Heating System Circulator Pumps & Circulator Relays

Heating System Circulator Pumps & Circulator Relays

- home

Circulator pump sources, circulator pump installation & repair manuals

- POST a QUESTION or COMMENT about this article topic.

Hot water heating circulators or circulator pumps: install, troubleshoot, repair advice: this article series discusses Circulator Pumps: how to find, inspect, diagnose, and repair problems with Hot Water Heating System Circulator Pumps or circulator pump relay switches and controls.

This article series answers most questions about Heating System Boiler Controls on central heating systems to aid in troubleshooting, inspection, diagnosis, and repairs.

Circulator pump relay switches & controls on heating systems: Troubleshooting & Repair Guide, How to tell if a heating circulator pump is working, Why do some heating zones work and others not, why does heat come out of zones where thermostats are not calling for heat?

How to fix an air-bound heating system and blocked circulator pump,

How to cure circulator pump noises, Where should a circulator pump be installed on a heating boiler? On the inlet or on the outlet side of the boiler? Use of air exit tanks and circulator pumps on heating boilers.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Install, Dagnose & Fix Heating Circulator Pumps

Heating circulator pumps or "zone circulators" are used to force hot water from the heating boiler through radianting devices such as hot water baseboards or radiators. The circulator is switched on as needed or in some designs may be wired to run continuously.

Heating circulator pumps or "zone circulators" are used to force hot water from the heating boiler through radianting devices such as hot water baseboards or radiators. The circulator is switched on as needed or in some designs may be wired to run continuously.

Our photo at left of a red B&G heating circulator pump shows equipment more than twenty years old and still spinning along nicely.

Proper installation, protection from leaks, and lubrication at annual service can give a long circulator life. Poor maintenance or improper installation can give less happy results.

[Click to enlarge any image]

After a brief introduction we describe what goes wrong (or how to get things to go right with heating zone circulator pumps.

We also link to related articles for circulator choices, installation, troubleshooting, repair or replacement.

Also see Checks for Circulator Operation.

How Hot Water Heating Circulators Work: One vs Multiple Circulators

Hot water may be circulated throughout multiple zones using a single circulator pump and individual zone flow control valves, or each heating zone may be built with its own individual circulator pump.

Either approach to individual heating zone control can work just fine - using zone valves or using individual circulators.

Our photo above shows a single circulator system (no zone valves are in the photo - this may be a single-zone heat system) while at left our photograph shows a three-zone heating system with three B&G circulators in a home in Two Harbors, MN.

You'll notice that one of the circulators has been replaced with a newer Bell & Gossett Circulator SLC-30.

See MULTIPLE HEATING ZONE CONTROL for as much argument as you can stand about multiple circulator pumps versus multiple zone valves for heating zone control.

What goes wrong with hot water heating circulator pumps and circulator switches?

The heating system circulator pump, such as the trio of pumps shown at the top of this page, is used to move hot water from the heating boiler out through one or more loops of piping in a building, through heating devices such as radiators, heating baseboards, or convector units, then through return piping back to the heating boiler.

When the water temperature drops to a pre-set level the heating boiler will re-heat the water.

[Click to enlarge any image]

The circulator relay is an electrical switch which, in response to a request for heat from a thermostat, turns on the circulator pump.

See RELAY CONTROL SWITCHES for details about how the circulator pump relay operates.

Single Circulator Heating Systems, One or Multiple Heating Zones

Some heating systems use a single circulator to move hot water through the building's heating devices (convectors, radiators or baseboards).

In a one-circulator system, the building may still divide its heat into various zones or sub-areas of individual heat control, by using either individual radiators in rooms or perhaps by using electrically controlled zone valves which open and close flow of hot water through sub-loops in the building heating piping.

Also see ZONE VALVES, HEATING - home.

Even a single zone heating system might use two circulator pumps. In this case the second circulator is being used to control a separate indirect-fired water heating system to provide domestic hot water for washing and bathing.

See INDIRECT FIRED WATER HEATERS.

Multiple Circulator Heating Systems, Multiple Heating Zones

Some heating systems use multiple circulators to provide heat to individual building areas or "zones".

In this case each heating zone will have its own thermostat which, acting as a low-voltage "heat on-off switch" will turn on individual circulator pumps when heat is desired in that zone.

Details are

at CIRCULATOR PUMP RELAYS & OTHER CONTROLS.

Also see RELAY CONTROL SWITCHES for details about how circulator relay controls work.

Mixed Multiple Circulator Heating Systems Plus Zone Valves

Less common are mixed heating zone systems in which multiple circulators are used but one or more of the circulators feeds a heating water pipe which is subsequently divided into additional sub-zones of heat control, each sub-zone being controlled by a zone valve.

We often see this arrangement when the building owner/manager wants to sub-divide an existing heating zone into multiple zones of control.

Before assuming the heating system is not working when the thermostat is calling for heat, feel the radiators or baseboards to see if they are getting hot.

On a call for heat at the thermostat, if the heating boiler is already hot (above the lower limit or cut-in temperature) then the circulator should turn on and move hot water to the baseboards or radiators.

Click to enlarge any image]

Only after the boiler temperature drops below the cut-in temperature will the heating boiler turn on to re-heat the water. The connection between the thermostat and the heating boiler turning on or off is indirect.

