Drywall Cracks

Drywall Cracks

Cause & prevention of cracks or ridging in plasterboard or gypsum board ceilings & walls

- POST a QUESTION or COMMENT about plasterboard cracks, drywall cracks, gypsum board cracking & movement

Drywall cracks in ceilings or walls:

Where, when & why does drywall crack? Coefficients of thermal and moisture expansion & contraction or movement for gypsum board products.

This article describes the common causes of all types of cracks that appear in drywall or gypsum board or plasterboard walls & ceilings in building interiors. Illustrations show where cracks are most likely to appear, explain why, and suggest both repair approaches to drywall cracks and how to prevent cracking in plasterboard or gypsum board.

Photo at page top: severe settlement cracks around windows in an Alaskan home. Soil, foundation, and frost problems were causing severe ongoing movement in this structure.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Causes & Types of Cracks in Drywall, Plasterboard, Gypsum Board Walls & Ceilings

Article contents - Causes of drywall or gypsum board cracking, sorted by categories

- DRYWALL CRACKS

- DRYWALL INSTALLATION DETAILS / ERRORS

- FOUNDATION SETTLEMENT / FROST HEAVES

- FRAMING SHRINKAGE / QUALITY

- MOISTURE EXPANSION / SHRINKAGE

- SETTLEMENT / FOUNDATION DEFECTS

- THERMAL EXPANSION / SHRINKAGE

- PREVENT SIDE or BUTT JOINT CRACKS

- PREVENT TRUSS ARCH CRACKS

- RIDGING, GYPSUM BOARD GRC

- TRUSS UPLIFT, ROOF - separate article

Gypsum Board Installation Error contribution to gypsum board cracks & damage

Drywall installation snafus: poor support or connections, over-cuts with a drywall knife at corners of openings, failure to provide for seasonal or other variations in temperature & moisture, improper joint finishing, possibly omission of drywall tape at some gaps, cracks, or repairs.

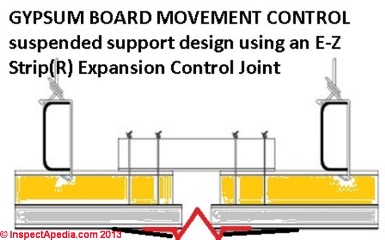

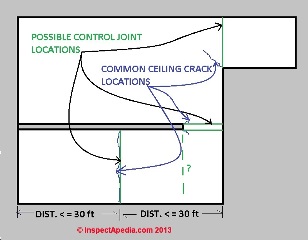

Drywall movement control joints omitted on long drywall runs in ceilings (sketch at left) or walls, distances over 30 ft. Control joints may also be needed at common ceiling or wall stress points such as at "L", "T", "U" or "I" shape ceiling or wall intersections like those shown in our sketch above.

See DRYWALL CONTROL JOINTS

[Click to enlarge and show detail for any image]

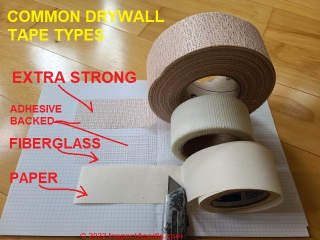

Drywall tape type used for corners: do not use mesh type drywall tape in building corners nor at ceiling/wall joints. It may be easier to install than paper tape but it is not as strong and is more tear-prone.

Long runs of continuous drywall, especially if more than 30 feet or about 10 meters in its long dimension are likely to suffer expansion/contraction cracking and possibly ridging if control joints are omitted.

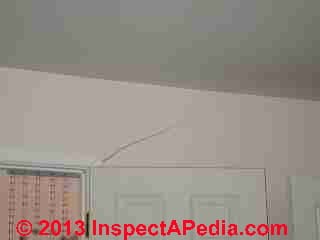

Our drywall ceiling photographs above and below show a continuous ceiling that runs the length of this home, or 64 1/2 feet in total distance.

The ceiling width is interrupted near one end by the distant partition wall you can see in the left hand photo, but the ceiling continues to open up into another room at that end of the house.

The ceiling crack shown in our photograph at above right occurs almost in the center of this long ceiling run. Seasonally as temperatures and humidity vary the width of this ceiling crack also changes from close to hairline (warm humid summer months) to nearly 1/8" in width (cold dry winter months).

Using the coefficients of thermal and moisture expansion and contraction in drywall found

at PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS, and with a "ballpark" estimate of seasonal temperature variation of 20 degrees and relative humidity variation of 30%,

we calculate that the total expansion or contraction range force over this ceiling length (744 inches) is about 0.138" (thermal) and 0.145" (moisture) for a total of about 0.28 or 3/10 of an inch - more than a quarter of an inch - more than enough to cause a huge ceiling crack.

Why do we see that the actual ceiling crack is not nearly this wide?

Because the 744 inch long ceiling is not unrestrained while the coefficients of thermal and humidity expansion and shrinkage are for unrestrained gypsum board. This ceiling's gypsum board is nailed to the underside of flat roof rafters spaced 16" o.c., distributing much of the thermal and humidity-related expansion and contraction forces over a large area.

Still we see an ugly wintertime crack in this ceiling and a noticeable summertime crack as well. There is not much point in just taping over this crack without installing control joints in this ceiling.

Metal corner beads are more crack and separation prone in drywall installations than plastic tape-on or glue-on (using spray adhesive) or mud-on corner bead material.

Building foundation settlement, frost heave, foundation drainage contributions to gypsum board cracks & damage

Frost heaving foundations can cause differential movement in building walls that causes severe tearing or cracking in plasterboard, gypsum board, or drywall.

Photo above left: shear cracking shows up at the inside drywall corner of two exterior walls of a New York building.

This cracking was caused by differential frost heaving.

Below you can see the corresponding crack in masonry block foundation supporting the building walls. High soil water content, drainage difficulties, and freezing climate explain this damage.

See FOUNDATION CRACKS & DAMAGE GUIDE

To repair this drywall crack and to reduce the chances of its reappearance, we

- Took care to direct surface runoff away from the corner of this building

- Used the heavy-duty self-reinforced mesh drywall tape shown at the top of our photograph just below.

- Took great care in troweling joint compound into the corner to avoid cutting the mesh tape with the drywall knife - easy enough to do if you use a special drywall corner trowel.

I [DF] use a Marshalltown No. 23 corner drywall tool, as shown below. - At DRYWALL INSTALLATION Best Practices Steve Bliss notes: If using fiberglass mesh rather than paper tape use setting-type joint compound to embed the mesh, since it is not as strong as paper tape.

Building framing shrinkage & framing quality contribution to gypsum board cracks & damage

Framing shrinkage & other snafus: using wet lumber, pressure treated and still wet lumber, or poor quality framing connections that permit movement and settlement that can in turn lead to drywall cracks, tears, or drywall joint tape separation.

In a demonstration that the ceiling crack stress point sketch is not just theory, our photos just above show cracks at the taped intersection of ceiling to partition wall at a natural stress point. This crack appeared in less than a year after new construction.

The underlying cause may have been a combination of framing shrinkage and slight sagging of the supporting floor structure.

