Heating Boiler Clearance Distances

Heating Boiler Clearance Distances

Fire clearances, working space, other offsets

- POST a QUESTION or COMMENT about how to buy, install, maintain, and fix warm air heating boilers, ductwork, and controls

Hot water (hydronic) & steam boiler installation clearances & fire clearances:

What are the required clearance distances around a heating boiler: here we provide a table of recommended working space and fire clearances for oil and gas fired heating boilers.

This article series answers just about any question about hot water or steam heating system troubleshooting, inspection, diagnosis, and repairs in residential buildings and homes. If your heat is by forced warm air use the on page search box for FURNACE CLEARANCES.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

General Clearance Space Requirements at Boilers

In most general terms, and using the model IRC International Residential Code, you are required to provide

In most general terms, and using the model IRC International Residential Code, you are required to provide

- Working space:

at least 30" x 30" of free, level working space in front of a heating boiler - Clearance to combustibles:

and there must be sufficient space to meet clearances fro combustibles that vary depending on the boiler's fuel (oil vs. gas). - Manufacturer's requirements:

the installation must meet other clearance requirements specified in the boiler's installation manual as provided by its manufacturer. Even the most-spartan manufacturer's instructions will include text something like this:

Provide adequate clearance for normal inspection and maintenance purposes and allow proper clearances for combustion air. - source: AJAX BOILER MANUAL [PDF] - Space between boilers & water heater or other:

if more than one heater is installed, the clearance between any component of the boiler and any other heater or heating equipment shall be not less than 36 inches

More of those sources are given at the end of this article.

Photo above: a terrible steam boiler installation that we inspected in Gramercy Park, New York City.

[Click to enlarge any image]

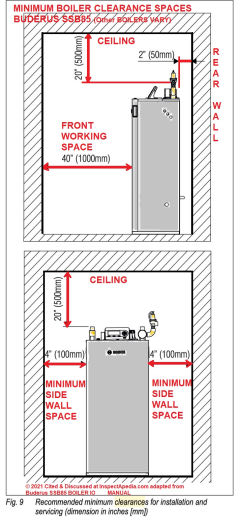

Below: example of minimum boiler clearance spaces and working space, adapted from

the BUDERUS SSB85 BOILER IO MANUAL [PDF] as an example.

Watch out: the specific boiler clearances for your heating boiler will vary; check your manufacturer's IO manual. For example, Buderus specifies 40-inches in front of the boiler - that's more than is specified in the IRC cited below.

Watch out: the specific boiler clearances for your heating boiler will vary; check your manufacturer's IO manual. For example, Buderus specifies 40-inches in front of the boiler - that's more than is specified in the IRC cited below.

All of the model building codes agree that when the manufacturer's specifications are more demanding, those are what shall be followed.

IRC (2012) Chapter 13, General Mechanical System Requirements

Section M1305 Appliance Access

M1305.1 Appliance access for inspection service, repair and replacement.

Appliances shall be accessible for inspection, service, repair and replacement without removing permanent construction, other appliances, or any other piping or ducts not connected to the appliance being inspected, serviced, repaired or replaced.

A level working space at least 30 inches deep and 30 inches wide (762 mm by 762 mm) shall be provided in front of the control side to service an appliance.

Installation of room heaters shall be permitted with at least an 18-inch (457 mm) working space.

A platform shall not be required for room heaters.

Below we excerpt from the New York City boiler code as a model and general boiler clearance spacing guideline, followed by other model and code or manufacturer's requirements citations.

(11.1.4.4). d. Spaces around furnaces and boilers and other heaters.

- A clear working space of at least eighteen inches on the sides and twenty-four inches

on the top

shall be provided around all furnaces and boilers except that boilers, furnaces and other heaters using gas fuel, approved by the board and when installed in private dwellings which do not have a cellar, may be installed in accordance with the approval of the board.

Such separation shall be maintained with respect to walls as well as pumps and other apparatus used in connection with the heating plant. - Combustible material shall be at least six feet away from the front, four feet away from

the top and three feet away from the sides

of furnaces or boilers, including enclosures.

These separations may be reduced one-half when at least one and one-half inches of asbestos insulating material or its equivalent is applied to the furnace or combustible material.

