Flood Damage Repairs for Heating Systems

Flood Damage Repairs for Heating Systems

How to

restore flooded heating boilers, furnaces, water heaters

- POST a QUESTION or COMMENT about cleaning & repairing flooded heating equipment: oil & gas or electric boilers, furnaces, water heaters

How to clean & restart flooded heating equipment or restore a flooded water heater to service:

This article describes procedures for inspection and repair of flooded heating appliances: flooded heating boilers, furnaces, and water heaters. We include post-flood start-up procedures for air conditioners, air handlers, heating boilers, furnaces, and water heaters.

Area flooding due to storms or building flooding due to a fire or burst water pipe can leave heating appliances inoperative as well as unsafe to use unless adequate inspection, cleaning, and repair or replacement of certain parts are made.

Our page top photo shows a client pointing to the level reached by flood waters in a building basement - the heating boiler, water heater, and other basement appliances had been inundated with muddy water from area flooding.

Different depths of flooding have different implications for inspection & repair of heating appliances after hurricanes, rising flood waters, burst pipe leaks, of sewer backups. We describe recommended safety checks, inspections, & repairs for flood-damaged water heaters, boilers & furnaces.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Flood Response: Inspection & Repair Advice for Flooded Heating Boilers, Furnaces, Water Heaters

This article describes air conditioning & heating system components that you need to inspect, clean, repair or replace after the equipment has been partially or completely flooded or otherwise damaged by a flood or other disaster.

For each component we explain what needs to be done to safely return the component and the system to safe reliable operation to provide building heat or hot water.

We include links to articles giving further details about cleaning, troubleshooting, or repair if needed.

Article Series Contents

- HEATING EQUIPMENT, FLOOD DAMAGE REPAIR

- RE-START a FLOODED OIL BURNER: what steps are needed to get an oil fired heating boiler, furnace or water heater going after a flood?

- AIR HANDLERS: air conditioning & warm air furnace flood or storm restoration steps

- BOILERS: hot water or steam heating system flood or storm restoration steps

- BASEBOARD or RADIATORS inspection & restoration after a flood

- CHIMNEYS: check the chimneys, flues, and vents after building flooding or other disasters

- COMBUSTION CHAMBER & chamber liner: dry or replace after flooding

- CONTROLS On heating equipment: how to inspect, test, or (usually) replace after flooding

- DUCT SYSTEM FLOOD or WATER DAMAGE - separate article

- GAS BURNERS & Gas Fuel System & gas piping & appliance checks after building flooding or other disaster

- INSULATION in air handler, boiler, furnace or water heater insulation inspection & cleaning/replacement after a flood or other disaster

- OIL FIRED HEATERS: oil burner, fuel unit oil filter & oil piping, valves & oil tank restoration to service after building flooding or other disaster

- PRESSURE TEMPERTURE RELIEF VALVE assembly inspection & restoration after a flood or other disaster

- FLOOD DAMAGED WATER HEATER REPAIR: Checks & tests for restoring a flooded or storm damaged water heater to service

- FLOOD DAMAGE RESTORATION RESEARCH & STANDARDS on restoring flood damaged buildings

How to Restore Heating Systems or Water Heaters to Operation after a Flood or Other Disaster

Question: How do I get my oil fired water heater, boiler, or furnace running again after building flooding?

I am having problems restarting the water heater ever since hurricane Irene slammed into New Jersey and my basement flooded. We changed the motor and oil filter, but are having problems getting oil to feed through the lines I was wondering if there were suggestions. - Antoinette

Reply: recommended inspection & cleaning, replacement or repair points for oil fired water heaters, heating boilers, furnaces after a flood or other disaster

When an oil fired water heater has been flooded, such as by hurricane Irene that flooded the Northeastern U.S. in August 2011, there are a number of concerns that need to be addressed.

