Protection Bollards for Mechanical Equipment

Protection Bollards for Mechanical Equipment

Security barriers protect boilers, furnaces, gas meters, oil tanks, water heaters from vehicle damage

- POST a QUESTION or COMMENT about methods of protection of mechanical equipment from vehicle impact in vulnerable locations: garages, parking areas, etc.

Bollards or security barriers are heavy duty vertical posts used to protect mechanical equipment from damage from vehicles.

When heating equipment such as boilers or furnaces, water heaters or oil tanks are located in a garage or where a gas meter is located outdoors in a location where the equipment could be struck by a vehicle the equipment must be protected.

A suitable barrier such as a bollard (described here) can prevent a car or truck pulling into a garage or parking lot from striking the gas meter.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Protection Bollards for Mechanical Equipment & Hydrants

Bollards or protective pipes or similar barriers, are required by national or local codes in most jurisdictions to protect key site features from damage.

Bollards or protective pipes or similar barriers, are required by national or local codes in most jurisdictions to protect key site features from damage.

Bollards are also installed in locations to prevent deliberate ramming by a vehicle or to control traffic movement. Typical protective bollard standards specify 2" to 6" diameter concrete filled pipes set into the soil or slab.

Photo: bollards protecting gas meters at this Tucson Arizona building. These bollards were placed less than 3 ft. apart, a technical violation of ADA standards but because they are not in a passage area in our OPINION that's not an issue.

You can see that the bollards did their job, one having already been struck and bent over. In our opinion these bollards are under-sized in diameter and strength.

[Click to enlarge any image]

Examples of places where protective bollards are required include both outdoor and sometimes indoor components, such as those that we list here:

- Air conditioning compressors or heat pumps if located where subject to vehicle impact

- Building security, for high-risk locations subject to vehicle impact, such as embassies

- Electrical equipment if located where it is subject to vehicle impact

- Fire Hydrants

- Gas Meters

- Heating equipment such as furnaces, water heaters, boilers, located where the equipment could be struck by a vehicle

- Oil tanks (above-ground) outdoors or indoors in a garage where the tank could be struck by a vehicle

- Walkways and entrances to buildings where bollards are needed to protect pedestrians from traffic.

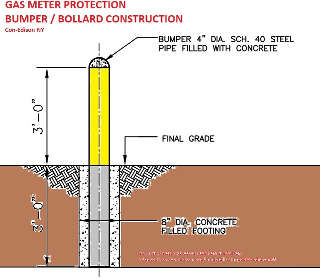

For example, gas meters and other mechanical equipment located where it could be bumped or struck by a vehicle must be protected from damage. The most-common protective device is a bollard: a short, thick post, usually concrete-filled steel, set into the soil at a depth adequate to withstand impact by a vehicle.

Bollards, or "mooring bollards" in their original use, were a short, thick post on the deck of a ship or along a dock used to tie the boat to the dock.

Bollards are also installed in locations to prevent deliberate ramming by a vehicle or to control traffic movement. Typical protective bollard standards specify 2" to 6" diameter concrete filled pipes set into the soil or slab.

Bollard Construction / Installation Requirements

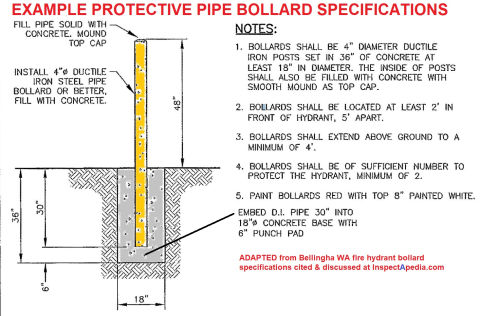

Sketch above: adapted from Bellingham Washington's bollard installation guidelines for fire hydrant protection, is a more-detailed sketch showing typical bollard construction details.

As a gas service customer, in most jurisdictions it is your responsibility to protect the gas meter from harm. Typical wording such as that from ENSTAR natural gas, advises customers as follows:

As a customer, it is your responsibility to protect the meter from harm. Any meters located in vehicle-accessible areas, such as on or along a wall adjacent to a road, driveway, or parking area, shall be protected by 4″ bollards (preferred) or a concrete barrier. Standard curbs, curb stones, or sidewalks do not satisfy this requirement. Bollards are steel posts that are installed in the ground and filled with concrete, thereby preventing the meter from being struck and damaged by a vehicle. - (Enstar 2022)

Watch out: the requirements for installing a suitable protective bollard or pipe barrier depend on a collection of factors including the equipment or location being protected, the size of vehicles and access of vehicles to the area, soil properties, and local codes and ordnances.

