Fiber Cement Siding Curling or Lifting at Joints or Ends

Fiber Cement Siding Curling or Lifting at Joints or Ends

Causes & prevention of fiber cement siding curl-up or lifting at board ends

- POST a QUESTION or COMMENT about installing fiber cement siding troubleshooting, defect causes, remedies, warranties, warranty claims

Curling or Lifting Fiber Cement Siding, Causes & Preventive Measures:

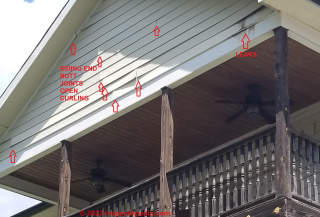

This field report of fiber cement siding lifting or curling complaints describes movement or curls observed at butt joints or at vertical trim abutments in Nichiha 1/2" thick fiber cement siding.

The observation of this condition on several homes and in installations of various levels of workmanship and analysis of site and material conditions suggest that differential moisture in the material is an important factor in siding curl or lift problems.

This article series describes the types of problems that occur in fiber cement siding shingle & shake installations in North America, including fiber cement shingle shrinkage gaps at butt joints, cracks, breaks, and loose or buckling shakes.

We describe various fiber cement siding complaints: open butt joint gaps, buckled siding, loose siding, nailing failures, moisture effects, and we include opinions, field observations, and research on the causes & effects of these conditions.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Curling at Butt Joint Gaps in Thick Fiber Cement Siding

Note: the reader-comments appearing at points in this article were provided by a reader whose siding is further illustrated and discussed

at SIDING, FIBER CEMENT SHINGLE DEFECT DIAGNOSIS - Troubleshooting gaps, breaks, peeling, bowing, loose fiber cement siding: causes, remedies. Nichiha Fiber Cement products, performance & warranty field report.

[Click to enlarge any image]

This looks a little like curling, as much as a 1/2" board could - but more definitely end effects rather than a whole board phenomena. I was only speculating -- attached are two photos [of 1/2" thick Nichiha Fiber Cement siding]that seem to lend some support the idea though.

Imagine two cement fiber boards with unprimed cut ends lying end to end on a floor in a lab. Make sure the ends "butt" up against each other -- touching with "moderate" contact. Say we put a few screws in the boards towards the middle to secure them in place to the floor. Through some magical laboratory radiation process we cause the butted ends of the boards to warp or bend upward. Say initially the first inch of the board(s) and then all the way to your 6 inches.

Looking down from above at the point where the boards meet a gap will appear and get larger. Its a visual gap from above -- but its not due to any "shrinkage" of the board.

The gap resulted from the "lifting" the ends in the Z axis, not due to separation in the Y axis. Anyway -- don't know anymore what my point here really was?

But if in the field this kind of thing is happening just on the ends over a whole lot of temp/moisture cycles who knows ... maybe phase one is unseen and expansionary in the y axis, there's board movement, pushing on adjacent boards, pushing on trim even, nails loosen ... and you end up with a permanent physical gap not a shrinkage gap -- or sometimes the stair step effect I've seen -- before moving on to the actual buckling phase which requires deeper saturation.

Note that my installer told me everything was "tight" at installation. And I believe him because the east and north sides are still tight with no gaps at all. -

E.D. 12/15/2014

Probable Explanation of Fiber Cement Board Siding Curling at Butt Joints

You are describing a gap that appears due to buckling or curling ends of the boards - limited perhaps at its upper end by the overlap of the next course of siding.

You are describing a gap that appears due to buckling or curling ends of the boards - limited perhaps at its upper end by the overlap of the next course of siding.

But in the photo at left there are wide open butt joints at board ends combined with a lifting or curling of the boards away from the building wall. There is also no visible compression damage at the board ends. This fiber cement board lifting and curling is almost certainly a different pheonomenon.

Indeed I can imagine that if the board ends are getting wet - you might see curling - this is a different phenomenon than the main butt joint gap shrinkage problem that I and everybody and his uncle usually talk about.