Before addressing flooded water heaters, boilers, or furnaces, if your building has been flooded,

see FLOOD DAMAGE ASSESSMENT, SAFETY & CLEANUP for advice about priorities of entry, diagnosis & repair of homes or other buildings after flooding from any cause.

CMHC provides this nice summary statement, for which we provide actual how-to details in this article:

If they have been soaked, consult an HVAC (Heating,Ventilation and Air Conditioning) contractor to replace the furnace blower motor, switches and controls, insulation and filters.

Inspect all flooded forced air heating ducts and return-duct pans and have them cleaned out or replaced. Seek advice from your local utility about a water heater that has been wet. Refrigerators and freezers may need to be replaced. [8]

Now to the flooded water heater: you report having taken two important post-flood steps by changing parts (motor and oil filter) but below we have listed suggestions that might help get the water heater (or a flooded heating boiler or furnace) running again and also assure its safety and forward life.

The extent of disassembly, inspection, and replacement of parts of any heating appliance (water heater, furnace, boiler) after building flooding depends on the height reached by floodwaters and perhaps also the duration of flooding.

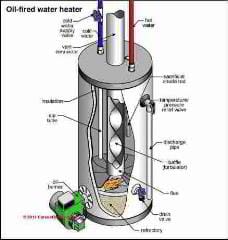

Our flood damage photo at the top of this page shows our client pointing to flood water markings on the heating system expansion tank - water had nearly filled the basement of this home - the heating boiler had been completely under water. Our oil fired water heater sketch (left, - Courtesy Carson Dunlop Associates, used with permission) shows the internals of that appliance and illustrates what gets wet at different flood water levels.

Certainly any water heater, boiler,or furnace component that was under-water or soaked needs to be inspected, and as appropriate, cleaned or replaced. On the other hand, basement flooding that did not even reach the level of the oil burner assembly may have left that component intact, but still may have entered and damaged the heating appliance combustion chamber.

We list and describe procedures for every post-flood inspection and repair point for air conditioner air handlers, boilers, furnaces, and water heaters in the text below.

Air conditioning & warm air furnace flood or storm restoration steps

Check the air handler, blower assemblies, filters, & duct system of air conditioning or warm air heating systems after flooding or other disasters

The level of cleaning, repair or replacement of a flooded air handler used for air conditioning or warm air heating depends on the depth to which the unit was flooded and on just what components have become wet or flooded.

If the heating equipment was exposed to just a wet floor or even an inch of water it may be possible to quickly return the system to operation.

But if the heating equipment was soaked (such as during extinguishment of a fire) or flooded (by rising floodwaters) then its safety controls, motors, switches, combustion chamber and other components that were wet or flooded will need cleaning, repair, or replacement, as we will describe below.

For detailed assistance with heating or cooling equipment that won't run after you've cleaned and replaced parts, see these articles:

- DIAGNOSTIC GUIDE A/C or HEAT PUMP

- DIAGNOSTIC DETAILS A/C or HEAT PUMP

- DIAGNOSE & FIX HEATING PROBLEMS-FURNACE - what to check if the furnace won't run or is not working properly

- FURNACES, HEATING - flooded air handlers and blower assemblies need to be cleaned, sanitized, lubricated, controls replaced, motors checked, tested, possibly replaced

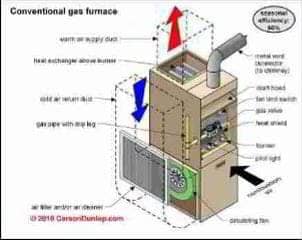

The sketch at left illustrates basic parts of a conventional gas fired warm air heating furnace; image courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Boilers: hot water or steam heating systems flood damage restoration

Check the boiler, controls, combustion chamber, fuel system after flooding or other disasters

...

...

The level of cleaning, repair or replacement of a flooded air handler used for air conditioning or warm air heating depends on the depth to which the unit was flooded and on just what components have become wet or flooded. We discuss gas burners or oil burners separately below.