Therefore these examples and also the actual protective bollard specifications and installation documents given below may not meet the requirements of your specific installation. Check with your local building officials.

Following is a description of typical or example bollard installation parameters we provide bollard test standards, bollard installation standards, and related guidelines from various authorities.

Typical Bollard Installation Specifications

Typical bollards are permanently-installed, usually set into concrete; removable, pop-up, retractable, bolt-down bollards are widely used as well - we include bollard specifications for those products below as well. Specialty bollards such as bendable and "slow-stop" bollards are not discussed here.

Above and below, protective bollards installed at the entry to the Castle Point New York Veterans Administration hospital.

- Bollard Spacing: at least 24" in front of hydrant (e.g.);

Maximum bollard spacing: 5 ft apart (where multiple bollards are needed) (this is the maximum spacing between bollards, intended to block typical vehicles .

Watch out: if smaller vehicles can be expected at a particular location needing protection from bollards, then this five foot maximum may need to be reduced to be sure that the space is less than the minimum vehicle width. An example might be a 3 or 4 ft. spacing of bollards where fork-lift trucks are in use.

Minimum bollard spacing: 3 ft. apart. The reason bollards are spaced no less than 3 ft. apart is to comply with ADA / accessibility guidelines.

Really? bollards might be found spaced closer than 3 ft. where necessary in some locations that are not also a passage or walkway.

- Bollard Diameter & Construction: 4" galvanized steel pipe, concrete filled

- Bollard height above ground: 36" or 1 meter, 48" in some jurisdictions

- Bollard depth below ground: 24" to 36", up to six feet in some circumstances

Some bollard installations permit bolt-down bollards that are secured to bolts pre-set into a concrete base. - Permanent Bollard support/fill: 15" - 18" diameter or larger opening, filled with concrete to ground surface; top of fill should be smooth mounded to drain and avoid water or frost damage;

6" Gravel or concrete required as a "punch pad" or fill forming the base onto which the bollard or ground sleeve is set.

Note: Some installations may require reinforcement of the concrete bollard base using steel re-bar

- Removable Bollards may be a bolt-down type, lift-out type that are set into a ground sleeve, or a retractable or pop-up type protective bollard.

- Ground sleeve for removable bollards (where required):

Some bollard installations where a ground sleeve is installed to permit insertion or removal of the actual bollard itself may require a round steel re-bar "cage" inserted into the bollard base excavation along with a suitably-sized PVC ground sleeve before the hole is filled with concrete. - Bollard covers: colored plastic bollard covers are provided by various manufacturers - e.g. see Post Guard cited below.

Example of Oil Tank Protection Bollard Installation Procedure

Step 1: prepare the opening for bollard installation.

Notice - above - that in order to have adequate working space, the hole cut into the concrete floor of this garage was prepared before the new oil tank was set in place.

These photos illustrate the installation of a 4-inch concrete-filled steel bollard installed inside a garage to meet local building code requirements in a New York home.

Below: the oil tank and its containment bin have been installed - a cardboard box sits atop the bollard hole that had been cut into the floor.

The local building official's view was that even though the above-ground oil tank in this garage was installed in a corner where it would be impossible for it to be struck by a vehicle exiting the garage, it was possible for a high-speed vehicle to strike the building, crash through the building's exterior wall, smash the oil tank, sufficiently to cause an oil leak.

To comply with the building department's requirement for oil tank protection, the environmental company who installed the above ground oil tank and its containment bin (shown in these photos) installed the protective bollard as we describe here.

Details of the replacement of an old (not leaking) above ground oil storage tank with the new tank shown here are given

at OIL TANK REPLACEMENT PROCEDURE

Below: the workers used an impact hammer-drill to deepen the hole into which the bollard would be set in concrete.

Step 2: test fit the bollard to check height above the finished floor or ground surface.

With additional excavation completed, the hole is ready for a "test-fit" of the protective bollard. The required bollard depth is specified by the local building official;

Step 3: pour concrete around the bollard.

Once the bollard is set onto a gravel base in the hole and tested for fit, for required height above the finished floor, it is held plumb as the concrete is poured around its base.

Step 4: keep the bollard plumb - vertical during concrete pour.

By checking two or more times during placement of the concrete around the bollard, it is kept plumb (dead vertical) or is adjusted to plumb if needed.

Step 5. Finish the concrete around the bollard base.

