Interior Wall Coverings

Interior Wall Coverings

A Guide to Building Age & Choices of Wall Sheathing or Coverings Indoors

- POST a QUESTION or COMMENT about ages & types of wall & ceiling materials, installations & practices

Guide to beaverboard, drywall, plaster & paneling on interior walls:

Ages & types of finish materials used for interior walls & ceilings: here we provide a photo guide to identifying types of plaster, lath, Beaver board, Upson Board, and Drywall to help identify these interior building wall and ceiling coverings and as an aid in determining the age of a building.

This article discusses the identification and history of older interior building surface materials such plaster and lath, Beaverboard, and Drywall - materials that were used to form the (usually) non-structural surface of building interior ceilings and walls.

Our page top photo shows hand-split wooden lath backing for a plaster interior wall.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Guide to Plaster & Drywall & Other Interior Wall Coverings as Indicators of Building Age

Article Series Contents

- DRYWALL, FIBERBOARD, PLASTER INTERIORS

- ASBESTOS CEMENT CEILING & WALL PANELS

- ASBESTOS in DRYWALL - separate article

- BEAVERBOARD - separate article

- UPSON BOARD - MDF used as interior sheathing and in many other applications from puzzles to oil paintings

- COATING TYPE CEILING & WALL SURFACES: CATALOG OF

- DRYWALL & GYPSUM BOARD - separate article

- DRYWALL TYPE IDENTIFICATION STAMPS - separate article

- FIBERBOARD SHEATHING - separate article, Beaverboard, Nu-Wood, Insulite, and many others on building exteriors & interiors

- GYPSUM BOARD PLASTER LATH SYSTEMS - rock lath

- HARDBOARD BATHROOM & KITCHEN PANELS

- MASONITE & HARDBOARD CEILING & WALL COVERINGS

- METAL LATH for PLASTER

- PANELING, WOOD & WAINSCOTING

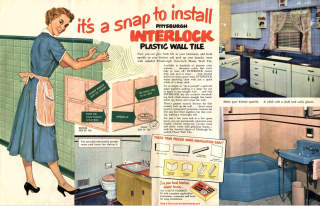

- PLASTIC INTERLOCKING BATH TILES

- SACKETT BOARD

- SHEATHING, GYPSUM BOARD - gypsum panels used for exterior sheathing, water-resistant, were also used in some interior construction such as kitchens and bathrooms

- UPSON BOARD

- WOOD FIBRE INSULATING PANELS

- WOOD LATH for PLASTER or STUCCO

Above we show a photograph of hand-split wood lath and plaster wall, from the wall-cavity side. Ca 1800. There are several generations of plaster and lath, plaster board, and drywall which have been used in buildings.

[Click to enlarge any image]

History of Types Interior Plaster: split wood lath, sawn wood lath, expanded metal lath, "rock lath" or plasterboard, drywall, & tainted Chinese drywall

The age of a building can be determined quite accurately by documentation, but when documents are not readily available, visual clues such as those available during a professional home inspection can still determine when a house was built by examining its components, building materials, even nails, fasteners, and types of saw cuts on lumber.

We name and illustrate these and discuss their periods of use below as an aid in finding out how old a building is and tracing its history.

Asbestos Cement & Fiber Cement Fireproof Ceiling & Wall Panels

Asbestos-cement panels and later non-asbestos-containing fiber-cement panels were widely used as fireproof coverings for walls, ceilings, even floors in various applications such as in boiler rooms as well as in chemical laboratories and other areas where an inert, durable, fire-resistant surface was needed.

See CEMENT ASBESTOS SHEET PRODUCTS for the age, history of and details about cement-asbestos fireproof panels used in and on buildings.

History of Beaver Board & Upson Board Wall Coverings in North America

Beaver-board and Upson Board are a wood fiber product used as an inexpensive interior wall covering and draft blocker from about 1903 when Beaver Board was invented by J.P. Lewis in Beaver Falls, NY, to the 1950s, with its near-twin product Upson Board continuing in use into at least the 1980's.

Our photographs (below) show this product from it's back or wall cavity side. On the exposed side this wood fiberboard product was usually painted and its joints covered with wood lath or other trim.

In some applications Beaverboard or UpsonBoard was covered with wallpaper. Still later in the life of many buildings where Beaver Board was installed it was later covered with drywall to provide a more fire-resistant surface.

Beaverboard takes its name from the Beaver N.Y. and the Beaver Board Companies that produced this product until that firm was purchased by Certain Teed Prod cuts in 1928. Beaver Board and Upson Board were produced by the Beaver Wood Fibre Company Limited, in Thorold, Ontario.

Beaver board's competition was from Upson Processed board (John Upson, Upson Company, Lockport, NY) which was produced beginning in 1910.

As late as the 1950's Upson Board was used in prefabricated houses and exterior building sheathing and in recreational vehicles.

Upson purchased the Beaver Board plant from CertainTeed in 1955. Upson began its decline in the 1970's and closed in 1984, opening later that year as Niagara Fiberboard.

Beaverboard and other paper or fiberboard products were used for exterior wall sheathing, as we show in this photograph at left.

How to Identify Beaver Board

Beaver Board was marked on the back of each sheet with an ink-stamped trademark and brand.

Details about BeaverBoard used on interior walls and ceilings are found

at BEAVERBOARD in our article on building sheathing materials identification.

Upson Board Identification

Upson Board, a medium-density fiberboard made from recycled wood fibers, embossed its marking into the board itself, and a "Blue Center" (illustrated below thanks to one of our readers) runs through every piece of the board.

See details now found at

UPSON BOARD - MDF used as interior sheathing and in many other applications from puzzles to oil paintings

Ceiling & Wall Covering Materials Using Plaster, Drywall / Gypsum Board, or Stucco

This list of common ceiling and wall coverings is in order roughly by age or history of use. It is thus not in alphabetical order.

- Mud

used as a plaster over split wood lath or woven wood lath

An example of mud plaster is below in this article

at MUD PLASTER - Horsehair

mixed with plaster or cement for building exterior wall covering.

A photo of horse hair plaster is shown here, courtesy of an InspectApedia.com reader who had this material tested for asbestos - which was found to be absent.

See PLASTER INGREDIENTS, MIX, PROPERTIES for details about this early plaster material. - Plaster of paris

applied in at least two layers,a rough brown or scratch coat and a smooth white plaster top coat over hand split or sawn wood lath.