On most heating systems the thermostat turns the circulator pump on or off and the temperature of the heating water turns the heating boiler on or off.

Our photo (above left) shows leaks at the circulator pump mounting flanges. Notice those rust stains on the bottom circulator mounting flange.

See CIRCULATOR PUMP LEAKS

- The circulator pump may be leaky - often leaks occur at the circulator pump mounting flanges - a leak we describe in detail

at LEAKS at CIRCULATORS. (See our photo, above left). - The circulator pump may not be running at all. The result can be no heat delivered to the occupied space, or heat may be delivered but only very slowly, as hot water is rising through the heating system by convection rather than being forced (more quickly) by the circulator pump assembly.

Because some circulator pumps are very quiet and may have no visibly moving parts (Taco® for example), below we explain how to determine whether or not the circulator is working at all.

At CIRCULATOR WONT START we include some diagnostic questions & answers.

At BYPASS CIRCULATOR we discuss running the boiler even if the circulator won't run - The circulator pump seems to run only intermittently, or starts and stops in short bursts. This is often a control or relay or wiring defect. See our Q&A discussion

at CIRCULATOR RUNS INTERMITTENTLY

Also

See RELAY CONTROL SWITCHES for details about how the circulator pump relay operates.> - The circulator pump may be running but heat does not enter some building areas - part of the system may be air-bound. We introduce this topic below and explain how to correct an air bound heating system

at AIR-BOUND HEATING SYSTEMS. Beginning at that article we also give several repair methods to fix an air-bound heating system.

If heat is reaching some but not all radiators, and where we do not think the circulator pump is the problem, take a look at our diagnostics found

at COLD HOT WATER RADIATOR or BASEBOARD - The circulator pump may be running but baseboards or radiators don't get hot enough.

While it is possible for a damaged impeller, low voltage, damaged circulator pump motor or similar defects to result in some but not enough hot water movement through the hydronic heating system, more often I find that the circulator is either moving hot water at its rated capacity or it's not moving anything.

A circulator pump may be running at its rated flow capacity but other problems such as a partly-closed zone valve, an obstruction in the heating system, or under-sized heating supply and return piping (too-small diameter), or under-capacity baseboards or radiators are at fault, resulting in heat being delivered at too low a temperature or too slow a rate to a building area.

Where heat supply and return piping are too small in diameter, changing out baseboards or radiators to higher capacity units, or changing the circulator pump to a higher capacity (flow rate) unit may solve the problem.

See CIRCULATORS VARIABLE SPEED

At WEAK HEAT we provide FAQs about troubleshooting cases in which hot water is delivered to radiators or baseboards or fan convetors but these devices do not get hot enough. - The circulator pump motor may run but the pump may not be moving water - less common than air-bound heating systems are mehanical defects in the circulator pump itself. This occurs if the circulator pump vanes or other internal parts have become damaged.

The circulator motor will run but the circulator does not pump. If the circulator motor runs but there is no temperature change on the heating system piping on the inlet and outlet side of the pump then this could be the problem.

- The circulator pump is noisy - this can be due to a variety of problems. Start by making sure that your system does not contain excess air since this is a very common hydronic heating complaint. See these three articles on purging air from hot water heat systems:

- AIR BLEEDER VALVES

- AIR BOUND BOILERS &* RADIATORS

- AIR SCOOPS SEPARATORS PURGERS.

A bearing could be failing in the circulator pump; in this case the pump will need repair or replacement. If you are mounting a new circulator pump assembly in an existing bracket,for example when just the pump impeller and housing are being replaced, make certain that the pump is properly mounted and supported in position.

We found an entire series of circulator pump failures at the same mounting point (photo, above-left) because every replacement had been mounted askew, placing stress on the Bell & Gossett circulator pump shaft.

For some circulator pump models, particularly if the circulator pump is used in a multiple-pump installation, the pump's internal check valve could be a noise source.

Taco, a manufacturer of circulator pumps and other heating system equipment, says that circulator noise can be due to the built in check valve on a radiant heating system and that the fix is to remove the check valve from the pump.

- High Mineral-Content Water & Circulator Pump Problems - in a closed hydronic system, because the same water remains in the system forever except when emptied for service (or if there is a leak), the mineral content of the original water loaded into the heating system is not normally a problem.

In open pumping systems where new water is constantly introduced, mineral content in the water can clog and damage circulator pump internal moving parts. Here is a diagnostic example from Taco.

It is very unusual for a circulator to fail, but there are 4 basic modes of failure:

- Oxygen in the system oxides the rotor laminations. The corrosion build up acts like a brake and stalls the rotor of the pump.

- A weakness in the motor winding.

- A loose wire or connection that needs to be repaired.

- If there are many minerals in the water, they plate out on the rotor and eventually stall it. [DF - note that this will be a problem on open systems but not on a closed system that does not take in new water]

If the problem is a stalled circulator pump rotor, Taco has a replacement cartridge.

If the motor is bad, you'll need a new pump. If you drain your system and put in fresh water, or if you have a leak where new water is being added all the time, oxygen and minerals will be continually added to the system.