It's a new one to me, and surprising, more so in 1/2" thick FC material. I suspect this particular manifestation may be related to the thicker Nichiha Fiber Cement products and to a moisture differential across the board thickness, probably related to moisture uptake on the board's inner surface.

On the FC clad buildings I've examined the buckling was not focused on ends of boards and the gaps were between boards that more or less remained in the same plane.

Perhaps you've described a "new" product complaint. Certainly I"m doubtful that such a condition will ever heal itself.

Before moving on to examples in wood boards or wood flooring (given below), it's worth noting that these two roofing material "curls" have different etiologies and different manifestations. Indeed one can arrive at a credible explanation for the curling fiber cement board ends in your photos by study of causes and manifestations of curling on other building materials.

See FISHMOUTHING ASPHALT SHINGLES

and also

see CURLING ASPHALT SHINGLES for examples of moisture differential-related curling in other building materials.

OPINION: The cause of these curling ends of fiber cement boards seen at the butt joints is most likely the result of water passing behind the siding, entering at the butt joint gaps or water entering behind the siding at other building leak points such as improperly-flashed window or door tops.

Water entering at the butt joint where the curling is observed may be sufficient to cause this warping. But also, water entering the wall at butt joints or other openings higher on the wall may show up as a cumulative effect that would explain why there may be more curled or lifted siding at butt joints lower on the wall than higher on the same wall with the same exposure.

When the back side of a board is set and sun hits and dries the exposed side the board curls towards the dry side. This is true for wood products but also for some fiber cement products.

Where a fiber cement siding butt joint occurs the board ends are more exposed to wetting than along the un-cut length of the board. Possibly the combination of that increased water and the presence of the combined curling-lifting force of two open board ends is more able to overcome the resistance offered by the next lapped course of siding above. As well, the lower portions of these boards are more open to free movement.

In addition, the board ends are mechanically less-constrained against curling than the center portions of the same fiber cement board product.

Fiber Cement Board Curling due to Moisture Differential

[Click to enlarge any image]

Above is a photo of curling extending back more than 1.5 feet at either end of the butt joints of an un-cut, factory-coated board all of whose surfaces were installed intact. This photo is discussed in more detail

at MOISTURE ABSORPTION into FIBER CEMENT SIDING

I've looked closely at uneven material drying and curling for other materials.

Additional forces at work here besides the sources of movement: differences in moisture and temperature across the board thickness, are the compressibility of the material and elasticity of the fiber cement siding material. Wood boards, once cupped due to moisture effects tend to retain that cupped set even after the boards are uniformly dry.

That's because the wood cells in the concave side of the cupped board have been compressed.

We'd need to see material test data for fiber cement but it seems obvious that fiber cement, even products containing wood fibers, should be less compressible than wood. So one would expect to see the curling increase and decrease as wall moisture conditions vary. This is in fact what you reported.

and

see BARK SIDE UP or DOWN on DECKS & STEPS?

I theorize further that this problem may actually be worse for thicker FC boards than for thinner products - surprising the manufacturer who thought that thicker boards would resist buckling or curling.

The explanation is that in a thicker board there is more opportunity for a significant moisture gradient across the thickness of the board - it dries out more slowly and more unevenly than a thinner board. So the curling forces overwhelm the resistance of the thicker material.

Dargontina (2007) questions the benefits of going to a thicker fiber cement material.

Reader follow-up:

Look at the photo under the window -- of the short section of cut siding. A definite bowing up at both cut edges.

Looking at other boards, even whole boards with both ends factory finished -- they appear to be trying to do the same thing.

If they are well restrained at the corners, as they appear to be in the close up photo -- there appears to be curling up at the lower corner and/or possibly an upward slope to the whole bottom of the board. - E.D. 12/17/2014

...

...

[Click to enlarge any image]

Reply:

Are you thinking, even slightly that since you see up-bends on factory primed un-cut ends that perhaps the water is entering through the board surface and that what I call curling is occuring more noticeably at the ends because they are less constrained?