Our photo (above right) shows that the oil fired heating boiler was flooded enough to place all of the oil burner key parts under at least some water - this system should not be operated before it is cleaned and restored by an expert.

Our photo (above left) provides two heating equipment flooding observations

- The heating boiler or furnace was set up on blocks, a clue that someone was aware of at least the possibility of exposure of the heater to wet floors - which in turn tells us that the building may have had a history of water entry and wet basement or floors

- The heater was recently flooded to about 4-inches above the unit's base - possibly floodwaters did not reach the oil or gas burner itself.

For detailed assistance see these articles:

- DIAGNOSE & FIX HEATING PROBLEMS-BOILER - what to check if the hot water or steam boiler won't run or doesn't work properly

- BOILER CONTROLS & SWITCHES (many controls on oil fired heating boilers are the same on oil fired water heaters)

What oil fired water heater or boiler parts are usually replaced after a building flood or similar fire or disaster?

Safety controls (see below) and insulation in heating equipment are usually replaced after flooding or other wetting disaster events like hurricanes or storms.

Baseboard heat or radiators inspection & restoration after a flood or other disaster

Inspect the heating piping, baseboards, or radiators for leaks or mechanical damage, especially if there is any evidence of movement of or in the building.

If hot water heating system pipes were drained or if pipes broke and lost water, you will need to purge air from the system and to check circulator pump(s) and zone valves (if used);

If pumps or valves or control relays were submerged most heating service professionals will replace controls and will dry and test electric motors before returning them to service.

See AIRBOUND HEAT SYSTEM REPAIR by WATER FEED VALVE for assistance with purging air out of heating piping, baseboards, or radiators.

Chimneys: check the chimneys, flues, and vents after building flooding or other disasters

A cracked, plugged, or leaky chimney can cause fires or carbon monoxide poisoning.

Be sure you check metal and brick chimneys for cracks, damage, signs of movement, as well as for obstructions by dirt, debris. Also check for visible gaps, or leaks before lighting the furnace or a fire.

In addition, a thorough inspection of the combustion chamber for damage and debris must be conducted before the equipment is returned to service. Mud, sludge, debris anywhere inside of the heating appliance (combustion chamber, heat exchanger, chimneys, flues) has to be removed and the appliance cleaned. In addition, if area flooding sent flood waters inside of chimneys or flues (don't forget the chimney base and cleanout door) those areas need to be opened, inspected, cleaned.

- For a complete guide to chimney inspection, diagnosis & repair s

ee CHIMNEY INSPECTION DIAGNOSIS REPAIR

Combustion chamber & chamber liner: dry or replace after flooding

Most oil fired heating equipment use a masonry (fire brick) or synethetic fabric combustion chamber liner. The liner heats to very hot during oil burner operation - a condition that helps assure complete combustion of fuel oil being sprayed into the combustion chamber.

Watch out: Firing up a flooded oil fired heating appliance before the combustion chamber liner has been dried or replaced risks damaging that component and possibly damaging the heater itself. Ask your service technician about the condition of the combustion chamber.

Controls on heating appliances: inspect, test, or (usually) replace after flooding

Heating appliance (water heater, boiler, furnace) safety and limit switches and controls that have been flooded, in our OPINION, should be replaced. These include controls such as an aquastat, cad cell relay, stack relay, or fan limit control switch.

Circulator pump relays, while not safety devices themselves, may be inoperable after flooding without disassembly, dryout and cleaning - a procedure that may cost more than the cost to replace the control. Other electrical components such as electrical wiring may be re-usable after inspection.

Watch out: electrical panels and circuit breakers that have been flooded should be replaced as even if they "look" fine, we're not confident that internal working parts have not been damaged by water, corrosion, or even silt and debris.

The risk is that a flooded circuit breaker has become mechanically damaged or corroded internally such that it may not trip properly in response to an overcurrent or short circuit that may occur when you are restoring power to the building or later in the future. The risk is thus a shock or fire.