Boilers, furnaces and other heaters using gas fuel, approved by the board shall be installed with clearances from combustible material in accordance with the approval of the board. - Gas-fired window or wall-type vented recessed heaters

approved by the board, including those which have sealed combustion chambers and which are so constructed and installed that all air for combustion is derived from outside of the building and all flue gases are discharged to the outside of the building, shall be installed with the clearances from combustible material in accordance with the approval of the board. - In rooms where fuel oil burning equipment is installed the ceiling shall be insulated

with material or assemblies having a fire resistive rating of at least one hour and extending at least four feet on sides and rear, and eight feet in front of the furnace, except that in private dwellings No. 16 U.S. gage sheet metal may be substituted for one hour fire resistive rating protection.

If the ceiling is constructed throughout so as to have a fire resistive rating of at least one hour the installation may be omitted.

However, the board may adopt rules prescribing fire protective measures and minimum spaces for and around furnaces, boilers or installations of fuel oil burning equipment. Such rules shall be adopted as the board may deem necessary and proper for the safety, protection and welfare of the city and its inhabitants.

If the board shall adopt such rules, the provisions of paragraph one, two and four of this subdivision shall not apply to such furnaces, boilers or installations of fuel oil burning equipment as are included within the purview of such rules.

- Source: NYC Boiler Code cited below

- Connecticut, BOILER DESIGN, CONSTRUCTION, INSTALLATION, REPAIR, USE and OPERATION [PDF] Connecticut Title 29, Public Safet7 & State Police retrieved 2021/06/12 original source https://eregulations.ct.gov/eRegsPortal/Browse/getDocument?guid=%7BE0A4E155-0400-C316-920E-3C716C1B5BB3%7D

Sec. 29-232-46. CLEARANCE

All boilers shall be so located that adequate space will be provided for the proper operation of the boiler and its appurtenances, for the inspection of all surfaces, tubes, water walls, economizers, piping, valves and other equipment and for their necessary maintenance and repair. (Effective August 25, 1987) - New York City, ARTICLE 12. HEATING APPLIANCES, COMBUSTION AND CHIMNEYS [PDF] New York City, NY, retrieved 2021/06/12 original source: https://www1.nyc.gov/assets/buildings/building_code/1938BC_ARTICLE12.pdf

- OSHA, BOILER SAFETY [PDF] OSHA, (2017) - retrieved 2021/06/12 original source: https://www.safetymanualosha.com/boiler-safety/

Excerpt: The area around the boiler should be kept clean of dust and debris, and no flammable materials should be stored near any boiler.

Mechanical Code 1004 Boilers: Section 1004.3 Working Clearance Requirements for Boilers

Clearances shall be maintained around boilers, generators, heaters, tanks and related equipment and appliances so as to permit inspection, servicing, repair, replacement and visibility of all gauges.

Where boilers are installed or replaced, clearance shall be provided to allow access for inspection, maintenance and repair. Passageways around all sides of boilers shall have an unobstructed width of not less than 18 inches (457 mm), unless otherwise approved.

1004.3.1 Top Clearance

Clearances from the tops of boilers to the ceiling or other overhead obstruction shall be in accordance with Table 1004.3.1. [adapted below]

Boiler Top Clearance Distances |

|

| Boiler Type | Clearance from |

| All boilers with manholes on top of the boiler except where a greater clearance is required in this table. |

3 ft |

| All boilers without manholes on top of the boiler except high-pressure steam boilers and where a greater clearance is required in this table. |

2 |

| High-pressure steam boilers with steam generating capacity not exceeding 5,000 pounds per hour. |

3 |

| High-pressure steam boilers with steam generating capacity exceeding 5,000 pounds per hour. |

7 |

| High-pressure steam boilers having heating surface not exceeding 1,000 square feet. |

3 |

| High-pressure steam boilers having heating surface in excess of 1,000 square feet. |

7 |

| High-pressure steam boilers with input not exceeding 5,000,000 Btu/h. |

3 |

| High-pressure steam boilers with input in excess of 5,000,000 Btu/h. |

7 |

| Steam-heating boilers and hot water-heating boilers with input exceeding 5,000,000 Btu/h. |

3 |

| Steam-heating boilers exceeding 5,000 pounds of steam per hour. |

3 |

| Steam-heating boilers and hot water-heating boilers having heating surface exceeding 1,000 square feet. |

3 |

1004.4 Mounting for Boilers

Equipment shall be set or mounted on a level base capable of supporting and distributing the weight contained thereon. Boilers, tanks and equipment shall be secured in accordance with the manufacturer's installation instructions.