The wall corner projecting into the room is directly above a stairwell cutout. Floor settlement actually pulled this corner down, separating it from a rigid I-beam roof structure.

We will repair this crack by cutting out the separated paper drywall tape and re-taping the joint on both sides of the partition wall corner-to-ceiling juncture. But this little repair is a bit of trouble as re-painting the ceiling and wall will also be needed. In my OPINION (DF) this is normal new construction cracking that is difficult to prevent.

Our photo at left shows the original drywall being installed on the same ceiling as in the drywall tape joint separation photographs above.

You can see that the sheetrockers took care to hang a full piece of drywall that extended past the partition wall corner precisely because they knew that this was a stress point.

That detail worked - we did not see a tear in the drywall itself. What did ensue was enough downwards movement to stress and open the drywall tape at the partition wall-to-ceiling joint.

Below is a second example of a similar effect. Here we see a complex soffit structure carrying windows and suspended from a conventionally-framed 2x12 ceiling structure. Here, too, cracks appeared in the ceiling as the structure below moved downwards.

[Click to enlarge the photo at left to see this drywall ceiling crack in more detail].

Framing flexing - drywall cracks: in interior ceilings or cathedral-ceilings not framed to modern construction standards for stiffness we may see cracks, often at drywall joints, caused by flexing in the ceiling structure.

Particularly in some older homes with minimal attic floor framing that was originally intended only to support the weight of a plaster ceiling, we may see ceiling cracks caused by building occupants (or home inspectors) who clambered around in the attic area above, stepping on framing members never intended to bear their weight.

- Framing bowed, bent, uneven: installing drywall or gypsum board across uneven surfaces due to inconsistent or sloppy framing can add to material stresses that ultimately show up as plasterboard cracks.

Such cracks are most likely to appear when a side joint or end butt joint appear over or close to a framing variation extremity.

Use furring, cutting, trimming or similar measures to flatten out the install surface and to minimize these stresses, and avoid placing a taped joint over stress points. - Framing over-spanned: drywall installed at right angles to the supporting framing can span 24" (1/2" or 5/8" thick drywall) on walls, but on ceilings 1/2-inch or 5/8-inch drywall can span

24 inches only if it is installed perpendicular to the joists

and supports less than 1.3 pounds per square foot (psf ) of

insulation.

Otherwise, 16-inch on-center spacing is recommended. With latex spray textures or airless spraying of latex paints, perpendicular installation over 16-inch on center framing is recommended to prevent sagging. - S. Bliss, Best Drywall Practices - Roof truss uplift: arching roof or floor trusses caused by moisture/temperature differences between truss upper & lower members. The truss uplift problem is less likely to occur in an interior ceiling supporting a floor above because both sides of the ceiling/floor structure are within conditioned space, making for more uniform temperatures and moisture levels across the truss.

See TRUSS UPLIFT, ROOF for details.

Moisture or relative humidity variation contribution to gypsum board cracks & damage

Moisture or humidity variation: significant changes in the building moisture level or thus in the moisture content of plasterboard or gypsum board can cause expansion or shrinkage sufficient to produce a 1/16" wide or larger crack even if other forces are not in play.

Details of the coefficients of thermal expansion (or contraction) and the coefficients of moisture-related expansion and shrinkage of plasterboard are

at PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS.

Structure or Foundation Settlement contribution to gypsum board cracks & damage

Settlement in buildings causes plasterboard cracks & tears: for any reason: framing shrinkage, foundation damage, site drainage problems, earthquake movement or slab settlement can cause significant gypsum board damage.

Below we give several examples of types of building movement traced to settlement and causing significant interior wall or ceiling cracking.

Backfill settlement in New York: the photographs below illustrate severe settlement in a New York home. Unlike the Alaskan house above (damaged by construction on thawing permafrost), the home below had been constructed on backfill over a stream bed.

Seasonal water flowing below the building appears to have contributed to severe slab and foundation damage that telegraphed upwards through this home as floor-wall separation, ceiling-wall separation, and cracks at windows and doors of the home shows in the photos just above.

By noting the plasterboard crack locations, patterns, angles, and dimensions it was apparent that they all pointed to settlement in the supporting slab.

Checking the finished basement floor for level we confirmed that the floor was settling significantly towards the building center.

Permafrost settlement in Alaska: The two photographs above show severe plasterboard cracking in the same Alaskan home illustrated at the top of this page.

In the above photo, settlement and drywall tearing cracks appeared at a horizontal drywall joint to the right of a door jamb (a poor location for a drywall joint and exacerbated by the use of mesh tape that is not as strong or tear resistant as paper tape).

[Click to enlarge and see detail for any image]

In our second drywall cracking photo just above we see a typical diagonal gypsum board crack extending down and to the left of a window opening.

The window trim has been pulled apart as well. These cracks are not to be blamed on the drywall installation: this home had suffered movement in excess of what plasterboard is expected to endure.

This building is discussed in more detail

Earthquake damage to walls in California:

Earthquake damage crack patterns characteristic of the Northridge earthquake in California in January 1994 are illustrated by our photo shown at left.

This crack pattern appears here in a stucco exterior, but it was duplicated on drywall interiors as well.

Buildings suffering this extent of damage require structural repair or possibly replacement.

Details are

at EARTHQUAKE DAMAGED FOUNDATIONS.

Temperature variation contribution to gypsum board cracks & damage

Temperature variation: significant changes in the building interior temperature or thus in the temperature of plasterboard or gypsum board can cause expansion or shrinkage sufficient to produce a 1/16" wide or larger crack even if other forces are not in play.

Even if building temperatures are kept steady after construction is complete, drywall installation temperatures may contribute to subsequent cracks: mudding drywall in cold buildings increases drying times and may increase the crack risk.

Large variations in building temperature or moisture level or both. For example, leaving a building un-heated in a freezing climate or turning off air conditioning & dehumidification in a wet or humid climate.

See HUMIDITY CONTROL & TARGETS INDOORS

and also DRYWALL MOLD TESTING.

Details are at PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS.

How to Prevent Drywall Cracks at Drywall Side or End Butt Joints

Use kiln-dried lumber for framing walls and ceilings. As Steve Bliss points out

at DRYWALL INSTALLATION Best Practices, " With wet or poor-quality framing, there are bound to be problems in the drywall finish. With dry lumber and proper detailing, however, drywall problems can be kept to a minimum."

Use drywall screws instead of drywall nails. Set the screws just below the drywall paper surface but not so deep as to cut through the paper.

When hanging drywall on a ceiling supported by the lower chord of roof trusses, review the suggestions

at TRUSS UPLIFT, ROOF, including using clips rather than screws or nails to secure drywall within a few feet of either side of building center partitions that run at right angles to the lower chord of the roof trusses.

The floating drywall corner method described

at INTERIOR FINISHES: BEST PRACTICES can also be used to float the ceiling drywall over the center partitions.

Inside corners at walls and between walls and ceilings are stress points for drywall and common places for cracks or nail pops. Leaving one side of the joint free to move without fasteners will eliminate most of these problems.

