Fiber Cement Siding Defects

Fiber Cement Siding Defects

How to troubleshoot fiber cement siding problems: peeling, breaks, loose, buckled, gaps, butt joint openings, caulking issues, paint failures

- POST a QUESTION or COMMENT about installing fiber cement siding troubleshooting, defect causes, remedies, warranties, warranty claims

Fiber cement siding defects, failures, problem troubleshooting:

This article describes the types of problems that occur in fiber cement siding installations in North America, including siding shrinkage gaps at butt joints, cracks, breaks, and loose or buckling siding boards or shakes.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Fiber Cement Lap Siding Board Installation SNAFUs

Article Series Contents

Article Series Contents

- SIDING, FIBER CEMENT SHINGLE DEFECT DIAGNOSIS

- BUCKLING FIBER CEMENT SIDING

- BUTT JOINT CURLING in FIBER CEMENT SIDING

- BUTT JOINT GAPS & FIBER CEMENT SIDING SHRINKAGE

- BUTT JOINT BACK FLASHING OMITTED

- CAULKING ERRORS on FIBER CEMENT SIDING

- FIBER CEMENT SIDING NAILING ERRORS

- HOUSEWRAP DAMAGE

- HOMEOWNER COMMENTS on FIBER CEMENT SIDING

- LOOSE FIBER CEMENT SIDING, NAILING FAILURES

- PRIME COAT on END CUTS of FIBER CEMENT SIDING

- SIDING CLEARANCE TO GROUND

- SIDING FIBER CEMENT COEFFICIENTS of EXPANSION

- SIDING, FIBER CEMENT GAP & CAULK SPECS

- SIDING, FIBER CEMENT GAPS

- SIDING, FIBER CEMENT GAP CURE

- SIDING, FIBER CEMENT IDENTIFICATION

- SIDING, FIBER CEMENT NAILING DEFECTS

- SPLITS in FIBER CEMENT SIDING

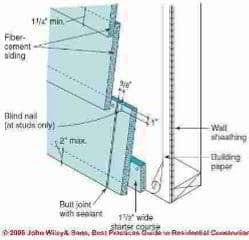

- STARTER STRIP for FIBER CEMENT SIDING

- MOISTURE ABSORPTION into FIBER CEMENT SIDING

- SIDING, FIBER CEMENT MOISTURE LEVELS

- TEMPERATURE EFFECTS on FIBER CEMENT SIDING

Fiber Cement Siding Butt Joint Gaps Mean Extra Leaks in the Exterior Wall

Gaps at butt joints in fiber cement siding as well as questions about where caulk should and should not be applied are discussed separately

As you can see in our fiber cement lap siding butt joint gap photo at left, the gap is unattractive; in this installation we see the housewrap in the siding gap opening - telling us that there was no back-flashing and that wind-blown rain will certainly pass behind the siding at rates above usual - possibly leading to leaks into the building walls.

Other fiber cement installation & maintenance problems are described in the remainder of this article. .

But whose fiber cement siding is this?

Installed in 2003 the siding has been "repaired" (caulked butt joints) at least once, with gaps continuing to open, leading to a very unhappy homeowner.

Our second siding gap photo (below left) tells more about the history of this fiber cement siding installation.

Counterfeit "brand name" Fiber Cement Siding?

The combination of an open lap siding butt joint and torn caulk in the same opening tells us that someone tried caulking the butt joint gaps, probably shortly after the fiber cement siding was installed.

Continued fibre cement siding shrinkage tore the caulk and increased the butt joint gap significantly.

Some manufacturer's instructions make clear that caulking of the butt joint in pre-finished textured lap siding is not recommended - most likely because the result is a still more ugly cosmetic defect.

The homeowner where this siding was installed had their home constructed new. The owners thought they were contracting for HardiPlank® siding. On investigation James Hardie's rep informed the homeowner, their attorney, and their special invetigator (not us) that the product was not from James Hardie. There was a suggestion that the product was from CertainTeed.

With assistance from the repair contractor, Galow Homes, [19] we visited the site both at initial siding assessment (2012) and during siding removal and exploration (2013), to collect fiber cement siding samples for further investigation. No one seemed to know whose fiber cement siding was installed. We confirmed that the siding was not made by James Hardie nor by Certainteed.

- At SIDING, FIBER CEMENT IDENTIFICATION we show that this is almost certainly not a CertainTeed produce either.

