Tips for Removing Fiber Cement Siding

Tips for Removing Fiber Cement Siding

- POST a QUESTION or COMMENT about the cause & cure of butt joint gaps in fiber-cement siding & about fiber cement siding installation

Fiber cement siding removal procedures to minimize dust & to permit possible salvage & re-use of the material.

This article describes How to remove fiber cement siding with minimum damage or hazardous silica dust, and why owners decided to remove fiber cement siding from their home and to replace it with James Hardie's HardiePlank fiber cement product.

The article details just how the old fiber cement siding was removed with minimum damage.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Fiber Cement Siding Removal Procedures

Why remove building fiber cement siding?

Why remove building fiber cement siding?

Generally we do not recommend removing building siding in good condition, even if there are cosmetic issues that need to be addressed.

But if building siding is extensively damaged, or so badly installed that building wall leaks are widespread and damaging the building, one might consider removing and replacing all or more limited sections of the wall siding on the building.

At SIDING, FIBER CEMENT GAPS

and further

at SIDING, FIBER CEMENT MOISTURE LEVELS we describe a ten year old fiber cement siding installation that came to the building owners' attention because of large butt joint gaps in the lap siding installation.

When owners asked for advice from several building inspectors, industry consultants, and siding contractors, they learned that the product they thought they were buying, HardiePlank fiber cement siding, was not what their original contractor installed.

Watch out: this article describes the removal of fiber cement lap siding - horizontal "boards" such as shown in our photos. These procedures are not suitable for the removal of fiber cement shingles nor asbestos cement shingles. If you are working with those siding shingle materials and need to remove shingles for repair,

see ASBESTOS CEMENT SHINGLE REMOVAL.

Why remove limited sections of fiber cement siding

But even if there is no sound reason for removal of all fiber cement siding from a building, it may be necessary to remove sections of damaged FC siding such as the impact-damaged siding shown in our photograph at left.

Note that that damaged FC siding was at a different property from the "counterfeit" bad siding job installation discussed here and illustrated just above.

The siding damage you see in this photo was caused by a vehicle or by an impact.

Mechanical damage to fiber cement siding is described in more detail at SIDING, FIBER CEMENT DEFECTS.

Visible & Hidden Trouble Points in & Behind the Original FC Siding Installation

Further close-up inspection by the repair contractor, Galow Homes, as well as by the author (DJF) found numerous other siding installation SNAFUS including:

- Widespread rotted trim and window and door damage due to improper original installation

- Omission of required window & door flashings

- Omission of caulk where it should have been installed

- Omission of back-flashing at siding butt joints. If the housewrap had been properly installed and if butt joints had remained tight between the ends of adjoining fiber cement siding boards we doubt that this would be much of a worry on most buildings.

On this building where the FC butt joints were open like wide gaping howling mouths (see our photo at left), the housewrap was improperly installed, and wall leaks over the life of the structure were likely. - Omission of required clearance between siding ends and vertical trim, contributing to siding buckling in some locations.

- Improper and inadequate nailing, leaving the fiber cement siding loose, buckling, and in some locations literally falling off of the building. At some locations, once the upper course of siding had been removed, we could simply pull some siding nails out of the building wall barehanded.

- Installation of caulk where its use was not recommended (at gaps in lap siding butt jointds)

And more FC siding installation snafus were discovered as we began pulling the old material off of the building, including

- Improperly installed housewrap that contributed to leaks

See HOUSEWRAP AIR & VAPOR BARRIERS - Previously hidden leaks into the building walls

Photos of these SNAFUs are at SIDING, FIBER CEMENT DEFECTS.

It seemed likely that had the home been more than just ten years old, more extensive rot, insect damage, wall cavity mold contamination, and lost insulation values would all have accured.

The owners ultimately decided to remove the siding, thinking that either the material would be salvaged and re-installed correctly, or the "counterfeit" fiber cement siding woudl be replaced entirely with new product.

The contractor at the job we investigated considered the remove and salvage approach, though there would be some lost material due to damage during removal.