The installer finishes the concrete surface around the bollard. As this is an indoor installation the concrete around the bollard base was kept level with the rest of the floor. For an outdoor installation the code official may want the concrete slightly mounded to drain away from the bollard itself.

Below: the finished bollard is in place;

Watch out: until the concrete has set solid you should take care not to disturb the bollard's position.

Special thanks to Larry Roosa and Enviro Clean Oil Tank Services, the company who did the work to remove the old above ground oil tank (AST), install the new one, connect it to the heating boiler and confirm that the boiler worked properly with its new fuel supply, and finally, to install the oil tank protective bollard required by the local building department.

The company's steps in replacing an AST can be seen

at OIL TANK REPLACEMENT PROCEDURE

- Enviro Clean Oil Tank Services, Box 454 Wurtsoboro NY 12790, USA, Tel: 845-888-8265 Email: info@envirocleants.com Website: https://www.envirocleantankservices.com/

Bollard Failures: wrong size or improper installation

Photo above: this faux-bollard, in San Miguel de Allende in Guanajuato, was installed with so shallow a penetration into the roadway that at the first modest tap from a vehicle it keeled over dead in the road.

[Click to enlarge any image]

The protective bollard installation sketch shown at the top of this page showing an 8-inch diameter bollard specifies a three-foot set-depth for bollards, and specifies as well that concrete is used to secure the bollard's base or footing.

Watch out: if a protective bollard is not made of sufficiently-strong material, if it is not buried or set in concrete to an adequate depth, it cannot do its job.

Below: More Bad Bollards in a parking area in Fishkill, New York (June 2021):

Bad bollards in our photo above show unsafe conditions:

- A thin metal pipe stuck through an automotive wheel well in an ineffective try at "protecting" that compressor/condenser unit from getting smashed as vehicles try to turn around or back out of a rather small parking area in a commercial neighbourhood of Fishkill, New York. We call these faux bollards.

- A tipped-over bollard leaning towards the gas meters and gas pressure regulator it hopes to protect. If not buried at enough depth we call these faux bollards as well.

- A leaning bollard (white text) leading us to suspect that the bollards in front of this pair of gas meters are not placed at adequate depth into the soil or lack adequate concrete piers or support below ground.

Below: the single yellow bollard at this Hyde Park New York property may be inadequate to protect the gas piping to the right of the meter, though some additional protection is provided by the concrete bumpers along the edge of the parking lot.

Below: in our OPINION these I-beam protection posts installed along a building in Two Harbors Minnesota are not adequate to protect all of the gas meters from damage by a vehicle pulling into the parking area. They are also too-far apart (more than 5 ft.).

Below: another gas meter protection bollard set up in Two Harbors.

Watch out: State, provincial, and/or local building code specifications for your area may vary from these example clearance distances and damage protection means. Consult with your local building department.

Codes, Standards, Installation Specifications for Security Bollards

Protection for Fire Hydrants, Gas Meters, Oil Tanks, Other Equipment or Site Features

Photo, from the Purdue Aboveground Petroleum Tanks guide cited below, illustrates yellow bollards installed to prevent vehicles from hitting the oil storage tanks.

- 2015 IBC INTERNATIONAL BUILDING CODE [PDF] - temporarily offline, original file: /Design/2015-IBC-Bellevue-WA_unlocked.pdf available on request - as adopted by Bellevue Washington, includes the same caveat:

IBC 1104.6 Security Barriers

Security barriers including, but not limited to, security bollards and security check points shall not obstruct a required accessible route or accessible means of egress.

Exception: Where security barriers incorporate elements that cannot comply with these requirements, such as certain metal detectors, fluoroscopes or other similar devices, the accessible route shall be permitted to be provided adjacent to security screening devices.

The accessible route shall permit persons with disabilities passing around security barriers to maintain visual contact with their personal items to the same extent provided others passing through the security barrier. - ADA STANDARDS 2010 [PDF] include provision that a bollard or other security barrier may not obstruct safety exits or means of egress.

Excerpt:

206.8 Security Barriers. Security barriers, including but not limited to, security bollards and security check points, shall not obstruct a required accessible route or accessible means of egress. - AS-503-STANDARD-DESIGN-HANDBOOK [PDF]

- ASTM F3016 / F3016M - 19 Standard Test Method for Surrogate Testing of Vehicle Impact Protective Devices at Low Speeds, available from ASTM https://www.astm.org/Standards/F3016.htm

Excerpts:

5.1 This test method provides a procedure to establish a penetration rating for vehicle protective devices subjected to low-speed vehicle impact. Knowing the penetration rating provides the end user with the ability to select an appropriate protective device for site-specific conditions.