Two coat and three-coat plaster on lath systems are detailed

at PLASTER TYPES & METHODS in BUILDINGS - Plaster

wall or ceiling coverings of the same general formula was later applied

over EXPANDED METAL LATH

See PLASTER TYPE IDENTIFICATION for a photo guide to different plastering systems used in buildings for walls, ceilings, and fireproofing..

For plaster type surfaces used on building exteriors,

see STUCCO WALL METHODS & INSTALLATION. - Gypsum Board / Gyp-Rock / Rock Lath:

Plasterboard with round holes punched at regular intervals substituted for the plaster scratch coat, nailed to wall studs, eliminating the wood lath requirement. A top coat of plaster was applied to the plaster board.

"Ears" of oozing plaster pushed through the round holes helped hold the plaster top coat in place. Essentially synonymous are drywall, gyp rock, gypsum board, plasterboard when used as a backer for a top coat of plaster.

For details about gypsum board used as a plaster base

see GYPSUM BOARD ROCK LATH SYSTEMS

Sackett Board

Above: probably Sackett Board, a USG product first produced by US Gypsum after USG's purchase of the Sackett Plaster Board Company in 1909.

- Sackett Board:

Sackett Board, first produced by the Sackett Plaster Board Company, was formed of multiple layers of paper and plaster such as the product shown in our reader photo above.

The Sackett Board appears to have been top-coated with a layer of plaster.

Sackett Board was probably the first gypsum-board product widely-used as a wall and ceiling covering, typically top coated with a finish-layer of plaster.

See SACKETT BOARD for details. - Stucco wall & ceiling coatings

on interior surfaces may be installed as traditional stucco, a cementious product, or as a stucco look-alike using textured paints or coatings including drywall or plaster.

See SIDING EIFS & STUCCO - topic home, for a detailed article series about this material and its use on both exteriors and interiors of buildings. - Drywall,

a lighter gypsum formula, with joints taped with paper (later fiberglass or plastic mesh) and coated with joint compound. Available in 1/4", 3/8", 1/2", and 3/4" thickness, typically 4' x 8' or4' x 12'. Earlier drywall was secured with drywall nails;

Modern drywall is secured to wall studs using machine-driven drywall screws or in some applications glue as well as drywall screws.

The composition of modern drywall or gypsum board is given

at DRYWALL & GYPSUM BOARD

Also see DRYWALL TYPE IDENTIFICATION STAMPS

Gypsum Board Lath for Plaster Walls & Ceilings = Rock Lath

Our photo (above left) shows perforated gypsum board panels that were used as plaster lath.

Solid gypsum board (below) was also used as a support for a plaster finish coat. Often this material was applied in two-foot widths - a feature that the inspector may spot by noticing scalloped ceilings and walls or even cracks that appear regularly on 24" centers.

According to some patent disclosures (given below on this page) non-perforated gypsum board panels used as a plaster base included versions with depressions or indentations to better-receive and adhere the plaster top coats.

We provide a more-detailed discussion

at GYPSUM BOARD ROCK LATH SYSTEMS - perforated or solid gypsum boards as plaster base: "Rock lath", including the history of use of "rock lath" or perforated gypsum board or "button board" as a plaster base or lath-substitute material.

Expanded Mesh Metal Lath for Plaster Walls

Our photo shows expanded mesh metal lath used as plaster lath support for ceilings and walls; this material was also used on building exterior walls to support a stucco finish. Metal lath was on occasion used also to support poured concrete ceilings (shown here) - unlikely to provide adequate strength for a thick pour unless additional reinforcement was used.

Depending on building age we may find a mixture of multiple types of plaster support, wood lath, gypsum board lath, and metal lath. Wall or ceiling or stucco crack patterns may follow the borders of metal lath segments, especially if the lath was not securely nailed.

See PLASTER LATH, METAL for details about the types, uses, & installation of expanded metal lath.

See PLASTER TYPE IDENTIFICATION for details about plaster used in or on buildings. .

Masonite™ and Other Hardboard Interior Wall & Ceiling Products: Identification

Masonite hardboard panels are often found as a utility cladding in buildings on walls and ceilings. This article explains the utility usage of hardboard interior products, and we exclude wood or wood-like wall or ceiling paneling products.

Those are discussed

at HISTORY of the USE of WOOD & OTHER WALL PANELING in North America.

History, more photos, & dates of the invention, production, & use of Masonite™ and similar hardboard products are

at HARDBOARD MASONITE™ & OTHER BRANDS

Bathroom & Kitchen Laminated Hardboard Panels

Laminated Masonite® and other hardboard products have been widely used as water-resistant panels to cover walls and sometimes ceilings in bathrooms, kitchens, and other work areas.

Laminated Masonite® and other hardboard products have been widely used as water-resistant panels to cover walls and sometimes ceilings in bathrooms, kitchens, and other work areas.

A hard thin plastic laminate was applied to the hardboard surface to simulate marble, tile, or other materials.

Laminated hardboard was widely used in other applications as well, including baby furniture, lab surfaces, RVs, cabins, ornamental wall wall coverings simulating tile, in various pre-fabricated structures, and even in some automobile door panels and airplane panels.

Cleverly the U.S. army used a shipping crate for latrine parts that combined tempered Masonite or the like panels that formed a lining to convert the shipping crate to a latrine enclosure. (Sheffield 1955).

Above: laminated hardboard as a bath tub surround in an older U.S. home. Scratches or nicks in the surface of the hardboard allow water to penetrate, causing the dark brown ringed stains at this tub surround.

Other water penetration in older hardboard wall coverings can cause the formation of a roughened or rippled surface.

When water damage is severe the hardboard softens, swells, and may leak into the wall cavity.

See also IDENTIFY Masonite™ and other hardboard Sheet and Siding Building Materials

Because of its lighter weight and alternative production means hardboard-based wall and ceiling coverings found a place where previously cementious products such as asbestos cement or later fiber cement board was used on walls and ceilings as a fireproof wallboard.

Also see CEMENT ASBESTOS SHEET PRODUCTS

Below: another coated Masonite® type hardboard used around a bath tub.