Fiber Cement Siding Installed When "Too Wet" - Shrinkage Gaps

A chief cause of excessive fiber cement lap siding shrinkage in new installations is the installation of siding while it is too wet. Manufacturer's instructions generally say that the contractor should not install wet siding.

Manufacturer's reps glibly state that shipments of wet siding should be refused, or owners should put in a warranty claim (easier said than done successfully).

Our photo shows water inside the plastic wrap on a bundle of new fiber cement siding. But just how wet is "too wet" and how the siding contractor is supposed to decide that the material is too wet to install is left a mystery.

- Details are at SIDING, FIBER CEMENT MOISTURE LEVELS

and a case study of butt joint shrinkage gaps traced to probably too-wet siding at time of installation is described

at SIDING, FIBER CEMENT GAPS.

Missing Caulk of Fiber Cement Siding at Vertical Trim Joints

In any event, the installation troubles documented here are largely attributable to failure to follow fiber cement board lap siding installation specifications from either of the major U.S. manufacturers.

At left we illustrate another failure to follow the manufacturer's installation instructions. The siding is not caulked at its abutment to vertical trim.

JamesHardie's installation guide recommends caulking at the abutment of HardiePlank siding boards to vertical trim boards.

CertainTeed's installation guide has the same recommendation and is an extensive document with plenty of advice for the installing contractor and homeowner.

Generally the manufacturers do not recommend caulking at factory-painted fiber cement siding butt joints, presumably because it creates a cosmetic defect; some instructions permit caulking at primed (and smooth) siding, presumably because the caulk "cosmetic defect" will be hidden by the finish paint job.

- At CERTAINTEED WeatherBoards™ we discuss how to identify Certainteed fiber cement products.

At left we illustrate another failure to follow the manufacturer's installation instructions. JamesHardie's installation guide recommends installation of weather flashing behind the horizontal lap siding board butt joints and requires it in some products - it was omitted completely in this installation.

Similar advice is found in the CertainTeed lap siding installation guide.

Improper or Inadequate Nailing of Fiber Cement Siding - Loose Siding

And of course the fact that I can lift the board away from the wall suggests inadequate nailing as well.

And of course the fact that I can lift the board away from the wall suggests inadequate nailing as well..

Unfortunately more nailing defects were apparent at the gable ends of the home where the lap siding abutted (or was supposed to abut) the gable end trim.

Left un-nailed the corners of most of these siding boards were curling away from the building. .

Consistent with our earlier warning that one bad installation feature suggests more SNAFUs are in store, even in a casual inspection we noticed other disappointing details on this home that was less than ten years old:

- Rotted trim at windows and doors

- Openings left un-sealed where mechanicals penetrated the building walls

- Clogged non-functional weep holes in brick veneers

- Improperly-constructed masonry patio and steps abutting wood siding and trim, settling, trip hazards, rot

Exposed Nails in Fiber Cement Siding

This discussion moved to SIDING, FIBER CEMENT NAILING DEFECTS

Buckled or Warped Fiber Cement Siding

In our OPINION fiber cement siding is not likely to actually "warp", as it's a cementious product; but indeed if the product is not properly installed, including end gaps at vertical trim abutments and proper nailing using the specified fasteners, at the specified intervals, and nailed into sound sheathing of adequate thickness or into wall studs, then expansion due to moisture uptake and/or thermal changes may result in buckling of the material, particularly on sun-exposed walls.

My finger is pointing to an area of buckled fiber cement siding above a garage door; we think that the buckling occurred because of failure to provide the required clearance gap at the abutment of siding ends to vertical trim, but feeble nailing may also have been a factor.

Missing Head Flashing at Windows & Doors Leads to Window & Trim Rot

The omission of head flashing over windows & doors invites leaks behind the siding, rotted window & door trim, and a need for early exterior window & trim repairs or replacement.

The home in our photo was about ten years old. We found rotted trim on all sides of the structure.

- Details about proper window flashing are

at WINDOW FLASHING & SEALING Guide - Details about door flashing are

at DOOR FLASHING DETAILS

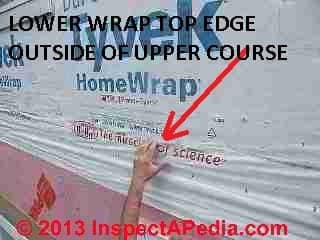

Improperly-Installed HouseWrap Means Wall Leaks Behind Fiber Cement or Most Other Siding Products

When the siding was removed from the building in our photos we saw that the installers had installed the building house wrap improperly.

The top edge of lower sections of housewrap were lapped over rather than under upper housewrap sections.