Whatever the reason, it is unusual for a 00 pump to fail.

- Circulator pump location - where to put the pump, on the supply side or return side of the boiler?

We were taught that circulator pumps may have a longer life and run cooler if placed at the return side of the boiler where the returning heating water is cooler than it was on first leaving the supply side of the boiler. But at least some manufacturers say it doesn't matter.

Here is Taco's position on circulator pump position:

All of the "00" pumps can be used on the supply side or the return. It is preferable to put a circulator on the output of a boiler, but the expansion tank should be between the boiler and the pump section. Most of our "00" iron pumps have a max water temperature of 230ºF.

The max for the bronze is 220ºF. 160ºF is cold. No matter what the water temperature is, the motor housing will be hot. There will be no change in performance or life. - Taco FAQ

See details at CIRCULATOR PUMP MOUNT LOCATIONS - Circulator pump is not capable of pumping against the head pressure of water in the heating system: each manufacturer provides a table of their circulator pump models and the head pressure against which the pump can work, at various flow rates.

Many residential heating circulator pumps do not have a large "lift" capacity and depend on the heating piping to be full of water without any air blockages in order to function satisfactorily. Increasing the "cold" pressure of the water in the heating system may be necessary, especially in buildings taller than two stories. An alternative is to connect an additional circulator pump in series with the first one.

The gallons per minute (GPM) that a pump puts out are dependent on the head produced by the pump.

The system resistance is the controlling factor in determining the flow produced by a pump. As the flow increases in a piping system, the resistance or pressure drop rises at the rate of the square of the ratio of the flows.

For example, if the resistance of the system is 2 ft. at 3 GPM, at (6 gpm/3 GPM)² x 2 ft.= 8 ft. Using this equation we can generate a system resistance curve and plot it on the pump curve.

The point where the system resistance curve and the pump curve intersect is the maximum flow that the pump will produce in that piping system.

If any [circulator] pump is put in series with another pump, the heads are additive at the same flow. To increase the flow, the [circulator] pumps have to be put in parallel. With pumps in parallel, the flows are additive at the same head. When [circulator] pumps are put in series, install a nipple between 2 flanges.

Bolt the discharge of one [circulator] pump to one flange, and the suction of the other [circulator] pump to the other flange." - TacoFAQs - - Circulator pump position: Watch out: be sure that the circulator pump is installed as the manufacturer describes. While most circulator pumps can pump heating water in just about any position, there are some positional constraints. For example, quoting from B&G:

The Series LR Circulator can be installed to discharge up or down, horizontally, left or right, but the motor shaft must remain in the horizontal position, the arrow on the body must point in the direction of the flow, the conduit box must be positioned on the top or to the side of the motor housing. - "Instruction Manual, Bell & Gossett Series LR Circulators" [see References]

-

Circulator pump won't stop: this is not necessarily a defect - it depends on how your heating system was designed and wired. In some areas the circulator runs all winter and the thermostat just turns the boiler on and off. For diagnostic questions & answers about circulators that run continuously

see CIRCULATOR WONT STOP.

- Too much heat or un-wanted heat: Other cases of un-wanted heat may occur if hot water circulates through the heating system piping even when the circulator is OFF. Often this problem is traced to a check valve that's not working or a zone valve that's stuck open. See our diagnostic Q&A's

at UNWANTED HEAT

Also see CHECK VALVES, HEATING SYSTEM

Question: I recently installed a Radiant Mixing Block to heat 2 zones of radiant floor. When the block injection pump injects at the 20–40% range, it makes a growling noise that sounds similar to dry bearing. Any suggestions?

Answer: The check valve in the inlet connect from the boiler supply line is making the noise. To prove a point, put an ice cube on the radiant supply sensor which should make the injection pump speed up. If the noise goes away when the pump speeds up, then it is the check.

To eliminate the noise, break the hot water supply connection and unscrew the adaptor fitting from the block manifold. Look inside that connection and you should see the check and a snap ring holding it in place. Remove the snap ring and then the check. Reinstall the adaptor fitting and re-splice the copper tubing.

This noise problem has occurred once in a while and we are developing a new check that should overcome it. At this time, this is our only solution and I have not heard of any problem operating without the check. -- Taco FAQ 01/15/2009

If the boiler runs but the heating baseboard or radiators in an area do not get hot, the problem could be

- The thermostat - where multiple thermostats and heating zones are installed, the boiler may be running but the thermostat for a given zone may not be calling for heat; or the boiler may be running to make domestic hot water and even a single zone may not be calling for heat.

See THERMOSTATS. - The zone valve - may be stuck closed, if your system is using zone valves.

See ZONE VALVES, HEATING - The heating system may be air-bound - part of the system piping, baseboards, convectors, or radiators may be air-bound. We introduce this topic below and explain how to correct an air bound heating system at

AIR-BOUND HEATING SYSTEMS. - The circulator pump itself may have stopped working - some common circulator pump brands shown at this website in our diagnostic articles include Bell & Gossett™, Grundfoss™, and Taco™ - these are discussed at

CIRCULATOR DIAGNOSTICS - A heating zone manual control valve, flow balancing valve, or check valve may be manually or accidentally closed or stuck shut.