History, Research, Examples of Unitized Bathroom Wall & Ceiling Coverings & Tub Surrounds Using Coated or Laminated-Surface Hardboard

- Tenunon, Charles G., "Building unit." U.S. Patent 2,130,911, issued September 20, 1938.[Using cementious material or fiber cement or asbestos cement board - a precursor to the products discussed above]

Excerpts:

It has been proposed heretofore to form building units to simulate brick of regular outline with horizontally and vertically extending mortar spaces or mortar simulating lines but such constructions are not capable of use in simulating material of irregular outline such as the uneven edges of stone, rubble or broken slate.

It has also been proposed to form shingles and siding with irregular edges but these edges are free and tend to curl up or to be displaced by the wind.

Flooring such as linoleum is sometimes formed to simulate broken flagstones or the like but such materials are expensive and are not adapted for use on open porches or in courtyards and similar locations where it is exposed to the weather. - Nilson, Stanley E., "Shower cabinet." U.S. Patent 2,423,722, issued July 8, 1947. This patent was originally assigned to the Fiat Metal Mfg. Co. describing an earlier sheet-metal shower enclosure.

- Sheffield, Frederick T., "Shipping crate for latrine fixtures convertible into complementary latrine structure." U.S. Patent 2,712,164, issued July 5, 1955.

- Gick, James E., "Ornamental tile and method of fabrication." U.S. Patent 2,982,042, issued May 2, 1961. [Using ceramic tile bonded to Masonite type hardboard]

Excerpts:

In the conventional construction of a tile panel having a relief design with a mosaic background, for example, the relief design is incorporated in one or more ceramic plaques much larger than the individual mosaic bodies, and the plaque or plaques are cemented to a base member along with the mosaic background bodies.

Such a construction is relatively expensive for a number of reasons.

...

As heretofore stated, the relief design D is customarily embodied ina-'=ceramic plaque which is also bonded to the base member, being made of linocellulose hard board which is commercially available under the trade name Masonite. - King, Bernie E., "Unitized bathroom structure." U.S. Patent 3,110,907, issued November 19, 1963. This patent was assigned to the Rohr Corporation.

Excerpt:

As may best be seen in FIGS. 3, 4-and 8, the bottom of tub 20 is reinforced with a tempered Masonite'board'57 so that any weight concentrations applied to the bottom surface 56 of the tub are evenly distributed over its surface area.

In the tub floor construction as shown, a reinforced plastic layer is applied above and below the Masonite board 57, the upper layer "56 of which is formed concurrently with the fabrication of the aforementioned gel coat 43 and reinforced layer 47 of plastic shell 28.

The Masonite board '57 is then applied to this initial plastic layer 56 and the additional layer, or outer plastic bottom layer 58 of the tub, is thereafter applied to the board 57 to thus completely encapsulate the board within the reinforced plastic. - Wokas, Albert L., "Prefabricated bathrooms and prefabricated restrooms." U.S. Patent 3,162,863, issued December 29, 1964.

Excerpts:

This invention relates to the prefabrication of rooms, especially restrooms which may or may not contain baths. It is especially concerned with the prefabrication of two restrooms which are built together as a single unit package ready for installation in a building.

These package units are made up of walls, floors, ceilings, doors, and completely equipped interiors, including all the plumbing fixtures, water lines, and waste lines in place, tested and ready for use when the package units are delivered to the sites. - Dobija, Michael J. "Tub surround." U.S. Patent 4,109,426, issued August 29, 1978. This patent was assigned to the Masonite Corporation. Excerpt:

A tub surround includes first and second identical corner sections and first, second and third identical panel portions. The tub surround is assembled by positioning a first panel between the two corner sections thereby defining one wall. The remaining panel sections are joined with each of the corner portions to define second and third walls.

Each corner section includes first and second legs extending at right angles from each other.

The ends of the legs extending from the corner sections lie on a plane parallel to and separated from the plane of each side thereby defining a joint behind which the edges of the panels may be positioned. The corner sections further include shelves extending between the legs of the corner sections.

On 2021-05-27 by (mod) - is it "safe" to say this bath wall "tile" contains asbestos?

If by "safe to call this wall covering asbestos" you mean" is it very likely that I'm right and it's an asbestos material: my answer is no, we have no basis to know what that material is from your photo alone,

but

If by "safe" you mean "am I erring on the safe side by treating an unknown wall-covering fake tiles as asbestos" - sure, it's always "safer" to treat an unknown material as possibly hazardous.

If you look at the material more-closely you may see that it is actually a wood-based fiberboard or hardboard product laminated with a plastic or vinyl skin to resemble tile - as that was a very common wall covering.

At our description of Masonite-type hardboard products found

at HARDBOARD MASONITE™ & OTHER BRANDS

we include the1960s magazine advertisement for interior bathroom Masonite™ temprtile wallboard shown above. Temprtile was a hardboard-backed wall covered with a laminated plastic "skin" covering simulating ceramic tile, installed by gluing sheets of the surfaced hardboard to the original walls.

At our description [above on this page]

we note that

Laminated Masonite® and other hardboard products have been widely used as water-resistant panels to cover walls and sometimes ceilings in bathrooms, kitchens, and other work areas.

A hard thin plastic laminate was applied to the hardboard surface to simulate marble, tile, or other materials.

Meanwhile, take a closer look at the edge or at any points of wear or damage to see if you can identify brown woody fibrous backerboard - and attach a sharp photo of what you find here as a page bottom "Comment".

Watch out: some floor and wall covering adhesives also contained asbestos - avoid making a dusty mess.

Those details are at ASBESTOS-CONTAINING MASTIC DANGEROUS?

On 2021-05-27 by Ty

Is it safe to say that this material contains asbestos? Might be hard to tell from only one image

On 2021-05-27 - by (mod) -

@Ty,

@Ty,

Sure it's safe to cover that old faux-tile wall material, but take care first to satisfy yourself that there were no leaks into the wall cavities as there could be a hidden mold problem; the time to find and clean up any leak damage is exactly now rather than later when the bathroom has been finished.

On 2021-05-27 by Ty

First time home buyer and bought a house that was built in the 1930's and remodeled around 1960. We have seen there is asbestos flooring in parts of the house but my question is about a recent finding during a bathroom demo. The blue tile is in a sheet of vinyl with no specific dimensions. It has a circular or flower like adhesive on the back of the sheet. Is it safe to say this is asbestos? Is it safe to cover?