1004.5 Floors below Boilers

Boilers shall be mounted on floors of non-combustible construction, unless listed for mounting on combustible flooring.

1004.6 Boiler Rooms and Enclosures

Boiler rooms and enclosures and access thereto shall comply with the International Building Code and Chapter 3 of this code. Boiler rooms shall be equipped with a floor drain or other approved means for disposing of liquid waste.

Notes to the table & boiler clearance code citations above

- Source: CHAPTER 10 BOILERS, WATER HEATES and PRESSURE VEHICLES, Mechanical Code of Maryland (2018) [PDF] - Building codes are available from the various U.S. states and also, we recommend trying https://up.codes/ for access to building codes

These heating boiler clearance requirements are excerpted from Maryland's adoption of the UMC or Uniform Mechanical Code in 2018, the code for Boilers, Water Heaters and Pressure Vehicles. Following this description we include specific detailed clearance requirements for

OIL BOILER CLEARANCE DISTANCES and also for

GAS BOILER CLEARANCE DISTANCES - BUILDING CODE DOWNLOADS

Other Boiler Clearance Guidelines

Below we cite New York Building Code section 4-6.4 as an example of clearance for boilers in a new space not previously used as a boiler room:

Section 4-6.4 - Clearance for boilers installed after march 31, 1965 in a space or room not previously used to house a boiler

(a) Building wall or partition clearance.

The clearance between any component on the side or rear of a boiler and any wall or partition of the building in which it is installed shall be not less than 24 inches where the rated gross capacity is less than 5,000,000 Btu per hour.

Where the rated gross capacity exceeds 5,000,000 Btu per hour, the clearance to any unprotected combustible construction shall be not less than 36 inches.

(b) Clearance from other boilers or equipment.

The clearance between any component of the boiler and any other boiler or equipment shall be not less than 24 inches.

(c) Front operating clearance.

The clearance from the front wall or head or heat generating apparatus of the boiler, whichever is closer to the building wall partition or other equipment, shall be not less than four feet where the rated gross capacity is less than 5,000,000 Btu per hour.

Where the rated gross capacity exceeds 5,000,000 Btu per hour, such clearance shall be not less than six feet.

(d) Working platform-vertical clearance.

When working platforms, required for boilers where the distance from the floor to the top of the boiler or boiler setting exceeds eight feet, are installed on top of a boiler for operating or maintenance purposes, the clearance from the working surface of such platform to the lowest point of any overhead structure shall be not less than seven feet.

Source:

- N.Y. Comp. Codes R. & Regs. Tit. 12 § 4-6.4 https://casetext.com/, retrieved 2021/06/12

- US DOE, OIL FIRED BOILERS, CODE COMPLIANCE BRIEF [PDF] U.S. Department of Energy, Office of Energy Efficiency & Renewable Energy, retrieved 2022/-08/31, original source: https://basc.pnnl.gov/code-compliance/oil-fired-boilers-code-compliance-brief

Excerpts:

The intent of this brief is to provide code-related information about oil-fired boilers to help ensure that the measure will be accepted as being in compliance with the code.

Providing notes for code officials on how to plan reviews and conduct field inspections can help builders or remodelers design installations and prepare construction documents, and provide jurisdictional officials with information for reviews, inspection and acceptance.

Providing the same information to all interested parties (e.g., code officials, builders, designers, etc.) is expected to result in increased compliance and fewer innovations being questioned at the time of plan review and/or field inspection.

... The focus of this brief is on boiler efficiency, sizing requirements, controls, combustion air, and pipe insulation for the 2015 version of the IRC/IECC.

Oil Boiler Clearance Distances

[in process, meanwhile see the clearance distances specified above on this page; reader contributions are invited. Use the page top or bottom CONTACT link or post suggestions as a comment at the bottom of this page]

Oil Fired Boiler Venting

Following is excerpted from the New York City Boiler code cited below.

(11.3.9.6) f. Clearances for Smoke Pipe or Breeching.

1. (a) The minimum distance between any smoke pipe or breeching and any combustible material or construction shall be eighteen inches in the case of low temperature heating devices and thirty-six inches for medium or high temperature heating devices, except that, when such combustible material is protected with at least two inches of asbestos or in some other approved manner, such clearance may be reduced one-half.

(b) The board may adopt rules prescribing fire protective measures and minimum distances between smoke pipes or breechings and any combustible materials or construction.