To be clear we both want to find the best data rather than wanting to be the one who was right. - DF

Reader follow-up:

Yes - I am helping you win and me lose a case of cheap Mexican beer.

A small price to pay!

The bowing at the ends is seen again here in third board up. With more of a curl in the lower right corner if you see it from the side. - E.D. 12/17/2014

Reader follow-up:

I propose this is simply mechanical bowing due to expansionary heat forces. Nothing to do with moisture.

Why this board and none of the others? All must have at least one cut ends. In this section there appear to be no butt joints. This board because he just cut it a little too big and jammed it in there. Nothing to do with water.

In fact, although it may be an optical illusion -- if you look closely at the board immediately above -- it appears to be bowed slightly in the opposite direction with the center rising a bit. Maybe. Although for the most part you might expect the confinement of the sheathing to always force the bowing at the ends outward. - E.D. 12/19/2014

Reply: comparing thermal expansion to moisture expansion in fiber cement siding

[Click to enlarge any image]

The effects of thermal expansion in FC siding are small in comparison with those attributed to moisture up-take.

See FIBER CEMENT COEFFICIENTS of EXPANSION

From the rather distant perspective of your photos (and still more distance as the crow flies), these instances look to me like curling up board ends that are not in contact with one another - they look very different from Doggett's expanded crushed FC panel sides that are visibly damaged and that remain either in contact or very close together, and not curl-lifted over the field of the product.

I think these are very different phenomena.

We could make a more reliable assessment of your siding by a very close examination of the board ends, both under a stereo microscope and a high powered microscope. (When you remove some siding save some of these for mailing to our forensic lab).

If the effects you see on your home were from expansion and compression we'll see that plainly at the board ends.

One can see it in Doggett's photos even macroscopically. More sophisticated core cuts across the thickness of the curved or curled FC boards may also show, under the microscope, both the composite differences attributed to the Hatcheck machine production process, and possibly delamination and curling associated with moisture uptake.

Remember that the effects of moisture expansion are much greater than thermal expansion in FC products. And if a board is wet before installation it is in expanded condition and will principally shrink after installation - thus the butt joint gaps with ends showing no compression effects that one would have seen had there first been expansion.

Distinguish Fiber Cement Gapped & End-Lift or Curling Board Ends from Rippled Fiber Cement Siding

Other investigators and owners have reported rippling and uneven siding board lapping at fiber cement siding boards installed as a single board (no cuts) butted tightly beween vertical trim on buildings.

That rippled FC siding may be caused by board expansion from moisture, thermal effects, or both. A forensic examination of such walls would probably sort out the roles of leaks, mositure, tempearature, and installation nailing and board tightness against trim. - zumBrunnen (undated).

It appears to us [DF] that there are these distinctions between curled end-lift at fiber cement siding and rippled fiber cement siding

Notes to the table above

[1] Table development is in process. CONTACT US to comment or contribute. InspectAPedia is an independent publisher of building, environmental, and forensic inspection, diagnosis, and repair information provided free to the public - we have no business nor financial connection with any manufacturer or service provider discussed at our website.

[2] Rippling fiber cement siding is described by

- zumBrunnen (blog), "Fiber Cement Siding - Part 1", zumBrunnen Building Consultants, Inc., Plaza 400, 5881 Glenridge Drive, Suite 110, Atlanta, GA 30328

Main: 404.601.4050 Email: info@zumbrunnen.com Tel: 404-601-4040 Website: http://zumbrunnen.com/

[3] Curling fiber cement siding board ends are described at SIDING, FIBER CEMENT CURL / LIFT DEFECTS - you are on this page

In explaining rippled FC siding zumBrunnen, an Atlanata GA (USA) building consultant offers:

Unpainted plank ends –cut ends need to be either painted or treated with caulking. The manufacturer’s written instructions call for painted ends. It is our opinion a bead of caulk is substandard to painted ends.

Some of these caulked joints will fail and these unpainted planks will then be exposed to wind driven rain and ice, and can deteriorate from the moisture. If this occurs and causes material damage, we would expect the manufacturer to void his warranty.