On ceilings, place the first screws 7 to 12 inches in from the corner and support the ceiling drywall with the wall panels. Also, do not fasten the top 8 inches of the wall panels.

No screws should go into the top plate, where shrinkage may occur. Similarly, leave one side unfastened at wall-to-wall corners, but make sure it rests against solid wood backing or drywall clips (see Figure 5-1).

Prevent Drywall Cracks Caused by roof truss (or on occasion floor truss) uplift

Nail pops found in some building ceilings and actual tears or cracks at the wall/ceiling juncture at building walls located under the center of certain roof trusses when moisture & temperature differences between the truss bottom chord and upper members cause the truss to arch.

Details and more illustrations of the roof truss uplift problem & more steps to prevent drywall cracking & nail pops are found at

TRUSS UPLIFT, ROOF

The drawings of roof truss uplift and corrective measures for truss uplift shown here are provided courtesy of Carson Dunlop Associates and appears in their Illustrated Home.

Also see CEILING FINISHES INTERIOR

and

see BEST INTERIOR FINISH PRACTICES

GRC: Gypsum Board Joint Ridging & Cracking

Drywall / Gypsum Board / Plasterboard Butt-Joint Ridging Causes & Prevention

As this article series discusses the expansion and shrinkage effects of drywall or gypsum board ceilings and walls (plasterboard in the U.K., Australia, New Zealand and other countries), we include this description of cosmetic damage caused by expansion rather than material shrinkage stresses.

GRC or gypsum ridging and cracking has been reported world-wide, with most writers commenting from Australia, Canada, New Zealand, the U.K. and the U.S. [1][2][4]

[Click to enlarge any image]

The Gypsum Association's definition of ridging is

Joint ridging, also called beading, is a uniform, fine line deformation occurring at gypsum board joints.

It is usually caused by compression of the edges or ends of the finished and decorated gypsum board resulting from the edges or ends being forced together from exposure to alternating periods of high and low temperature and humidity extremes due to thermal or hygrometric expansion. - [10] Repair of Gypsum Board Joint Ridging ( GA-221-00 )

Note: both ridging and cracking in gypsum board may both appear in the same installation.

For example, ridging may appear when forces (thermal expansion, moisture expansion) cause the material to expand, while cracks or tears may appear in plasterboard or gypsum board when the opposite site conditions (cooler temperatures and more dry conditions) cause gypsum board to contract.

OPINION: As we note below, many experts opine that the dominant forces in drywall cracking or tears are probably framing shrinkage and building movement - a view with which I agree. However gypsum board joint ridging is almost certainly going to be due only to expansion forces alone and would be expected to appear particularly at long runs of unrelieved (no control joints) drywall exposed to high moisture and high temperature or the two combined.

Suggestions for preventing gypsum board ridging include:

- Inspect, document and correct building framing defects such as gaps, poor nailing or open framing joints before hanging the drywall.

- Do not hang gypsum board on wet or pressure treated framed ceilings or walls without special design provisions such as the use of resilient channel supports.

- Inspect, document, and correct site drainage, footing drain defects, building leaks and other sources of abnormal building moisture or of abnormal building movement, settlement, framing shrinkage.

- Manage building & gypsum board humidity and temperature: Document the building humidity and temperature at the time of drywall application [and we recommend documenting as well the actual temperature and humidity level or moisture level of the drywall product being installed), and document abnormal variations in building temperature and humidity indoors beyond its design parameters.

Gypsum board should be allowed to reach temperature and humidity consistent with the building interior where it is to be installed before it is hung or applied. - Additional measures to avoid ridging may include back-blocking or supporting at butt joints (extra cost, rarely used - DF)

- Repair recurrent problem areas by supporting drywall on resilient channels

- Use control joints at problem or stress points and in areas of drywall extending beyond 30 feet of unbroken or unrelieved panels.

- See the SBCA's detailed recommendations at "Gypsum Joint Ridging and Cracking" [1]

Drywall Crack, Movement, Failure Research

- Aimone-Martin, C. T., and V. L. Rosenhaim. "Comparative measurements of structure and crack motions during blasting and other environmental forces." In Vibrations from Blasting: Workshop hosted by Fragblast 9-the 9th International Symposium on Rock Fragmentation by Blasting, p. 97. CRC Press, 2009.

- ASTM C 473–07 Standard Test Methods for Physical Testing of Gypsum Panel Products, ASTM (2009), Volume 04.01.

- Barve, Prasad S., Lalit S. Thakur, Ruchi P. Barve, Jaimin K. Shah, and Neha P. Patel. DETECTION AND SIZING STUDY OF CRACKS: A CASE STUDY [PDF] International Journal of Advance Research in Engineering, Science & Technology (IJAREST) 2, no. 8 (2015): 84-91.

Abstract

Commonly occurring cracking in structures need investigation for their causes so as to allow engineers to carry out suitable repair and remedial measures. If the concept behind various causes of cracking is understood by engineers, the repair and remedies could be made more effective.

To examine the exact causes it is necessary to observe carefully, the location, shape, size, depth, behavior and other characteristics of the cracks, and to collect information about specifications of the job, time of construction and past history of the structure. The first sight of crack is important to be known by the engineer.

Structural cracks are the one whose inherent cause lies in either in incorrect design, or faulty construction or overloading and are the one which can endanger the safety of a given structure.

On the other hand, the non-structural cracks are the one which have the underlying origin due to moisture or thermal fluctuations, elastic deformation, creep, chemical reaction, or reason related to the foundation soil such as it movement or settlement or unhindered vegetation. Non-structural cracks are mostly due to internally induced stresses in building materials and these generally do not directly result in structural weakening.

Non uniform settlement is usually the most problematic, as it leads to structural distortions and therefore not only to serviceability but also ultimate limit states.

In this case study, cracks are detected, crack width and depth are measured, and their profile is plotted. It is hoped that the remedial and control measures for repair and prevention of cracks that are suggested in the conclusion, will prove useful and help the engineers to take decisions for quality construction. Keywords- Cracks; Crack profile; Crack pattern; Remedial measures; Control measures - Caulfield, Daniel F., DIMENSIONAL STABILITY OF PAPER: PAPERMAKING METHODS AND STABILIZATION OF CELL WALLS [PDF] (1988) US FPL, Madison WI retrieved 2021/11/18 original source: https://www.fpl.fs.fed.us/documnts/pdf1988/caulf88a.pdf

Excerpt:

Like other wood-based materials, paper also exhibits dimensional changes as a result of changes in moisture content that, at times, can seriously limit the performance and usefulness of paper.

This dimensional instability of paper arises ultimately from the moisture sensitivity and swelling of the cell wall. In the dry state, the wood cell wall is almost poreless, yet it can take up moisture from the surrounding atmosphere while it seemingly remains dry.

This absorption of water on the vast internal surfaces within the cell wall results in a change in external dimensions. As the moisture of the surrounding environment increases, more water is accommodated within the cell wall until saturation is reached. I

n an ordinary wood fiber, the moisture content of the cell wall at the fiber saturation point is considered to be about 30 percent (30g of water/100g of dry fiber).