[Photo above]

This Q&A on possible asbestos in faux or "fake" bathroom or kitchen wall tiles was posted originally

at ASBESTOS FLOORING IDENTIFICATION

Interlocking Plastic Wall Tiles

Some 1950s and 1960s "faux" bathroom and kitchen walls were covered using interlocking plastic tiles produced by companies using this new "space-age" material

Some 1950s and 1960s "faux" bathroom and kitchen walls were covered using interlocking plastic tiles produced by companies using this new "space-age" material

Shown here is "Pittsburgh Interlock Plastic Wall Tile" first patented in 1943 (Pauli) and popular in North America from the 1940s through 1960s, probably most-often as a retrofit wall covering in existing bathrooms when homeowners got tired of repairing or re-painting water-damaged walls.

Plastic interlocking kitchen and bath tiles were, perhaps, a more-durable alternative to HARDBOARD BATHROOM & KITCHEN PANELS in areas where water splashing was likely.

In the U.S., Pittsburgh enjoyed a long and historic role in the development of bath and kitchen wall tiles in the U.S., making it no accident that the Pittsburgh Interlocking Plastic Wall Tile product originated there.

While the first ceramic tiles in the U.S. were probably produced by the US Pottery in Bennington, Vermont, it was the Pittsburg Encaustic Tile Company who had the first commercial success with ceramic wall tiles beginning in 1876.

These key patent disclosures help us assign possible dates to homes where plastic interlocking wall tiles are or were used. For old house restorers who like plastic wall tiles you may find some of these products still for sale as "antique" building products on web-stores like e-Bay.

- Pauli, Jr Charles D. WALL TILE [PDF] U.S. Patent 2,323,417, issued July 6, 1943.

Excerpt: My invention has for its primary object the provision, as a new article of manufacture, of a compact, light-weight, durable tile of homogeneous synthetic plastic, which may be conveniently applied to and upon a wall, which is uniquely provided with interlocking members for enabling rigid, water-proof securement of the tiles together and in place on a wall, which may be efficiently and economically fabricated by high-production molding methods and to substantially any desired shape without distortion and strain, and which is highly satisfactory in the performance of its intended functions.

[Editor's note: my mother Teal, entertaining herself while expecting, glued tiles like this to what was my future bathroom wall after I was produced in September of the same year.] - Brown, Richard G. INTERLOCKING WALL TILE [PDF] U.S. Patent 2,490,577, issued December 6, 1949, filed by and assigned to the Pittsburgh Plastic Tile Company

Excerpt:

The tiles preferably are made of a plastic suc has polystyrene although they may be made of other materials. The tiles are affixed to a wall by applying a gob of mastic cement to the rear face of the tile and pressing the tile against a wall. - Lopina, Joseph J. INTERLOCKING PLASTIC TILE [PDF] U.S. Patent 2,627,744, issued February 10, 1953.

Excerpt: It is an object of this invention to provide tile which dispenses with the need for the mastic defining beadsv between the adjoining tiles thereby eliminating the expensive wiping operation and enabling the use of cheaper mastics as substantially all of the mastic used in the mounting of my novel tile is concealed by the tile themselves. - Luster, Carl J., and Richard G. Brown. INTERLOCKING WALL TILE [PDF] U.S. Patent 2,693,102, issued November 2, 1954. filed by and assigned to the Pittasburgh Plastic Tile Company

Excerpt:

The present invention relates to interlocking wall tile and more particularly to improvements in the construction and shape of the tile and the interlocking formations thereof. Interlocking tile as heretofore commercialized is illus trated by United States Letters Patent 2,323,417, issued July 6, 1943, to Charles D. Pauli, Jr., and 2,490,577, issued December 6, 1949, to Richard G. Brown.

Wood Lath Systems Supporting Plaster or Stucco in Older Homes: Hand split vs. Sawn Wood Lath

Above and also in another photo shown earlier in this article series, we include a photograph of hand-split wood lath and plaster wall, from the wall-cavity side of a U.S. home built around 1800. There are several generations of plaster and lath, plaster board, and drywall which have been used

in buildings.

Details about the types of wood lath used to support plaster or stucco on building walls, ceilings, or exteriors are

at WOOD LATH for PLASTER or STUCCO.

Inspecting old interior walls with care can yield interesting and perhaps useful historical information about the structure. Below I'm demonstrating that this plaster-lath wall also sported four layers of wallpaper atop the originally-plastered wall surface.

History & Types of Wood and Wood-Product Wall Paneling in North America

Early Colonial Wall Paneling & Wainscoting

Early colonial paneling is described by Isham.

A concise history of wall coverings in residential buildings, more photos, & dates in process, CONTACT us, contributions invited.

Shown at left, colonial style wall paneling in the historic Suffolk Resolves House (1774) in Milton MA.

Wainscot Wall Covering

Definition: Wainscoting or "wainscot" is a wood wall finish applied to the lower portion of a building interior, typically about three to four feet up from floor level, and usually capped with a chair rail and usually applied with board edge joints butted vertically as in our photo.

Traditional wainscot is constructed by nailing individual boards to the wall surface. Modern "wainscot" panels are sold in 4' x 8' sheets and cut to fit, producing a beadboard surface that looks like traditional wainscot.

Wainscot is an old term, possibly from the 1300's, that in its contemporary usage derives from the British Wainscot, "a fine grade of oak imported for woodwork" - Merriam Webster.

In North America wainscot has been in use since the colonial era.

Our photo (left) illustrates beadboard type wainscot wall paneling in a Victorian home built in Poughkeepsie, NY in 1900.

Wooden wall paneling - tongue and groove pine and other woods

Wooden wall paneling made of individual boards, often tongue-and-groove common or knotty pine, was most often nailed vertically from floor to ceiling and finished with wall trim at both of those levels.

In North America solid 3/4" thick v-grooved vertical tongue-and-groove pine paneling on building interior walls was particularly popular from about 1945 through the 1960's.

Above: 3/4" thick pine boards installed as pine paneling by the author in a Poughkeepsie NY home.

On 2019-09-29 by Georgette - what do we call this kind of paneling and how can it be updated?

Can someone please tell me the name of this dated wall finishing technique and possibly suggestions on how to update it without taking away from its character? Thanks very much

Can someone please tell me the name of this dated wall finishing technique and possibly suggestions on how to update it without taking away from its character? Thanks very much

On 2019-09-29 by (mod) - modernize sliced horizontal log custom wood paneling?