1/8” gap not provided – the 1/8” gap is not a requirement for the material warranty but a best practice. This comment is contrary to manufacturer’s written instructions. We are concerned that if gaps are not provided, thermal expansion will contribute to the warping and rippling that we have observed around the site.

If this occurs and causes material damage, we would expect the manufacturer to void his warranty.

Warping and rippling of planks – this issue remains unresolved and an answer is forthcoming - zumBrunnen Building Consultants, Atlanta GA, (undated) cited in detail atReferences or Citations

Bottom line on causes of fiber cement curling or lifting at board ends

OPINION: We suspect that curling or lifting problems at the board-ends of fiber cement siding are the result of the combination of the following factors:

- Fiber Cement Siding Moisture Differential across the thickness of the fiber cement siding causing curling towards the dry or more warm side of the material. Expect to see differences in the extent of FC siding curling or lifting on building walls with different exposures, with more significant curling occurring on sun-exposed walls and on walls more exposed to driving rain or ocean spray.

- Fiber Cement Siding Moisture entry into the siding, probably from its back side, typically due to leaks into the wall system at open butt joint gaps, at improperly-flashed or un-flashed butt joint gaps over the field of the wall, at improperly flashed or sealed window or door head or side trim, or omission of sealant at vertical trim abutments

See - BUTT JOINT GAPS & FIBER CEMENT SIDING SHRINKAGE

- BUTT JOINT BACK FLASHING OMITTED

- CAULKING ERRORS on FIBER CEMENT SIDING

- FIBER CEMENT SIDING NAILING ERRORS: failure to terminate butt joints over a wall stud may be a factor in explaining lifting or horizontal lapped board siding curling or lifting ends as the board ends are not as firmly secured by nailing only into wall sheathing.

- Fiber Cement Siding Temperature effects may play a role in curling or cupping FC siding as well but we suspect this is a less significant factor.

- Fiber Cement SiIding thickness: because it is apparent that there is likely to be more moisture variation across the thickness of a thicker siding material this curling lifting effect in fiber cement siding may be more frequent where thicker siding materials are installed, such as Nichiha's 1/2" thick fiber cement horizontal board lap siding.

Minimize these effects by following the manufacturer's installation instructions with particular care in flashing, sealing, and in avoiding the installation of FC siding if it is wet or at high moisture content.

FIber Cement Siding Manufacturer Contact Information

- Nichiha Fiber Cement, 6465 E Johns Crossing, Suite 250 Johns Creek, GA 30097, USA, Tel: 1.866.424.4421

or 770-805-9466

Fax: 770-805-946 , Website: http://www.nichiha.com/ Email: info@nichiha.com

The company provides a variety of technical details about their fiber cement products, found at http://www.nichiha.com/resources/technical-documents including- General Instructions for All Nichiha Siding Products, http://nichiha.com/images/uploads/Sierra_Install_Brochure.pdf

These instructions include this advice:

Contact your local dealer or Nichiha Customer Service Representative toll-free at 1-866-424-4421 immediately, should you have any questions about Sierra Premium and NichiFrontier products

Nichiha fiber cement siding products have been earning their stripes in commercial settings for years. Fiber cement is a versatile, sustainable, high-performance product that makes as much sense for a home as it does for commercial building. You’ll be impressed with the many and varied looks of Nichiha products, but the performance will amaze you.NichiBoard delivers the look of lap and the performance of fiber cement at price that makes it an outstanding value and an easy choice. Both products will never warp, rot or fall victim to pests. Every single piece is factory primed, perfectly uniform and guaranteed to perform.

[This is described in the product literature as fiber cement lap siding boards. Nichiha has been producing fiber cement products since the 1970's and began producing residential fiber cement siding products in the 1990's. - Ed. .]

- General Instructions for All Nichiha Siding Products, http://nichiha.com/images/uploads/Sierra_Install_Brochure.pdf

- Our complete list of fiber cement siding manufacturers is at SIDING, FIBER CEMENT home

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: curled fiber cement siding ends - are joints the issue?