But in a pulped fiber, the fiber saturation point may be several times larger. Pulp fibers can easily have fiber saturation points of 70 to 80 percent.(1) Never-dried pulp fibers have been reported to have fiber saturation points of 200 percent.(2) T

he large fiber saturation points of chemical pulp fibers are partially caused by removing the encrusting lignin and partially caused by the mechanical treatment of the fibers. - Dowding, Charles H. CRACK MESUREMENT: NEW APPROACH TO ADDRESSING BLASTING COMPLAINTS [PDF] Professor of Civil Engineering, Northwestern University, retrieved 2021/11/18 original source: http://www.civil.northwestern.edu/people/dowding/acm/publications/dowding/Aggman.pdf

Excerpt:

Blasting complaints are consuming an increasing amount of time and resources. This worsening situation has spawned new methods for relaying the public’s concerns.

The direct measurement of crack response to both long term environmental and blast vibration effects with the same sensor exemplifies one new approach, which can be helpful in the process of educating quarry neighbors about the large impact of the environmental changes.

This comparison of long-term and vibratory crack response demonstrates that the silent response of cracks to environmental changes is larger than that produced by blasting, which is felt and heard. - Dowding, Charles H., and JEFFREY E. Meissner. "Response of Un-Cracked Drywall Joints and Sheets to Blast Vibration and Weather." In Proceedings of the 37th Annual Conference on Explosives & Blasting Technique, International Society of Explosive Engineers. 2011.

- Dowding, C. H., C. Aimone-Martin, V. Rosenhaim, and J. Meissner. "Crack Response to Blast Vibrations and Moisture Induced Volumetric Changes in Foundation Soils." In Proceedings of 35th Conference on Explosives and Blasting Technique, International Society of Explosives Engineers. 2009.

- Dowding, C. H., C. Aimone-Martin, V. Rosenhaim, and J. Meissner. CRACK RESPONSE TO BLAST VIBRATIONS AND MOISTURE INDUCED VOLUMETRIC CHANGES IN FOUNDATION SOILS [PDF] In Proceedings of 35th Conference on Explosives and Blasting Technique, International Society of Explosives Engineers. 2009.|

Abstract

In this paper vibratory crack response is compared to that produced by volumetric changes in foundation soils induced by natural events. These natural phenomena include changes in the water table, changes in soil moisture, and formation of ice lenses to name a few. Previous papers have compared vibratory responses of cracks to atmospheric effects such as those produced by the passage of weather fronts and daily changes in temperature and humidity. Periodicity of these atmospheric effects is on the order of a day to half a dozen days.

Thus it is possible to observe atmospheric effects with measurement over a period of weeks to several months. On the other hand, crack response produced by volumetric changes in foundation soils occurs over a period of many months and/or may be seasonal in nature if not longer in the case of drought. Thus its measurement requires long periods of observation (many months to significant fractions of a year) or observation during critical seasons.

Since it occurs over long periods of time, its observation may be obscured by climatologically induced crack response. These soil volume changes are compared with climatic data to describe the correlative nature of crack response in time with the soil volume change phenomena and likely climatic causes. - Meissner, JEFFREY E., and CHARLES H. Dowding. RESPONSE OF UNCRACKED DRYWALL JOINTS AND PANELS TO BLAST VIBRATION AND WEATHER [PDF] [8MB file] In Proceedings of the 37th Conference on Explosives and Blasting Technique, International Society of Explosive Engineers, Cleveland, OH, February. 2011.

- Milner, Henry R., and Con Y. Adam. "Plasterboard peaking and cracking under timber roof trusses." In Australasian Conference on the Mechanics of Structures and Materials 1999, pp. 83-88. AA Balkema, 1999.

- Pali, Tatiana, Sarmad Shakeel, and Raffaele Landolfo. EXPERIMENTAL INVESTIGATION ON THE SEISMIC PERFORMANCE OF LWS DRYWALL ARCHITECTURAL NON-STRUCTURAL ELEMENTS [PDF] In 4th International Workshop on the Seismic Performance of Non-Structural Elements (SPONSE), Pavia, Italy. 2019.

Abstract excerpt:

The paper presents the research activity carried out for evaluating the seismic performance of Lightweight Steel (LWS) drywall architectural non-structural elements made of Cold-Formed Steel (CFS) profiles sheathed with gypsum-based or cement-based boards, i.e. indoor partition walls, outdoor façade walls and suspended continuous ceilings. - Restrepo, José I., and Andrew M. Bersofsky. "Performance characteristics of light gage steel stud partition walls." Thin-Walled Structures 49, no. 2 (2011): 317-324.

[Includes comments on drywall cracking, buckling, crushing, etc.] - Roberts, C. C. EVALUATING CRACKS in BUILDINGS [PDF] C. Roberts Consulting Engineers Inc., Big Rock IL 60511 USA Email: CCR@croberts.com Web: http//www. croberts. com (2012): 56.

- Spies, Henry R. WHAT'S HAPPENING TO MY NEW HOUSE? (2005) BRC Building Research Council, U. Illinois Urbana Champlain School of Architecture, Circular Series Index No. A1. 7 (2005).

- Thulin, F. A. "Seismic Testing of a three-hour fire-rated steel-framed gypsum drywall partition for nuclear plants." (1983).

- Woeste, Frank & Joe Loferski, ALL THINGS WOOD Unpredictable Nature & Cause of Cracks at Gypsum Panel Joints Perpendicular to Framing [PDF] (2017). Revised version of an article first published in the May 2012 issue of The Construction Specifier,

www.constructionspecifier.com.

Excerpt:

In some arid parts of the Southwest, the occurrence and recurrence of cracks at taped gypsum panel (drywall) joints between panels in residential projects have been reported in trade magazines since the mid-1990s.

In some homes of a project, one or two cracks or ridges appear at the finished drywall joint on the long side of panels which are typically installed perpendicular to a wood truss or solid-sawn-joist span. Cracks are more common than ridges, and we will refer to both collectively as “joint cracks.” - RHINOBOARD for CEILINGS, [PDF] Gyhproc Saint Gobain, 1 Shale Rd,N1 Business park,

Intersection of Old JHB Rd and Tlokwa Street, Kosmosdal, Centurion, South Africa, Tel: +27 12 657 2800, Customer contact centre, 0860 27 28 29, Website: www.gyproc.co.za,or www.isover.co.za retrieved 2017/08/31, original source: http://www.gyproc.co.za/products/walls/rhinoboard

RhinoBoard Square-Edge produced by Gyproc SA is a fire-resistant ceiling material with the following specifications, excerpted from the company's web page cited below:

Subject to loading detail, suspension should not exceed 1200mm centres

The suspension must not be out of plumb (vertical) more than 25mm for each 150mm of plenum depth and in no case should exceed 500mm to a 3000mm depth

Whenever the above is exceeded and/or when the hanger suspension is more than 2000mm long, then a sub grid is recommended. Should suspension be vertical, then a 4200mm drop would be acceptable using hanger strap

In no case should suspension be from other services in the ceiling void

A hanger suspension point within 400mm from the wall angle or shadow moulding must be installed on main tees and cross tees

Two steel pop rivets with a shear strength three times that of the maximum allowed ceiling load is to be used

When securing wire to tee, it should be wound tightly around itself at least three times

Should the ceiling mass exceed 20kg/m2, a sub grid is required and a consulting engineer should recommend suitable suspension - retrieved 2017/09/01, original source: http://www.gyproc.co.za/products/ceilings/rhinoboard-0 - A distinctly different product, Rhino Board™, is a polypropylene honeycomb sheet made of cylindrical polyolefin tube straws bonded into a close-packed hexagonal matrix to produce a low bulk density material manufactured in a proprietary process by Rhinoboardwj, 2711 Karsten Court SE, Albuquerque, NM 87102 USA, Tel: (505) 842-5100, Email: info@rhinoboardwj.com, also distributed in Europe.