If the heating boiler itself if does not turn on in a response to a call for heat

see NO HEAT - BOILER.

Circulator Pump Failure or Noise Diagnostic Checklist

Question: repeated failure of circulator pump on tankless water heater

Question: repeated failure of circulator pump on tankless water heater

2019/01/23 Randall Smith said:

We had a circulator on our indirect HW heater die (loud noises) and replaced. This had initial problems due to air in the pipes, but once fixed there was little/no hot water and within a day the new circulator died as well.

Plumber suggested a control value that is supposed to control flow was broken and opened it fully, noting this would make the hot water very hot (adults only in house) and would need to be fixed properly soon.

Now, however, we are hearing the new circulator struggle with loud humming noises. Any ideas? Many thanks!

This Q&A appeared originally at INDIRECT FIRED WATER HEATER FAQs

Reply: some diagnostic checkpoints for noisy or failed circulator pumps: Causes & Effects

Randall

Thanks for an interesting and also of course troubling question. One can but suspect that we have not gotten down to the root cause of the problem.

It would be helpful to have

- the brand and model of circulator pump installed

- photos of the circulator, heater, boiler, piping and controls between them

- the operating temperature at the boiler

It's not clear to me how an anti-scald valve (I think that's the device your plumber calls a control valve) would cause circulator pump failure. Hydronic heating circulator pumps are designed to handle boiler water at the temperatures that occur normally in the heating system - up to close to 200 degF.

Obvious & Subtle Causes of Heating or Hot Water Circulator Pump Failure

- Pump or hot wter piping is air-bound, the pump is actually not damaged.

See AIR-BOUND HEATING SYSTEMS - Bad Circuator Pump Mounting the pump askew in its bracket, stressing the pump drive shaft bearings and causing leaks and repeated motor failures

- Improper Circuator Pump lubrication of the circulator pump: wrong oil, insufficient quantity, frequency

- Low voltage to the Circuator Pump (motor may run hot)

- Circulator Pump ran air-bound and was damaged, due to excessive air in the system -

see AIR-BOUND HEATING SYSTEMS - Circulator Pump installed backwards - pumping in the wrong direction; also it's best to put the pump on the return side of the heating loop where temperatures are lower and pump life is longer

- Wrong Circulator Pump speed: variable speed pump set to wrong speed - too slow (radiators or heating loop too cool, pump runs longer)

- Improper Circulator Pump control - pump runs continuously and is a model not rated for continuous operation

- Circulator Pump Piping errors: (rare & subtle) - improper piping installation, burrs, bends, obstructing water flow and causing turbulence in the pump, similar to excessive velocity if pump speed is too high (on variable speed pumps)

- Corrosion or debris: (rare) very corrosive or very hard water, including scale or debris that blocks or jams the impeller

- Circulator Pump Leaks left un-repaired, worse, leaks that drip onto electrical components

- Defective or damaged Circulator Pump motor (motor may run hot, vibrate excessively, be unusually noisy, fail to pump proper volume) - if the defect originated at the factory, replacing the pump with another made in the same batch at the same time may simply repeat the problem.

- Excessive Circulator Pump temperature, running the equipment hotter than recommended by the manufacturer

Circulator pump company contact information & installation & repair manuals

- Also see AIR-BOUND HEATING SYSTEMS for diagnosis and repair steps

- Armstrong ARMSTRONG ASTRO CIRCULATOR PUMP MANUAL [PDF] Armstrong Fluid Technology,

Excerpt: Armstrong Astro 2 circulators are designed for closed hydronic or potable water systems. Their intended use is for circulating water or glycol solutions. For pumping domestic water use non-ferrous lead free bronze or stainless steel body pump construction.

Toronto 23 bertrand avenue toronto, ontario canada m1l 2p3 +1 416 755 2291

Buffalo 93 east avenue north tonawanda, new york u.s.a. 14120-6594 +1 716 693 8813

Birmingham heywood wharf, mucklow hill halesowen, west midlands united kingdom b62 8dj +44 (0) 8444 145 145

Manchester wolverton street manchester united kingdom m11 2et +44 (0) 8444 145 145

Bangalore #59, first floor, 3rd main margosa road, malleswaram bangalore, india 560 003 +91 (0) 80 4906 3555

Shanghai no. 1619 hu hang road, xi du township feng xian district, shanghai p.r.c. 201401 +86 21 3756 6696

São Paulo rua josé semião rodrigues agostinho, 1370 galpão 6 embu das artes sao paulo, brazil +55 11 4781 5500 - Bell & Gossett Air Separators and other heating system components, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379 . Air separators are discussed by B&G at http://www.bellgossett.com/homeowners/BG-airseparator.asp

- B&G: "Instruction Manual, Bell & Gossett Series LR Circulators" P86101D, Mayu 2012, Xylem Inc. 8200 N. Austin Avenue Morton Grove, Illinois 60053 Phone: (847) 966-3700 Fax: (847) 965-8379 www.xyleminc.com/brands/bellgossett

See BELL & GOSSETT B&G EQUIPMENT MANUALS & CONTACT for our complete collection of B&G circulator manuals - Also see BOILER CONTROLS & SWITCHES