Georgette,

I see custom wood wall paneling using horizontal boards made from rough-cut lumber sawn to retain the original profile of the tree from which the boards were sawn; I have not found a special name for this custom design.

While there are other sliced wood wall hangings and paneling designs yours may be unique and in my opinion well worth preserving.

However informal names include:

Wood-Slice wall paneling, Wood Tree Slice Wall Paneling, Sliced Log Wall Paneling, Horizontal Log Slice Wall Paneling.

For in-fill between the horizontal log slices we see in your wooden wall paneling, it appears that solid wood, probably a laminate or plywood was used as a backer panel over which the horizontal log slices were glued or nailed.

Without knowing what you have in mind by the word "update" I can't make a suggestion for reserving the walls as shown other than to leave them alone. Certainly painting the surfaces or interlacing with drywall would be in my view a travesty.

You could consider changing the floor covering and furnishings to items more consonant with the room's original design.

In a most extreme effort you could disassemble and lightly sand the log slices and all of the wood paneling to obtain a lighter color without giving up the wood paneling design and its special rough-cut tree shape feature.

Please tell us the country and city where this building is located and the age of the building and its type.

Also take a look

Readers who have more to say about this paneling are invited to POST a QUESTION or COMMENT below on this page.

Wall paneling in 4' x 8' sheets

By the 1970's in the U.S. and Canada, the use of solid tongue-and groove wall paneling was more often replaced by thinner 4' x 8' sheets of wood veneer paneling sections.

Shown above is a typical thin plywood veneer type wall paneling installed in the 1970's. A concise history of veneer-type wall paneling in residential buildings, more photos, & dates in process, CONTACT us, contributions invited.

Also see SHEATHING, FIBERBOARD ASBESTOS CONTENT

More examples of wood wall paneling designs are

at PANELING, WOOD, OTHER where we show examples of custom wood paneling and horizontal log slice paneling.

Hardboard, MDF & Composite Wall Paneling

A wide range of more than 50 popular smooth, textured, and grooved hardboard wall paneling products sold in sheets, typically 4' x 8' continues in popular use in North America, Australia, New Zealand, and Europe. Similar to plywood-based wood paneling, hardboard panels are provided in various surface designs and colors of which a few examples are shown above, excerpted from Lowes building supply website in 2021.

Similar interior wall and ceiling panels of softer MDF and fiberboard have been in popular use since at lest the 1940s. A modern example, in "raw" or un-coated form, is shown below.

Above: three detailed photos of MDF paneling as provided by Canadian supplier EliteTrimworks

The panels above are also used in cabinetry and other interior applications.

Similar wall paneling products are sold then in these categories, all similar in external or finished appearance:

- FRP / Fiberglass-Reinforced Plastic Panels

- Hardboard wall & ceiling panels

- Polyurethane wall & ceiling panels, faux marble and other surface appearances

- PVC wall & ceiling panels

- V-Grooved Raw MDF paneling like the product shown above, from EliteTrimworks (elitetrimworks.com)

- Vinyl wall panels

- Wainscoting Panels - beadboard, of any of these materials

- Wood or plywood-based wall & ceiling panels

Current installation methods for these wall or ceiling panels

- Adhesive-only paneling

- Adhesive and rivet paneling

- Nails and adhesive paneling

- Nail-up paneling

- Peel-and stick paneling

MDF Paneling Resources

- EliteTrimworks, 25 Royal Group Cres #8 in Woodbridge (Toronto), ON., L4H 1X9 (on the SW corner of Hwy 7 & Hwy 27) Toll Free 888-898-1665 Website: https://www.elitetrimworks.com/ Tel: 905.760.1665

- Georgia Pacific, DECORATIVE WALL PANEL INSTALLATION INSTRUCTIONS [PDF] (2009) retrieved 2021/02/08 original source: https://images.homedepot-static.com/catalog/pdfImages/3a/3aaa9eb1-fc8c-41d8-9d0c-bb37963be415.pdf

- WallDesign, MDF WALL PANEL USE & CARE INSTRUCTIONS [PDF] retrieved 2021/02/08 original source: https://images.homedepot-static.com/catalog/pdfImages/1e/1ed66aa5-4780-4c2b-a0d8-0272830fd84f.pdf

- WallDesign, MDF WALL PANEL USE & INSTALLATION INSTRUCTIONS [PDF] retrieved 2021/02/08 original source: https://images.homedepot-static.com/catalog/pdfImages/6c/6c9d8f3d-ee27-4971-83ce-ead7cd00129e.pdf

Wood-Lath Plaster Systems

Above photograph shows the more-regular width sawn wood lath used to support plaster in a home constructed ca 1865. Details about wood-lath plaster systems are

at WOOD LATH for PLASTER or STUCCO - separate article

Drywall Composition, Ingredients, History

This information is now on its own page:

Identifying Stamps on Drywall Used for Interior Wall & Ceiling Surfaces

This discussion has moved to this separate page:

DRYWALL TYPE IDENTIFICATION STAMPS

Also see additional drywall identifying number stamps found

at DRYWALL GYPSUM BOARD Used for Exterior Wall Sheathing.

Where there indoor environmental concerns or corrosion damage to electrical wiring, copper pipes, air conditioning equipment, etc. be sure to

Drywall Gypsum Board Used for Exterior Wall Sheathing

Details are now at EXTERIOR USE GYPSUM BOARD

and at SHEATHING, GYPSUM BOARD

Also see DRYWALL MOLD RESISTANT for an interior drywall reported to resist mold growth.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-03-07 by InspectApedia Editor - can rising roof trusses cause damage lower on affected walls?

@Nikki KC,

That's an interesting question: can rising roof trusses cause damage lower on affected walls?

All of the damage cases I've seen [DF] have been at the ceiling wall intersection or quite close to it, usually as a tear or opening at the ceiling-wall joint and occasionally as cracks or bulges along the ceiling at the underside of trusses close to the affected wall.

It is very speculative, but I suppose conceivable that depending on just how a wall was framed and how drywall was attached to its studs, a rising truss might try to lift the whole wall and thus produce stresses that caused nail or screw pops lower on the wall surfaces.

