Oil Burner Fuel Unit Air Bleed Procedure

Oil Burner Fuel Unit Air Bleed Procedure

Remove air from heating oil lines & pump

- POST a QUESTION or COMMENT air blockage & air removal from oil heating piping & oil burners

Oil burner fuel unit air removal process:

Air enters the heating oil piping system if you have run out of heating oil and will remain even after the oil tank has been re-filled. Air can also enter the piping system at leaky fittings.

Air in heating oil piping or at the oil burner will either prevent the oil burner from running at all or it may risk a puffback explosion.

Here we describe two methods for removing air from heating oil lines and from the oil pump or fuel unit on oil-fired heating equipment.

This article series describes the function, diagnosis, adjustment, and repair of oil burner fuel units or "oil pumps", and we provide related oil burner fuel unit safety, heating system efficiency and heating cost savings advice.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to bleed air out of oil piping and oil burner fuel units

Beckett points out in their oil burner installation instructions that it is essential to vent air out of the oil piping and out of the fuel unit itself during installation.

Beckett points out in their oil burner installation instructions that it is essential to vent air out of the oil piping and out of the fuel unit itself during installation.

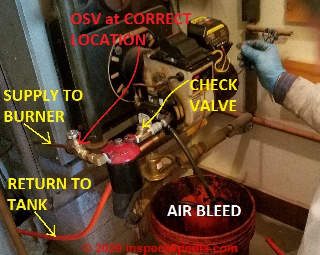

In the oil burner fuel unit shown at left, the AIR BLEEDER valve on the fuel unit is labelled at the lower left.

[Click to enlarge any image]

You'll see a rounded fitting that looks suspiciously like an automobile brake system bleeder valve installed on fuel units for that purpose.

We attach a clear plastic tube to the fitting, put the other end of the fitting into a clear jar where we can watch for the end of air bubbles, then run the system and loosen the oil system air bleeder valve to pump oil and air through the fuel unit until no more air bubbles are occurring.

This procedure will usually be necessary if an oil fired heating system has run completely out of oil as well as after servicing to replace an oil filter or to repair oil line piping.

Two reasons why oil piping system air bleeding / air removal is essential:

- Oil Burner Won't Run: If too much air is inside the piping and fuel unit the pump will become air-locked and it won't deliver heating oil to the oil burner nozzle.

Other causes for oil burner failure are

at OIL BURNER WONT RUN. - Puffback explosion risk: Even if the piping is delivering oil to the oil burner, air in the system expands after the oil burner stops, pushing un-burned oil into the combustion chamber causing dirty, noisy oil burner start-ups (as that old un-burned oil is ignited), and risking a dangerous or damaging oil burner "puffback" later.

Details are

at PUFFBACKS, OIL BURNER.

Two air-bleed or air removal points on a the oil piping of an oil burner system

1. The air bleeder screw on the oil canister - for one-line oil piping systems & above-ground oil storage tanks

1. The air bleeder screw on the oil canister - for one-line oil piping systems & above-ground oil storage tanks

The small air bleeder screw found on the cap of some (not all) oil filter canisters will bleed some of the air out of the canister and oil line IF the oil storage tank oil level is higher in elevation than the canister top.

This is done with the burner OFF.

In the photo I'm using a pencil to point to the air bleed screw on a General brand oil filter canister.

This screw is normally used to remove air from the canister when the oil filter has been replaced.

Put a pan underneath the oil filter canister to catch oil that will run out around the air bleeder screw.

The screw is loosened and you wait until you see oil coming out of the opening, then it's re-tightened, taking care not to strip the threads on the small screw.

Watch out: you do not need to fully remove the screw (though some techs do that). Just loosening it may be enough to see an oil-air mix flow.

When oil flow freely out around the screw or from the screw opening you re-tighten the screw.

Watch out: don't lose the small washer-gasket used under this screw or the oil canister will leak oil out and air in, causing improper and even unsafe oil burner operation.

Normally we replace that tiny washer when we change the oil filter. You can see details about the oil filter canister and the three critical sealing gaskets it needs

Also

where we describe the sources of air & oil leaks at and around the heating oil filter.