- Also see BOILER CONTROLS: MANUALS for HEATING SYSTEMS

- Grundfos, Poul Due Jensens Vej 7

DK-8850 Bjerringbro, Denmark

Tel.: +45 87501400

retrieved 2020/04/15, original source: https://www.grundfos.com/service-support/encyclopedia-search/air-vent.html

GRUNDFOS Kansas City 17100 West 118th Terrace Olathe, Kansas 66061 USA Phone: (913) 227-3400 www.grundfos.us

GRUNDFOS Canada 2941 Brighton Road Oakville, Ontario L6H 6C9 Canada Phone: +1-905 829 9533 www.grundfos.ca

GRUNDFOS México Boulevard TLC No. 15 Parque Industrial Stiva Aeropuerto C.P. 66600 Apodaca, N.L. México Phone: 011-52-81-8144 4000 Fax: 011-52-81-8144 4010 www.grundfos.mx

GRUNDFOS ALPHA SERIES VARIABLE SPEED CIRCULATOR PUMP INSTALLATION [PDF] Grundfos Pumps Corporation 17100 W. 118th Terrace Olathe, Kansas 66061 Telephone: (913) 227-3400 Fax: (913) 227-3500

GRUNDFOS UP SERIES CIRCULATOR PUMPS INSTALLATION GUIDE [PDF]

Excerpts:

Closed systems Model UP(S) 15, 26, 43 and 50 series pumps with cast iron pump housings are designed to pump water compatible with their cast iron construction. They are recommended for use in closed hydronic systems (i.e. airless, non- potable water).

Open systems Model UP(S) 15, 26, 43 and 50 series pumps with stainless steel or bronze pump housings are designed to pump water compatible with their construction and can be used in both open and closed systems.

Grundfos UPS15-58 and UP15-42F CIRCULATOR INSTALLATION INSTRUCTIONS [PDF]

GRUNDFOS UP(S) 15 HOT WATER CIRCULATING PUMP MANUAL [PDF] (2014) used on recirculating domestic hot water systems

GRUNDFOS UP(S) 15 HOT WATER CIRCULATING PUMP MANUAL [PDF] (2011) used on recirculating domestic hot water systems

VENTING AIR from HEATING SYSTEMS [PDF] Grundfos, , sources of air in hydronic heating systems and methods for getting rid of it (and why we care)

Grundfos offers this source of circulator pump manuals: https://www.grundfos.com/grundfos-for-engineers/project-assistance-search-page/how-to-find-installation-and-operation-manuals-online.html - Honeywell Sparco AMX circulators air purgers, air scoops, and other heating system components & controls,

Honeywell International Inc. 1985 Douglas Drive North Golden Valley, MN 55422 USA

Honeywell Limited-Honeywell Limitée 35 Dynamic Drive Toronto, Ontario M1V 4Z9 Canada Email: customer.honeywell.com

See HONEYWELL CONTROLS On HVAC Equipment, thermostats, primary controls, zone valves - for our complete list of Honeywell controls & manuals

HONEYWELL AMX Series DirectConnect MANUAL [PDF] (2010) Any application requiring accurate control of water temperature based on mixing of hot and cold water,

- Raypak, Installation and Operation Instructions, Raytherm Residential Boilers [PDF] courtesy of Raypak®, and technical advisor Wayne Hoffman, personal communication 5/11/2009. Mr. Hoffman is a technical advisor with more than 30 years experience in the heating field. r

Raypak is a Rheem company that provides hydronic heating boilers for residential, pool, and commercial use. Raypak can be contacted at 866-583-0664 for technical support or for assistance in selecting the proper heating equipment for a specific application. Rheem Corporation is a manufacturer of water heaters and heating equipment including Ruud heating and cooling products.

Websites: http://www.raypak.com and http://www.rheem.com/ - Taco circulators, air scoops and other heating system components & controls: Taco Inc., 1160 Cranston Street, Cranston, RI 02920 / (401) 942-8000 / Fax (401) 942-2360 Taco (Canada) Ltd., 6180 Ordan Drive, Mississauga, Ontario L5T 2B3 / (905) 564-9422 / Fax (905) 564-9436 www.taco-hvac.com

See details and manuals found at TACO CIRCULATORS & CONTROLS

Taco also has some helpful FAQs that are useful in diagnosing circulator problems - see http://www.taco-hvac.com/en/faq.html# - Also see Circulator Pump Relays cited at RELAY CONTROL SWITCHES

- WATTS HOT WATER CIRCULATOR DIAGNOSTIC MANUAL [PDF] Watts Premier, Inc., Phoenix, AZ 85027 Phone: 800-752-5582 www.wattspremier.com

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-11-05 - by (mod) -

If I understand the wiring question properly this quote from a typical Lochinvar manual may be useful:

The sidewall fan/powered vent cap MUST be interlocked with the units control system to start the fan on a call for heat and prove fan operation before the boiler fires.

Watch out: However rather than speculate and with the apology that I just don't know enough about the system you're discussing to have a confident opinion that it is safe or unsafe, why don't you give the boiler manufacturer a call and ask them directly. That would be the most authoritative source.

See the contact information as well as a list of boiler manuals found

at LOCHINVAR HEATING BOILERS or call their Technical support: 800-722-2101

On 2020-11-05 by Anonymous

Because the son-in-law thinks credentials carry more weight. It must be fine if the tech said so.