Perhaps you can attach some photos - one per comment - to let us see what's happening. I don't think that drywall "lumps" would be due to rising roof trusses if the "lump" is found to be actual blobs of joint compound unless someone tried to do a prior repair but worked rather sloppily.

On 2023-03-07 by Nikki KC

Greetings Is it possible for Attic Trusses that are causing corner uplift issues, to also cause drywall issues on the walls. For example, we are noticing lumps over the closet and on the side of the walls. There is a closet behind the wall. We are not sure where these imperfections are coming from.

On 2022-07-08 by InspectApedia-911 (mod)

@Melanie L.,

Sorry but I can't make out anything in your photo. Are you asking about wall paneling, ceilings, or flooring.? I'm guessing you're asking about walls but I really can't see them.

On 2022-07-08 by Melanie L.

Do you know what type of paneling this is?

On 2022-06-05 by InspectApedia-911 (mod) - 1930s Georgia home's tongue and groove clapboard siding

@Michael H.,

Bevelled edge or ship lap tongue and groove clapboard siding, possibly cedar.

On 2022-06-05 by Michael H.

I'm trying to identify what type of Tongue and Groove wall I have behind the sheet rock in my home. The house was built in the 1930's in Northwest, Georgia... Thanks for the help.

On 2022-03-16 by Inspectapedia Com Moderator

@Rob,

In the Recommended Articles list please take a look at (and compare your material with)

FIBERBOARD CEILING & WALL COVERINGS

FIBERBOARD PANEL REPAIR

FIBERBOARD SHEATHING - home

FIBERBOARD SHEATHING IDENTIFICATION

OR it may be a hardboard product as I suggested earlier.

Those are usually a plant fibre, not asbestos.

On 2022-03-15 by Rob

@Inspectapedia Com Moderator, it's actually on the walls in 2 rooms. It was underneath paneling. It's almost like cardboard with paper on top, glued in some spots but mostly nailed. You can just pull it off and it comes off in sheets if your'e careful. I am really just wondering about asbestos. It looked just like a fiber paper product to me and I didn't consider the possibilty of asbestos. Could it be some kind of cardboard wallpaper?

On 2022-03-15 by Inspectapedia Com Moderator - laminate on hardboard, sometimes used in kitchens and baths

@Rob,

That looks like a laminate on hardboard, sometimes used in kitchens and baths.

On 2022-03-15 by Rob

I can’t find anything anywhere on what this could be. It’s on top of tongue and groove wood in a 1940’s house. Looks like wallpaper on top but doesn’t seem to be vinyl. It’s very thin. It’s in 2 different rooms and they look similar in texture and color.

On 2022-03-07 by Inspectapedia Com Moderator - window leaks and walls need repair

@Lindsey,

From the slightly-indented regular fasteners through your wallboard at the left side of your photo I think we're seeing a type of either gypsum wallboard or fiberboard/beaverboard. The former has a gypsum or plaster-like core and the latter is a wood fiber product.

See identification details at

FIBERBOARD CEILING & WALL COVERINGS

and

DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

I also see evidence of a history of leaks, at least over the window - that needs further investigation for hidden damage, mold, rot.

On 2022-03-06 by Lindsey

I'm wondering if you can tell me what this is? And if it has asbestos in it? All the walls in my house how are like this and I'm trying to modernize my house, but trying to make this smooth to paint takes forever. There was wallpaper over it.

@Brandy Billington,

Is the back of that material black asphalt-like impregnated paper?

Is the material very paper-thin or is it thick like linoleum flooring? (It looks like an asphalt-backed sheet flooring or asphalt-paper backed wallpaper)

What is its thickness? Show me an edge and a back view.

On 2021-04-15 by Brandy Billington

Trying to determine what this is. The house is 70yrs old and originally done in shiplap.

Then this was placed over it with possibly wall paper then wood paneling.. Before I dig into it more, I would just like to know what it is.

On 2021-02-08 by Camille theisen

Thank you very much for your help!

On 2021-02-08 - by (mod) -

I'm pretty sure that that is a medium density fiberboard paneling.

On 2021-02-08 by Camille theisen

This is what the back of the paneling looks like if it helps any..

I believe the house was built in 1976. Not sure that's when paneling went up though. I didn't measure it, will measure when we go back next week to do more work on the house, but if I had to estimate, I'd say 1/2" or a little less. It's not particularly hard, bent a bit with crowbar before breaking. Not sure you can tell, but it has a wood grain look to it.

On 2021-02-08 - by (mod) -

That looks like a grooved hardboard paneling such as made by masonite and others, or more-likely, a softer MDF (Medium-Density Fiberboard) grooved paneling product like the one we show below from elitetrimworks.com

For your photo: What is its thickness? How hard is it?

See

HARDBOARD MASONITE™ & OTHER BRANDS

at the end of that article you'll see a link to related articles and products

Also you'll want to review the examples at

HISTORY of the USE of WOOD & OTHER WALL PANELING

or if it's about 5/8" thick and rather soft, see examples at

FIBERBOARD SHEATHING IDENTIFICATION

And for similar exterior wall coverings

SIDING HARDBOARD

Adding:

If you know the age of the paneling that would be helpful.

On 2021-02-08 by Camille theisen

Hi, we recently purchased a home built in 1976. The owner did some quirky things. I'm trying to find out what this paneling is and if it could have asbestos in it. Thank you very much for any help!

On 2020-12-04 - by (mod) - hair reinforcement in plasterboard - drywall suggests age

Thanks Jake, that sure looks like a single piece of drywall or gypsum board.

Thanks Jake, that sure looks like a single piece of drywall or gypsum board.

We can but think that you have spotted a discontinuity in the production run mix of filler. That sort of thing does happen in manufacturing as we've seen in a range of products such as asphalt roofing. The production line runs continuously but the mix of incoming ingredients may vary.

But from the 1970s finding animal hair in what looks like conventional drywall would be quite odd.

That's surely an older plasterboard.

Asbestos was used in some but not all such products so, unfortunately, from eyeballing it alone we can't say if your plasterboard contains asbestos.

If you find any stampings or markings or remains of an identifying paper strip, often found at the ends of the drywall, that'd be interesting, but it looks as if all that was torn off.

For other readers:

Above a closeup of the gypsum board or drywall or plasterboard we're discussing, excerpted from Jake's earlier photo.

On 2020-12-04 by Jake

Here is a picture of the whole piece. The perspective is looking up at the floor joists in the basement.

