sparks and combustion gases into the building - risking a fire as well as possible dangerous carbon monoxide gas release.

More Oil Burner Startup problems: noises and clues of puff back: if you see flapping at the barometric damper or if you see or hear vibrations in the system, prompt service is needed

Details about these "explosion" sounds at oil burner start-up are at

OIL BURNER SOOT & PUFFBACKS.

And a common cause of puffbacks, oil piping leaks, are discussed

at OIL SUPPLY LINE PIPING LEAKS.

Also see BANGING BOOMING NOISE DIAGNOSIS & CURE - home - Electric motor noises: a modest humming is normal at most electric motors;

see ELECTRIC MOTOR NOISE DIAGNOSIS for diagnostics - Hums and clicks or buzzing: can be a sign of an oil burner that has gone "off on safety" - the burner needs cleaning, adjustment, repair. Other hums may be traced to a failing control or control transformer.

See OIL BURNER HUMMING NOISE

and

See OIL BURNER BUZZING NOISE

and because humming sounds at oil fired heating equipment can originate at or be transmitted by the heating oil piping,

see OIL LINE BUZZ & VIBRATION CURE - Noises during oil burner startup - a "rumbling" sound (which usually continues all during operation" or a "stumbling" sound in the combustion chamber probably indicates that the system needs inspection and cleaning.

Watch out: incomplete combustion and oil burner start-up or shut-down problems can lead to a dangerous PUFFBACK EXPLOSION. Such systems need service by a trained expert.

Some noise is normal however, but the normal sounds tend to be more smooth and continuous.

See OIL BURNER RUMBLING NOISE where we give the causes, hazards, and cures for oil burner rumbling. - Noises during oil burner shut-down - a stumbling or rumbling after the oil burner motor has stopped, indicate that oil is continuing to leak into the combustion chamber and risks a dangerous puffback - see "Noises during oil burner startup" above. Immediate service is recommended.

- Oil burner motor or fuel unit noises of shrieks or grinding coming from the electric motor or oil pump on the oil burner mean that immediate service is needed - probably a bearing is failing. Beckett (1989) noted that excessive oil burner motor noise may be due to excessive motor shaft end play.

Details about the cause, diagnosis & cure of noisy oil burner electric motors are

at ELECTRIC MOTOR NOISE DIAGNOSIS. - Furnace noises of shrieks, whining, or grinding coming from the electric motor or blower assembly of a furnace air handler probably mean that the system has a bad bearing (or fan belt) and prompt repair service is needed.

It's best to shut down such a system since certain failures, such as sucking a furnace filter into the blower assembly, can lead to overheating and cause a fire. - Noises from radiators or heating baseboards: clanking pipes or sharp snapping noises may be heard as a normal consequence of expansion of metals during the heating cycle.

These noises can often be eliminated or reduced by careful routing of piping and by allowing room around heating pipes for expansion, but probably not eliminated in the case of hot water baseboards.- Bubbling or rumbling noises in hot water heating piping can be caused by air in the heating lines. If the amount of air becomes excessive the system may be unable to circulate hot water and extra steps to bleed unwanted air will be required.

- Hissing sounds such as air escaping from radiators or other piping where air bleeder valves are installed are normal but should be brief and uncommon. If you constantly hear air hissing from radiator bleed valves double check that you understand what kind of heat you have - hissing from bleeder valves on steam heat radiators as heat is coming up in the building is normal.

- Noises from Oil Tanks or Oil Piping: Vibrations of the heating oil piping, especially if installed passing overhead along building framing and if installed without sound isolation can use the ceiling as a giant speaker and may be quite loud.

See OIL LINE BUZZ & VIBRATION CURE - Noises from air leaks: on furnaces (hot air systems) we sometimes find that an air leak in the duct system or air handler, or quite often around the air filter itself, can make lots of noise.

- Rattling noises at the oil burner: typically indicate a loose part or failing bearing.