To me it's insanity to leave the ignition interlock disconnected, but it's not my call. I just want to be sure it's not dangerous.

On 2020-11-04 - by (mod) - Lochinvar CBN-135M9 boiler system also has the flow switch wired to the outdoor temp sensor input

Zap

I don't know for sure.

Why not ask the tech to return and restore the wiring to the manufacturer's specs?

On 2020-11-03 by zapster

My daughter and son-in-law have a Lochinvar CBN-135M9 boiler system with 4 zone controls. It also has the flow switch wired to the outdoor temp sensor input. According to the installation manual it should be wired to an ignition delay circuit to keep it from firing if the circulator isn't running.

It was apparently installed that way initially (2014) and has been heating since then, tho one upstairs circuit is very difficult to bleed the air out of. They had an HVAC guy come out to clean and inspect, and he left the wiring as-is. This strikes me as possibly dangerous--the ignition lockout is disabled, and the temp sensor is seeing a dead short across it.

Should we be worried about this weird arrangement?

Could the short across the temp inputs be holding the pressure down to account for the bleed difficulty?

On 2020-10-30 - by (mod) -

Jim

If you remove the thermostat wires and then jumper the two thermostat terminals right on the zone valve does it open? And when it opens does the circulator start? Does this zone have its own separate circulator?

If so, because Taco circulators are so quiet, you may need simply to feel pipes to see if the outlet side of the circ gets hot when calling for heat;

Keep in mind that the heating zone could simply be airbound (search the ARTICLE INDEX for AIRBOUND HEATING SYSTEMS to see what to do) or your hydronic water-to-air unit itself could be blocked, air-bound, or have a fan that's not working.

On 2020-10-30 by Jim

1 zone is not working. Heat or ac. Hydronic air with circulator pumps. Heat works fine in other zone. Hot water zone works as well. System is 8 years old. Everything has always worked. Batteries in thermostats replaced. I even swapped out each thermostat. Same zone still doesn't work. I swapped out cubes in taco switch relay with other zone

. Still doesn't work. Fuse is good. All thermostat wires are tight. I'm thinking its circulator pump grunfos 3 speed. One thing to not when thermostat clicks for heat the red light does not come on for that zone. (Would light still come even if circulator pump is bad.

On 2020-10-24 2 by Victoria Lazier

We had a radiant underfloor hydronic system installed 4 years ago. We have already had 3 pumps fail. Is this to be expected or is it due to underlying issues that at be related to poor installation.

Thank you

On 2020-04-30 0 - by (mod) -

Let me know if that works for you

On 2020-04-30 - by (mod) -

Yes there will be a separate circulator switch. Follow the wires

On 2020-04-29 by Anonymous

thank you so much for your response, I guess I was not very clear, I am in Canada, I have turned the fuse for the heater off but every once in a while (not constantly) the circulator will come on,

so if I understand you correctly there is a separate switch for the circulator? I am a widow whose husband looked after all this and I am sorry to sound so ignorant.

On 2020-04-29 - by (mod) -

Anon:

Depending on where you live, your heating system may have been set up so that the circulator runs continuously, with the room thermostat's turning the boiler on and off as needed on a call for heat. That's how hot water (hydronic) heating systems are usually installed in Canada.

In the U.S., more-often the thermostat turns the circulator on and off and the water temperature turns the boiler's burner on and off as needed.

So if yours is an "always-on" installation then you'll want to find the separate electrical power switch for the circulator(s) and flip it off - taking care to remember to turn in back on at the start of heating season.

If yours is NOT a "circulator always-on" system, then I would look for shorted thermostat wires or a stuck circulator relay that needs repair or replacement.

Thanks for asking a helpful question. Let me know what your service tech finds.

On 2020-04-29 by Anonymous

I have infloor heat and in May turn the heat off but often I hear the circulator going . It is eaten by electric

On 2020-03-08 - by (mod) - short hot water circulator life on an indirect-fired water heater system

KT

This is certainly a troublesome problem report: short hot water circulator life on an indirect-fired water heater system.

I agree that steam heat boilers often produce a lot of scale as well as rust and crud - which is why the steam controls like the boiler Low Water Cutoff need to be flushed monthly.

So we're circulating silty steam boiler water from the steam boiler's water reservoir through the heat exchanger in the indirect water heater. And you report that's killing the circulator pumps.

I would discuss with your service tech

1. do we need to go through a more-aggressive cleanout flush of the steam boiler?

2. do we need to use a water conditioner or treatment additive in the steam boiler to reduce the rust and scale problem?

(those are good for the boiler and heating system as well)

3. should we install a large particle filter in the indirect water heater line from the boiler ahead of the circulator pump?

4. Should we be installing a scale-tolerant circulator pump? Grundfos, Taco, Liang and Watts all make circulator pumps that can tolerate some scale in the heating water.

On 2020-03-07 by KT

12 yr. old Amtrol indirect-fired water heater's 3d circulation pump is failing, extremely noisy and struggling.

Tank is still fine, apparently-- way past warranty of course.

