Fiber Cement Siding Nailing Defects

Fiber Cement Siding Nailing Defects

FC siding & shingle nailing guides, mistakes, repairs

- POST a QUESTION or COMMENT about installing fiber cement siding troubleshooting, defect causes, remedies, warranties, warranty claims

Fiber cement siding defects, failures, problem troubleshooting:

This article describes the types of problems that occur in fiber cement siding installations in North America, including siding shrinkage gaps at butt joints, cracks, breaks, and loose or buckling siding boards or shakes.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Improper or Inadequate Nailing of Fiber Cement Siding - Loose Siding

Here we illustrate FC siding defects that can be traced to nailing errors including:

Inadquate number of nails

Wrong type of nails

Nails improperly located

Exposed nails where blind nailing was preferred

Damage to the siding during nailing

Nails into an inadequate sheathing (too thin, too soft, damaged, rotted) or that should have caught a stud and didn 't

In my first loose fiber cement siding photo, the fact that I can lift the board away from the wall suggests inadequate nailing - nails omitted.

Unfortunately more nailing defects were apparent at the gable ends of the home where the lap siding abutted (or was supposed to abut) the gable end trim.

Left un-nailed the corners of most of these siding boards were curling away from the building. .

Consistent with our earlier warning that one bad installation feature suggests more SNAFUs are in store, even in a casual inspection we noticed other disappointing details on this home that was less than ten years old:

- Rotted trim at windows and doors

- Openings left un-sealed where mechanicals penetrated the building walls

- Clogged non-functional weep holes in brick veneers

- Improperly-constructed masonry patio and steps abutting wood siding and trim, settling, trip hazards, rot

Exposed Nails in HardieBoard® or in Fiber Cement Siding

Question: Damage, peeling and discoloration has occurred around many nails in Hardi Board & Batten Siding

Question: Damage, peeling and discoloration has occurred around many nails in Hardi Board & Batten Siding

2018/12/25 Evan said:

I've had Hardi Board and Batten installed for less than one year.

Damage, peeling and discoloration has occurred around many nails.

Please see photos.

Reply:

That looks like a surface nail or face-nailed fastener that was poorly set and patched over around a hammer ding-mark.

If face nailing is required the nails should be driven just flush with the surface, not into-it and not breaking the board surface. And painting-over is not normally recommended.

If many of your nails look like the photo then the siding installation was not the best job. Also I raise question about whether or not the proper type of nail was used.

Here is what the company says about face nailing their product:

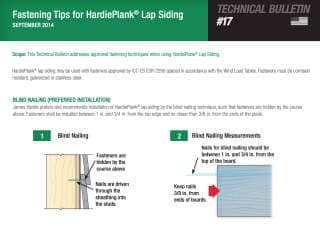

Face nailing is applicable where dictated by building code, in high wind areas, and when fastening is to OSB or equivalent sheathing without penetrating into studs.

Face nailing exposes the fastener head to the elements and allows for the fastener to penetrate through two sheets of overlapped plank.

Fasteners shall be installed between 3/4 in. and 1 in. from the bottom edge of the board and the head must be snug, not counter sunk or overdriven. ( JamesHardie 2014)

So from your photo I suspect

- That the wrong nail type was used - a small-headed nail

- The nail may not be properly located as it appears to be popping

- There was a nailing error - a hammer ding - leaving a crescent depression in the siding

- A repair effort was made using a filler and maybe a paint.

- I also see some red discoloration that suggests that whatever was used to fill the hammer ding may be inviting a leach-out of the binder in the Hardi-Board siding.

- I can't comment on the nail location from just your single photo.

It is possible to fix this damage by removing the bad sealant, setting the nail. sealing the surface against bleeding (perhaps lacquer primer), filling with a Hardie-approved filler, and painting with a color-matched paint. However unless you make a suitable modeling tool every one of these damage spots will remain rather noticeable.

Illustration: from James Hardie Siding Products BEST PRACTICES – INSTALLATION GUIDE SIDING AND TRIM PRODUCTS pp 43-70 pages on board and batten installation.

None of the illustrations specifically address vertical batten nailing, and the presumption is that nails follow the face-nailing instructions for other HardieBoard trim.