5.2 The protective device penetration rating does not imply that a device will perform as rated in all site conditions, approach routes, and topography. Also, this test method requires that the specimen only be tested at a specific impact location and, therefore, not all locations of impact can be tested and validated for a penetration rating. Other impact locations may provide different penetration ratings. - Australia, AusGrid, NS113 SITE SELECTION AND CONSTRUCTION DESIGN

REQUIREMENTS FOR CHAMBER SUBSTATIONS [PDF] (2021) Ausgrid, GPO Box 4009, Sydney, NSW 2001 Australia, Ausgrid ABN 78 508 211 731

Excerpt:

This Network Standard applies to site selection, design and construction of new contestable and non-contestable chamber substation installations and refurbishment of existing chamber substations. - Australia, AusNet, GAS METER LOCATION, Single & Multi Occupancy Premises, TECHNICAL STANDARD [PDF] (2018), AusNet Services, Locked Bag 13051, Melbourne VIC 8001 Australia, Email: customersupport@ausnetservices.com.au Tel: 1300 360 795 - retrieved 2022/03/06 original source: https://ausnetservices.com.au/-/media/Files/AusNet/New-Connections/Gas/Supporting-Documents/TS-4352.ashx?la=en

Excerpt:

This standard gives requirements for the location of gas meters, with a capacity not exceeding 65 Sm 3 /h, on single and multi-occupancy residential premises. For gas meters with a capacity exceeding that covered by this standard for residential premises refer to Gas Networks, AusNet Services. - Australia, Ergon, Distribution Network Standard

Standard for Site Selection and

Construction Requirements for

CHAMBER SUBSTATIONS [PDF] Ergon Energy, RESIDENTIAL

GENERAL ENQUIRIES

13 10 46 Web: ergon.com.au/ - retrieved 2022/03/06 original source: https://www.ergon.com.au/__data/assets/pdf_file/0017/326330/STNW3390.pdf

Excerpts:

These standards created and made available are for the construction of Ergon Energy infrastructure. These standards ensure meeting of Ergon Energy’s requirements. External companies should not use these standards to construct non-Ergon Energy assets. If this standard is a printed version, to ensure compliance, reference must be made to the Ergon Energy internet site www.ergon.com.au to obtain the latest version

Abstract:

This Standard provides minimum site selection, building design and construction requirements for the establishment of new Chamber Substations with ratings up to and including 22kV. This Standard applies to Surface, Elevated, Upper Level and Basement Chamber Substations, Switching Station Chambers and Chambers for High Voltage Customer Connections. Keywords: Chamber Substation, Substation, Indoor - Australia, JEMENA NETWORK OPERATOR RULES (NOR) GAS SUPPLY ACT 1996 (NSW) GAS SUPPLY (SAFETY AND NETWORK MANAGEMENT) REGULATION 2013 (NSW) , Jemena, PO Box 1220 North Sydney NSW 2059 Australia, Tel: 1300 137 078 - retrieved 2022/03/06 original source: https://jemena.com.au/getattachment/053538db-2149-4d3e-bf11-26188bc0dea5/Network-Operator-Rules.aspx

- Canada, ATCO, GAS METER BOX LOCATION HANDBOOK [PDF] (2020) ATCO Head Office at ATCO Park

5302 Forand Street S.W.

Calgary, Alberta

ATCO Guest Services: (403) 292-7500 - ATCO has offices in Canada, the United States, Mexico, Australia, and Europe. - retrieved 2022/03/06 original source: https://www.atco.com/content/dam/web/atco-australia/for-business/gas/atco-gas-meter-location-handbook-feb-2020.pdf

Excerpt:

ATCO owns and maintains the underground network of gas pipelines in Western Australia, bringing gas to over 750,000 homes and businesses. ATCO distributes natural gas in the Perth metropolitan area, Geraldton, Bunbury, Busselton, Harvey and Kalgoorlie. ATCO also distributes LPG in Albany via its underground network. This Handbook provides guidance for installing your gas meter box and service for safe, reliable and efficient connection to all of ATCO’s distribution networks.

New developments typically have buildings that occupy a larger portion of the block and there are an increasing number of developments located in elevated positions. The changing designs of these developments can compromise standard gas meter box locations. ATCO wishes to avoid delays by providing information to the industry at design stage, eliminating costly alterations and variations during construction.