This oil filter canister air bleeding procedure won't work with a buried oil storage tank, but, then, buried tanks almost certainly will be using a two-line oil piping system that is self-priming.

2. The air bleeder fitting on the fuel unit - for one-line oil piping systems

The tech attaches a clear plastic tube of suitable length to the air bleeder fitting on the fuel unit on the oil burner, the burner is forced on, perhaps using a wire jumper on thermostat terminals, the tech puts the other end of the tube into a receiver, typically a quart or larger in size, often a small bucket.

The tech attaches a clear plastic tube of suitable length to the air bleeder fitting on the fuel unit on the oil burner, the burner is forced on, perhaps using a wire jumper on thermostat terminals, the tech puts the other end of the tube into a receiver, typically a quart or larger in size, often a small bucket.

We describe the steps in this procedure just below.

You can begin to see why this is not a procedure for the homeowner.

My photo shows a Beckett CleanCut A2EA-6258 fuel unit. The oil / air bleeder fitting is at lower right and circled in blue.

Then with burner on she opens the bleeder screw until foamy air-filled oil starts coming out.

When the oil runs clear without bubbles she closes the bleeder.

Watch out: be sure to tell your service tech that you pressed the re-set button repeatedly. Even though there was not sufficient oil delivery for the burner to run, there could be a puffback explosion risk.

The tech will inspect the combustion chamber and if in her opinon it's oil-soaked the chamber may need to be cleaned or left to dry a time before turning on the oil burner.

I DO NOT recommend that you try these procedures if you're not trained and equipped to do so.

Steps in Air Bleeding / Air Removal from Oil Piping & Burner at Fuel Unit on a One-Pipe System

Watch out: Do not allow oil to spray into a hot combustion chamber while bleeding air from the pump. Install a gauge in the nozzle discharge port tubing or fully open the pump bleed valve to prevent oil spray from accumulating in the combustion chamber during the air bleed procedure. - Weil-McLain cited below.

Failure to take this precaution risks an explosion; see details

- Open the oil line shutoff valves feeding the oil burner.

- Initial burner adjustment for air bleeding: For some oil burners such as the WeilMcLain AF/AFG, Close air band and partially open air shutter. This is

an initial air setting for the pump bleeding procedure

only. Additional adjustments must be made with

instruments.

Really? For an oil burner already installed and tuned, and when air is being bled following running out of oil, the service tech usually skips this step. - Set the room thermostat all the way up - this will cause the oil burner motor to run when power to the burner is restored or when its reset button is reset.

Some techs avoid entering the home to adjust the thermostat, perferring to simply jump-wire the thermostat terminals at the appropriate heating control such as in the aquastat.

If the boiler is already hot, it may be necessary to run all of the heating zones so that the boiler won't shut down at its high limit during this operation. - Start the oil burner and arrange the primary control for continuous burner operation as we gave in step 3 above. If power to the burner was turned off, you'll need to restore it.

Technical note: Some oil burners such as the Beckett AF/AFG series oil burners used on Weil-McLain and other boilers and furnaces have a special air bleeding procedure that is operated as described below.

Watch out: the procedure below is for Beckett AF/AFG series oil burners. Other oil burners may have no special procedure or will have a different procedure for keeping the burner operating during air bleed-out. Consult the oil burner manual for your system. Also

see SPECIAL OIL BURNER PRIMING & AIR PURGING INSTRUCTIONS below.

After the burner starts, press and hold the reset button for 15 seconds until the yellow light turns on. This indicates that the button has been held long enough.

Release the reset button. The yellow light will turn off and the burner will start up again.

At burner start up, click the reset button while the igniter is still on. This will transition the control to a dedicated Pump Prime mode, during which the motor, igniter, and valve are powered for four minutes. The yellow light will be on.

At the end of 4 minutes, the yellow light will turn off and the control will automatically return to standby mode. - Weil-McLain / Beckett AF/AFG manual cited below.

- Turn the bleed valve counter clockwise about 1/2 turn for fast air purging.

Watch out: DO NOT completely remove the air bleeder fitting. That's not necessary and it will make a terrible oil-spill mess if you do so.

Watch out: First attach a 1/4" I.D. clear plastic hose that empties the air/oil mix into a suitable container.