A topical use of this Rhino Board™ product is service as " a lightweight and durable cutting surface for abrasive or straight water jet cutting" . Website: http://www.rhinoboardwj.com/ - [1] "Gypsum Joint Ridging and Cracking", (2009), SBCA Tech Notes, Structural Building Components Association, 6300 Enterprise Lane Madison WI 53719, (608) 274-4849, (608) 274-3329 FAX, retrieved 12/11/2013, original source http://support.sbcindustry.com/images/technotes/T-GypsumInstallation09.pdf

- [1a] Paul F. Schofield, Kevin S. Knight, Iona C. Stretrton, "Thermal Expansion of gypsum investigated by neutron powder diffraction", (1996) Manuscript, retrieved 12/11/2013, original source: http://www.minsocam.org/msa/ammin/toc/ Articles_Free/1996/Schofield_p847-851_96.pdf

- [1b] Azree Othman Mydin, "Gypsum Board Thermal Properties Exposed to High Temperature and Fire Condition", (2012), University Sains Malaysia School of Housing Building and Planning, retrieved 12/11/2013, original source: http://www.ce.tuiasi.ro/~bipcons/Archive/325.pdf

- [2] "Gypsum Board Typical Mechanical And Physical Properties (GA-235-10)", (2010) Gypsum Association, 6525 Belcrest Road, Suite 480, Hyattsville MD 20782, retrieved 12/11/2013, original source: http://www.gypsum.org/wp/wp-content/uploads/2011/11/GA-235-10.pdf

- [3] Drywall or plasterboard standards: ASTM D3678

- Drywall or plasterboard standards: ASTM C1047

- Drywall or plasterboard standards: ASTM D4216-99

- Drywall or plasterboard standards: Canadian Codes [pending CSA citations]

- ASTM C 473 specifies the maximum deflection in humidified gypsum board for interiors, for ceiling board, and for exterior gypsum soffit board

- Drywall or plasterboard standards: ASTM C840

- Drywall or plasterboard standards: ASTM C844

- Drywall or plasterboard standards: Gypsum Association GA -216

- Drywall or plasterboard standards: Gypsum Association GA -234 (Fire-Resistant Applications)

- Drywall or plasterboard standards: Australian Standard AS2311–1992 for The Painting of Buildings (when painting plasterboard walls & ceilings)

- [4] Boral Plasterboard (Australia), "Boral Plasterboard Installation Manual", August 2007, PB103, Tel: 1800-811 222 (in Australia), Email: tecassist@boral.com.au, Website: www.boral.com.au, ACT: 7 Barrier St, Fyshwick 2609, Tel: 02 6280-4243. Other Boral Plasterboard offices are in New South Wales, Northern Territory, Queensland, South Australia, Tasmania, Victoria, Western Australia, and the company has an export department.

- [4a] Boral, "Plasterboard Specifications", retrieved 12/11/2013, original source: http://www.boral.com.au/plasterboardexport/ plasterboard_specifications.asp

- [5] British Gypsum Co., "Gyproc Control Joint, Products Plasterboard Accessories", Website: www.british-gypsum.com.

- [6] George M. Kutcher, Jr., "Don't Overlook Control Joints in Drywall Construction", National Gypsum Company, Tel: 1-800-NATIONAL, www.nationalgypsum.com, retrieved 12/10/13, original source: http://www.nationalgypsum.com/resources/tech-talk-controljoint.htm

- [7] National Gypsum Company, "Gypsum Board Systems", 12th Ed., (2000), (Gold Bond® brand gypsumboard products), website: http://www.nationalgypsum.com

- [8] George M. Kutcher, Jr., "Don't Overlook Control Joints in Drywall Construction", National Gypsum Company, retrieved 12/10/2013, original soruce: http://www.nationalgypsum.com/resources /tech-talk-controljoint.htm

- [9] "Design Essentials for Controlling Movement Induced Stresses in Building Materials", Winstone Wallboards, Ltd., Winstone Gypsum, Dec. 2009, Winstone Wallboards Ltd

219 Opawa Road

PO Box 1983

Christchurch

New Zealand

Phone: +64-3-332-3159, and Winstone Wallboards Ltd

37 Felix St

PO Box 12-256

Penrose

Auckland

New Zealand, Tel: +64-9-633-0100, Email: gypsum@gib.co.nz, Toll free: 0800 475 475.

Note: per Winstone: for large ceilings, AS/NZS 2589 specifies that all sheet end butt joints are backblocked (to reinforce the joint where such joints are not meeting over a ceiling joist). [This is a reinforcement detail for unsupported butt joints, not a wallboard movement control joint detail.

The company's article does recommend that installers insert control joints at the junction of wallboard ceilings at hallways vs large open spaces - Ed. ]- Cracking and Building Movement, Dickinson & Thornton, 2006

- BRANZ Bulletin 418 July 2001 ’Providing for Thermal and Moisture Movement’

- Cracking and Building Movement, Dickinson & Thornton, 2006

- NZS 3602 Timber & Wood Based Products for use in Building

- Wood Processing Newsletter SCION July 2003 Simpson & Turner

- ‘A Field Study of moisture performance of roofs etc.’ Technical Report 127. 1994 Cunningham et al

- ‘Plasterboard Peaking and Cracking under Timber R oof Trusses’ 1999 - Prof H Robert Milner, BE, MEngSc, PhD, FIEAust, AIWSc and CY Adam, BE, MEngSC Monash Engineering Timber Centre, Monash University, Australia

- ‘Walls & Ceilings’ Magazine ‘Drywall Cracking on a Global Scale’ By Greg Campbell March 9, 2001 ix AS/NZS2589 2007 – Gypsum Linings - Application & Finishing

- [10] Repair of Gypsum Board Joint Ridging ( GA-221-00 )

- [12] "Finishing Drywall Systems", U.S. Gypsum (USG) Corporation [copy on file as USG_Finishing_Drywall_Systems_Ch5.pdf] 2009

- [13] "Sheetrock® All Purpose Joint Compound - Select for professional drywall finishing", Submittal Sheet 09250

- [14] "Quality Drywall Finishing in All Kinds of Weather", USG Folder J-75 (out of print), U.S. Gypsum corporation

- [15] Gypsum Construction Guide, National Gypsum Corporation

- [16] Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- [16a] R.S. Means, The Gypsum Construction Handbook, 6th Ed., J. Wiley, (2009), ISBN 978-0-87629-258-7, quoting J. Wiley & Sons:

One of the construction industry's longest-running, most relied-on references, The Gypsum Construction Handbook was first published by the U.S. Gypsum Company in 1904. For more than a century and through several editions, the book has become a trusted standard. This new 6th edition is an illustrated, comprehensive, and authoritative guide on all facets of gypsum construction.