The requirements in this handbook are to be followed by all Responsible Persons (Developers, Builders, Gasfitters, Owners, Customers, and any related Contractors) to help avoid delays or additional work and costs being incurred. This Handbook is a “live” document and is subject to change. - Canada, CSA, NATURAL GAS and PROPANE INSTALLATION HANDBOOK CSA-B149 [PDF] (2000) Published in February 2000 by CSA International

178 Rexdale Boulevard

Toronto, Ontario

Canada M9W 1R3

- CSA Standard B149.1, Natural Gas and Propane Installation Code.

- CARPENTRY-MCRP-3-17.7C Z [PDF] U.S. Navy Carpentry Manual, Excerpt:

Bollards, single- or double-bitt, are steel or cast-iron posts to which large ships are tied. They prevent ships' lines from riding up off the post. Bollards may have waist diameters smaller than ton diameters and may have caps, or projecting, rounded horns.

Double-bitt bollards are also known as double bitts or double steamship bitts. Bollard bodies may be hollow for filling with concrete after installation They are usually designed to take line pulls of about 35 tons.

Photo: besides protecting gas meters, tanks, oil tanks and mechanical equipment, bollards are used to protect walkways and entrances such as at this VA hospital.

- EC Magazine, "Code Questions & Answers", (February 2000 Q&A discussing August 1999 magazine issue) Electrical Contractor Magazine, 3 Bethesda Metro Center, Suite 1100 Bethesda, MD 20814 USA Tel: 301.657.3110 Website: http://www.ecmag.com/

- Enstar Natural Gas, "Meter Protection", Enstar, Anchorage Administrative Office, 3000 Spenard Rd. Anchorage, AK 99503-3606, USA, Tel: 907-277-5551 - retrieved 2022/03/06, original source: https://www.enstarnaturalgas.com/safety-education/customer-responsibilities/meter-bollards/ Enstar is an AltaGas company.

- Formex, Formex® PIPE GUARD SPECIFICATIONS (Bollards) [PDF] , retrieved 2021/04/20 original source: http://www.formex.net/pipe-guards.pdf

Note: Authors: Virginia Commonwealth University Department of Chemical Engineering ChemEngine 601 West Main Street Richmond, Virginia 23284 Research Performed By Joseph Russell Gulu Sandhu

Excerpt: Bollards are U-shaped steel forms which are hollow on the inside. They are used as barriers to vehicle collisions. Based on crash test data, a passenger car of average size weighing 1.2 tons (2400 lbs) traveling at 40 mph will generate a force during impact equivalent to 50 tons, when it strikes a bollard.

Commonly, bollards are specified with a 4-inch diameter, filled with concrete, and set into the ground at a depth of 12 inches.

This specification is not based on any reported scientific data [Emphasis ours - Ed.], but instead has just been used in the industry as a common standard. Clearly, with the forces generated during a vehicle collision, a quantitative analysis must be performed to specify a properly designed bollard system.

... A bollard’s ability to properly stop a vehicle is a function of several variables. These are the diameter of the pipe, the wall thickness, the height above ground, the depth into the ground, the area of the base, the soil and concrete type of the base, the structural properties of the steel, the vehicle speed and mass, and the whether or not concrete is used to fill the bollard. - GAS METER CODES & CLEARANCE DISTANCES

- GAS METER CODES & STANDARDS

- Geyer, Wayne B. & Jim Wisuri, HANDBOOK OF STORAGE TANK SYSTEMS [PDF] Steel Tank Institute, Lake Zuricch, IL, New York, Basil, Marcel Dekker, Inc., 270 Madison Avenue, New York, NY 10016 USA Tel: 212-696-9000; fax: 212-685-4540 & Eastern Hemisphere Distribution,

Marcel Dekker AG

Hutgasse 4, Postfach 812, CH-4001 Basel, Switzerland tel: 41-61-261-8482; fax: 41-61-261-8896

Excerpt: 2. Security: Fencing or bollards will be needed to prevent damage from major or minor vehicle collisions. Security is addressed in both National Fire Protection Association (NFPA) codes and the U.S. Environmental Protection Agency’s Spill Prevention Control and Countermeasures (SPCC) regulation.

Again, this is not a one-size-fits-all question.

For example, in Alaska, a fence can cause considerable problems in snow removal operations that are necessary to ensure access to an AST. - IRC Mechanical Code Section 69. APPLIANCES INSTALLED IN GARAGES. Section M1307 IRC 2009 - furnace (or boiler or water heater etc) in a garage

M1307.3.1 Protection from impact.