First of all, the article on Cement Siding Repair Advice & Specifications SIDING, FIBER CEMENT SHINGLE DEFECT DIAGNOSIS was very helpful.

First of all, the article on Cement Siding Repair Advice & Specifications SIDING, FIBER CEMENT SHINGLE DEFECT DIAGNOSIS was very helpful.

Particularly the section on SIDING, FIBER CEMENT BUCKLING FIBER CEMENT SIDING seems to address the issue on this house (built 2012) that we have a back up offer on.

Helpful stuff. It appears to my layman's eye that the installer may not have provided for adequate butt joint gaps which is causing all this buckling, but there may be other issues going on.

Do you concur that the joints are the issue, and is it likely cheaper and better to simply replace all the siding, to attempt to correct each buckling issue.

They also attempted a paint job, which is incomplete. We do not know how long the buckling has been there.

I've attached 2 photos of the worst areas (which happen to have southern exposure, if that is a factor, and then another couple side shots of the other sides that aren't as bad. It might give context on whether there is an underlying issue that has nothing to do with the joint ends.

This home, shown above, is in Tennessee.

Thanks in advance for any insights. - Anonymous by private email 2022/08/06

Moderator reply: badly curled fiber cement siding ends, leaks behind siding, risk of hidden damage, cost to cure?

That siding looks as if it was not properly-nailed to the building; there are more problems than simply too-tight siding board end butt joints: curling, lifting, loose, leaks.

That siding looks as if it was not properly-nailed to the building; there are more problems than simply too-tight siding board end butt joints: curling, lifting, loose, leaks.

If the siding is badly buckled it may be less costly and more effective to replace it but that's a very expensive job.

I'd want an onsite diagnostic inspection by someone with experience before commiting to a course of action.

That dark color partial paint job on some of the house walls, variations in color of siding boards, as well as the badly curved, loose fiber cement (FC) siding board ends suggests a history of partial efforts, most-apparently unsuccessful, to tend to the condition of the building exterior.

Watch out: There is certainly more of concern at this home than your comments have noted. For example your image of the upper gable end shows staining indicative of extended leakage behind the siding at the lower right corner.

A more-through inspection in the attic space and other connected building areas is needed, to look for rot, mold, etc.

Your images suggest inexperienced or inexpert building management that should suggest to an experienced home inspector that she needs to be alert for more SNAFUS across other topics and areas of the home.

Reader follow-up:

Very helpful! Yes, the drainspouts onto the deck make no sense, we all agreed.

Our realtor suggested that ivy had grown up into that dark area by the gable, but you raise a more ominous possibility. We would follow your suggestion on the inspection-- that's if we move forward.

Removing and residing a house this size can be estimated at approximately what, $10k? $50k? More?

Moderator reply:

Removing and disposing of fiber cement siding in a home in Tennessee is likely to cost at least $3,000 TO $5,000, followed by installation of new siding, with material cost varying by siding material choice and of course building size and height, in the range of $20,000 to $40,000.

From these and your other photos it looks as if the home was under-construction, never finished, and allowed to deteriorate.

About buckling vs curl, I find that across a large population of readers (million a month in 52 countries) choice of words needs to be a bit inclusive.

In general, my own interpretation is that buckling occurs in the field of a siding board while curling occurs at ends. Your photos show both but more end-lifts and curling completely apart than buckling. Some other details suggest inadequate nailing.

Naturally one won't find just one narrow defect in a siding installation like this one.

Reader follow-up:

{we are] thinking if we have to remove it all, we replace it with something less costly, which is also worrisome. We will have to see what other options and major projects would be there.

Moderator reply:

If you decide to proceed with this home, which certainly might be plausible, take great care of that you don't become so distracted by one topic, such as this one, that's so captures your attention that you fail to inspect every component of the building thoroughly. It's quite likely that there will be other topics that indicate repair is needed elsewhere.

...