- Aquastat Functions - simple aquastats may be used as upper and lower limit controls on oil fired water heaters

- BOILER CONTROLS & SWITCHES (many controls on oil fired heating boilers are the same on oil fired water heaters)

- CAD CELL RELAY SWITCH FLAME SENSORS - turns off the oil burner if it does not achieve proper flame ignition

- CIRCULATOR PUMPS & RELAYS - may be used if the water heater is connected to a continuous hot water loop plumbing system or in (more rare) cases where an oil fired water heater is being used as a building area heating device (usually not code-approved)

- LIMIT SWITCHES, BOILERS combination aquastats or single-limit simple aquastats may be used as upper and lower limit controls on oil fired water heaters

- RELIEF VALVES - TP VALVES - required on every pressurized tank, including oil fired water heaters

- RESET SWITCH, HEATER PRIMARY CONTROL

- RESET SWITCH, ELECTRIC MOTOR

- STACK RELAY SWITCH - an older safety switch used to turn off the oil burner if successful burner flame ignition does not occur

Ductwork inspection & restoration after a flood or other disaster

The inspection points listed above pertain to oil fired heating devices that have been exposed to flooding or sewer backups. In addition, for building heating systems, the heat distribution system may also have been flooded, damaged, or require repairs and cleaning.

See FLOOD DAMAGE in DUCT WORK - flooded ducts need to be cleaned and sanitized and air filters replaced

Gas Burners & Gas Fuel System & gas piping & appliance checks after building flooding or other disaster

If the gas has been turned off at the main valve serving your home, you need to have a professional restore gas service to your home, relight pilot lights, and do a final check of the system.

If the gas valve serving only one appliance is turned off, then you can probably turn gas service back on, check for leaks, and then relight that appliance.

First, make sure the room is well-ventilated (open windows & doors to outside) and that there are no open flames anywhere. Then turn on the gas valve. Check for leaky pipes. Let the gas run for a minute or two to clean any air and impurities out of the pipes. Then turn the gas off for a minute to allow the gas in the air to go away before you light the appliance.

Watch out: if you smell gas, do not turn on or off electric switches, use a telephone or cell phone, nor use any other equipment or control that can create even the smallest spark. Doing so risks a catastrophic gas explosion.

For detailed assistance see these articles

- GAS BURNER FLAME & NOISE DEFECTS

- GAS BURNER SOOT CAUSE & CURE

- GAS BURNER PILOT LIGHT PROCEDURE

- GAS FIRED WATER HEATERS

- GAS FIREPLACES & GAS LOGS

- GAS IGNITER DIAGNOSIS & REPAIR

- GAS LEAK DETECTION, LP / NG

- GAS METER CODES & CLEARANCE DISTANCES

- GAS PILOT WON'T STAY LIT

- GAS PIPING, VALVES, CONTROLS - home

- TANKLESS WATER HEATERS

Propane, L-P, and Butane Heating Equipment & Systems

Propane, LP gas, or butane fuels are kept in pressurized tanks, so there is no electric pump to turn on, and provided that the tank was not empty, no flood water would be expected to enter the tank.

Watch out: check the gas tanks for signs of movement or floating. If the tank has moved at all from its original position, inspect the gas piping for loose or damaged connections, and repair them before attempting to turn on the gas.

Then follow the instructions above for gas systems.

Oil System oil burner, fuel unit, oil filter & oil piping checks after building flooding or other disaster

Oil burner assembly inspection & restoration after a flood or other disaster

In the reader question above s/he said that the "motor" was replaced. If you are not sure whether just the electric motor on the oil burner was replaced or whether the whole oil burner assembly was replaced,

see OIL BURNERS for an illustration of the different parts involved.

If the oil burner was submerged, and if only the oil burner's driving electric motor was replaced, additional disassembly and cleaning are probably in order to be sure that the oil burner nozzle, blower assembly, and other parts are clean and working properly.