Such rules shall be adopted as the board may deem necessary and proper for the safety, protection and welfare of the city and its inhabitants. If the board shall adopt such rules, the provisions of item a of paragraph one of this subdivision shall not apply to such furnaces, boilers or installations of fuel oil burning equipment as are included within the purview of such rules.

2. It shall be unlawful to pass any smoke pipe through any floor. (11.3.9.7).

g. Smoke Pipes Passing Through Partitions.

Smoke pipes from low temperature heating devices, passing through combustible partitions, shall be guarded by a double metal ventilating thimble twelve inches larger in diameter than the pipe, or by a metal tube built in brick work or other approved fire resistive materials, at least eight inches thick on all sides of the tube .

- Source: NYC Boiler Code cited below

- New York City, ARTICLE 12. HEATING APPLIANCES, COMBUSTION AND CHIMNEYS [PDF] New York City, NY, retrieved 2021/06/12 original source: https://www1.nyc.gov/assets/buildings/building_code/1938BC_ARTICLE12.pdf

- CLEARANCE DISTANCES for BUILDING SYSTEMS & FEATURES - provides articles describing fire and safety clearances for all types of chimneys and flue vent connectors

- See details at

FLUE VENT CONNECTOR FIRE CLEARANCE: OIL FIRED EQUIPMENT

Gas Boiler Clearance Distances

There are several gas or oil fired heating boiler clearance distance types:

- Clearance from combustibles - ranging from 0" to 18" to 36" (typically) depending on the fuel type (electric, gas, oil).

- Working space or clearance distances - that may allow 0 on 1-3 sides but always requires working space at least at the front, or at front + rear if access to a blower or filter are at the unit rear side.

Typically for gas boilers there must be a minimum of 24" front accessibility to the boiler, and any access door or panel must have enough clearance space to permit removal of the largest component in the equipment. - Direct vent terminal clearance distances: distance from the exhaust vent at the exterior wall to building features such as gas meter outlet, windows, doors, balconies, building corners, clearance over a driveway or paved sidewalk.

These range from 0" to 7 ft. - this set of distances is surely not what your maintenance guys were discussing regarding your clothes dryer. Details are

at GAS APPLIANCE / HEATER DIRECT VENT CLEARANCES - Flue vent connector clearance distances: distance from the flue vent connector of "flue pipe" to combustibles

see FLUE VENT CONNECTOR FIRE CLEARANCE: GAS FIRED EQUIPMENT

- Chimney clearances: for heaters vented into a metal or masonry chimney, clearance distances around the chimney and chimney top including chimney top to roof.

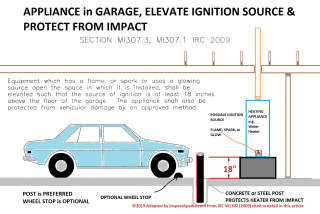

- Location related clearances: for heaters installed in a garage or in another location subject to hazards of gas accumulation at floor level or subject to impact by a vehicle, protection and elevation above the floor are required.

Typical Minimum Clearance Distances for Gas Boilers |

||

| Clearance Topic | Clearance Distance | Comment / Reference |

| General boiler clearances & working space | ||

| Must meet all manufacturer's clearance specifications | Various | See I&O Manual for the specific brand & model heater |

| Must meet all local & national building, fire, electrical, fuel-gas codes | Check with local code officials | |

| Service / working space - front | 24" | Notes 1, 2 |

| Service / working space - other sides, panels | Note 2 | |

| Combustion air openings & nearest closed panel or door | 3" | Note 3, do not block air flow into combustion air intake |

| Combustion air & ventilation openings | not blocked by anything, including snow | |

| Space for addition of cooling coil | Note 4 | |

| Attic installations | Notes 6, 7, service access to front, limited framing contact, may be suspended | |

| Burner & ignition above garage floor | 18" | Note 5 |

| Crawl space installations | Note 8 | |

...

| Clearance Topic | Clearance Distance | Comment / Reference |

| Gas Boiler Clearance to combustibles, model dependent | ||

| Sides to combustible surface | 0 - 1" | Note 1 |

| Front to combustible surface | 3 - 18" | Note 1 |

| Top to combustible surface | 1" | Note 1 |

| Flue, condensing boiler, plastic vent | 0" | Notes 1, 10. |

| Flue through masonry chimney w/ other appliances, stainless steel type 29-4C | Note 11 | |

| Condensate drain elevation | 4-6" | Note 9 |

| Attic installation of horizontal unit | Note 7 | |

Notes & References for the table above:

1. AMERICAN STANDARD GAS FURNACE INSTALLATION MANUAL [PDF] (2008), American Standard Heating & Air Conditioning, A341624P07, Upflow / Horizontal gas furnaces, Downflow / Horizontal gas furnaces, Models CUX1B040A9241A CUX1B060A9361A CUX1B080A9421A CUX1C100A9481A CUX1D100A9601A CUX1D120A9601A CDX1B040A9241A CDX1B060A9361A CDX1B080A9421A CDX1C100A9481A CDX1D120A9601A Pub. No. 41-5016-07

2. Any access door or panel must permit removal of the largest component in the heater at that location

3. Combustion air requirements: see COMBUSTION AIR DEFECTS

5. Garage installations: Boilers installed in a garage must place burners & ignition source no less than 18" above the floor & boiler must be protected from physical damage from vehicles

See details at PROTECTION BOLLARDS for MECHANICAL EQUIPMENT

6. Attic installations: uncommon for heating boilers

8. Crawl space installations: uncommon; in a crawl space on a pad or other noncombustible material which will raise the unit for sufficient protection from moisture.

9. Condensate drain elevation space: a condensing boiler in a crawl space must also be elevated approximately 4-6 inches to allow clearance for the condensate drain to exit the cabinet

10. Condensing boiler venting: American Gas Association has certified the design of condensing boilers for a minimum of 0" clearance from combustible materials with a single wall plastic vent pipe.

See DIRECT VENTS / SIDE WALL VENTS for a complete table of recommended clearance distances from a direct vent gas appliance terminal to other building components or features.

See also CONDENSING BOILERS/FURNACES

11. Masonry flue or shared flue venting: Where the system is routed to the outdoors through an existing masonry chimney containing flue products from another gas appliance, or where required by local codes, then 3" venting of Type 29-4C stainless

steel must be used in place of PVC material.

Elevate Heating Boiler Ignition Source & Protect Boiler from Impact

Appliances having an ignition source shall be elevated such that the source of ignition is not less than 18 inches (457 mm) above the floor in garages.

For the purpose of this section, rooms or spaces that are not part of the living space of a dwelling unit and that communicate with a private garage through openings shall be considered to be part of the garage.

See details at ELEVATE OIL or GAS BURNER 18" ABOVE GARAGE FLOOR - IRC Requirement

Also,

Appliances shall not be installed in a location subject to vehicle damage except where protected by approved barriers.

See details at PROTECTION BOLLARDS for MECHANICAL EQUIPMENT

Original source of the text and illustration above:

- Stevens WA, COMMONLY USED RESIDENTIAL BUILDING CODES, IRC 2009, [PDF] retrieved 2019/05/08 original source: co.stevens.wa.us/landservices/documents/MECHANICALSECTION.pdf

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: is an un-stable heavy object next to the heating boiler OK?

Can you spot the elephant in this room?

Can you spot the elephant in this room?

Why hasn't anyone noticed the large cast iron stove, tipped off of its stand and leaning towards a working furnace!

How did it get there, or was the furnace installed with it already there?

I don't think they got a permit for that arrangement. What could an inspector say about this?

Are clearance issues often met up with in your line of work? - Anonymous by private email 2021/06/11

Moderator reply: safety hazards of stuff stored too close to heating equipment

The cast iron stove (black arrow in photo) looks to me like a cook stove in the basement of what may indeed be a pre-1900 building (stone foundation).

Atop the stove bottom we see the back of the cookstove (orange arrow) and in the photo it appears that the stove, with some apparatus piled on top of it, may be leaning towards the boiler - an unsafe condition as I'll discuss in a moment.

As to how that stove got there, in some older homes cooking was done in a basement kitchen, but without a bit of information about the building in this photo: its age, country, city, history, construction, I can't say how this cookstove was used. It looks like a wood-burner but could have been a coal burner. In any event, it's an antique.

It would be no surprise to find an antique cookstove stored in a basement, left there by someone who valued it but had no place to display it.

There are two topics to discuss:

- Intrusions into working space around the newer Weil McLain heating boiler pointed-to by the green arrow; (looks like a gas unit but again I can't see much); besides needing working space to maintain heating equipment, some obstructions can block air flow or even form a fire hazard. (I doubt the antique stove is doing either).