Appliances shall not be installed in a location subject to vehicle damage except where protected by approved barriers.

Original source: Stevens WA, COMMONLY USED RESIDENTIAL BUILDING CODES, IRC 2009, [PDF] retrieved 2019/05/08 original source: http://www.co.stevens.wa.us/landservices/documents/MECHANICALSECTION.pdf

Other sections of this mechanical code are given at CHIMNEY HEIGHT & CLEARANCE CODE - Kenny, Gary, ME PUC, PROTECTING GAS FACILITIES from VEHICLES & OTHER DAMAGE [PDF] ME PUC, Maine Government (2011) presentation slides

- LP / PROPANE GAS TANKS clearance distances and installation specifications.

- PG&E Greenbook, ELECTRIC & GAS SERVICE REQUIREMENTS 2020-2021 [PDF] Pacific Gas and Electric Company Technical Document Management Mail Code N9H P.O. Box 770000 San Francisco, CA 94177 USA, - retrieved 2022/03/06 original source: https://www.pge.com/pge_global/common/pdfs/services/building-and-renovation/greenbook-manual-online/greenbook_manual_full.pdf

- PG&E Greenbook, ELECTRIC & GAS SERVICE REQUIREMENTS 2017-2018 [PDF] Pacific Gas & Electric Co.

Excerpt:

8. Install, own, and maintain physical protection such as bollards or barrier posts and/or enclosures, as may be required. - PSEG, GAS APPLIANCES & GS PIPING GAS SERVICE REQUIREMENTS [PDF] (2017)

Excerpt: If an industrial or commercial customer requires a meter set to be installed in an area subjected to traffic conditions, the customer shall provide suitable protection (i.e. concrete bollards) to prevent meter set damage. - Pirro, Paul, PSE&G GAS METER SET PROTECTION BEST PRACTICES [PDF][ (2013)

Excerpts:

High pressure natural gas meter sets including High pressure natural gas meter sets, including regulators and associated piping, may present a si g gy p nificant hazard if damaged by vehicular im pact because the subsequent release of a large volume of gas may lead to ignition with resulting explosion, death, injury or property damage.

Appropriate protection of these facilities by the installation of an excess flow valve (EFV) or some physical barrier can mitigate or prevent damage.

N.J.A.C. 14:6 N.J.A.C. 14:6 -7.3(e) explains that the gas public 7.3(e) explains that the gas public utility shall ensure that any high pressure gas meter set connected to a new residential service line when an EFV is not feasible and the high pressure gas meter set is located within three feet or less of a vehicular zone, is protected.

This section is limited to locations within three feet or less of a vehicular zone which is a radial area or less of a vehicular zone which is a radial area extending out three feet from the meter set piping. - Post Guard 4-INCH BOLLARD SPECIFICATION SHEET [PDF] Post Guard, Encore Commercial Products, Inc., 37525 Interchange Dr.

Farmington Hills, MI 48335 USA, Tel: 866-737-8900 Email: info@postguard.com

Post Guard provides bollards, bollard covers, installation specifications and related products and accesories.

Post Guard CONCRETE-SET BOLLARD INSTALLATION INSTRCTIONS [PDF] Origin: Wasautile, PO Box 1520 Wausau, WI 54402-1520 800-388-8728 Fax 715-355-4627 www.wausautile.com

Post Guard REMOVABLE BOLLARD INSTALLATION SPECIFICATIONS [PDF] - Purdue University ABOVEGROUND PETROLEUM TANKS [PDF]

Excerpt:

The area where delivery trucks park to fill the ASTs—the “off-loading” area— should be close to and within clear sight of the tanks. Trucks should not be required to back up or make sharp turns. Tanks should be placed in an area accessible to employees and fuel delivery drivers, but away from the main traffic pattern and not visible from the highway.

Bollards should be installed to prevent trucks from backing into the tanks... - Puget Sound Energy Inc's 2014 gas meter clearance specifications, retrieved 8/19/2014, - original source: https://pse.com/accountsandservices/Construction/Documents/3885.pdf

- Questar Gas, "GOOD PRACTICES FOR GAS PIPING AND APPLIANCE INSTALLATIONS" [PDF] (2015) Questar Gas, now Dominion Energy, Website: https://www.dominionenergy.com/, - retrieved 2017/11/12, original source: https://www.questargas.com/brochures/59060_401.pdf