Make sure your main oil valve is turned off. Check your heating oil oil pump and oil burner assembly. If it got wet, have the oil burner and pump professionally checked and cleaned. If you want to clean it yourself, keep in mind that you will need replacement parts like oil burner nozzle, fuel unit screen, oil filter cartridge, and a clean heating oil supply ready to use when bleeding air and water from the system.

Look carefully for any signs of leaking oil; if you see any, call a professional. Look for signs that the pipes or oil tank moved during the flood. Oil tanks, even buried ones, will float when flooded. After you have turned the electricity back on, open the main valve and turn the pump on. Check for leaky pipes.

The amount of cleaning and parts replacement necessary for a heating system depends on the depth of flooding to which the equipment was exposed.

A heating boiler or furnace whose oil or gas burner was not submerged may be got running with a careful cleaning and inspection of the combustion chamber and (if hot air heat) duct system, and chimney. But if the oil or gas burner was flooded it will need to be disassembled, cleaned, some controls and parts replaced, and tested.

Watch out: Rather than risk the fire or safety hazards that ensue if a heating system safety control is not reliable, heating professionals will generally replace any heating system control (like an aquastat, cad cell relay, stack relay) that has been soaked or submerged.

This article continues to list all of the major components of oil fired heating equipment and how they should be cleaned, inspected, repaired or replaced after a flood or other disaster.

For detailed assistance with oil burner inspection, cleaning, repairs see:

- OIL BURNER FUEL UNIT - this is the oil pump on your oil burner

- OIL BURNER INSPECTION & REPAIR - home page for oil burners

- OIL or SEPTIC TANKS FLOATING UP

- OIL TANK WATER CONTAMINATION

- OIL TANK WATER REMOVAL

- RELIEF VALVE LEAKS

- RESET SWITCH, HEATER PRIMARY CONTROL

Oil filter assembly inspection & restoration after a flood or other disaster

It makes sense to replace an oil filter cartridge after a building has been flooded; the cartridge canister is normally air tight and thus water tight. But repair steps, movement of equipment, or other events may have contaminated the canister itself or oil tank or piping, sending more debris into the canister and filter. For this reason it makes sense to not just replace the filter, but inspect and clean the canister that holds the filter.

Remove the oil filter cartridge and replace it; we don't recommend operating the heating equipment without a cartridge and filter in place because of the high probability of debris clogging that will occur in the oil pump or oil burner nozzle. Remove any water found in the oil filter canister as well as sludge or debris before you replace the oil filter with a new one.

- See FILTERS, OIL on HEATING EQUIPMENT for detailed assistance.

Oil pump (fuel unit) internal filter screen assembly inspection & restoration after a flood or other disaster

Debris, sludge, water, rust particles are often found in the bottom of the oil filter canister. If these enter the oil burner's oil pump (properly, the fuel unit), its internal filter screen may also be clogged - I'd be sure that the fuel unit has had its filter screen replaced.

Debris in the oil burner fuel unit will clog its internal check valves and the oil burner nozzle too, damaging the pump and leading to improper, even unsafe oil burner operation or total loss of heat later on. Also a clogged filter screen can prevent the fuel unit from being able to pump oil from the tank - and could be mistaken for a blocked oil line.

- See OIL PUMP FUEL UNIT for details.

Oil piping: How to check & repair heating oil piping on flooded water heaters, boilers or furnace after a flood or other disaster

If oil piping has become contaminated with sludge, it may be possible to blow the lines clear, but if not, oil line replacement will be needed unless the piping has been broken, kinked or mechanically damaged (as can occur if flooding cause an oil tank to float or move).

Oil lines between an oil tank and the water heater can become blocked with sludge, silt, mud, and even water or sewage if the lines are open to the flooding environment. If you have this problem, when the oil burner motor runs (the oil fuel unit is trying to pump oil) and you try to bleed air from the oil piping system you will find that no fuel is flowing from the oil tank to the burner motor.