- Damage hazards for the heating boiler should the stove tip over and impact the heater.

As you'll read above on this page, working space is needed in front of heating equipment - at last 30".

In addition tipping-over heavy objects near enough to the boiler that it could be struck by falling piles of stored items is dangerous. The risks include

- Damage a safety control such as a temperature-pressure relief valve, risking a potential BLEVE explosion (search InspectSpedia.com for that term to read details)

- Break a pipe, causing a basement flood, water damage, mold contamination, and in winter, loss of heat, freeze damage, other losses

- Cause a fire if combustibles fall into contact with hot surfaces such as the flue vent connector

- Produce fatal carbon monoxide gas if obstructions block combustion air flow into a gas fired appliance or if its flue vent connector should be knocked off. (I see no signs of that in your photo)

Code inspectors and professional building inspectors, home inspectors, service technicians and others find obstructions like those shown in your photo all too often.

One would expect any of them to either move items to perform their work safely or to ask the building owner to move items both to permit working space and to keep the system free from potentially unsafe obstructions and stored materials.

Do accidents ever happen because of stuff stored precariously close to heating equipment? Of course. Your question must be rhetorical.

All of the gas boiler combustion products were venting into the home ...

Working as a home inspector decades ago I often went early to my inspection site in order to become familiar with it before my attention had to be divided between the building and the client.

At a New York inspection I arrived even earlier than usual.

I'd been told that the owners would be at home, and indeed an automobile was in the driveway.

I rang the doorbell to let the owners know I was on-site. Nobody came to the door.

"They may still be asleep," I guessed.

I walked around the exterior of the home in the cold winter air, noticing the usual topics of surface runoff, siding, windows, roof, chimney.... Chimney?

I paused at the home's right side, considering what I could see: it was cold and surely their heater must be running.

But there was no evidence of warm flue gases exiting the chimney.

There in front of me was a low window in the foundation, giving view of the basement. I could see a gas fired heating boiler through the window. And though my hearing was never the sharpest, I thought I heard it running.

I bent over for a closer-look.

"Oh my god" The gas boiler was running full-tilt, but something had fallen against the boiler's flue-vent connector, knocking it apart. The boiler was venting all of its combustion gases right into the basement, and of course those gases would pass upstairs!

All of the gas boiler combustion products were venting into the home, and had been for who-knew how long!

In a panic that the family might be dead or dying from carbon monoxide poisoning, (that would explain why no one answered the doorbell), I ran to the front door, rang the bell repeatedly and pounded loudly on the door while shouting.

I don't remember what I shouted.

I remember being really afraid.

Considering that people in the house were surely dead or dying I had no choice but to enter immediately, however I could.

I kicked in a living room window, leapt through, and ran, heart pounding, to each of the bedrooms ...

No one. There wasn't a soul in the home.

Having turned off the heater and opened windows and doors to air-out the flue gas-filled home, as I was opening the last window my inspection clients pulled into the driveway.

My client, Fred, looked at the smashed window and turned to me with the strangest expression mixing curiosity, wonder, and a little fear.

"I kicked in a window to save the occupants from carbon monoxide," I explained " but no one is at home." I showed my client the disconnected flue vent - which, incidentally, was trivial to repair. The chimney itself was not blocked.

We restored the flue vent connector, turned on the heat, checked the boiler's operation, completed the inspection, and before leaving I wrote a note of apology to the homeowner for kicking in their window. I'd pay for the repair.

I figured the owners would be furious.

They weren't. Instead, the owner called me to express his thanks.

"We were not at home," he agreed, "but we might have been."

...

Continue reading at HEATING BOILER INSPECTION GUIDE, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BOILER CLEARANCE DISTANCES

- BOILERS, HEATING - home

- CLEARANCE DISTANCE, HVAC

- CLEARANCE DISTANCES for BUILDING SYSTEMS & FEATURES - home

- ELEVATE OIL or GAS BURNER 18" ABOVE GARAGE FLOOR - IRC Requirement

- FIRE CLEARANCES INDOORS

- FURNACE CLEARANCE DISTANCES

- GAS APPLIANCE / HEATER DIRECT VENT CLEARANCES

- OIL TANK CLEARANCE DISTANCES & LOCATIONS

- PROTECTION BOLLARDS for MECHANICAL EQUIPMENT

Suggested citation for this web page

BOILER CLEARANCE DISTANCES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.