You'll find the newest product developments, installation methods, fire- and sound-rated construction information, illustrated framing-to-finish application instructions, estimating and planning information, and more.

System descriptions – together with full data on products, accessories, tools, equipment, and applications – help plan and estimate projects and ensure compliance with performance criteria.

Cost- and time-saving techniques keep the work on budget. New in the sixth edition are chapters on sustainable construction methods and products, building movement, fire resistance, heat transfer, sound transmission, and vapor/moisture control.

The Handbook covers both new construction and repair and remodeling and includes: framing drywall and veneer plaster joint treatment and plaster finishing interior cement board ceilings conventional plaster - [16b] Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- [17] Lath & Plaster Systems [copy on file as /interiors/LathPlaster_Nat_Gypsum.pdf ] - , 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- [18] Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster [copy on file as/interiors/Amico_lath-inside.pdf ] - from Amico, a lath and plaster accessory producer.

- [19] Plastering, PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

[copy on file as/interiors/Plastering_USG.pdf ] -

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started. - [20] Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- [21]

Drywall Finishing Council www.dwfc.org, Members: CertainTeed Gypsum • Freeman Products • Georgia Pacific Gypsum LLC • LaFarge North America • Magnum Products •

National Gypsum Company • Panel Rey SA • Rapid Set Cement • Saint-Gobain, Inc • Sherwin-Williams Company • Solid

Products, Inc. • Southern Wall Products • Trim-Tex, Inc. • United States Gypsum Company • Westpac Materials

- "Joint Compound Drying Time, the Impact of Environmental Conditions", Drywall Finishing Council, Retrieved 8/16/12, original source: http://www.dwfc.org/wp-content/files/2010_03_16_Joint_Compound_Drying.pdf [copy on file as Joint_Compound_Dry_Tmie_DWC.pdf]

- "Jobsite Conditions for Applying Interior Finishing Materials", Drywall Finishing Council, Retrieved 8/16/12, original source: http://www.dwfc.org/wp-content/files/2011_09_16_Interior_Job_Condition_Specifications.pdf [copy on file as Drywall_Finish_Conditions_DWC.pdf ]

- DWFC. Interior Job Condition Specifications For The Application of Drywall Joint Compounds,

Drywall Textures, and Paint/Coatings". Drywall Finishing Council, Incorporated. www.dwfc.org - DWFC. Recommended Specification for Preparations of Gypsum Board Surfaces Prior To Texture

Application, Drywall Finishing Council, Incorporated. www.dwfc.org - GA. GA-214, Recommended Levels of Gypsum Board Finish. Gypsum Association, 6525 Belcrest

Road - Suite 480. Hyattsville, MD 20782 www.gypsum.org - National Gypsum Company. ProForm Brand Drywall Finishing Products Construction Guide,

National Gypsum Company, 2001 Rexford Road, Charlotte, NC, 28211, www.nationalgypsum.com

- [22] The Gypsum Association www.gypsum.org Gypsum Construction Handbook H-17 [purchase at Amazon.com] . USG Corporation, 550 West Adams Street, Chicago, IL, 60661, www.usg.com

- [23] Painting and Decorating Contractors of America www.pdca.org Smartwood/Rainforest Alliance www.smartwood.org

- [24] "Joint Compounds", United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124, retrieved 8/16/12, original source: http://www.usg.com/interiors/joint-compounds.html [copy on file as Mud_Types_USG.pdf]

- [25] Gypsum Construction Guide, National Gypsum Corporation

- [26]

- [27] Lath & Plaster Systems, [PDF] 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- [28] Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster [PDF] Amico, a lath and plaster accessory producer.

- [29] Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- [30] PLASTERING, [PDF] PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-04-04 by Inspectapedia Com Moderator - basic drywall crack or earthquake cause?

@Anonymous,

Haha. Actually if you're referring to earthquake cracks in drywall, see the page top photo.

On 2022-04-04 by Anonymous

I think it can be a Earth quack

On 2022-03-10 by Inspectapedia Com Moderator

@Dan,

Then I would still suspect it is a common drywall crack occurring as the result of minor wood framing shrinkage and movement.

So it's a cosmetic concern; you can use mesh tape and joint compound to repair the crack, re-paint, and if we're both lucky you won't see further damage in that location from that cause.

On 2022-03-10 by Dan

@Inspectapedia Com Moderator,

Hello. Thanks for looking at this. It is wood framing with sheetrock. I don't see anything else like it in the house and no cracks in visible foundation.

On 2022-03-09 by Inspectapedia Com Moderator

@Dan,

What's the construction of the wall? Wood framing? Solid masonry?

Are there any other signs of building movement such as settling, sagging, bending, bowing, bulging walls or foundations?

If no, then this may be a common drywall crack occurring as the result of minor wood framing shrinkage and movement around a wood-framed window opening.

On 2022-03-09 by Dan

Hello,

Drywall crack at entryway from one room to another. Been this way for about 2-3 years. Very slow in growing if at all. .04" at bottom.

Any thoughts? Sheetrock bows in from other side at top and has been that way all along. Thanks!

On 2022-01-20 by Inspectapedia Com Moderator - fieldstone foundation home has drywall crack

@Jamie,

I can't see much but that looks like a hairline drywall crack at a seam and at a natural stress point in the building framing. I'd patch the crack with high-strength mesh tape and joint compound before re-painting. If the crack recurs or becomes wider that might merit further investigation.

On 2022-01-20 by Jamie

Here is a photo of the entire wall & I circled to where the crack is that you see in the first photo I uploaded.

For reference, our home is located in Iowa & was originally built in the 1900's (fieldstone foundation for the portion built in around 1930's, then a second fieldstone foundation for the addition built in 1960's & then in 2000's there was a garage added on which has cement foundation.)

In this photo the door to the left is going to the garage (Idk if the switch from fieldstone to stone foundation to cement would play a part or if the vaulted ceilings need something more?) It's hard to really gauge it based on things being level because it's a farm house & has never been "perfect"

On 2022-01-20 by Jamie

While painting I noticed a drywall crack that nearly extends from the corner of my wall to the ceiling. I tried to make it easier to see in the photo, but aside from the usual drywall crack fears (fieldstone foundation home), I'm unsure if it's more concerning because the line isn't clean cut straight up & down?