See OIL BURNER RATTLING NOISE - Rumbling noises at the oil burner: may be normal, especially if the noise has not changed, and can often be reduced by choice of a different oil burner nozzle.

But an increased rumbling noise can be a sign of burner, combustion chamber, or even chimney problems.

Watch out: in some cases rumbling noises at the oil burner indicate that the heating system is unsafe or that there could be an immediate emergency: a chimney fire.

See OIL BURNER RUMBLING NOISES - separate article offering complete details about the cause, dangers-of, and cures for rumbling sounds at the oil burner. - Snap crackle pop noises: possibly traced to an antifreeze contamination problem.

See OIL BURNER CRACKLE POP NOISES - Vibration and buzzing at oil burners: Common sources of vibration or sources of buzzing vibrating sounds in or close to an oil burner include:

- The oil burner electric drive motor bearings,

- the oil burner combustion air blower assembly bearings,

- inside the fuel unit or oil pump an out of balance internal part or more seriously, a failing fuel unit can produce vibrations that may be transmitted via oil piping (common)

- There is also usually a flexible rubber bushing (the coupling assembly) that connects the driving electric motor through the blower assembly to the fuel unit drive shaft. If that part is the problem you're in luck as it's a low-cost repair. (uncommon)

- oil burner assembly mounting bolts that are loose (uncommon)

- buzzing electrical components: on occasion a failing HVAC control will emit a buzzing sound, often traced to a faulty transformer or relay (common)

See HEATING SYSTEM BUZZING NOISE - buzzing or vibration noises at the heating equipment itself

and

SeeOIL LINE BUZZ & VIBRATION CURE - buzzing or vibration noises that seem to originate at or are transmitted by the oil piping

What can we do to reduce heating system operating noises?

Heating equipment located well out of occupied space, in an unoccupied basement, for example, are not usually a source of noise complaints in a building, though there are a few exceptions for which we have suggestions.

- Consult your heating service technician first to be sure that the heating system is operating normally and safely, before

attempting any other steps to reduce noises coming from the heating system.

Describe the heating system noise you are observing including the following that may help the service expert:- What is the character of the noise: bang, rumble, squeak, hum, hiss, etc.

- When does the noise occur: at oil burner start-up, continuously during burner operation, intermittently

- How long has the problem been occurring

- What visible clues of trouble are evident: soot

- What olfactory clues of oil burner trouble are evident: heating oil odors

- How to cure vibrations of the heating oil piping or oil tank: re-route piping between the oil tank and the oil burner

to remove any contact points with overhead ceiling framing or flooring;

if those contact points are necessary to support the line, be sure that the oil line is supported with noise-suppressing fittings (we use foam rubber and copper pipe clamps) and that the piping is well secured.

Details are at OIL LINE BUZZ & VIBRATION CURE - How to cure warm air heating system air duct or filter noises see

- LOOSE or LEAKY AIR CONDITIONING or HEATING DUCTS

- VIBRATION DAMPENERS & ASBESTOS at the AIR HANDLER - make sure your vibration "damper" (proper lingo is "dampener") is properly installed, sized, and not leaky.

- UNDER-SIZED RETURN AIR DUCTS can cause excessive duct noise since inadequate return air means the system is "return-air starved" and will suck air into the duct system at any available (and noisy) opening.

- ANALYSIS of the EFFECTIVENESS of AIR FILTERS on HVAC SYSETMSincludes discussion of air bypass leaks at air filters. Be sure to review this noise source as it's easy to correct.

- Oil Burner Noise Insulation: some of our readers suggest building an insulated box around the oil burner to reduce its noise.

Watch out! If you constrict or reduce the amount of combustion air available to the oil burner it will not operate properly and the system could become unsafe.

Be sure to discuss the design of any noise insulation scheme and its possible effects on combustion air or other heating system considerations with your heating service technician. - How to prevent oil burner puffbacks: be alert for signs of a developing oil burner puffback situation such as sooty heating equipment operation, heating oil odors, and stumbling oil burner operation.