This means that any water leaking behind the siding will find its way behind the housewrap, increasing chances of water entering the building wall cavity itself.

Water inside a building wall cavity means wet insulation, higher heating and cooling bills, mold contamination risks, and risk of wood structure attack by carpenter ants, termites, and wood-rotting fungi.

Details about the requirements for house wrap, product choices, and installation details are found

at HOUSEWRAP / SHEATHING WRAP and related articles provided there.

J-Channel Installation Defects with Fiber Cement Siding

Home Inspector Comment: Builders using vinyl-siding J-Channels with Fiber Cement Siding?

Builders are using J-channel windows, and other fittings and accessories originally designed for use with vinyl siding, but now with fiber-cement siding. In other words, they are using details that intentionally let water getting behind the siding, but not in a planned rain screen assembly.

Jame Hardie actually has a tech bulletin for this (attached, see p. 123), but I've literally never seen a builder use it (and when we contact Hardie about it they always side with the builders and claim that their recommendations are best practice but not required).

Builders claim that the WRB and tape window flashing suffice, but it makes no sense to me to dump water behind the siding.

The practice apparently does not violate any code provisions, window manufacturers have nothing to say about it, some fiber-cement manufacturers (other than Hardie) ignore it, others seem to address it in installation instructions but not to the extent that Hardie does.

Do you have any opinions or ideas about this, and/or do you know a building envelope consultant who might be interested?

I am thinking of proposing an article on this to JLC, but know it would need expertise of a building envelope specialist to carry any weight. - Anonymous pending agreement, the writer is a professional home inspector working in the South Eastern U.S. by email 2016/06/12

- James Hardie Fiber Cement Siding Best Practices, Appendix A, (2014) [PDF] available from James Hardie Corporation, 231 S. LaSalle St., Suite 2000

Reply: OPINION

The detail you mention and the manufacturers' bulletin combined with actual practices combined with manufacturer's defending builders (who they correctly see as their actual customer) is an important detail and might be a contributor to some of the buckled or other fibre cement sided home complaints that keep cropping up.

OPINION: Few builders were English majors and fewer are inclined to read the manufacturer's installation details, less to follow them. There are quite a few products & systems (e.g. EIFS) for which the manufacturer writes an installation specification that enables them to defend against product complaints by finding that the product is almost never in total compliance with the specs.

A good design is for what people will do in construction, not what they should do. The fiber cement complaints, while probably doing less total building harm than the EIFS issue, have some similar features.

A builder might think that by using housewrap and flashing tape around openings, the abutment to trim or windows and doors is not a critical joint.

But a read of the requirement to keep the FC siding dry until installed offers a clue. After all, this is an exterior cladding.

Why can't fiber cement siding get wet?

Perhaps because the back-coating is not so water-resistant as the exposed face of the siding. In turn that means that water running down the sheathing against the siding back is likely to contribute to water absorption. If the siding went on really dry (as it ought but often does not) I might expect some buckling problems to ensue.

I wouldn't go so far as to say the builder is "intentionally" letting water behind the siding but rather that they're ignoring both the practices guide and the problems that may ensue.

The Hardie practices you sent, on discussing use of J-channels, focuses on directing water out from behind siding at the bottom of the vertical J's but omits a top J-channel detail that can send enormous amounts of water running down the exterior wall above a window or door into the space behind the vertical J-channel.

Specifically, the installer has to cut the top long, then trim its J-channel face, leaving 1" or more tabs of the J-channel bottom that are bent down over the *outside* of the vertical J-channel's interior "U". This detail keeps water collected by that top horizontal "gutter" from being sent into the wall behind the siding regardless of whether the siding is vinyl, aluminum or FC.

- Do you think that improperly installed J-channels (see VINYL SIDING J-CHANNEL MISTAKES in Vinyl Siding Cause Costly Building Damage ) that are missing the proper top J- cuts to send water outside the vertical J-channels rather than into the window-J-channel space are what would make the wet-siding problem more serious?

- Or do you think that the builder should omit J-channels entirely and caulk against horizontal and vertical trim?

- Do you think that water behind the FC siding is a concern for reasons other than buckling? E.g. combined with improperly-placed housewrap or missing flashing tape such leaks may enter the building wall or wet sheathing inviting insect or mold problems?

I'm neutral on Hardie's Optional rain screen suggestion for residential properties. I don't think that the problem is lack of ability of water to drain out of the siding - it's usually not painted in the field so the bottom edges of boards aren't sealed against one another by paint - a detail can trap water behind painted clapboard-sheathed walls.