Continue reading at BUTT JOINT GAPS & FIBER CEMENT SIDING SHRINKAGE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FIBER CEMENT SIDING DEFECTS - home

- FIBER CEMENT SHINGLE DEFECT DIAGNOSIS

- FIBER CEMENT SHINGLE CUTTING TOOLS

- FIBER CEMENT SHINGLE REPAIRS

- FIBER CEMENT SIDING BUCKLING

- FIBER CEMENT SIDING BUTT JOINT CURLING

- FIBER CEMENT SIDING BUTT JOINT GAPS & SHRINKAGE

- FIBER CEMENT SIDING BUTT JOINT BACK FLASHING OMITTED

- FIBER CEMENT SIDING CAULKING ERRORS

- FIBER CEMENT SIDING COEFFICIENTS of EXPANSION

- FIBER CEMENT SIDING CURL / LIFT DEFECTS

- FIBER CEMENT SIDING DEFECT DIAGNOSTIC QUESTIONS

- FIBER CEMENT SIDING END CUT PRIMER COAT

- FIBER CEMENT SIDING GAPS

- FIBER CEMENT SIDING GAP & CAULK SPECS

- FIBER CEMENT SIDING GAP CURE

- FIBER CEMENT SIDING NAILING DEFECTS

- FIBER CEMENT SIDING LOOSE, NAILING FAILURES

- FIBER CEMENT SIDING NAILING ERRORS

- FIBER CEMENT SIDING SPLITS

- FIBER CEMENT SIDING STARTER STRIPS

- GROUND CLEARANCE DISTANCE for SIDING

- HOUSEWRAP DAMAGE

- HOMEOWNER COMMENTS on FIBER CEMENT SIDING

- TEMPERATURE EFFECTS on FIBER CEMENT SIDING

- FIBER CEMENT SIDING IDENTIFICATION

- FIBER CEMENT SIDING MANUFACTURERS & Manuals

- FIBER CEMENT SIDING MOISTURE LEVELS

- FIBER CEMENT SIDING REPAIRS

Suggested citation for this web page

SIDING, FIBER CEMENT CURL / LIFT DEFECTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING SIDING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- zumBrunnen (blog), "Fiber Cement Siding - Part 1", zumBrunnen Building Consultants, Inc., Plaza 400, 5881 Glenridge Drive, Suite 110, Atlanta, GA 30328 Main: 404.601.4050 Email: info@zumbrunnen.com Tel: 404-601-4040 Website: http://zumbrunnen.com/, retrieved 12/21/2014, original source: http://zumbrunnen.com/fiber-cement-siding-part-1/

- zumBrunnen (blog), "Fiber Cement Siding - Part 1", zumBrunnen Building Consultants, Inc., Plaza 400, 5881 Glenridge Drive, Suite 110, Atlanta, GA 30328 Main: 404.601.4050 Email: info@zumbrunnen.com Tel: 404-601-4040 Website: http://zum retrieved 12/21/2014, original source: http://zumbrunnen.com/fiber-cement-siding-part-2/

- Doggett, Steven M., "Unexpected Expansion of Fiber Cement Panels [PDF] The Building Exnclosure (website), (14 Feb 2012), retrievedf 12/21/2014, original source: https://builtenv.wordpress.com/2012/02/14/ unexpected-expansion-of-fiber-cement-panels/

- Nichiha Fiber Cement, 6465 E Johns Crossing, Suite 250 Johns Creek, GA 30097, USA, Tel: 1.866.424.4421

or 770-805-9466 Fax: 770-805-946 , Website: http://www.nichiha.com/ Email: info@nichiha.com

The company provides a variety of technical details about their fiber cement products, found at http://www.nichiha.com/resources/technical-documents including- General Instructions for All Nichiha Siding Products, http://nichiha.com/images/uploads/Sierra_Install_Brochure.pdf

These instructions include this advice:

Contact your local dealer or Nichiha Customer Service Representative toll-free at 1-866-424-4421 immediately, should you have any questions about Sierra Premium and NichiFrontier products

- General Instructions for All Nichiha Siding Products, http://nichiha.com/images/uploads/Sierra_Install_Brochure.pdf