- SC,CA, BOLLARD SPECIFICATIONS for PRIVATE FIRE PROTECTION EQUIPMENT & FUEL TANKS [PDF] (2003) Santa Clara County Fire Marshal's Office, 70 W. Hedding St., East Wing, 7th Floor, San Jose CA 95110 Phone: (408) 299-5760, retrieved 2021/04/20 original source: https://www.sccgov.org/sites/dpd/DocsForms/Documents/CFMO_C1_Bollards.pdf

This standard pertains to fire hydrant protection, and to geneartor or fuel tank protective post locations using a 4-inch galvanized iron pipe, filled with concrete, and requires a six-foot-deep base set into a 15" diameter base filled with concrete. - Trelleborg, Mooring BOLLARD INSTALLATION & MAINTENANCE MANUAL [PDF] Trelleborg Marine and Infrastructure - these are bollards uses along shipping docks.

- U.S. DOS SD-STD-02.01 vehicle crash test limits for bollards, U.S. Department of State

Above: tall green bollards used for parking control and pedestrian safety at a Poughkeepsie market. The installer provided still-taller bollards painted blue to mark-off parking areas reserved for people of limited mobility or in wheelchairs - ADA.

- US CISA, GUIDE TO ACTIVE VEHICLE BARRIER (AVB) SPECIFICATION AND SELECTION RESOURCES [PDF] U.S. Cybersecurity and Infrastructure Security Agency Stop 0380

Department of Homeland Security

245 Murray Lane

Washington, D.C. 20528-0380, Website: https://www.cisa.gov/

Excerpts:

This resource guide is intended to provide information to help engineers, policy makers, security managers, intelligence analysts, and other security professionals successfully determine Active Vehicle Barrier (AVB) specifications and select appropriate AVB models for a particular site requiring restricted access.

The document presents an overview of AVB specification- and selection-related processes. It also provides an accompanying set of helpful resources, tools, and recommended practices gathered from the field to help professionals select AVB models that meet the desired specifications.

AVB specification refers to the determination of selection criteria for an AVB at a specific site. AVB selection refers to the identification of the best technology(s) to meet required specifications, when balanced against cost and additional selection considerations. - WA, Bellingham Gov., WA 804 FIRE HYDRANT BOLLARD SPECIFICATIONS [PDF] City of Bellingham WA, 210 Lottie Street Bellingham, Washington +1 (360) 778-8000 info@cob.org - retrieved 2021/04/20 original source: https://cob.org/wp-content/uploads/WA804.pdf

- Washington CONTRACTOR GUIDE [PDF] Washington State Gas, includes Gas Meter / Regulator Clearance Distances

Excerpt: Vehicle Traffic: Install meters and regulators away from roads, driveways, parking areas or other locations exposed to vehicle traffic or other external forces.

Where not practical to install meters and regulators away from such hazards, guards must be installed to protect the installation. Guards may consist of, but are not limited to, posts, bollards, railings, etc. - Xcel Energy PROTECTING NATURAL GAS METERS [PDF]

Excerpts:

While most of the gas system is underground, some equipment is not, such as gas meters. In instances where gas meters are within five feet of a driving surface, federal code and company standards require the installation of protective devices. This involves the installation of 2-4 inch diameter metal poles filled with concrete.

Referred to as bollards, these reduce the risk of vehicular damage to the gas meter, which could result in an unsafe situation.

... Bollards will be painted with a protective paint that will protect the pole from weather damage. After initial painting, you are welcome to repaint the bollards in whatever color you choose.

Regulations & Codes that Require Protection of Gas Meters & Regulators

U.S. Federal Regulations

192.353 Customer Meters and Regulators: Location.

- (a) Each meter and service regulator, whether inside or outside a building, must be installed in a readily accessible location and be protected from corrosion and other damage, including, if installed outside a building, vehicular damage that may be anticipated. However, the upstream regulator in a series may be buried.

192.355 Customer Meters and Regulators: Protection from Damage

- (b) Service regulator vents and relief vents. Service

regulator vents and relief vents must terminate

outdoors, and the outdoor terminal must:

(3) Be protected from damage caused by submergence in areas where flooding may occur.

Part 192, Subpart P - Gas Distribution Integrity Management, 192.1007(b) & 192.1015(b)(2) Identify Threats:

Among the threats that must be considered by both sections is “Other Outside Force Damage ”.

NFPA 58 (2004) 6.6.1 Installation of Containers, General Requirements:

- 6.6.1.2 LP-Gas containers or systems of which they are a part shall be protected from damage from vehicles.

NFPA 58 (2004) 6.6.6 Installation of Underground and Mounded Containers.