Amazing actually that any pump could survive, handling that rusty sludge from cast-iron steam pipes! Anybody know if its longevity is typical? About to have it replaced--

On 2019-01-23 by Randall Smith - new B&G Ecocirc 19-16 CCFXYZ

Thanks for the help! I've attached one image (can't seem to figure out how to do multiples) that shows the circulator, the water heater, and the pipes connecting them.

The new circulator is a B&G Ecocirc 19-16 CCFXYZ. The other (older) circulators for the house heat are by Taco, model 007-F4.

The water heater, if it matters, is an Amtrol 'Boiler Mate' WH-7P (41 gallons).

The operating temperature at the boiler is set at 190 now, had been 220. When doing the initial repair the plumber felt the ~200F+ & ~20psi was too high and reduced it to 190F max and 15psi. Not sure if this is related to our current problems.

On 2019-01-23 by (mod) - troubleshooting indirect water heater circulator pump failures

Yep, Clark Van Oyen's comments box code only permits one image per comment, but of course one can post multiple comments (and images at one per).

Yep, Clark Van Oyen's comments box code only permits one image per comment, but of course one can post multiple comments (and images at one per).

220F is too hot for a normal boiler and risks dumping at the TP Relief valve.

The best aquastat settings would be HI 200, LO 20 or more below the HI,

I might keep the DIFF circuit working and set DIFF to the max or 25. to keep heat in the boiler to speed response when the indirect heater ("zone") wants help from the boiler.

The indirect water heater runs as what looks to the boiler and aquastat as simply another heating zone.

Amtrol warns against scalding hazards and recommends a tempering valve.

If you give us the brand and model of your tempering valve we can be sure we've found the installation instructions and proper positioning information.

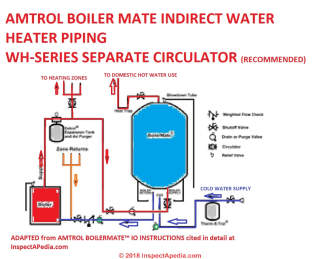

The sketch above is adapted from the Amtrol BoilerMate™ WH-series INSTALLATION MANUAL [PDF] (2012) AMTROL, 1400 Division Road, West Warwick, RI 02893 T: 401.884.6300 F: 401.885.2567 www.amtrol.com

Reader Question: radiator exploded after circulator pump repair

(Jan 30, 2014) Heather said:

I have a boiler for heat in my home with two circulator pumps that supply two different zones (upstairs and downstairs).

My circulator pump for the first floor went bad and was replaced, fixing the problem. The boiler itself had no issues.

An hour later, a radiator upstairs (different zone supplied by the other circulator pump) exploded and a 6 inch piece of metal was cast from the radiator causing water to flood the house.

This happened in a different zone connected to the other pump from the same boiler.

Could the exploded radiator in the other zone have been affected by the replacement of the circulator pump to the other zone?

I cant understand how this coincidentally happened when there seemed to be no problems with the supply to the zone on the second floor where it happened. Any feedback is appreciated.

This question was originally posted at HEATING SYSTEMS

Reply:

Heather,

This sounds horrible - and peculiar. Forensic investigators start by disbelieving coincidences.

But it's not clear why a radiator would explode under any circumstances. Really "explode" ? We're talking about hot water heat, at normal pressures under 30 PSI.

Watch out: if your heating system pressures were abnormally high (over 30 psi) then either your system was missing a critical safety device - a Temperature/pressure relief valve at the boiler - or the valve was installed but was jammed, or subverted, or not working.

IF that is is the case this is a VERY DANGEROUS condition as an exploding boiler can cause a BLEVE explosion of tremendous force. (Search InspectAPedia for Bleve explosion to read Details).

In short, a normal hot water heating circulator pump does not have great pumping power; if there was an overpressure problem in the system it seems more likely it came from another component. Naturally everbody involved in working on your system will be scared to admit fault. Focus on a thorough inspection of the heating boiler starting with

- the location, type and condition of pressure/temperature relief valve

- the normal operating pressure and temperature of the boiler

If on your own, before the heating company shows up, if you see high pressure readings on the boiler gauge (30 psi or above) or if you see water spilling out of a relief valve I would SHUT OFF THE SYSTEM immediately and would get the heck out of there.

Follow-up:

The PSI was not high before the repair. It was around 12. After the repair and the flooding upstairs, it is running around 18 psi now. I did look at the system this morning.

The only problem I see is that a pressure reducing valve has a slow drip from the bottom. The valve for the intake had been turned off last night to stem the flooding and then turned back on after the flow to that radiator was capped so I don't know if that affected the valve since it is about 10 inches away from the cutoff.

Reply:

12 PSI cold is normal for a typical 2 story home.

BTW I would not want to confuse an air bound system with one that is at too low pressure.

On 2014-11-06- by (mod) -

Mary depending on brand and model a new hydronic heating system (hot water) circulating pump costs between about $140. and $350. U.S. plus labor - the labor can vary depending on how much trouble it is to get to the equipment, and on details such as whether or not service valves are already installed on either side of the circulator since if there are none the technician will probably have to drain and refill the heating sytstem - adding time and cost.