I think that if housewrap and flashing tape are properly done we may still keep water out of the wall cavity itself. In that case it's the issue of wetting the siding back that's probably going to contribute to cosmetic complaints of buckling and bending. (There's a whole separate set of gripes about shrinkage of wet siding).

I note, however that Hardie says that while a rain screen is optional, they state up front in bold:

Note: James Hardie has a capillary break requirement when installing HardiePanel on a Multi-Family/ Commercial project. Please visit JamesHardieCommercial.com for further information. - Hardie FC Siding Best Practices cited above.

I've not personally seen a home with FC siding that used a furring applied siding mounting system over a rain screen.

Now you've gone and added another water intrusion point that I will have to add. Thanks; by this posting we'll welcome comments, information, field reports from other interested parties. Readers please use the page bottom COMMENTS BOX or find our email at page top or bottom CONTACT - Ed.

Paint Failures on Fiber Cement Siding

The peeling top coat on the siding shown above (Rhinebeck, NY) shows a white primer remaining in place on the fiber cement siding. The siding paint damage was largely due to excessive wetting from rain-splash.

- Details are at FIBER CEMENT SIDING PAINTS

Mechanical Damage to Fiber Cement Siding

The mechanical damage to fiber cement siding shown below is obviously from impact and is not a product defect. Just about any building siding material can be damaged by external events, though some products such as fiber cement siding, and asbestos cement shingle siding are more vulnerable to breakage compared with vinyl siding (which can still be punctured or broken under some conditions) or aluminum siding (which dents and which can still be punctured under certain conditions).

The repair for the damage shown above on a building in Rhinebeck, NY, requires that the damaged boards be removed and replaced.

Failure to repair punctures such as those we show means increased risk of wind-blown rain leakage into the wall structure.

Defects Discovered During Removal of Fiber Cement Siding

Discovery of More Original Siding Job Installation Errors

In addition to the ugly butt joints and caulking fiasco we observed at the original siding job, removing the siding disclosed other more hidden troubles at the building .

In fact, the progoma; siding had so many installation errors, missing flashing, crooked, trim rot around windows and doors, building leaks, that a patch job was in our opinion and that of the owner and contractor, likely to lead to a lifetime of aggravation for the building owners.

Our photos below illustrate what we found when taking a closer look at this installation: leaks at window tops and rotted trim everywhere on the building. This was a ten-year-old home.

My definition of non-destructive rot-inspection is if I can push my finger into the wood trim, it was already severely rotted - I didn't cause damage to the building. (Photo below).

At below left we can see why conventional brick mold window trim will be rotted on a fairly new house: the omission of head flashing over windows and doors combines with the soft common pine finger-jointed brick mold to rot and leak. And as you can see from my finger-poked rot hole above and at left, water would also have been entering the wall behind the siding.

In our photograph at above right you can see that the original siding installers (that was not by Galow Homes), the fellows were not quite sure about the truism that "water runs down hill" - the building house wrap was installed "upside down" with lower segments lapped outside or on top of upper segments, guaranteeing that any leaks past the siding itself would find a ready path behind the protective housewrap barrier and into the building walls.

The miracle of modern housewrap materials is not so wonderful if the product is not properly installed. In the photo below the contractor is demonstrating "backwards" installed housewrap that would readily admit water behind the wrap itself.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-08-14 by (mod) - how to fix & prevent wavy HardieBoard Siding

Remove the buckled fiberboard siding, check how it was nailed, check the clearances allowed at the ends of the boards at vertical trim, and if board is badly cupped you may need to replace it.

Remove the buckled fiberboard siding, check how it was nailed, check the clearances allowed at the ends of the boards at vertical trim, and if board is badly cupped you may need to replace it.

Watch out: when re-installing new or relaxed clapboard siding, including fiber cement siding like your James HardieBoard, be sure to leave 1/8" clearance at board ends to handle thermal and moisture expansion.

On 2020-08-12 by Jim

Wavy hardie board. How do you fix?

On 2020-06-02 - by (mod) -

Patricia

I'd like to see some sharp closeup photos of the damage (you can post one photo per comment). Also you'll want to know just what type of nail was used and how they were driven (power nailer, hammer, set in or driven flush &c.)

On 2020-06-02 by Anonymous

The house is located in Greeneville, Tennessee. The cracked siding doesn't appear to be specific to any side or part of the house. I will send pictures ASAP.