If you use a clear container (don't break it or you'll have a mess) you can immerse the end of the tub in heating oil and you can see when air bubbles stop coming out of the tube.

How long you need to bleed air depends on where air is suspected in the system (between tank and oil burner or just at the filter, for example) and the length of oil piping involved.

Keep bleeding the pump until oil runs clear in the tube, without froth or air bubbles. - Continue bleeding the unit for 15 seconds after the last air is seen. If you are hasty, Suntec and other manufacturers warn that the system may not work properly.

Ensure that all bubbles and froth are purged from the oil supply system before tightening the pump bleed valve. - Weil-McLain

Technical note: What if air and froth never stops appearing in the bleeder tube? In that case either

- you haven't bled long enough (guess at the length of oil piping that was air filled: longer pipes, more bleed time, up to 2-3 minutes though that's unusal.)

or

- there is an air leak in the oil piping system. In that case

see OIL FILTER LEAK POINTS first, then

see OIL SUPPLY LINE PIPING LEAKS to find and fix the air leak.

Technial note: what if you were not able to establish prime before the primary control automatically re-sets itself out of Pump Prime mode?

(Applicable only to certain oil burners like the Beckett AF/AFG models). In that case go back to the pump priming instructions in step 4 above or the equivalent in your oil burner instruction manual.

You may need to repeat steps 4-6. - Stop the air bleed procedure by tightening the bleed valve screw clockwise.

- Stop the call for heat. That means removing a jumper on thermostat terminals if you used one, and/or setting all of the room thermostats down to well below room temperature. Wait for the oil burner to turn off.

Clean the unit thoroughly wiping off any oil or dirt to make any future leaks or dirt problems apparent. - Prepare the oil burner for normal use. This means restoring or setting the oil burner air shutter to its normal position if you changed it at step 2 above.

Watch out: assure that the oil-fired heating equipment is free of oil and oil vapor before starting or resetting the burner. Otherwise you risk a puffback explosion. - Before leaving the job re-inspect to assure that there are no oil leaks at the air bleeder valve nor elsewhere, and that the oil burner responds and operates normally to a call for heat at a room thermostat.

Two pipe oil burner systems do not normally need to be air- bled since the fuel unit will return any excess air along with oil down the return line and back into the oil tank.

Question: I need to bleed air from the oil line but I’m afraid I will start a fire from the built up oil from pushing the reset button.

2018/03/12 Ellen said:

Regarding:

Watch out: Most heating technicians and inspectors will tell you to only press the reset button once. That's because we worry that a homeowner will keep pressing the button even though the oil burner flame is never igniting.

[Click to enlarge any image]

What happens if I have pushed the reset button several times? Does the excess oil ever drain away? How do I know if it is safe to bleed the line and try to ignite?

After my heating oil tank ran completely dry I had it refilled but it would not heat. I tried the reset button several times (maybe 8 or 10 pushes of the button).

Know I realize I need to bleed the line but I’m afraid I will start a fire from the built up oil from pushing the reset button.

1. Does this oil ever drain out so it is safe to ignite?

2. What can I do about this?

This question and reply were posted originally

at RESET SWITCH, HEATER REPAIR and also discussed by private email.

Reply: Procedures for bleeding air from the oil lines & filter canister after running out of oil

Bleeding air from an oil burner supply line is not something normally tried by a homeowner. You'd need at least a smidgen of training on which fittings are used, where to try to bleed air, how to avoid spilling oil all over the place.

Even knowing how to do the procedure I would prefer to ask the heating service tech to do the job.

Spilled heating oil is not, however highly flammable.

Watch out: What IS dangerous is to keep pressing that reset button. Don't do that. Each time the oil burner tries to start it's spraying some un-burned fuel oil into the combustion chamber.

When it is finally ignited, all of that collected fuel can cause dangerous

PUFFBACKS, OIL BURNER - an explosion of un-burned fuel that sends soot all over the place and can blow parts off of the heating system

With those warnings given, the two procedures for removing air from an oil heat piping system, fuel unit, and oil burner are given starting

at OIL BURNER FUEL UNIT AIR BLEED PROCEDURE and the procedure that would apply to your situation is given starting

at OIL BURNER FUEL UNIT AIR BLEEDER

Special Air Bleeding Instructions for some Oil Burner Models

Special Priming or Air Bleeding Instructions for Beckett AF/AFG Oil Burners

These additional instructions fit at step 4 of the

general OIL BURNER PUMP AIR PURGE & PRIMING instructions given above.