- Check that there is heating oil in the oil storage tank; check the oil tank gauge and check that the gauge is not stuck showing fuel on an empty tank.

see OIL TANK GAUGES - Check that the oil safety valves are properly opened - watch out these valves turn backwards from what you expect.

see OIL SUPPLY LINE SAFETY VALVES, OSVs - Check for water in the oil tank and remove it if present

see OIL TANK WATER REMOVAL - Check that the oil filter is not clogged

See OIL FILTERS on HEATING EQUIPMENT - If the oil line is clogged

see OIL LINE CLOGGING FIX for repair procedures. - On occasion the filter screen inside the oil burner fuel unit (oil pump) can become clogged

See OIL PUMP FUEL UNIT

But normally an oil line between the oil tank and oil burner, say at a water heater, is always full of fuel oil, and sealed against oil leaks out and air leaks in to the piping system. So dirt or water from outside the system would not easily enter the piping system.

How to bleed the oil piping properly to remove air from the system

Also be sure the service tech was following proper procedure for bleeding air out of the oil piping during service restoration.

Details are at HOW TO BLEED AIR out of oil piping and oil burner fuel units.

- For details on oil burner fuel unit installation, piping connections, controls, cleaning procedures, & how to bleed air out of an oil burner fuel unit and piping,

- see OIL BURNER FUEL UNIT.

- Details about spotting oil or air leaks in oil piping are found

at OIL SUPPLY LINE PIPING LEAKS. - Our complete guide to heating oil piping begins

at OIL TANK PIPING & PIPING DEFECTS.

Oil tanks: heating oil storage tank check for floating up, movement, leaks, debris or water contamination after a flood or other disaster

So how might debris enter and clog oil piping after a building flood? If the oil tank itself were flooded you might have water and mud or silt and dirt on the tank bottom - if your oil line feeds from the tank bottom all of that crud would enter the oil line. So a further check of the condition of the oil tank is in order.

A buried oil tank should, like the oil piping, be sealed against outside water entry (though in times of area flooding a partially empty oil tank might float-up and break lines or cause leaks).

Watch out: if a buried oil tank or even an above ground oil storage tank was not sufficiently full of oil during area flooding the tank may have floated up out of the ground or off of its (above ground oil tank) supports. The result of such movement will be bent, damaged oil piping, possibly leaks and an oil spill, and water and debris may have entered the oil storage tank. See

An above ground oil tank should be ok IF flood waters never rose high enough to enter the oil tank vent or fill piping.

If your oil tank itself checks out as not contaminated with water and dirt, and provided we are sure that the oil burner assembly was itself entirely replaced and that the oil pump (fuel unit) is working properly, and if you are unable to draw oil from the tank, the usual step employed by the service tech is to use a CO2 gas cartridge and special "gun" assembly that connects to the oil line and attempts to "blow out" an obstruction. If you are unable to make the line usable following that procedure, and provided we remain convinced that the line is the culprit, I'd have the service company run a new fuel line between the oil tank and the burner.

Details are at OIL TANK WATER REMOVAL and at OIL LINE CLOGGING FIX

Oil valves: check the heating oil supply valves (fire safety valves or fire-o-matic valves) for proper position (opened)

A fusible link oil piping shutoff valve should be found at the oil burner (just before the oil filter) and perhaps also at the oil storage tank. A valve at the oil tank is often used for service convenience if the oil piping exits at the tank bottom. If oil piping or the oil tank were open to floodwaters debris often collects right at the control valve.

See FIRE SAFETY CONTROLS for a discussion of oil piping fire safety valves.

Pressure temperature relief valve assembly inspection & restoration after a flood or other disaster

this important safety device should be flushed and tested as per the manufacturer's instructions.

Watch out: Dirt or debris in the relief valve interior could prevent its proper operation or, more often, it can cause the valve to leak if it has not been adequately cleaned.

See these detailed articles on relief valves

Insulation in air handler, boiler, furnace or water heater insulation inspection & cleaning/replacement after a flood or other disaster

Most heating appliances (water heaters, furnaces, boilers) include an insulated outer jacket or "skin" that helps keep heat and noise inside the device and that improve its operation.