- [1] "James Hardie's Mesothelioma and Asbestos Legacy Continues, 2009", web search 03/01/2011, www.survivingmesothelioma.com

- [2] Killer Company, James Hardie Exposed, Matt Peacock, Harper Collins Australia, ISBN: 9780733325809; ISBN10: 0733325807

- [3] " Anyone else have HardiePlank siding on their house?", Early Retirement.org online blog, retrieved 1/14/2013, original source: http://www.early-retirement.org/forums/f27/anyone-else-have- HardiePlank-siding-on-their-house-19475.html

- [4] - DIY Chatroom, retrieved 1/17/2013, original source http://www.diychatroom.com/f2/ certainteed-weatherboard-vs-HardiePlank-4638/

- [5] Certainteed Weatherboard fiber cement siding and trim products - see certainteed.com/ or see certainteed.com/resources/sidingandtrimspecsheet.pdf

- [5a] "CertainTeed WeatherBoards™ Fiber Cement Siding Installation Manual", CertainTeed Corporation, 2012, CertainTeed Corporation, PO Box 880, Valley Forge PA 19482, Professional Help Line: 800-233-8990, Consumer Help Line: 800-782-8777, Website: Certainteed.com www.certainteed.com/resources/fc017.pdf retrieved 4/11/2013, [copy on file as Certainteed_Fiber_Cement_Siding_Install_fc017.pdf ]

- [5b] "Certainteed WeatherBoards™ Fiber Cement Siding Best Practices for Effective Job Site Management", CertainTeed Corporation, retrieved 4/15/13 original source: www.certainteed.com Copy on file as Certainteed_FC_Handling Brochure-Contractor_FC063.pdf

- [6] "Moisture Control in buildings: Putting Building Science in Green Building," Alex Wilson, Environmental Building News, Vol. 12. No. 5. [Good tutorial, "Moisture 101" outlining the physics of moisture movement in buildings and a good but incomplete list of general suggestions for moisture control - inadequate attention given to exterior conditions such as roof and surface drainage defects which are among the most-common sources of building moisture and water entry.--DJF]

- [7] J. Tibbets, "Green Houses", NCBI, retrieved 1/17/2013, original source: http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1469482/

- [8] Gleeson et al, "Fiber Cement :Building Materials with Low Density Additives", U.S. Patent 8,182,606, B2 5/22/2012, [adding low volumes of volcanic ash & hollow ceramic microspheres to cellulose fiber-reinforced building materials.

- [9] Thanks to reader Marie Carr for James HardiePlank siding photograph and case history information. 06/01/2008

- [10] JamesHardie HardiePlank® Lap Siding information can be found at the company's web page on this material:

https://www.jameshardie.com/products_siding_hardieplankLapSiding.py - [11] "30-Year Limited Warranty HardiePlank® HZ5® Lap Siding, HardiePanel® HZ5® Vertical Siding,

HardieShingle® HZ5® Siding, HardieSoffit® HZ5® Panels", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [12] James Hardie Building Products, James Hardie CustomerLink™ Service Centre, 10 Colquhoun Street, Rosehill NSW 2142, Tel: 13 1103, Outside Australia 61 2 8837 4709, Fax: 1 800 818 819. Hardie has operations in Australia, Asia, Canada, Europe, New Zealand, United States, and the Philippines. The company is a significant producer of fiber cement siding and backerboard. Email: info@JamesHardie.com and Website https://www.jameshardie.com/

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 - 1-888 J-HARDIE

1-888 542-7343 or by email to info@JamesHardie.com - [12b] "Technical Bulletin #9, Joint Flashing at Field Butt Joints", JamesHardie, retrieved 4/15/2013, original source: www.jameshardie.com, copy on file as James_Hardie_9-joint-flashing.pdf - quoting:

This Technical Bulletin is an explanation supporting the announcement made by James Hardie on September 8th, 2008 withdrawing its recommendation on the use of caulk at field butt joints for HardiePlank® lap siding.