When I installed traditional wood board and batten siding we took care in nailing the battens to avoid splitting as the underlying boards expand and contract with changes in temperature and moisture.

To avoid that problem we either nailed the batten in the underlying board vertical butt joint gap so that the nail was not in either board - both boards could float below the batten

or we nailed the batten along one side so that it was nailed through just one of the two abutting vertical boards.

Above: a modern board and batten sided building I inspected in 2001 - this was not my siding job and this is NOT JamesHardie board and batten Hardieboard siding. In this photo we see that the apparently un-flashed horizontal joints are likely to lead to trouble.

It would help my analysis to see more photos and to know

- how many of these dings are present,

- where they are located in the siding,

- the age of the building

- the city and country of the building

- specific Hardie Product name if you have it

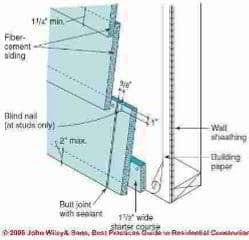

While there may be different requirements for the vertical battens, otherwise with just a few exceptions such as pin-backs at the bottom edge of the first course of siding and some trim details, there should be NO exposed nails with Hardi Board siding. siding is normally blind-nailed.

Here is a clip from the company's instructions

JamesHardie Siding installation tips are available in both detailed instructions and in technical bulletins from the manufacturer, some of which we provide here.

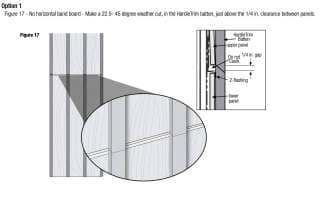

- FIBER CEMENT SIDING NAILING DETAILS - basic FC siding nailing procedures from Steve Bliss Best Construction Practices

- FASTENING TIPS FOR HARDIEPLANK® LAP SIDING SEPTEMBER 2014 Technical Bulletin No. 17 [PDF] JamesHardie Corporation, Website: www.jameshardie.com Tel: 1-800-442-7343 retrieved anew 2018/12/25 original source: www.jameshardie.com/JamesHardieMainSite/media/Site-Documents/TechnicalBulletins/17-fastening-tips-for-hardieplank-lap-siding.pdf

- James Hardie Siding Products BEST PRACTICES – INSTALLATION GUIDE SIDING AND TRIM PRODUCTS pp 1-31 [PDF] Version 9, April 2018, pp. 1-31, pertinent to HardiePlank®, HardieShingle®, HardiePane®, HardieTrim®, HardieSoffit®

Note: Instructions for face nailing HardieBoard trim and board and batten siding are given on p. 59 in the section cited below.

- James Hardie Siding Products BEST PRACTICES – INSTALLATION GUIDE SIDING AND TRIM PRODUCTS pp 43-70 [PDF] Version 9, April 2018, pp. 1-31, pertinent to HardiePlank®, HardieShingle®, HardiePane®, HardieTrim®, HardieSoffit®

- JamesHardie, HARDIEPANEL VERTICAL SIDING INSTALLATION GUIDE [PDF] (2013) pp. 108 - 116 in JamesHardie's Siding Installation Manual. JamesHardie Corporation, Website: www.jameshardie.com retrieved 2018/12/25, original source: https://www.buildsite.com/pdf/jameshardie/HardiePanel-Vertical-Siding-Product-Data-1015262.pdf

- James Hardie HardieTrim® Boards INSTRUCTIONS [PDF] (2018) retrieved 2018/12/25 original source: https://www.jameshardie.com/d2w/installation/hardietrim-44-54-hz10-us-en.pdf

Excerpt:

These instructions are to be used for HardieTrim® HZ10® Boards ONLY and are NOT VALID in the following states: AK, UT, ID, CO, WY, MT.

These instructions are also NOT valid in portions of WA, OR, CA, NV, AZ, NM. Enter your zip code at www.hardiezone.com to find out what zone applies to your location.

Use 2 in. minimum 16 ga. finish nails to attach HardieTrim boards to wood frame construction. ET&F or equivalent fasteners or screws may be used to attach HardieTrim

boards to steel frame construction.

Fastening instructions are similar for all applications. When using finish nails, position nails no closer than 1/2 in. from the edges of the trim and for all other fasteners no closer than 3/4 in.