Watch out: the procedure below is for Beckett AF/AFG series oil burners. Other oil burners may have no special procedure or will have a different procedure for keeping the burner operating during air bleed-out. Consult the oil burner manual for your system.

4.1. After the burner starts, press and hold the reset

button for 15 seconds until the yellow light turns on.

This indicates that the button has been held long

enough.

4.2. Release the reset button. The yellow light will turn

off and the burner will start up again.

4.3. At burner start up, click the reset button while the

igniter is still on. This will transition the control

to a dedicated Pump Prime mode, during which

the motor, igniter, and valve are powered for four

minutes. The yellow light will be on.

At the end of 4 minutes, the yellow light will turn off

and the control will automatically return to standby

mode. - Weil-McLain / Beckett AF/AFG manual cited below.

- BECKETT AF/AFG GOLD OIL BURNER SERIES MANUAL [PDF] retrieved 2017/12/31 original source: https://www.weil-mclain.com/sites/default/files/field-file/wgo-beckett-afg-burner-manual_1.pdf

Special Priming or Air Bleeding Instructions for Riello Oil Burners

Watch out: before running the Riello oil burner fuel unit during the priming or air-removal procedure below, to protect the pump gears, it is advisable to lubricate the pump prior to purging a lift

system. Apply oil through the VACUUM PORT (C).

Watch out: before running the Riello oil burner fuel unit during the priming or air-removal procedure below, to protect the pump gears, it is advisable to lubricate the pump prior to purging a lift

system. Apply oil through the VACUUM PORT (C).

- Loosen the bleeder valve (A).

- Disconnect nozzle oil supply line at the pump nozzle port (B).

- Attach a flexible plastic tube to the pump nozzle port, directing the oil flow into a bucket.

- Loosen the screws securing the air tube cover, allowing it to be removed freely.

- Holding the air tube cover in its proper location start the burner.

- When the solenoid valve is engaged, approximately 10 seconds after starting, remove the air tube cover and shine a light source on the photo-cell, allowing it to see false light.

- Run the burner until the fuel pump has been purged of air, then tighten the bleeder valve and immediately shut down the burner.

- Reinstall the air tube cover and nozzle line.

- The burner can now be started normally

Watch out: Omitting steps 2 and 3 will result in a collection of unburned oil in the combustion chamber creating a hazardous situation upon burner startup. [IE a puffback explosion]

- RIELLO OIL BURNER OPERATION MANUYAL [PDF] retrieved 2018/03/14, original source: http://serl.qc.ca/wp-content/uploads/2015/10/manuel40-F15.pdf

Oil Burner Air Bleeding Procedures in Oil Burner Manuals

- See OIL BURNER MANUALS for our complete set of free oil burner manual downloads

- BECKETT AF/AFG GOLD OIL BURNER SERIES MANUAL [PDF] retrieved 2017/12/31 original source: https://www.weil-mclain.com/sites/default/files/field-file/wgo-beckett-afg-burner-manual_1.pdf

- Suntec, "Installation Information for Suntec A-2000, A-7000 Single Stage and B-8000 two stage fuel units"Suntec Industries, 60 Aberdeen Drive, Glasgow KY 42141, 270-651-7116 (1725 rpm black label, 3450 rpm white label)ls.

- RIELLO OIL BURNER OPERATION MANUYAL [PDF] retrieved 2018/03/14, original source: http://serl.qc.ca/wp-content/uploads/2015/10/manuel40-F15.pdf

- WEIL McLAIN AF/AFG GOLD OIL SERIES OIL FIRED BOILERS MANUAL [PDF] with Beckett oil burners, retrieved 2018/03/14, original source: https://www.weil-mclain.com/sites/default/files/field-file/wgo-beckett-afg-burner-manual_1.pdf

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-01-24 - by (mod) - installing a filter in the return line of a 2-pipe heating oil system ?

Thanks for the note, Reybo, I'm pleased that you've found our website useful.