On 2021-07-31 by inspectapedia.com.moderator - drywall cracks only visible in winter

@ Rose

You shouldn't need to hire an engineer or even an experienced home inspector, though the latter, if a good one, could do the job; First, I'd expect an experienced drywall contractor to recognize the crack complaint and diagnose its cause;

I'd like to offer more specifics myself but I just can't see a thing in your photos.

The location of the crack, its relation to structural components and those materials and how they might move, and a confirmation that the movement is cyclical and only related to temperature changes are some of the important steps.

If you like, look at the page top EXPERTS directory, find a home inspector in your area, give her or him a call, discuss your concern, and ask if that falls within the inspector's expertise. Home inspectors vary widely from generalists who follow a checklist to people very experienced in construction methods, troubleshooting, diagnosis, repair.

On 2021-07-31 by Rose

@inspectapedia.com.moderator, the remodel was done several years ago. The room was completely gutted down to the studs. We had the ceiling made higher. We had them put in a 9 foot ceiling.

We installed windows and doors to the room. Most of the room are windows and patio door. Before the remodel we never had cracks in the drywall. After the remodel cracks appeared in the winter.

We live in the Cleveland , Ohio area and our winters are very cold. The room has heating and air conditioning and a dehumidifier. What type of inspector should I hire to determine the problem.

On 2021-07-11 by inspectapedia.com.moderator

@Rose,

Before proposing a "fix" to the -currently invisible- drywall cracking we need to diagnose the cause - so as to choose the right and effective repair of what sounds like a recurrent cosmetic issue.

Understanding how your building is constructed, and some contextual information about these building cracks: building construction type, materials, age, country, city of location, climate, soil conditions, and variation range of temperature and humidity are examples of data you and your onsite inspector will need to consider.

Common causes of cold weather drywall cracking include

- thermal movement of different building materials - see THERMAL EXPANSION of MATERIALS

and at the bottom of that page an index to key thermal movement articles

- rising roof trusses - affected by changes in both temperature and moisture level - see TRUSS UPLIFT, ROOF

- more-serious: foundation settlement or frost heaving - See FROST HEAVES, FOUNDATION, SLAB

Using the on-page box to Search InspectApedia for "thermal movement of materials" will find a broad range of examples of this sort of movement that can produce cracks in building materials

On 2021-07-11 by Rose

@inspectapedia.com.moderator, the reason you can’t see the crack is closes up in the summer. The cracks reappear in winter. They start at the corner of the soffit to the top of the window exact same patter on both sides of the room. Taping didn’t stop it from reoccurring.

On 2021-06-23 by inspectapedia.com.moderator

@Rose,

Sorry but I actually can't see the cracks of your photo.

If they are 1/8" or less in width, occurring at and following a right angle joint such as soffit to wall or soffit to ceiling, it's probably the case that you need a better taping job there.

On 2021-06-23 by Rose

We had a room completely gutted and remodeled. We had the ceiling vaulted. There is no attic above the room . It was an addition. It has a slab foundation. A soffit was added to install canister lights.

Since then we have cracks that appear from the corner of the soffit to the corner of the window. Identical crack on both sides of the room. The cracks only appear in the winter. What is it and how can it be corrected?

On 2021-02-23 by (mod) - it's "gypsym" wallboard, not "Egyptian" wallboard.

@Kathy M,

I meant "gypsum" wallboard as discussed in this article series.

Internet down, I was trying to reply using a cellphone and my phone is convinced it knows-better what I should be saying. (Nothing against Egyptians.)

On 2021-02-21 by Kathy M

Thanks Dan. I am not sure what Egyptian Board base is but will Google. Had a fire in 2015 in another part of the house and wondered if there may have been moisture in walls from where they hosed the house. or movement where we had to have some of the roof rebuilt. Also added 4 piers about 4 years ago so may have movement from that.I think I will get a home inspector to come look.

On 2021-02-04 - by (mod) -

My most complete advice that is more thorough than trying to make up an answer a new off the cuff is in the article above and others in this series so I hope that you will take a look.

My most complete advice that is more thorough than trying to make up an answer a new off the cuff is in the article above and others in this series so I hope that you will take a look.

I do notice however that in your photo we've lost what looks like a skim coat on an gypsum board base.

Or possibly we are seeing the separation and peeling of painted-ove wallpaper that is no longer well-adhered to the gypsum board surface.

So it could be that the skim coating was not properly applied such as applying it over dust or dirt, or it could be that there's been a leak or moisture problem. Those are some things to look for.

Typically I find and remove all of the loose material on the wall by feeling for bubbles or bulges, cutting around the damage with a drywall knife, removing the loose material, skim-coating with joint compound to fill the damaged areas, sanding smooth, priming, and painting.

Watch out: working on old homes with painted-over wallpaper I've sometimes found that it's hard to stop removing loose surface material; particularly when we wet the edges of the removed area by the application of joint compound, more painted-wallpaper loosens its grip on the wall surface below.

If that problem is sufficiently widespread it's less costly and faster to laminate a new layer of 1/4" drywall over the whole wall than to keep fiddling with patching, taping, etc.

On 2021-01-31 by Kathy M

65 yr old house previously remodeled in 70's & 80's. Cracking/peeling walls,bubbles and nail pops. Cause? How to repair?

[Photo above]

On 2020-10-13 - by (mod) -

Steve

Steve

Thanks so much for the comment: hearing from pros in the field is particularly helpful to everyone.

Before prescribing a repair or preventive measures for the ceiling-wall crack, if we can diagnose the cause with confidence we'll be more certain of the repair.

It's possible that you are seeing the infamous "rising roof truss" crack that occurs at an interior partition wall/ceiling juncture. In particular this crack shows up between ceiling and wall of a wall that is close to the middle of a building and runs parallel to the front and rear walls or roof eaves, AND where the roof is supported by trusses.

That problem occurs because of differences in arching of the truss upper and lower components that in turn are because the truss bottom chord that supports the drywall ceiling is buried in insulation.

The "fix" is to eliminate the screws or nails securing the drywall to the ceiling for a couple of feet on either side of that interior partition wall. In bad cases where the drywall is sufficiently damaged as to justify demolition and re-work, there are special clips that are used to hold the drywall to the wall top instead of the truss bottoms near the building center.

None of that repair needs to be done from that cramped attic;

Where I've fixed these cracks I either removed ceiling drywall screws that were into the truss bottom chord for a couple of feet on either side of the center partition wall or if nails were used, I use a punch to drive the nails all the way into the truss bottom, then patch the hole left in the ceiling and re-paint.

A second cause of cracking in the ceiling drywall may come from people or heavy storage over the area of damage - in particular when the ceiling is framed with minimal sized lumber; I've found this in cottages built in North America, the UK and Spain that date from the 1940s and 50s. But those areas of damage are different: the damage occurs closer to the center of the span, not right over the middle partition wall.

As it will help others and might encourage some useful comment, I will RE-POST this discussion over at

TRUSS UPLIFT, ROOF

And I'll be grateful if you can post a photo or if you have further comments, criticism, or suggestions.