If the insulation on a flooded appliance is still wet when the appliance is turned back on you might get lucky and dry it out during the next operating cycle. Or equipment might be damaged, or the insulation might need replacement. Ask your service technician about the condition of the appliance insulating jacket.

Watch out: flood waters in a disaster often contain sewage and other pathogens that can enter and contaminate any kind of building or appliance insulation. You might, at least temporarily, take a chance on using an appliance like a water heater whose insulation was partly wet, but floodwater contaminated insulation in equipment like an air handler or inside of duct work that is made of or lined with fiberglass insulation is unsanitary.

Blowing air from an air conditioner or heater into a building through pathogen-contaminated ductwork or air handlers is unsanitary and risks illness or disease. Such components should be replaced.

Flood Damaged Water Heaters

This topic is now at a separate article: FLOOD DAMAGED WATER HEATER REPAIR

Research & Standards for Restoration of Flooded Heating Equipment

- FEMA, RESTORING MECHANICAL, ELECTRICAL and PLUMBING SYSTEMS [PDF] (2013) for non-substantially damaged residential buildings, US FEMA, retrieved 2018/09/02, original source: https://www.fema.gov/media-library-data/1381404775001-64f574fe957f4911bc73afaf229f32ca/SandyRA3RestoringMEP_508_FINAL2.pdf

Really? This document offers basic advice on reducing the probability of damage to the systems listed. It is very scarce on specifics and offers almost no advice on restoration to service flood-damaged equipment. - FEMA, PROTECTING SERVICE EQUIPMENT [from flood damage] [PDF] Homeowners Guide to Retrofitting: six ways to protect your home from flooding

- HUD, REBUILD HEALTHY HOMES, Guide to Post-Disaster Restoration for a safe and healthy home [PDF] U.S. Department of Housing and Urban Development (HUD)

Excerpts:

INSPECT HEATING, VENTILATION, AND AIR-CONDITIONING (HVAC) SYSTEMS

What should I look for?

Examine the heating and cooling units and ductwork or piping for damage, separations and soot. Check to see if any components were flooded.

Look for signs of fire, rust, loose connections, and mold.

What should I do about it?

Combustion equipment (gas or oil furnaces, steam boilers, wood/pellet burning heaters), flues and fuel lines should be inspected by an equipment professional or the fire department.

This is needed after any event that could potentially cause a hidden crack or separation, even if you can’t see any damage.

When the heating or cooling system is turned on, if it makes an unusual noise, or emits odor or sparks, turn it off. Do not use it until checked by an HVAC equipment professional.

Watch out: this is questionable advice from HUD. DO NOT EVEN TURN ON the equipment that has been flooded before it has been inspected, because of the risk of shock, fire, or further damage.

Even if electrical equipment "runs" after flooding or after flooding and a dry-out effort, the fact that electrical switches, motors, contacts, or controls have been wet means that later on those components will corrode, making their service unreliable and possibly unsafe.

In addition there can be subtle fire hazards such as a flood-water damaged combustion chamber liner that is intended to keep an oil burner from burning through the furnace fire chamber walls.

Before the home is occupied, try to run the HVAC system for two or three days. This avoids exposure to the “first flush” of residue that may be in the system, and provides a trial run. Should I bring in a professional? A heating/ventilation/air conditioning (HVAC) professional should inspect, clean, and test the performance of a potentially damaged or soiled HVAC system.

Watch out: this is questionable advice from HUD.

If you operate any air handling equipment such as an air conditioner or furnace before the equipment has been restored or cleaned you are going to blow flood-water-contaminated droplets or dust into the rest of the duct system and into other building areas, and thus you will increase the ultimate cleanup and restoration cost.

Furthermore, some older heating systems made use of asbestos as insulation on pipes or in heating ducts. Any work that extends the movement of asbestos debris into other buildings is likely to increase the later cost of asbestos cleanup.