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 - 1-888 J-HARDIE

- [13] Instructions for application of HardiePlank lap siding can be found at https://www.jameshardie.com/products_siding_hardieplankLapSiding.py?openTab=jsnavLink4

- [14] "Homeowners Care and Maintenance Tips", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, included with product warranty information, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [15] "HardiePlank HZ5 Lap Siding Installation Requirements - Primed & Colorplus® Products",JamesHardie, November 2012, 1-800-9-HARDIE, 10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/install/hardieplank-hz5.pdf, [copy on file as Hardieplank-hz5_Install.pdf]

- [16] Technical Bulletin #9, Joint Flashing at Field Butt Joints, James Hardie corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/9-joint-flashing.pdf

- [17] Technical Bulletin #17, Fastening Tips for HardiePlank® Lap Siding, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/17 -fastening-tips-for%20-plank.pdf [copy on file]

- [18] Technical Bulletin #8, Expansion Characteristics of James Hardie® Siding Products, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/8-expansion-characteristics.pdf [copy on file]

- [20] MASONITE WOODRUF® ROOFING OR MASONITE OMNIWOOD® SIDING LAWSUIT SETTLEMENT NOTICE - PDF file

- [21] Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- [22] Roger Xu, 徐银杰 (my Chinese name), Ningbo Yihe Greenboard Co., Ltd., No.189, Longzhen Road, Nongkenchang, Longshan Town, Cixi, Ningbo, Zhejiang China, Tel: 0086-574-63974118/83887668 Fax:0086-574-63974129/83887670 Mobile: 0086-15924317823; E-Mail: sales6@yhboard.com; Skype: dajiezi107, www.yhboard.com/en, personal correspondence 3/21/2013

- [23] James Hardieplank, personal communication with Daniel Friedman, 6/6/2013. We called James Hardie to ask for guidance in determining just how much moisture was "too much" in Hardieplank siding, after observing that siding at a job arrived visibly wet from the factory even though still inside its original sealed plastic wrapping. We called James Hardie's technical support line where a courteous representative told us he would refer us to Hardie's expert Benjaman Batres. Our call to Mr. Batres was returned by Stephanie (declined to give last name) from James Hardie's customer warranty service department. Stephanie informed us that there are no moisture numbers, that it is not possible to measure moisture in fiber cement siding (utter nonsense!) and repeatedly advised "Just read our instructions" or "So file a claim". Don't count on much help from James Hardie's customer warranty department on siding shrinkage or butt joint gap concerns. Gaps at Hardieplank siding butt joints continue to appear in the Hardieplank installation. We are monitoring - DF 10/9/2013 Re: Eric Galow, project at 116 Coyote Ridge, Staatsburgh NY visited April-June 2013; My Call to Hardie at 888-542-7343 referred on to Benjaman Batres, 909-349-2976 Ultimately this stunningly rude customer service rep told me that "our conversation was over" or words to that effect - no help was forthcoming. Says if the siding arrives wet, refuse it (no idea of impact on contractor and no definitino of wet). Says "read our instructions", Says "the owner can fill out a claim form", I say "I've read your instructions, I dont' see how to determine what is wet;" She says "File a claim"; I ask last name, she says "this conversation is ending" I Say "but why do you keep saying read our instructions when I've done so and tell you there is no answer there ? I don't see any guide to define "too wet" or "dry enough". How do we figure this out. I say I thought you'd want to know that I opened factory-sealed product and it was soaking wet, visibly wet on top inside the wrapper, and moisture measurements into the bundle showed the center planks were much higher in moisture content". She says "If the contractor opens the product and it is wet he should refuse it".

- Sealants, Durability of Building Sealants (RILEM Proceedings), J.C. Beech, A.T. Wolf, Spon Press; illustrated edition (1995), ISBN-10: 0419210709, ISBN-13: 978-0419210702

This book presents the papers given at the RILEM Seminar held at the Building Research Establishment, Garston, UK in October 1994. The book provides an opportunity for researchers to review up-to-date progress towards the achievement of the objectives of the standardisation of laboratory techniques of sealants in the variety of service conditions to which they are exposed. - In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.