On 2020-10-13 by Steve

As a drywaller i see a lot of cracks on ceilings. That begin at a outside corner interior wall. And extend across most of the room's ceiling. I figure the cause is movement in ceiling rafters. Where one is extended across the entire distance of the exterior walls and the one next to it is supported by interior upper wall plates . the crack starts at these supported locations and extend across the distance of all the unsupported joists. Because stiffeners were not put in place to keep bowing from occurring

How can this problem be best corrected with minimal attic space to work in.

On 2020-05-13 by (mod) - common causes/cures for drywall cracks at a window

Brad

Brad

Thanks for an interesting and helpful question that I'd phrase as: Interior details to permit and cover drywall crack from cyclic building movement.

Given the location of the crack and the surrounding framing deign, I don't assume this drywall cracking and wall movement are due to foundation settlement nor expansive soils etc.

First: in my experience cracking at a location like the one shown in your photo - where there is an intersecting roof plane that can be difficult to tie to the main structure, and where there is a framed opening for a window (where header connections are critical) it's not a surprise to find evidence of movement.

The underlying problem could be inadequate header at the window, inadequate connections of the lower sloped-roof to the main structure, or a similar problem.

Second: expansive clay soils can damage more than drywall, also moving and damaging foundations and in extreme cases, plumbing connections. So it is worth investigating whether a soil watering or de-watering system, such as commonly used under buildings with expensive clay soils, is necessary and would be helpful.

Third : In the location shown in your photo, it would be easy to add wooden trim that is fastened only on one side of the moving wall. That would cover the crack and allow movement without any visual evidence in the room. You'll need to extend the trim and include it in the interior design for it to make sense. f

Watch out: Before pretending to repair the window cracks I'd want to be confident that there is no other movement in the structure that needs repair and that might indicate more serious need for improved structural connections of roof or window header.

If you are confident that there is no significant underlying structural concern, then a cosmetic approach is fine.

For areas of less total movement I've used reinforced mesh tape before taping over and repairing crack damage.

In some locations indoors, such as at a wall-ceiling juncture, we use clips to carry the drywall so that the building can move without telegraphing that movement into drywall cracks. Those clips are described in our article that discusses cracks caused by rising roof trusses. See

details at TRUSS UPLIFT, ROOF

Thanks for asking - let me know what questions or thoughts occur to you on this.

On 2020-05-13 by Brad Sherman

[Regarding the photo shown above]

Differential building settlement, a change in building materials (standard timber frame / brick pier for original house and thermacell polystyrene / concrete for new work on big concrete footings), and stress concentration at the window corner have contributed to this crack.

At one stage it opened and I filled the gap and repainted. It subsequently contracted and squeezed out my earlier repair. Now it’s opened up again. I would just like to straighten the lines and make things look more ‘planned’ because the clay soils here mean the expansion/contraction cycle will continue.

Can you advise what sort of approach is best suited to lessen the visual impact of inevitable future building movement?

On 2020-02-03 - by (mod) -

Susan

You ask a perfectly reasonable question but from just your text I don't know what's going on.

I use the "fear-o-meter" approach to decide how to act on questions like this.

What else can we find that raises or lowers our level of concern?

At what point do we cross an action threshold: or when do we cross the line between: keep an eye on it - and cut an opening or do other invasive inspection?

If there's no water entry, no mold, no smells, no signs of structural movement, you might wait to act.

To know for certain what's happening you'd need to remove the drywall (as less troublesome than digging up the foundation, a step that can cause its own problems).

Outside, keep roof runoff and surface runoff away from the foundation.

Search InspectApedia.com for FOUNDATION CRACK DAMAGE to see more detail.

On 2020-02-01 by Susan Swan

I have an almost 50 year old back split home, with the lower level is about 50% underground. The bottom of the windows in the downstairs at right at ground level. I just discovered a horizontal crack about 1/2 an inch under the window running the length of the window. The windows are probably 25 years old. Should I be worried that it is the foundation? The wall doesn't have any water stains and it doesn't smell mildewy in the area.

Question: how to repair cracked RhinoBoard

2017/08/31 Hennie said:

I have a flat roof and have problems with cracking and peeling ceilings. How do you repair it. It is Rhinoboard. Please help

Reply: first diagnose the cause of damage and decide if other building repairs are needed

Hennie,

Before suggesting a repair we want to know the cause of the cracking and we need to know (we meaning you mostly with some encouragement from the sidelines) if there is damage to the structure behind those cracks.

Otherwise a cosmetic repair may be wasted and a more-serious problem such as a leak, structural damage from loading, rot, or insects, may need to be repaired.

If you're using the RhinoBoard that's a product of GypRock Staint Gobain in South Africa (or similar) we're talking about a plasterboard that uses a foamed or aerated gypsum core bonded to paper liners: ivory coloured on one side and tan-brown on the other. Rhinoboard is non-combustible and is used on ceilings and walls.

Rhinoboard is sold square-edged and in tapered-edge formats, the latter making it easier to tape and plaster over joints before painting in what the manufacturer calls a monolithic finish as in the Gyproc Drywall System.

So you could remove peeled loose coating, skim coat the peeled areas with joint compound, then tape cracks and joints using a fibreglass mesh tape, then coat with joint compound out 18" wide across the crack to hide the damage.

But as I intended to emphasize that work would be wasted if we don't first diagnose the cause of the trouble you are seeing.

Besides cracking, the peeling could be telling us there are roof leaks to be found and repaired, and it could hint that there is a mold reservoir in the roof cavity. If I were repairing a Rhinoboard ceiling with those conditions I would

- make a test cut into the ceiling to inspect for water, leaks, mold, in the most-damaged, most-suspect areas.

- inspect the roof for leaks

- hold off on cosmetic repairs until those questions are answered.

If your Rhinoboard is suffering from recurrent cracks that have been repaired before, and if there are no building leaks above, then

Also see our discussion of drywall cracks and nail pops repairs

If you want to send me photos of the condition for comment use the page top or bottom CONTACT link and I may have more specific advice I can offer. Also it would help to know the country and city where your building is located.

...

Continue reading at DRYWALL CONTROL JOINTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see DRYWALL CRACK CAUSE FAQs - questions & answers posted originally here

Or see these

Recommended Articles

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home

- ASBESTOS in DRYWALL

- COATING TYPE CEILING & WALL SURFACES: CATALOG OF

- DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

- DRYWALL CONTROL JOINTS

- DRYWALL CRACK CAUSES & CURES

- DRYWALL FINISH LEVELS

- DRYWALL INSTALLATION Best Practices

- DRYWALL INSTALLATION HORIZONTAL vs VERTICAL

- DRYWALL NAIL POPS & DENTS

- FROST HEAVES, FOUNDATION, SLAB

- GYPSUM BOARD GYP ROCK SHEATHING

- GYPSUM BOARD PLASTER LATH SYSTEMS

- METAL LATH for PLASTER

- PLASTER TYPES & METHODS in BUILDINGS

- PLASTER INGREDIENTS, MIX, PROPERTIES

- PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS

- TRUSS UPLIFT, ROOF

- WOOD LATH for PLASTER or STUCCO

Suggested citation for this web page

DRYWALL CRACK CAUSES & CURES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.