Exception to my warning: after the air handling or heating equipment has been determined safe to turn-on, if you decide to run heating or air conditioning equipment before it has been cleaned, restored, sanitized, you might do so in hope of speeding the dryout of a flood-contaminated building in order to try to reduce mold growth in other wet materials.

However in doing so you should assume that you are risking further equipment damage and ductwork contamination that will increase those costs later.

A complete clean-up of flooded or moldy HVAC components should include the following procedures:

All flooded filter media and insulation in components should be removed. This might require cutting into or replacing insulation-lined ducts and components.

Only a high efficiency particulate air (HEPA) vacuum cleaner should be used to remove debris.

If contaminated with floodwater, sewage or mold, components should be sanitized or replaced. Only HVAC-safe biocides should be used.

WARNING: Chlorine bleach should NOT be used to disinfect HVAC equipment or any metals, since it is corrosive.

After cleaning, components should be dried and tested before use.

Combustion equipment should be tested for gas leaks, exhaust leaks and backdrafting (reverse flow of combustion gases into the home).

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: is a flooded gas hot water boiler repairable?

(May 12, 2015) Gunther said:

Can a gas hot water Boiler be fixed after immersion by a flood

Reply:

Gunther

Not to be glib, anything can be fixed. The question is whether or not there is damage beyond economical repair. The answer depends on just what got flooded. It's common to replace just lower portions, for example a burner and controls, that got flooded - often the boiler itself can be salvaged. In sum as Florida expert Mark Cramer says ... It Depends.

A professional inspecting the boiler for flood damage will see how deep the water came, what components were under water, and what components need to be repaired or replaced. If the total of those repairs approach the cost of a new boiler then it's new boiler time.

But often a flood of just a few inches on the floor or even flooding that covered the oil burner or gas burner does not destroy the boiler itself nor the controls and components that were mounted high enough to stay out of the water and that remained dry. In that case, particularly if the boiler is cast iron, it's likely to be salvageable after a complete cleanout, replacing the combustion chamber liner and replacing the burner and any other controls that were soaked.

Watch out: even if the heater will "run" after having been flooded it may not be safe to use without inspection, repair, and perhaps replacement of any controls that were wet. A safety control that has been wet may become corroded internally such that later it will fail to do its job.

Question: what to do when the flooded electric furnace won't run

(Dec 26, 2014) xMargie said:

My electric furnnace is flooded and won't run what can I do

Reply:

Margie

Watch out: Leave the system off. It is dangerous to turn on flooded electrical components or fuel burners before the whole system has been inspected or repaired as needed. Turn off electric power to the heater at the electric panel.

Watch out: don't even try to touch the electric panel or any other electrical devices or switches if your home is still flooded, wet, or if you are standing in water.

When we've faced this problem before, rather than turn on flooded and unsafe equipment we borrowed or rented portable heaters to help dry out the building or to provide needed heat.

Question:

(Dec 5, 2014) Surrey Furnace Repair said

Thanks author for your useful site and great shared to Plumbing Service. WOW !! Really awesome blog and information. I got valuable info here about Repairs for Heating Systems.

...

Continue reading at OIL TANK WATER REMOVAL or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BUILDING DAMAGE ASSESSMENT & REPAIR - home

- CHOOSE a FLOOD DAMAGE RESTORATION or MOLD REMEDIATOR

- CONFLICTS OF INTEREST

- ELECTRICAL SAFETY for FLOOD INSPECTORS

- FLOOD DAMAGE REPAIR PRIORITIES

- FLOOD DAMAGE CLEANUP & REPAIR GUIDE - home

- SEWAGE BACKUP, WHAT TO DO

- SOOT HAZARDS in BUILDINGS

- WATER & ICE IN DUCT WORK

Suggested citation for this web page

HEATING EQUIPMENT, FLOOD DAMAGE REPAIR at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.