On 2020-06-02 by Patricia Cascone

My house was built six years ago with hardie board siding and trim. The trim is starting to crack at the nail sites and it is also pulling away from the siding. What might cause this problem? How can it be fixed?

On 2020-01-03 - by (mod) -

Richard

I'd like to see photos of the cracked Hardiboard and to know the country and city of installation;

Sometimes we see thermal or moisture-related movement in siding that might stress boards and could explain both buckling and cracking, especially if the siding was tightly-butted against vertical trim such as at windows or doors; it'd be diagnostic to see which boards are cracked, the location of the cracks, differences on different sides of the building (sun, weather exposure differences etc.)

On 2020-01-02 by Richard Howard

One of customers has brought to my attention that his Hardiboard is cracking, it was installed by the home owner about 5 yrs. Ago any suggestions on cause?

On 2018-12-25 by (mod) -

Evan

Please see your question and my reply, now at

SIDING, FIBER CEMENT NAILING DEFECTS https://inspectapedia.com/exterior/Fiber-Cement-Siding-Nailing-Defects.php

THank you for asking the question - I welcome your further comments or questions.

On 2018-12-25 by Evan

I've had Hardi Board and Batten installed for less than one year. Damage, peeling and discoloration has occurred around many nails. Please see photos.

IMAGE LOST by older version of Comments code - now fixed. Please re-post the image if you can. Sorry. Mod.

On 2018-07-18 by (mod) -

WTPA:

Regarding the diagnosis of dark stains that appear to be coming through the paint on your fiber cement sided home, attacking, removing, or preventing stains will benefit from a better guess at their origin and nature.

I looked at your photos, and though information is very limited as they're distant and not sharp, I can see a pattern of dark areas that are clearly not due to rain splash-up: they are much too high on the siding and they are not in the splash-up pattern.

At SIDING DAMAGE by SPLASHBACK https://inspectapedia.com/BestPractices/Siding_Splashback_Damage.php

you'll see the characteristic regular horizontal line marking the top of rain-splash-up effects on the lower portion of building walls, in a regular pattern consistent with the location of the eaves of the spilling-roof line above.

From the pattern one must suspect some other "stain" cause. Without a closer look on-site by someone experienced with paint failures and building staining, I'm sorry to say my diagnosis cannot be more than speculation.

Mold growth in or under a paint coating is a possible cause: it would be diagnostic to know if the siding was ever painted on-site.

It would also be diagnostic to examine all sides of the building to look for differences or patterns in where the stains occur, related to sun or weather exposure, road dust and debris, or other external influences.

To post a photo at any InspectApedia page, simply begin a comment in the comment box, then click the "add image" button, and select the image file from its location on your computer; or if from your smartphone you are viewing InspectApedia.com pages such as SIDING, FIBER CEMENT DEFECTS (where I'll re-post one of your photos to permit helpful comments from other readers) you can also post a photo from your smart phone either from its image library or, as you'll see, there's an option to take a new photo during the posting process.

At STAIN DIAGNOSIS on BUILDING EXTERIORS https://inspectapedia.com/exterior/Stains_on_Exteriors.php you'll find a catalog of stains and their common causes - that article is worth a look.

At CONSULTANTS & EXPERTS DIRECTORIES https://inspectapedia.com/Expert-Consultants-Directory.php you might find a home inspector or paint failures expert who can help you diagnose your home's particular condition.

Let us know what you're told and post some sharper photos if you can and we may be able to offer other comments.

IMAGE LOST by older version of Comments code - now fixed. Please re-post the image if you can. Sorry. Mod.

On 2018-07-16 by wtpa@WCC.NET

Sent an email with pictures regarding issue below

On 2018-07-16 by wtpa@WCC.NET

We had Fiber Cement Siding installed on our home in 2013. It is beautiful and has none of the problems described above.

Except for one unusual problem. We have a metal roof on the second story and a metal roof that surrounds an 8' veranda porch. The siding on the second floor appears over the years to have been effected by rain dripping off the roof or back-splashing onto the siding that has caused gray streaks in wide areas of the siding.

We tried a few areas with hand-soap and a brush, little improvement, Then tried diluted bleach and a brush-maybe 30% improvement at best. The "graying" of the paint on the siding is now noticeable from the road. If you are able to expand the pictures, you can see the gray areas. Please help with any ideas you may have, Thank you, Joe Jeffers San Angelo, Texas

On 2017-06-02 by (mod) -

Bill,

I'm not clear what sort of siding you have installed: shingles or boards, nor if the concern is just for painting vs a possible asbestos concern if the siding were to be power-washed or cut/sawn etc.