The board is sandwiched between the HVAC ductwork and the joists. It is 1/2” thick and the paper is really thick and has a fine almost woven/dimpled texture.

One of my thoughts is that it is a heat-resistant product given where they installed it.

That said, there are a lot of crude patches in this house, so this may just be a random sheet of building material they used to provide a surface to mount the gas line to the furnace. The board could be as old as the late 70s, when the original furnace was put in.

Even if it is a gypsum product that just looks weird on one end, are there any old gypsum board products that incorporate hair-like material in the core?

On 2020-12-04 - by (mod) -

Interesting: the two ends look like different materials and different ages.

Are you confident you're looking at two ends of the exact-same material - with no butted, perhaps hidden, seam or joint?

On 2020-12-04 by Jake - The house is from 1900 in Mansfield, MA, USA

Thank you! I have attached a second image showing the other exposed cross-section, which appears to be a gypsum-like material with no fibrous elements (compared to the gray section in the other end, which appeared to have some kind of embedded fiber).

Thank you! I have attached a second image showing the other exposed cross-section, which appears to be a gypsum-like material with no fibrous elements (compared to the gray section in the other end, which appeared to have some kind of embedded fiber).

Does the variation across the two exposed ends (2 different materials visible on one side and one material visible on the other) suggest a manufacturing defect (maybe it was supposed to be two layers throughout)?

That difference is what threw me off.

The house is from 1900 in Mansfield, MA, USA.

This is the only place in the house where I have found this material.

The walls that I have worked on are either lath-and-plaster or modern drywall hung over the old lath.

On 2020-12-04 - by (mod) -

Thank you for the photo and plaster board question, Jake;

That looks like a plaster board that was used to support a finish coat (the white layer) of plaster as a substitute for wood or metal lath.

See PLASTER TYPES & METHODS in BUILDINGS

for identification keys, photos, guides.

Also let us know the country and city and age and type of building in your photo.

I have come across what I think is a wall covering product in my basement that seems different from everything discussed here. The only place it is used is sandwiched between the hot air supply duct and the floor joists above.

It has thick brown paper and the material inside appears to be variable.

On one exposed end it looks like there is a layer of horsehair plaster and a layer of gypsum (all encased in the paper) yet the other exposed end looks like a simple gypsum core.

I would like to remove it so I can clean up the area around and above my furnace and appropriately address whatever deficiency this seemingly slapdash effort was intended to fix (a lot of that in this house...) , but I would like to know what I am dealing with first.

If possible, I will post a few more pictures. If I can do only one, this is the exposed end that appears to show two different discrete materials sandwiched between the brown paper.

On 2020-11-06 - by (mod) -

Dick

I apologize for having to give a glib-sounding answer but sure, paneling of all sorts has been used in buildings to cover all sorts of conditions for centuries.

There is specific reason to assume that paneling is being used to cover asbestos unless we know more about the building, its construction, materials, history of environmental concerns and events.

On 2020-11-06 by Dick Harris

Was Panelling used to cover Abestos in bldgs in the late 1960s. And is the picture attached a water leak.

On 2020-10-25 - by (mod) -

I'm doubtful that you're glue will bond successfully to those surfaces but you probably could hold the fiberboard or other insulation in place with furring strips

On 2020-10-24 by Renae

My husband purchased his grandparents home that was built in the mid 70s. It has a detached garage that was finished on the inside. When we had them re-sided, my step son's crew damaged the outside sheets of fiberboard when pulling off the old siding on the garage.

This "fiberboard" is like cardboard crossed with corkboard.

It is soft. I don't really know what to call it. Anyway, when attaching the new siding, they didn't always hit studs, so there are loose nails and holes where it broke through.

I want to use the leftover insulation boards cut down to fit in between the studs, but I know that the nails will probably push out. Can I glue them to keep them in place?

On 2020-08-08 - by (mod) - plaster top coat adhesion failure

Priceton

Priceton

That looks as if a plaster skim coat is failing over the plaster brown coat. The crack pattern suggests that the failure is due to either high interior moisture (a hidden leak somewhere?) or poor original work.

Remove all of the loose material and if the base surface is sound and secure, then re-plaster the surface below.

On 2020-08-08 by Priceton

Paints peeling off this material in entire home. What is it and can it be refinished

On 2020-07-28 by Steve Absalonson

I'm remodeling a basement storage room that had water damage from above main-floor leaking window, poor roof gutter design and probably some adjacent unfinished crawl space moisture.

Previous owner semi-improved part of UNF basement into storage room with cheap (70s style) 4x8 wood veneer paneling.

Working with Insurance company, which says they will only reimburse for original wall paneling unless I can show that paneling does not meet current building codes.

Does the old wood paneling still satisfy typical residential building and remodel code requirements ?

Would like to only replace with moisture/mold resistant drywall/hardi-board etc.

Any other thoughts and considerations would be appreciated.

On 2020-07-18 - by (mod) -

That looks like brushed cedar paneling; A wire brush is used to remove the soft wood, leaving the exposed hardwood as raised ridges.

Lookalikes were manufactured of other materials as well.

On 2020-07-16 by Nancy

I am trying to identify the type of wood panel this is in our upstairs room.

Nancyh0001@gmail.com

On 2019-11-28 - by (mod) -

I can see much but it looks like a fiberboard product. See details

at FIBERBOARD SHEATHING IDENTIFICATION .

On 2019-11-28 by Chris

Can anyone give me information on this material thank you

On 2019-05-16 - by (mod) -

Anon:

Generally cellulose - wood-based products don't contain asbestos though there were some exceptions, probably traced to cross-contamination, discussed

at SHEATHING, FIBERBOARD ASBESTOS CONTENT

that could also appear in an interior wall product.

On 2019-05-11 by anonymous

Does wood paneling 4*8 grooved with a hard surface which resembles wood finish it looks like it is laminated to partilce board year 1968 and is nailed to the interior walls in my hallway in my house do these panels contain asbestos?

On 2019-05-11 by anonymous

Does wood veneer type panels from from year 1968 which is nailed to the interior wall in my hallway contain asbestos?

...

Continue reading at FIBERBOARD CEILING & WALL COVERINGS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see DRYWALL, FIBERBOARD, PLASTER INTERIOR FAQs - questions & answers posted originally on this page.