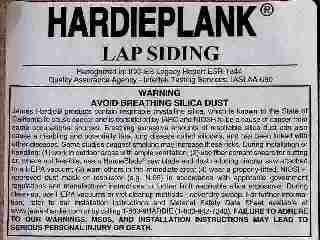

A second consideration during fiber cement siding material removal was the wish to avoid exposure to high levels of silica dust. Note the silica dust warning in the HardiePlank® product label shown at left.

Modern fiber cement products do not contain asbestos but silica dust from these products may be a hazard itself. Asbestos from older asbestos cement shingle siding and roofing products is a widely recognized hazards. For information about that different hazard, see ASBESTOS ROOFING / SIDING DUST.

How to Remove Fiber Cement Siding with Minimum Damage & Dust

Since the old counterfeit fiber cement siding was going to be removed anyway, the contractor chose to remove it with care, minimizing the damage, to give the owner the option of re-installing the orignial siding without gaps. (The owner later elected to toss the old siding and purchase new Hardieplank fiber cement siding - a step that was not without its own difficulties -

see SIDING, FIBER CEMENT MOISTURE LEVELS

Removing and reinstalling building siding, especially over a cosmetic issue, is a very costly approach but makes sense in some installations such as the fiasco of a fiber-cement siding installation job shown at SIDING, FIBER CEMENT GAPS.

Trying to just pull boards off of the building or pry them off will ... well basically it'll destroy the siding, breaking it at almost every attempt. In the photos above you can see how we used a nail punch to drive the siding nails through the siding to permit removal of the boards for possible re-use. After each board is punched and lifted carefully off of the wall we have to also pull all of the siding nails out of the sheathing to give a smooth surface for the next job.

At above right you can see the material lost on the back-side of the fiber cement siding boards when nails are punched through.

Watch out: when carrying any long fibre cement lap siding board, be sure to keep the board in the vertical or "as it would be on the wall" position. If you carry the board on the flat and it's got any length to it you're inviting breakage.

After "punching" to set the siding nails in through the fiber cement lap siding board, for boards more than about 6 feet in length, two workers should cooperate to carefully lift the board off of the building surface and carry it or hand it down for flat stacking under cover for protection from the weather.

Storing Re-Claimed Fiber Cement Lap Siding

The contractor stored the reclaimed lap siding indoors in the client's garage, stacked flat, and placed on a tarp to avoid picking up moisture from the floor.

Any loose debris was swept or HEPA vacuumed to avoid a possible silica dust hazard indoors, and the stack was also covered.

If the siding were to be re-used the contractor would have a bit of clean-up to do as well, to remove any caulk left adhered to the siding faces or ends. (Photo below).

The contractor would probably not bother to try chipping away at caulk bonded to the siding board ends; rather when the boards are being cut to size for re-use the messy ends will simply be chopped off before the board is cut to the new required length.

...

Continue reading at SIDING, FIBER CEMENT BOARD REPAIRS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommnded Articles

- SIDING, FIBER CEMENT

- CERTAINTEED WeatherBoards™

- CHINESE fiber cement siding

- FIBER CEMENT SIDING PAINTS

- FIBER CEMENT SHINGLE CUTTING TOOLS

- FIBER CEMENT SHINGLE REPAIRS

- JAMES HARDIEPLANK® FC SIDING

- NICHIHA ™ FIBER CEMENT SIDING FIELD REPORT

- SIDING CLEARANCE TO GROUND

- SIDING FIBER CEMENT COEFFICIENTS of EXPANSION

- SIDING, FIBER CEMENT CURL / LIFT DEFECTS

- SIDING, FIBER CEMENT DEFECTS - home

- SIDING, FIBER CEMENT DEFECT DIAGNOSTIC QUESTIONS

- SIDING, FIBER CEMENT GAP & CAULK SPECS

- SIDING, FIBER CEMENT GAPS

- SIDING, FIBER CEMENT GAP CURES

- SIDING, FIBER CEMENT IDENTIFICATION

- SIDING, FIBER CEMENT MAINTENANCE

- SIDING, FIBER CEMENT MOISTURE ABSORPTION

- SIDING, FIBER CEMENT MOISTURE LEVELS

- SIDING, FIBER CEMENT REMOVAL

- SIDING, FIBER CEMENT BOARD REPAIRS

- FIBER CEMENT PRODUCT MANUFACTURERS

- FIBER CEMENT PRODUCT STANDARDS

- FIBER CEMENT ROOF SHINGLE ASBESTOS TEST RESULTS

SIDING HARDBOARD IDENTIFICATION & CLAIMS

Suggested citation for this web page

SIDING, FIBER CEMENT REMOVAL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING SIDING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- James Hardie Fiber Cement Siding Best Practices, Appendix A, (2014) [PDF] available from James Hardie Corporation, 231 S. LaSalle St., Suite 2000