In my experience if we can remove loose paint and then use a primer/sealer that is recommended by the paint supplier as compatible with the top coat of paint, that will give the best results. Of course the surface has to be both clean and dry. The fiber cement shingle siding that I've painted held that paint very well.

I'd also look at the source of water damage: fixing gutters, for example.

On 2017-06-02 by Bill Raboin

The paint on our cement board siding is peeling in a few places where there is water splashing or running down. We tried repainting once and it peeled again in a year. We would like to avoid replacing all of the siding on the house as our contractor suggests as the product is no longer available and the siding is attractive except where peeling.

We've had gutters installed to reduce or eliminate the water issue. Is there a product we could use as a base coat that would allow repainting of the areas and prevent peeling again? Thanks for your help.

On 2016-07-10 by (mod) -

Frank:

Fiber cement siding won't "rot" but it will be water damaged, and worse, besides risking rot in the wall structure behind the siding, you are continuing to issue a platinum-engraved invitation to termites and carpenter ants to invade the building structure.

On 2016-07-09 by Frank

I just moved into a new house and the previous owners built some planter beds right up against the house. The soil and decorative stone came up about 3inches onto the wood siding causing the wood siding to rot.

I want to replace the siding with fiber cement siding, but I'm curious to know if I replace the soil and decorative stone to the same hight as it was before, will the fiber cement siding also eventually rot as well?

I look foreword to hearing back from you.

Thanks,

On 2016-04-09 by (mod) -

Anon;

Please use the page bottom CONTACT link to send me some sharp photos and I'll ask some diagnostic questions and offer some opinions.

I would not just nail down buckled siding; let's first understand what's going on. I would also not jump to tear it off.

When was the siding installed?

What is the brand & product ID.

Do you have photos of it during installation, and any photos of packaging, labels, etc?

Also I'd like to see closeups of the points of abutment to vertical trim near where buckling is occurring, photos of the buckled siding looking up below the edge board, and in-situ photos of the building from a more distant view.

On 2016-04-09 by Anonymous

I have a new house with fiber cement siding on it. The siding has already started to buckle at the abutment of siding ends and some of the siding is loose and can be pulled away from the house.The builder wants to nail the siding where it it buckling and loose. I feel that this will not solve the problem the result of bad installation.

I feel that the siding must be torn down and resided.Please comment.

Frank burke

...

Continue reading at SIDING, FIBER CEMENT DEFECT DIAGNOSTIC QUESTIONS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS & FIBER CEMENT ROOFING - home