I'm not at all familiar with installing a filter in the return line of a 2-pipe heating oil system and I'm pretty nervous about it. ANY restriction on the return line is prohibited as risking blowing the oil pump seals and setting the building on fire.

And a big 1-gallon filter on a residential system is pretty unusual; maybe the installer was afraid of restricting the return (so why not put a filter where it belongs, on the input?) or maybe she already knew that this particular system was being fed oil sludge from an old oil tank.

Besides, putting the filter on the return side means we send all of the crud into the oil pump, into the nozzle and into the oil combustion system - exactly what we're trying to avoid.

In turn, fouling up the oil combustion can be exactly what leads to a puffback explosion.

Watch out: also, ANY possible restriction (such as a blocked or clogged oil filter) on the return line of a two pipe oil delivery system to an oil burner is unsafe, risking a blown fuel unit seal and potentially a building fire.

All of which make one wonder who set up your system and whether or not they were trained.

I'm not the most-knowledgable guy about this topic but back in 1984 if you were in upstate NY or in my hometown of Richmond I'd have been happy to come by to show you the air bleed procedure as at the time I was actually servicing oil fired equipment.

And my oil burner school teacher would have had some ##&@@!! things to say about your installation.

On 2020-01-24 by Reybo - oil filter installed on the fuel unit oil return line?

Just discovered this site in 2020 after having to educate myself on servicing my 1952 Quiet May furnace. I needed you in 1984 when we moved in.

During that summer I saw that the company whose sticker showed they maintained the equipment had installed a 1 gallon(!) oil filter in the return line. Right .. the return line, and none in the supply.

I could write a book about this system: the failure every January, the Bantam burner that matched no description of its instruction book and allowed no standard adjusting tools, and the time the safety switch failed and I discovered it was running without fire after 20 minutes. Bad?

If I wasn't working in the next room and had a 6th sense, it would have been days of pumping oil into the firebox, soaking the brick.

Of course soaking did happen. After I replaced the safety switch, I opened the door to the box and let it air for 7 24-hour days. Then I turned the power on. You could call the explosion a "puffback" but that would ignore that the entire unit jumped on the floor with a huge bang and the chimney vent was blasted across the room. It missed my head by nearly a foot. The firebricks were still on fire 5 days later.

In time I replaced the Bantam with a used Beckett and became a normal Virginia house.

On 2020-01-09 by (mod) - where the heck is the air bleeder screw on this Beckett oil burner's oil pump?

On 2020-01-09 by (mod) - where the heck is the air bleeder screw on this Beckett oil burner's oil pump?

Colin

I couldn't see the air bleeder screw in your photos either.

Take a look at the bleeder fitting at the top of this page in the very first photo. It's Circled.

Almost every fuel unit that has an air bleed while have a fitting that looks like that and last for some reason it was removed and plugged.

If you can give me a clear photo of the label or brand or just tell me the brand and model of the fuel unit (oil pump) on your Beckett burner then we can for-sure point out the location of the air bleeder fitting.

On 2020-01-09 by Colin

On 2020-01-09 by Colin

On 2020-01-09 by Colin

Hi - I am trying to locate the bleeder on my Beckett oil pump but it is not obvious. Ive added some pictures. Can you help me identify what each of the labeled parts are for and where I may find the bleeder? Thanks

On 2018-10-04 by (mod) -

At our home page for oil burner fuel units OIL BURNER FUEL UNIT

we explain that The typical fuel unit used on modern oil burners does not have a high lift capacity - perhaps 6 feet would be a safe lift level for a one-line oil pipe installation.

A two line oil piping system, required for buried oil tanks or oil tanks located below the oil burner, increases the "lift" capacity of the fuel unit and also nearly eliminates oil piping priming problems.

The specific lift capacity will depend in the pump brand and model.

On 2018-10-03 by Brian

I am installing a new diesel tank with top openings. Will be pump in the 'burner' be powerful enough to suck fuel from 1.7 metres above? Do I need an additional electric pump?

...