- [1] "James Hardie's Mesothelioma and Asbestos Legacy Continues, 2009", web search 03/01/2011, www.survivingmesothelioma.com

- [2] Killer Company, James Hardie Exposed, Matt Peacock, Harper Collins Australia, ISBN: 9780733325809; ISBN10: 0733325807

- [3] " Anyone else have HardiePlank siding on their house?", Early Retirement.org online blog, retrieved 1/14/2013, original source: http://www.early-retirement.org/forums/f27/anyone-else-have- HardiePlank-siding-on-their-house-19475.html

- [4] - DIY Chatroom, retrieved 1/17/2013, original source http://www.diychatroom.com/f2/ certainteed-weatherboard-vs-HardiePlank-4638/

- [5] Certainteed Weatherboard fiber cement siding and trim products - see certainteed.com/ or see certainteed.com/resources/sidingandtrimspecsheet.pdf

- [5a] "CertainTeed WeatherBoards™ Fiber Cement Siding Installation Manual", CertainTeed Corporation, 2012, CertainTeed Corporation, PO Box 880, Valley Forge PA 19482, Professional Help Line: 800-233-8990, Consumer Help Line: 800-782-8777, Website: Certainteed.com www.certainteed.com/resources/fc017.pdf retrieved 4/11/2013, [copy on file as Certainteed_Fiber_Cement_Siding_Install_fc017.pdf ]

- [5b] "Certainteed WeatherBoards™ Fiber Cement Siding Best Practices for Effective Job Site Management", CertainTeed Corporation, retrieved 4/15/13 original source: www.certainteed.com Copy on file as Certainteed_FC_Handling Brochure-Contractor_FC063.pdf

- [5c] Personal communication, M. Smith, CertainTeed Corp, Customer Service, to D Friedman 4/16/2013

- [5d] Consumer Services CertainTeed Corporation 803 Belden Road Jackson, MI 49203 Toll Free #: 800.999.3654 Fax #: 517.787.0023 Email: jtc.conservfc@saint-gobain.com

- [6] "Moisture Control in buildings: Putting Building Science in Green Building," Alex Wilson, Environmental Building News, Vol. 12. No. 5. [Good tutorial, "Moisture 101" outlining the physics of moisture movement in buildings and a good but incomplete list of general suggestions for moisture control - inadequate attention given to exterior conditions such as roof and surface drainage defects which are among the most-common sources of building moisture and water entry.--DJF]

- [7] J. Tibbets, "Green Houses", NCBI, retrieved 1/17/2013, original source: http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1469482/

- [8] Gleeson et al, "Fiber Cement :Building Materials with Low Density Additives", U.S. Patent 8,182,606, B2 5/22/2012, [adding low volumes of volcanic ash & hollow ceramic microspheres to cellulose fiber-reinforced building materials.

- [9] Thanks to reader Marie Carr for James HardiePlank siding photograph and case history information. 06/01/2008

- [10] JamesHardie HardiePlank® Lap Siding information can be found at the company's web page on this material:

https://www.jameshardie.com/products_siding_hardieplankLapSiding.py - [11] "30-Year Limited Warranty

HardiePlank® HZ5® Lap Siding, HardiePanel® HZ5® Vertical Siding,

HardieShingle® HZ5® Siding, HardieSoffit® HZ5® Panels", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [12] James Hardie Building Products, James Hardie CustomerLink™ Service Centre, 10 Colquhoun Street, Rosehill NSW 2142, Tel: 13 1103, Outside Australia 61 2 8837 4709,