Often a small "bang" at oil burner startup is a sign of a mini-puffback that may be developing into a major BANG that will leave you sorry you waited to call your service technician.

Watch out: Because puffbacks can be caused by a variety of problems (oil piping line leaks, dirty oil burner nozzle assembly, fuel or combustion air problems, simply failure to maintain the system) a trained service technician is needed.

See OIL BURNER SOOT & PUFFBACKS

Articles at this website describe how to inspect, troubleshoot and repair heating and air conditioning systems to inform home owners, buyers, and home inspectors of common heating system defects.

...

Continue reading at OIL BURNER NOISE / ODOR DIAGNOSTIC INDEX or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see OIL BURNER NOISE DIAGNOSTIC FAQs - questions and answers posted originally on this page

Or see these

Recommended Articles

- HEAT WON'T TURN ON

- HEATING SYSTEM NOISE DIAGNOSIS

- ODORS in AIR HANDLERS & DUCT WORK

- OIL BURNER INSPECTION & REPAIR - home

- BUILDING EXTERIOR Oil Burner Trouble

- BUILDING INTERIOR Oil Burner Trouble

- OIL TANK EFFECTS on OIL BURNER

- BOILER / FURNACE ROOM TROUBLE SIGNS

- OIL BURNER VISUAL INSPECTION

- OIL BURNER OPERATING TROUBLE

- OIL BURNER INSIDE TROUBLE

- OIL BURNER SMOKE TEST

- OIL BURNER NOISE SMOKE ODORS - home

- OIL BURNER NOISE / ODOR DIAGNOSTIC INDEX

- OIL BURNER BANGING NOISE

- OIL BURNER BUZZING NOISE

- OIL BURNER CHOKING SOUND

- OIL BURNER CLANKING NOISE

- OIL BURNER CLICKING SOUND

- OIL BURNER CRACKLE POP NOISES

- OIL BURNER PIPING GURGLING

- OIL BURNER HUMMING NOISE

- OIL BURNER RATTLING NOISE

- OIL BURNER ROARING NOISE

- OIL BURNER RUMBLING NOISE

- OIL BURNER SQUEAING & HIGH PITCHED SOUNDS

- OIL BURNER START & STOP NOISES

- OIL BURNER SOUNDPROOFING

- OIL BURNER SOOT & PUFFBACKS

- OIL BURNER WONT RUN - Diagnostic Steps - what to check in what order

- HEAT WON'T TURN ON

Suggested citation for this web page

OIL BURNER NOISE SMOKE ODORS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING OIL, OIL BURNERS, OIL FIRED HEATERS, OIL TANKS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Beckett Oil Burners, "Burner Motor Service Facts", Beckett Corporation, Technical Information, 15 June 1989 [copy on file as PDF].

- Lanthier, George, "Noise and Moisture, Using scare tactics” may be necessary when installing a new heating system", Fuel Oil News, M2MEDIA360, 1030 W. Higgins Road Suite 230, Park Ridge, IL 60068 847-720-5600 02/1/2006. Web: fueloilnews.com/me2/default.asp

According to Fuel Oil News, George Lanthier owns Firedragon Enterprises and is the author of nine books on oil heating and heating systems. He is a teaching consultant and expert witness on oil heating systems. He can be contacted at 132 Lowell Street, Arlington, MA 02474-2756. His phone number is (781) 646-2584 and he can be faxed at (781) 641-7099. He can also be contacted through his Web site FiredragonEnt.com - OIL BURNER EQUIPMENT WIRING, George Lanthier

- The Cmr 4.00 Guide: a Detailed Guide to the Massachusetts Regulation on Oil burning Equipment, George Lanthier

- The hot water handbook: An advanced primer on domestic hot water, George Lanthier

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.