Continue reading at OIL BURNER FUEL UNIT or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FUEL UNIT BRANDS & PROPERTIES

- FUEL UNIT INSTALLATION & ADJUSTMENT PROCEDURES

- OIL BURNER FUEL UNIT - home

- OIL BURNER FUEL UNIT AIR BLEED PROCEDURE

- OIL BURNER FUEL UNIT ANNUAL MAINTENANCE, SERVICE & REPAIR PROCEDURES

- OIL BURNER INSPECTION & REPAIR home page for oil burner diagnosis and repair

- OIL BURNER MANUALS

- OIL BURNER NOZZLE GUIDE

- OIL BURNER WONT RUN - Diagnostic Steps - what to check in what order

- OIL FILTER LEAK POINTS - air leaks in and oil leaks out at the filter

- OIL SUPPLY & RETURN LINE DE-AERATORS Tigerloop™ - remove air bubbles from oil piping systems

- OIL SUPPLY LINE PIPING LEAKS - oil leaks out also mean air leaks in to the system

- PUFFBACKS, OIL BURNER

Suggested citation for this web page

OIL BURNER FUEL UNIT AIR BLEED PROCEDURE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING OIL, OIL BURNERS, OIL FIRED HEATERS, OIL TANKS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1]AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING, [PDF online copy of this book] Frank D. Graham, Theo. Audel & Co., New York 1946, 1947, 1955 (out of print, copies occasionally available from antique book dealers and on EBay). Use THIS LINK to read a free online copy of this helpful classic textbook.

- [2] Beckett Model SR Oil Burner Instruction Manual, R.W. Beckett Corporation, PO Box 1289, Elyria OH 44036 and R.W. Beckett Canada, Ltd., 430 Laird St., Guelph, Ontario, Canada N1G 3x7

- [3] Thanks to Bottini Fuel service technician Bob for discussing the buzzing aquastat relay problem, 4/18/2012. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

- [4] Beckett Model SF Oil Burner Instruction Manual, op.cit.

- [5] Sunstrand Corporation - Sunstrand Fuel Units, 4949 Harrison Avenue P.O. Box 7003 Rockford, Illinois 61125-7003 U.S.A. Telephone: (815) 226-6000 Fax: (815) 226-5399 http://www.sundstrand.com

- [6] Sunstrand Transmission Service Manual, May 1974, web search 08/19/2011, original source: http://www.cushmantrackster.com/pay-pdfs/sundstrand.pdf - Sunstrand Series 15 hydrostatic transmissions

- [7] Webster Fuel Pumps & Valves, Capitol City Tool, Inc., http://www.websterfuelpumps.com/

- [8] Suntec Model A-7400 Fuel Unit Solenoid Dumping Pump,

Suntec Industries Inc., 60 Aberdeen Drive - PO Box 5000 Glasgow, KY 42142-5000 - USA Tel : 270 651 7116 - Fax : 270 651 9276 e-Mail : info@suntecpumps.com and

Suntec Industries France, 1 Rue Lavoisier - B.P. 102 F-21603 LONGVIC Cedex - FRANCE Tel : +33 (0)3 80 70 60 70 - Fax : +33 (0)3 80 70 61 11 e-Mail : information@suntec.fr, [copy on file as /heating/Oil pumps fuel units/Sunted_Solenoid_DumpingPPump.pdf] ,

Also /Suntech_Solonoid_Safety_Valves.pdf (brochure)

web search 4/19/12, original source: http://www.suntecpumps.com/Suntecus/PDFs/Form%202740%20

-%20Solenoid%20Dumping%20Pump.pdf - [9] Suntec Model PRV-38 Oil Safety Valve Installation Information, Suntec Industries Inc., 60 Aberdeen Drive - PO Box 5000

Glasgow, KY 42142-5000 - USA

Tel : 270 651 7116 - Fax : 270 651 9276

e-Mail : info@suntecpumps.com and

Suntec Industries France, 1 Rue Lavoisier - B.P. 102 F-21603 LONGVIC Cedex - FRANCE Tel : +33 (0)3 80 70 60 70 - Fax : +33 (0)3 80 70 61 11 e-Mail : information@suntec.fr, [copy on file as /heating/Oil pumps fuel units/Form 2155 - PRV-38 Installation.pdf]. You can download this file from Suntec's website. - Fuel Oil & Oil Heating Magazine, 3621 Hill Rd., Parsippany, NJ 07054, 973-331-9545

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.