Fax: 1 800 818 819. Hardie has operations in Australia, Asia, Canada, Europe, New Zealand, United States, and the Philippines. The company is a significant producer of fiber cement siding and backerboard. Email: info@JamesHardie.com and Website https://www.jameshardie.com/

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 -

1-888 J-HARDIE

1-888 542-7343 or by email to info@JamesHardie.com - [12b] "Technical Bulletin #9, Joint Flashing at Field Butt Joints", JamesHardie, retrieved 4/15/2013, original source: www.jameshardie.com, copy on file as James_Hardie_9-joint-flashing.pdf - quoting:

This Technical Bulletin is an explanation supporting the announcement made by James Hardie on September 8th, 2008 withdrawing its recommendation on the use of caulk at field butt joints for HardiePlank® lap siding. - [12] Hardiplank James Hardie warranty claims information:Tel: (866) 375-8603, Email: claims.administration@jameshardie.com

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 -

1-888 J-HARDIE

- [13] Instructions for application of HardiePlank lap siding can be found at https://www.jameshardie.com/products_siding_hardieplankLapSiding.py?openTab=jsnavLink4

- [14] "Homeowners Care and Maintenance Tips", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, included with product warranty information, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [15] "HardiePlank HZ5 Lap Siding Installation Requirements - Primed & Colorplus® Products",JamesHardie, November 2012, 1-800-9-HARDIE, 10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/install/hardieplank-hz5.pdf, [copy on file as Hardieplank-hz5_Install.pdf]

- [16] Technical Bulletin #9, Joint Flashing at Field Butt Joints, James Hardie corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/9-joint-flashing.pdf

- [17] Technical Bulletin #17, Fastening Tips for HardiePlank® Lap Siding, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/17 -fastening-tips-for%20-plank.pdf [copy on file]

- [18] Technical Bulletin #8, Expansion Characteristics of James Hardie® Siding Products, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/8-expansion-characteristics.pdf [copy on file]

- [19] Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions. Personal communication 3/20/2013.

- [20] Johnston, Colin D., Fiber-reinforced cements and concretes. Vol. 3., Taylor & Francis, (CRC Press) 2000. ISBN-10: 9056996940 ISBN-13: 978-9056996949, "This book summarizes and simplifies the results of a considerable body of research and practical experience with a wide range of fiber-reinforced cementitious composites."

- [21] Hugh Cairns, Subject 2 Home Inspections, is a professional home inspector in British Columbia, Canada, with offices in Kelowna B.C. and Kamloops B.C. He contributed the American Cemwood photo used at the top and within this article. Mr. Cairns can be contacted by telephone: 250-808-5777, or by email: okanagan@subject2homeinspections.com

- [22] Roger Xu, 徐银杰 (my Chinese name), Ningbo Yihe Greenboard Co., Ltd., No.189, Longzhen Road, Nongkenchang, Longshan Town, Cixi, Ningbo, Zhejiang China, Tel: 0086-574-63974118/83887668 Fax:0086-574-63974129/83887670 Mobile: 0086-15924317823; E-Mail: sales6@yhboard.com; Skype: dajiezi107, www.yhboard.com/en, personal correspondence 3/21/2013

- [23] James Hardieplank, personal communication with Daniel Friedman, 6/6/2013. We called James Hardie to ask for guidance in determining just how much moisture was "too much" in Hardieplank siding, after observing that siding at a job arrived visibly wet from the factory even though still inside its original sealed plastic wrapping. We called James Hardie's technical support line where a courteous representative told us he would refer us to Hardie's expert Benjaman Batres. Our call to Mr. Batres was returned by Stephanie (declined to give last name) from James Hardie's customer warranty service department. Stephanie informed us that there are no moisture numbers, that it is not possible to measure moisture in fiber cement siding (utter nonsense!) and repeatedly advised "Just read our instructions" or "So file a claim". Don't count on much help from James Hardie's customer warranty department on siding shrinkage or butt joint gap concerns. Gaps at Hardieplank siding butt joints continue to appear in the Hardieplank installation.

- MASONITE WOODRUF® ROOFING OR MASONITE OMNIWOOD® SIDING LAWSUIT SETTLEMENT NOTICE - PDF file

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.