- ASBESTOS ROOFING / SIDING DUST

- CERTAINTEED WeatherBoards™

- CHINESE FIBER CEMENT SIDING

- FIBER CEMENT PRODUCT STANDARDS

- FIBER CEMENT ROOF SHINGLE ASBESTOS TEST RESULTS

- FIBER CEMENT SIDING - home

- FIBER CEMENT SIDING DEFECTS - home

- FIBER CEMENT SHINGLE DEFECT DIAGNOSIS

- FIBER CEMENT SHINGLE CUTTING TOOLS

- FIBER CEMENT SHINGLE REPAIRS

- FIBER CEMENT SIDING BUCKLING

- FIBER CEMENT SIDING BUTT JOINT CURLING

- FIBER CEMENT SIDING BUTT JOINT GAPS & SHRINKAGE

- FIBER CEMENT SIDING BUTT JOINT BACK FLASHING OMITTED

- FIBER CEMENT SIDING CAULKING ERRORS

- FIBER CEMENT SIDING COEFFICIENTS of EXPANSION

- FIBER CEMENT SIDING CURL / LIFT DEFECTS

- FIBER CEMENT SIDING DEFECT DIAGNOSTIC QUESTIONS

- FIBER CEMENT SIDING END CUT PRIMER COAT

- FIBER CEMENT SIDING GAPS

- FIBER CEMENT SIDING GAP & CAULK SPECS

- FIBER CEMENT SIDING GAP CURE

- FIBER CEMENT SIDING NAILING DEFECTS

- FIBER CEMENT SIDING LOOSE, NAILING FAILURES

- FIBER CEMENT SIDING NAILING ERRORS

- FIBER CEMENT SIDING SPLITS

- FIBER CEMENT SIDING STARTER STRIPS

- GROUND CLEARANCE DISTANCE for SIDING

- HOUSEWRAP DAMAGE

- HOMEOWNER COMMENTS on FIBER CEMENT SIDING

- TEMPERATURE EFFECTS on FIBER CEMENT SIDING

- FIBER CEMENT SIDING IDENTIFICATION

- FIBER CEMENT SIDING MANUFACTURERS & Manuals

- FIBER CEMENT SIDING MAINTENANCE

- FIBER CEMENT SIDING MOISTURE ABSORPTION

- FIBER CEMENT SIDING MOISTURE LEVELS

- FIBER CEMENT SIDING PAINTS

- FIBER CEMENT SIDING REMOVAL

- FIBER CEMENT SIDING REPAIRS

- JAMES HARDIEPLANK® FC SIDING

- JAMES HARDIE HARDIEPLANK INSTALLATION GUIDES & MANUALS

- NICHIHA ™ FIBER CEMENT SIDING FIELD REPORT

- FIBER CEMENT PRODUCT STANDARDS

- FIBER CEMENT ROOF SHINGLE ASBESTOS TEST RESULTS

- SIDING HARDBOARD IDENTIFICATION & CLAIMS

- SIDING CLEARANCE TO GROUND

Suggested citation for this web page

SIDING, FIBER CEMENT DEFECTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING SIDING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- James Hardie Fiber Cement Siding Best Practices, Appendix A, (2014) [PDF] available from James Hardie Corporation, 231 S. LaSalle St., Suite 2000

Chicago, Illinois 60604, USA, Website: https://www.jameshardie.com or in Canada: http://www.jameshardie.ca - [2] Killer Company, James Hardie Exposed, Matt Peacock, Harper Collins Australia, ISBN: 9780733325809; ISBN10: 0733325807

- [3] " Anyone else have HardiePlank siding on their house?", Early Retirement.org online blog, retrieved 1/14/2013, original source: http://www.early-retirement.org/forums/f27/anyone-else-have- HardiePlank-siding-on-their-house-19475.html

- [4] - DIY Chatroom, retrieved 1/17/2013, original source http://www.diychatroom.com/f2/ certainteed-weatherboard-vs-HardiePlank-4638/

- [5] Certainteed Weatherboard fiber cement siding and trim products - see certainteed.com/ or see certainteed.com/resources/sidingandtrimspecsheet.pdf

- [5a] "CertainTeed WeatherBoards™ Fiber Cement Siding Installation Manual", CertainTeed Corporation, 2012, CertainTeed Corporation, PO Box 880, Valley Forge PA 19482, Professional Help Line: 800-233-8990, Consumer Help Line: 800-782-8777, Website: Certainteed.com www.certainteed.com/resources/fc017.pdf retrieved 4/11/2013, [copy on file as Certainteed_Fiber_Cement_Siding_Install_fc017.pdf ]

- [5b] "Certainteed WeatherBoards™ Fiber Cement Siding Best Practices for Effective Job Site Management", CertainTeed Corporation, retrieved 4/15/13 original source: www.certainteed.com Copy on file as Certainteed_FC_Handling Brochure-Contractor_FC063.pdf

- [6] "Moisture Control in buildings: Putting Building Science in Green Building," Alex Wilson, Environmental Building News, Vol. 12. No. 5. [Good tutorial, "Moisture 101" outlining the physics of moisture movement in buildings and a good but incomplete list of general suggestions for moisture control - inadequate attention given to exterior conditions such as roof and surface drainage defects which are among the most-common sources of building moisture and water entry.--DJF]

- [7] J. Tibbets, "Green Houses", NCBI, retrieved 1/17/2013, original source: http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1469482/

- [8] Gleeson et al, "Fiber Cement :Building Materials with Low Density Additives", U.S. Patent 8,182,606, B2 5/22/2012, [adding low volumes of volcanic ash & hollow ceramic microspheres to cellulose fiber-reinforced building materials.

- [9] Thanks to reader Marie Carr for James HardiePlank siding photograph and case history information. 06/01/2008

- [10] JamesHardie HardiePlank® Lap Siding information can be found at the company's web page on this material:

https://www.jameshardie.com/products_siding_hardieplankLapSiding.py - [11] "30-Year Limited Warranty

HardiePlank® HZ5® Lap Siding, HardiePanel® HZ5® Vertical Siding,

HardieShingle® HZ5® Siding, HardieSoffit® HZ5® Panels", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [12] James Hardie Building Products, James Hardie CustomerLink™ Service Centre, 10 Colquhoun Street, Rosehill NSW 2142, Tel: 13 1103, Outside Australia 61 2 8837 4709,