6.6.6.1(C) Protection shall be provided for the fitting housing, housing cover, tank connections, and piping against vehicular damage.

6.6.6.1(D) Where containers are installed underground within 10 ft (3 m) of where vehicular traffic can be expected, protection against vehicular damage shall be provided for the fitting housing, housing cover, tank connections, and piping.

6.8.3.10 Aboveground piping shall be supported and protected against physical damage by vehicles.

6.15.5.3 Vapor meters shall be installed so as to minimize the possibility of physical damage.

- (Kenny 2011)

Example of Regulations for Protection of Gas Meters

Using Main as an example citing Maine Rule Chapter 420 (Natural Gas)

- 5.B.1. Gas meters, aboveground tanks, domes of underground tanks, and distribution system facilities located adjacent to a roadway, street, alley, drieway, easement, or otherwise susceptible to damage from motor vehicles shall be provided protective barries on each side exposed to vehicluar traffic.

- 5.B.2. Gas meters, regulators, and aboveground pipeline facilities located in areas subject to vehicular damage shall be provided adequate barriers on each side exposed to vehicluar traffic.

Operators that have above-ground piping and appurtenances at commercial and industrial facilities shall consider the potential for damage to the gas facilities frome quipment used in the operation and maintenance of that faciltiy and provide adquate protection. - 5.B.2.a. Regulators, meters, and other equipment installed in the piping system shall be protected from the forces anticipated as a result of accumulated snow or falling snow and/or ice.

- (Kenny 2011)

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-03-10 by (mod) - what is the minimum size for a galvanized steel pole bollard?

@Kari, you'll want to check with your local building code official to see what she will approve.

A "standard" bollard used in that location is 4 1/2" in diameter, as this example below sold by Uline.

On 2021-03-10 by Kari

We are going to put up a protective pole/bollard in front of our gas meter since the neighbor's driveway is only 3 - 1/2 feet away. Does anyone know the minimum size required for the galvanized steel pole? We have a 3 inch one that we were hoping we could use.

On 2020-06-14 by (mod)

Parry,

If by "pole" you're referring to what we call "bollards" in the article above, we need to keep the bollard or pole far enough from the gas meter to provide - or at least not to meaningfully-block the standard working distance around the meter.

All of those are detailed at GAS METER CLEARANCE DISTANCES https://inspectapedia.com/plumbing/Gas_Meter_Clearances.php

On 2020-06-12 by Parry

How far does the pole have to be from the gas meter for residential?

On 2020-02-26 (mod) - inadequate protection for gas meter - bollards needed

Gilbert

Gilbert

Model codes as well as your local building inspector will almost certainly require one or more protective bollards installed such that it becomes impossible to drive directly into the meter.

Although I see a pipe pipe cage built around meter it appears to me that that would not be adequate no accepted by any competent building inspector.

See details on the page above.

On 2020-02-26 by Gilbert

My gas meter is located at the side corner of my house, which is also the driveway of my next door neughbor. Recently, i noticed my neighbor park his truck close to my gas meter with the tail pipe facing my meter. What does the laws take on this?

This Q&A were posted originally

at GAS METER CODES & CLEARANCE DISTANCES

On 2018-05-12 by Tim

Could you please provide the proper clearance for installing the bollards to protect a gas meter in Winnipeg. how far apart, how far from the building or meter etc.

On 2017-04-13 by Anonymous - install a barrier to protect the gas meter from being struck by a vehicle

You will need to install a barrier to protect the gas meter from being struck by a vehicle

See details above on this page.

On 2017-04-13 by Mary

We are building a new home and our neighbor's side loading garage ran it's driveway only a few feet from our gas meter. If the driveway is slippery, they would back up into our meter.

What are the regulations for a gas meter and an adjacent driveway with vehicle passage

...

Continue reading at GAS METER CODES & CLEARANCE DISTANCES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BOILER CLEARANCE DISTANCES

- ELECTRIC METER CLEARANCE DISTANCES & WORKING SPACE

- FURNACE CLEARANCE DISTANCES

- GAS METERS

- GAS METER CODES & CLEARANCE DISTANCES

- ELEVATE OIL or GAS BURNER 18" ABOVE GARAGE FLOOR - IRC Requirement

- OIL TANK REPLACEMENT PROCEDURE - required addition of a protective bollard

- OIL TANK SUPPORT

- WATER HEATER SAFETY

Suggested citation for this web page

PROTECTION BOLLARDS for MECHANICAL EQUIPMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to GAS APPLIANCES, PIPING, CONTROLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.