On 2014-11-05 by Mary

How much should it cost to replace a circulator pump in a single family rowhome? I have a 9 yr old Bryant boiler. Not sure of the make or BTU. Thanks

On 2014-10-27 by Steve M

Have a new Crown Bimini 90,000 BTU heater installed. cut supply lines on first floor to separate upstairs and downstairs to two zones. Both have a common return though. When i turn either zone on, the supply line of the zone not on stays cold but all the radiators get hot. The zone that is not on takes longer to get hot but still does eventually.

Thinking there still may be some air in the lines but cant think of anything else that would be causing this.

FYI..boiler was ran with a boiler loop. Both zone supply lines have a circulator attached with a common 3rd circulator on the return near the boiler.

Thanks in advance

On 2014-10-23 by Teresa

A WATTS Model 500800 circulation pump delivered hot water within about 5 seconds to the house main shower (vs. 1 minute before its installation)and to other faucets throughout the house.

BUT when house was recently retrofitted for entire replacement of 75 year-old plumping pipes, the shower water runs and runs cold before getting even somewhat warm.

However, other faucets in the house are delivering hot water even better than before. The plumber is puzzled since he did not touch the plumbing for the shower (he did some adjustments with shower handle). It surely cannot be coincidental that non-delivery of hot shower water coincides with pipe replacement and installation of a new water heater.

Any ideas what might be causing the problem? Air in a pipe? A missing hook-up somewhere?

On 2014-08-18- by (mod) -

I'd start by looking for vibration, e.g. from a circulator, transmitted via piping or buliding framing.

On 2014-08-18- by (mod) -

Re-posting

8/17/14 AUTHOR:Anonymous (no email)

COMMENT:We had a tankless water heater put in a few years ago and everything was fine. A few months ago we redid a downstairs bathroom and had a circulator put in at the same time. Ever since then whenever the downstairs bathroom shower is being used there is a drone/humming noise upstais. Any ideas? Thanks

On 2011-10-21 by construction

good tutorial

Question: circulator pump cost

See CIRCULATOR PUMP REPAIR FAQs

Question: circulator mounting position vs system pressure

See CIRCULATOR PUMP REPAIR FAQs

How to Hook Up Multiple Circulators or Zones

We moved this discussion to a new article: please see MULTIPLE HEATING ZONE CONTROL

Question: circulator pump won't start

We moved this discussion to a new article: please see CIRCULATOR WONT RUN

Question: circulator pump runs intermittently

We moved this discussion to a new article: please see CIRCULATOR PUMP RUNS INTERMITTENTLY

Weak Heat Questions

We have moved this discussion to a new article: please see WEAK HEAT, WEAK CIRCULATOR, TOO COOL

Question: Circulator Pump Noises, heating system noises

We have moved this discussion to a new article: please see CIRCULATOR NOISES.

Also see HEATING SYSTEM NOISE DIAGNOSIS for a more broad range of heating noise diagnosis & repair procedures.

Question: circulator pump runs even when we are not asking for heat

See CIRCULATOR PUMP REPAIR FAQs

...

Continue reading at BYPASS a BAD CIRCULATOR or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CIRCULATOR PUMP REPAIR FAQs - questions & answers posted originally on this page - for diagnostic questions & answers about heating circulator pumps & circulator relays

Or see these

Recommended Articles

- AIR BLEEDER VALVES

- AIR SCOOPS PURGERS SEPARATORS

- AIR-BOUND HEATING SYSTEMS

- CIRCULATOR PUMPS & RELAYS

- BELL & GOSSETT B&G EQUIPMENT MANUALS & CONTACT

- CIRCULATOR PUMP BASICS

- WHAT GOES WRONG WITH HEATING CIRCULATORS?

- BYPASS a BAD CIRCULATOR

- CIRCULATOR COSTS

- CIRCULATOR NOISES

- CIRCULATOR OPERATION CHECKS

- CIRCULATOR PUMP LEAKS

- CIRCULATOR PUMP MANUALS

- CIRCULATOR PUMP MOTOR or BEARING FAILURE

- CIRCULATOR PUMP MOUNT LOCATIONS

- CIRCULATOR PUMP MOUNT POSITION

- CIRCULATOR PUMP RELAYS & OTHER CONTROLS

- CIRCULATOR PUMP RELAY CHATTERING

- CIRCULATOR PUMP WON'T START

- CIRCULATOR PUMP WON'T STOP RUNNING

- CIRCULATOR PUMP RUNS INTERMITTENTLY

- CIRCULATOR PUMP SPEED SELECTION & ADJUSTMENT

- CIRCULATORS VARIABLE SPEED

- MULTIPLE CIRCULATORS HOW TO HOOK UP

- MULTIPLE HEATING ZONE CONTROL

- TACO CIRCULATORS & CONTROLS

- WEAK HEAT, WEAK CIRCULATOR, TOO COOL

- CIRCULATOR PUMPS vs ZONE VALVES

- HOT WATER CIRCULATOR PUMP SPEEDS DELIVERY using a hot water circulator on domestic hot water supply to fixtures

- MANUALS & PARTS GUIDES - HVAC - home

- MANUALS for HEATING & A/C SYSTEM CONTROLS

Suggested citation for this web page

CIRCULATOR PUMPS & RELAYS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.