Fasteners must be no closer than 1 in. from ends of trim and spaced a maximum of 16 in. O.C. Ensure trim is adequately fastened.

James Hardie recommends using stainless steel finish nails when installing HardieTrim products.

...

Continue reading at SIDING, FIBER CEMENT DEFECT DIAGNOSTIC QUESTIONS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see this

FC Siding Defect Article Series Contents

- SIDING, FIBER CEMENT DEFECTS - home

- SIDING, FIBER CEMENT SHINGLE DEFECT DIAGNOSIS

- SIDING, FIBER CEMENT DEFECT DIAGNOSTIC QUESTIONS

- BUCKLING FIBER CEMENT SIDING

- BUTT JOINT CURLING in FIBER CEMENT SIDING

- BUTT JOINT GAPS & FIBER CEMENT SIDING SHRINKAGE

- BUTT JOINT BACK FLASHING OMITTED

- CAULKING ERRORS on FIBER CEMENT SIDING

- FIBER CEMENT SIDING NAILING ERRORS

- HOUSEWRAP DAMAGE

- HOMEOWNER COMMENTS on FIBER CEMENT SIDING

- LOOSE FIBER CEMENT SIDING, NAILING FAILURES

- PRIME COAT on END CUTS of FIBER CEMENT SIDING

- SPLITS in FIBER CEMENT SIDING

- STARTER STRIP for FIBER CEMENT SIDING

- MOISTURE ABSORPTION into FIBER CEMENT SIDING

- TEMPERATURE EFFECTS on FIBER CEMENT SIDING

- MANUFACTURER CONTACT INFORMATION

SIDING HARDBOARD IDENTIFICATION & CLAIMS

Suggested citation for this web page

SIDING, FIBER CEMENT NAILING DEFECTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING SIDING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- James Hardie Fiber Cement Siding Best Practices, Appendix A, (2014) [PDF] available from James Hardie Corporation, 231 S. LaSalle St., Suite 2000

Chicago, Illinois 60604, USA, Website: https://www.jameshardie.com or in Canada: http://www.jameshardie.ca - [2] Killer Company, James Hardie Exposed, Matt Peacock, Harper Collins Australia, ISBN: 9780733325809; ISBN10: 0733325807

- [3] " Anyone else have HardiePlank siding on their house?", Early Retirement.org online blog, retrieved 1/14/2013, original source: http://www.early-retirement.org/forums/f27/anyone-else-have- HardiePlank-siding-on-their-house-19475.html

- [4] - DIY Chatroom, retrieved 1/17/2013, original source http://www.diychatroom.com/f2/ certainteed-weatherboard-vs-HardiePlank-4638/

- [5] Certainteed Weatherboard fiber cement siding and trim products - see certainteed.com/ or see certainteed.com/resources/sidingandtrimspecsheet.pdf

- [5a] "CertainTeed WeatherBoards™ Fiber Cement Siding Installation Manual", CertainTeed Corporation, 2012, CertainTeed Corporation, PO Box 880, Valley Forge PA 19482, Professional Help Line: 800-233-8990, Consumer Help Line: 800-782-8777, Website: Certainteed.com www.certainteed.com/resources/fc017.pdf retrieved 4/11/2013, [copy on file as Certainteed_Fiber_Cement_Siding_Install_fc017.pdf ]

- [5b] "Certainteed WeatherBoards™ Fiber Cement Siding Best Practices for Effective Job Site Management", CertainTeed Corporation, retrieved 4/15/13 original source: www.certainteed.com Copy on file as Certainteed_FC_Handling Brochure-Contractor_FC063.pdf

- [6] "Moisture Control in buildings: Putting Building Science in Green Building," Alex Wilson, Environmental Building News, Vol. 12. No. 5. [Good tutorial, "Moisture 101" outlining the physics of moisture movement in buildings and a good but incomplete list of general suggestions for moisture control - inadequate attention given to exterior conditions such as roof and surface drainage defects which are among the most-common sources of building moisture and water entry.--DJF]

- [7] J. Tibbets, "Green Houses", NCBI, retrieved 1/17/2013, original source: http://www.ncbi.nlm.nih.gov/pmc/articles/PMC1469482/

- [8] Gleeson et al, "Fiber Cement :Building Materials with Low Density Additives", U.S. Patent 8,182,606, B2 5/22/2012, [adding low volumes of volcanic ash & hollow ceramic microspheres to cellulose fiber-reinforced building materials.