Or see these

Recommended Articles

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home

- ASBESTOS CEMENT CEILING & WALL PANELS

- ASBESTOS in DRYWALL

- BEAVERBOARD

- BESTWALL DRYWALL ASBESTOS

- CELOTEX HISTORY & PRODUCTS

- CHINESE DRYWALL HAZARDS

- COATING TYPE CEILING & WALL SURFACES: CATALOG OF

- DOMTAR GYPROC ASBESTOS?

- DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

- DRYWALL CONTROL JOINTS

- DRYWALL CRACK CAUSES & CURES

- DRYWALL FINISH LEVELS

- DRYWALL TYPE IDENTIFICATION STAMPS - codes identify intended use, features

- DRYWALL INSTALLATION Best Practices

- DRYWALL MANUFACTURER IDENTIFICATION STAMPS & DATE CODES - alphabetical list

- DRYWALL GREEN LOW TOXICITY MAGNESIUM OXIDE MgO

- DRYWALL MOLD RESISTANT

- DRYWALL NAIL POPS

- DRYWALL TYPE IDENTIFICATION STAMPS

- FIBERBOARD CEILING & WALL COVERINGS

- FIBERBOARD PANEL REPAIR

- FIBERBOARD SHEATHING - home

- FIBERBOARD SHEATHING IDENTIFICATION

- GYPSUM BOARD GYP ROCK SHEATHING

- GYPSUM BOARD PLASTER LATH SYSTEMS

- HARDBOARD BATHROOM & KITCHEN PANELS

- HOMASOTE HISTORY & PRODUCTS

- IGNIFUGE GYPSUM BOARD ASBESTOS?

- MASONITE & HARDBOARD CEILING & WALL COVERINGS

- METAL LATH for PLASTER

- NATIONAL GYPSUM DRYWALL ASBESTOS?

- NU-WOOD PANELS

- PAPERBOARD PRODUCTS CONTENTS

- PANELING, WOOD & WAINSCOTING

- PICTURE HANGING NAILS

- PLASTER TYPES & METHODS in BUILDINGS

- PLASTER INGREDIENTS, MIX, PROPERTIES

- PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS

- SACKETT BOARD

- SHEATHING, GYPSUM BOARD

- SUNDEALA BOARD COMPOSITION & HISTORY

- UPSON BOARD

- WALL FINISHES INTERIOR

- WOOD LATH for PLASTER or STUCCO

Suggested citation for this web page

DRYWALL, FIBERBOARD, PLASTER INTERIORS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about ages & types of wall & ceiling materials, installations & practices.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Carson Dunlop, Associates, Toronto, have provided us with (and we recommend) Carson Dunlop Weldon & Associates'Technical Reference Guide to manufacturer's model and serial number information for heating and cooling equipment ($69.00 U.S.). Technical Reference Guide, Carson Dunlop Weldon & Associates, Ltd., 120 Carlton St. Suite 407, Toronto, Ontario, M5A 4K2 Canada, ISBN 1-895585-90-2 165pp.

- America's Favorite Homes, mail-order catalogues as a guide to popular early 20th-century houses, Robert Schweitzer, Michael W.R. Davis, 1990, Wayne State University Press ISBN 0814320066 (may be available from Wayne State University Press)

- American Plywood Association, APA, "Portland Manufacturing Company, No. 1, a series of monographs on the history of plywood manufacturing",Plywood Pioneers Association, 31 March, 1967, www.apawood.org

- Isham: "An Example of Colonial Paneling", Norman Morrison Isham, The Metropolitan Museum of Art Bulletin, Vol. 6, No. 5 (May, 1911), pp. 112-116, available by JSTOR.

- Manufactured & Modular Homes: Modular Building Systems Association, MBSA, modularhousing.com, is a trade association promoting and providing links to contact modular builders in North America. Also see the Manufactured Home Owners Association, MHOAA, at www.mhoaa.us. The Manufactured Home Owners Association of America is a National Organization dedicated to the protection of the rights of all people living in Manufactured Housing in the United States.

- Pergo AB, division of Perstorp AB, is a Swedish manufacturer or modern laminate flooring products. Information about the U.S. company can be found at http://www.pergo.com where we obtained historical data used in our discussion of the age of flooring materials in buildings.

- Plank House Construction: webslog from plankhouse.wordpress.com/2009/01/25/plank-house-construction/ and where plank houses were built by native Americans, see

Large 1:6 Scale Plank House Construction / P8094228, Photographer: Mike Meuser

06/12/2007 documented at yurokplankhouse.com where scale model Museum quality Yurok Plank Houses are being sold to raise money for the Blue Creek -Ah Pah Traditional Yurok Village project - bluecreekahpah.org - Scott C. LeMarr has provided his file of keys to decode Furnace and Water Heater Age from the data provided on the manufacturer's equipment labels. Mr. LeMarr is a professional home inspector, Certified Professional Inspector/President, MASTER Indoor Environmental Specialist (MIES). Vice President of Wisconsin NACHI. He and his company, Honest Home Inspections [ Website: www.HonestHomeInspections.com ], LLC. can be reached at 262-424-5587 or by email to scott@honesthomeinspections.com

- Weaver: Beaver Board and Upson Board: Beaver Board and Upson Board: History and Conservation of Early Wallboard, Shelby Weaver, APT Bulletin, Vol. 28, No. 2/3 (1997), pp. 71-78, Association for Preservation Technology International (APT), available online at JSTOR.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- America's Favorite Homes, mail-order catalogues as a guide to popular early 20th-century houses, Robert Schweitzer, Michael W.R. Davis, 1990, Wayne State University Press ISBN 0814320066 (may be available from Wayne State University Press)

- American Plywood Association, APA, "Portland Manufacturing Company, No. 1, a series of monographs on the history of plywood manufacturing",Plywood Pioneers Association, 31 March, 1967, www.apawood.org

- Photo of very rough in-wall brick nogging at an architects website

- Construction Drawings and Details, Rosemary Kilmer

- "An Example of Colonial Paneling", Norman Morrison Isham, The Metropolitan Museum of Art Bulletin, Vol. 6, No. 5 (May, 1911), pp. 112-116, available by JSTOR.

- Nogging: See this PHOTO of exposed bricks on a building exterior On a building exterior in Canada. [Thanks to Carson Dunlop, Toronto - see References below].

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.