Fax: 1 800 818 819. Hardie has operations in Australia, Asia, Canada, Europe, New Zealand, United States, and the Philippines. The company is a significant producer of fiber cement siding and backerboard. Email: info@JamesHardie.com and Website https://www.jameshardie.com/

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 -

1-888 J-HARDIE

1-888 542-7343 or by email to info@JamesHardie.com - [12b] "Technical Bulletin #9, Joint Flashing at Field Butt Joints", JamesHardie, retrieved 4/15/2013, original source: www.jameshardie.com, copy on file as James_Hardie_9-joint-flashing.pdf - quoting:

This Technical Bulletin is an explanation supporting the announcement made by James Hardie on September 8th, 2008 withdrawing its recommendation on the use of caulk at field butt joints for HardiePlank® lap siding.

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 -

1-888 J-HARDIE

- [13] Instructions for application of HardiePlank lap siding can be found at https://www.jameshardie.com/products_siding_hardieplankLapSiding.py?openTab=jsnavLink4

- [14] "Homeowners Care and Maintenance Tips", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, included with product warranty information, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [15] "HardiePlank HZ5 Lap Siding Installation Requirements - Primed & Colorplus® Products",JamesHardie, November 2012, 1-800-9-HARDIE, 10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/install/hardieplank-hz5.pdf, [copy on file as Hardieplank-hz5_Install.pdf]

- [16] Technical Bulletin #9, Joint Flashing at Field Butt Joints, James Hardie corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/9-joint-flashing.pdf

- [17] Technical Bulletin #17, Fastening Tips for HardiePlank® Lap Siding, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/17 -fastening-tips-for%20-plank.pdf [copy on file]

- [18] Technical Bulletin #8, Expansion Characteristics of James Hardie® Siding Products, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/8-expansion-characteristics.pdf [copy on file]

- [19] Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions. Personal communication 3/20/2013.

- [20] MASONITE WOODRUF® ROOFING OR MASONITE OMNIWOOD® SIDING LAWSUIT SETTLEMENT NOTICE - PDF file

- [21] Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- [22] Roger Xu, 徐银杰 (my Chinese name), Ningbo Yihe Greenboard Co., Ltd., No.189, Longzhen Road, Nongkenchang, Longshan Town, Cixi, Ningbo, Zhejiang China, Tel: 0086-574-63974118/83887668 Fax:0086-574-63974129/83887670 Mobile: 0086-15924317823; E-Mail: sales6@yhboard.com; Skype: dajiezi107, www.yhboard.com/en, personal correspondence 3/21/2013

- [23] James Hardieplank, personal communication with Daniel Friedman, 6/6/2013. We called James Hardie to ask for guidance in determining just how much moisture was "too much" in Hardieplank siding, after observing that siding at a job arrived visibly wet from the factory even though still inside its original sealed plastic wrapping. We called James Hardie's technical support line where a courteous representative told us he would refer us to Hardie's expert Benjaman Batres. Our call to Mr. Batres was returned by Stephanie (declined to give last name) from James Hardie's customer warranty service department. Stephanie informed us that there are no moisture numbers, that it is not possible to measure moisture in fiber cement siding (utter nonsense!) and repeatedly advised "Just read our instructions" or "So file a claim". Don't count on much help from James Hardie's customer warranty department on siding shrinkage or butt joint gap concerns. Gaps at Hardieplank siding butt joints continue to appear in the Hardieplank installation.

- Sealants, Durability of Building Sealants (RILEM Proceedings), J.C. Beech, A.T. Wolf, Spon Press; illustrated edition (1995), ISBN-10: 0419210709, ISBN-13: 978-0419210702

This book presents the papers given at the RILEM Seminar held at the Building Research Establishment, Garston, UK in October 1994. The book provides an opportunity for researchers to review up-to-date progress towards the achievement of the objectives of the standardisation of laboratory techniques of sealants in the variety of service conditions to which they are exposed. - Staining, Prevention of Premature Staining in New buildings, Phil Parnham, Taylor & Francis; 1996, ISBN-10: 0419171304, ISBN-13: 978-0419171300

The appearance of ugly staining early in a buildings life, ruins an otherwise pleasing appearance, tarnishes the image of the owners and gives rise to costly refurbishment works. In this book Phil Parnham raises a number of questions that should be considered whenever a new building is being designed or built. These are: * why has staining become so prominent; * what causes premature staining; which parts of new buildings are likely to be affected; * how can it be avoided? By using a number of highly illustrated case studies, the author answers these questions and ends by suggesting measures that should be taken by all design and construction professionals to prevent premature staining. - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.