- [9] Thanks to reader Marie Carr for James HardiePlank siding photograph and case history information. 06/01/2008

- [10] JamesHardie HardiePlank® Lap Siding information can be found at the company's web page on this material:

https://www.jameshardie.com/products_siding_hardieplankLapSiding.py - [11] "30-Year Limited Warranty

HardiePlank® HZ5® Lap Siding, HardiePanel® HZ5® Vertical Siding,

HardieShingle® HZ5® Siding, HardieSoffit® HZ5® Panels", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [12] James Hardie Building Products, James Hardie CustomerLink™ Service Centre, 10 Colquhoun Street, Rosehill NSW 2142, Tel: 13 1103, Outside Australia 61 2 8837 4709,

Fax: 1 800 818 819. Hardie has operations in Australia, Asia, Canada, Europe, New Zealand, United States, and the Philippines. The company is a significant producer of fiber cement siding and backerboard. Email: info@JamesHardie.com and Website https://www.jameshardie.com/

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 -

1-888 J-HARDIE

1-888 542-7343 or by email to info@JamesHardie.com - [12b] "Technical Bulletin #9, Joint Flashing at Field Butt Joints", JamesHardie, retrieved 4/15/2013, original source: www.jameshardie.com, copy on file as James_Hardie_9-joint-flashing.pdf - quoting:

This Technical Bulletin is an explanation supporting the announcement made by James Hardie on September 8th, 2008 withdrawing its recommendation on the use of caulk at field butt joints for HardiePlank® lap siding.

- JamesHardie Corporation, in the U.S. can be contacted at 26300 La Alameda, Suite 400,

Mission Viejo, California 92691 -

1-888 J-HARDIE

- [13] Instructions for application of HardiePlank lap siding can be found at https://www.jameshardie.com/products_siding_hardieplankLapSiding.py?openTab=jsnavLink4

- [14] "Homeowners Care and Maintenance Tips", 1-800-9-HARDIE

10901 Elm Avenue Fontana, CA 92337, included with product warranty information, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/warranty/hz5.pdf [copy on file as Hardieplank_Warranty_hz5.pdf] - [15] "HardiePlank HZ5 Lap Siding Installation Requirements - Primed & Colorplus® Products",JamesHardie, November 2012, 1-800-9-HARDIE, 10901 Elm Avenue Fontana, CA 92337, retrieved 1/18/2013, original source: https://www.jameshardie.com/pdf/install/hardieplank-hz5.pdf, [copy on file as Hardieplank-hz5_Install.pdf]

- [16] Technical Bulletin #9, Joint Flashing at Field Butt Joints, James Hardie corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/9-joint-flashing.pdf

- [17] Technical Bulletin #17, Fastening Tips for HardiePlank® Lap Siding, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/17 -fastening-tips-for%20-plank.pdf [copy on file]

- [18] Technical Bulletin #8, Expansion Characteristics of James Hardie® Siding Products, James Hardie Corporation, retrieved 1/19/2013, original source: https://www.jameshardie.com/pdf/technical-bulletins/8-expansion-characteristics.pdf [copy on file]

- [23] James Hardieplank, personal communication with Daniel Friedman, 6/6/2013. We called James Hardie to ask for guidance in determining just how much moisture was "too much" in Hardieplank siding, after observing that siding at a job arrived visibly wet from the factory even though still inside its original sealed plastic wrapping. We called James Hardie's technical support line where a courteous representative told us he would refer us to Hardie's expert Benjaman Batres. Our call to Mr. Batres was returned by Stephanie (declined to give last name) from James Hardie's customer warranty service department. Stephanie informed us that there are no moisture numbers, that it is not possible to measure moisture in fiber cement siding (utter nonsense!) and repeatedly advised "Just read our instructions" or "So file a claim". Don't count on much help from James Hardie's customer warranty department on siding shrinkage or butt joint gap concerns. Gaps at Hardieplank siding butt joints continue to appear in the Hardieplank installation.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.