Rock Lath - Gypsum Board Lath

Rock Lath - Gypsum Board Lath

Perforated or solid gypsum or plaster boards

as base for wall or ceiling plaster.

Some partitions made using USG Rock Lath contain asbestos.

- POST a QUESTION or COMMENT about rock lath, button board, gypsum board as plaster base or to replace traditional wood lath or metal lath plaster ceilings & walls.

Rock lath or button board was used as a base for wall and ceiling plaster systems as early as 1918.

Here we will illustrate several types of gypsum board lath or "rock lath", including both perforated and solid gypsum board over which plaster was applied to form a finished wall or ceiling.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Gypsum Board Lath Sheets Used for Plaster Walls & Ceilings = Rock Lath, Plaster Lath, or Rock Lathe

Synonyms: Gypsum Board Lath Sheets Used for Plaster Walls & Ceilings = Rock Lath, Plaster Lath, Rock Lathe & Button Board

Perforated Gypsum Board Lath

Our photo (above) shows perforated gypsum board panels that were used as plaster lath. Both perforated and solid gypsum board panels were sold for use as a base for finish wall and ceiling plaster.

Plasterboard with round holes punched at regular intervals substituted for the plaster scratch coat, nailed to wall studs, eliminating the wood lath requirement. A top coat of plaster was applied to the plaster board. "Ears" of oozing plaster pushed through the round holes helped hold the plaster top coat in place

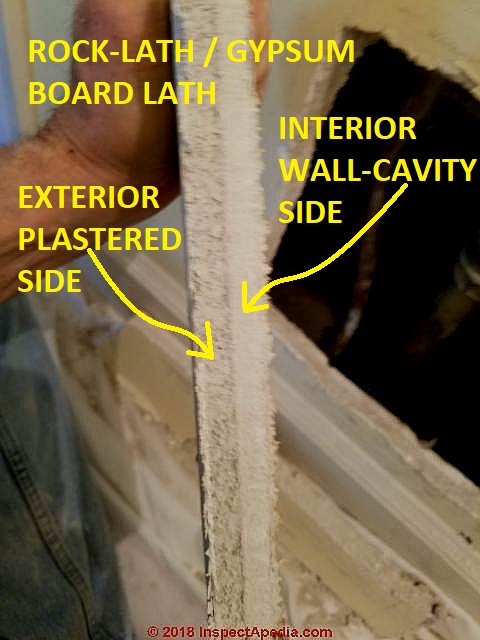

Our wall cross section cutaway photograph of gypsum board lath installed on a New York home (photo above shows how these walls are constructed, and you can see quite clearly the top coats of plaster that were applied over the gypsum board itself. [Click any image for an enlarged, detailed view.]

Here is another photograph of a PLASTER WALL TEST CUT [photo] that shows a closeup of the layers of plaster board and top coats that make up the wall surface in a 1930's-built home whose plaster-board lath included wood fiber reinforcing materials.

Contemporary gypsum lath products include GoldBond® brand gypsum board products including Kal-Kore brand plaster base panels sold by National Gypsum Corporation. Kal-Kore plaster base panels are designed as a base for veneer plaster, but these can also be used as basecoat plasters for Gypsolite, Two-Way Hardwall (National Gypsum products) or other conventional plasters.

Kal-Kore plaster base is sold in 4' and 8' widths and in 8' to 16' lengths - considerably larger than the older plaster-board lath systems shown above and just below where we describe regular rectangular bulges in plaster ceilings and walls.

Board lath and how it is applied are described in Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, and in US Gypsum's Gypsum Construction Handbook [book for sale link] as well as other publications. VanDenBranden/Hartsell explain the popularity of board lath as a plaster base [paraphrasing]:

- Board lath is rigid, strong, stable, and reduces the possibility of dirt filtering through the mortar to stain the surface

- Board lath is insulating, strengthens the framework of the structure, and the gypsum board is fire resistant

- Board lath requires the least amount of mortar to cover the surface

Gypsum Board Lath is provided in a variety of sizes, thicknesses, and types, most commonly 3/8" x 16" x 48" in dimension, solid or perforated with 3/4" diameter round holes punched 4" o.c. to provide mechanical keys, improving adhesion and fire rating of the surface. Our photo (above) shows mortar passing through the holes in perforated board lath.

Here is another example of perforated gypsum board plaster lath or rock lath, taken from a 1945 Greenville South Carolina home, courtesy of reader - 2020/11/03 Stephanie F. Nichols, Greenville SC

Watch out: only gypsum mortar can be applied over gypsum lath. Never apply lime mortar, portland cement, any other kind of binding agent to gypsum lath.

Also, perforated board lath should not be used on ceilings where it is supported only at edges, because the perforations weaken the lath.

But this is not the only type of plaster lath board or gypsum lath board found in homes. Above the product includes an insulating layer of up to 1/2" of wood or paper fiber insulating board on its innermost layer.

That layer is placed against the wall studs or in a masonry building against the masonry wall.

Insulating gypsum lath plaster boards

(not shown here) are similar to the gypsum board lath discussed above, but include aluminum foil laminated to the wall or ceiling cavity side of the board. Installed with a 3/4" air space before any ensuing insulation, this material adds about the same R-value as 1/2" insulating board.

Solid Gypsum Board Lath or Rock Lath

Solid gypsum board products: gypsum-based fire-resistant tiles were first produced by US Gypsum in 1916, a predecessor of paper-covered gypsum board used as a plaster lath base and later in lighter form as modern drywall. U.S. Gypsum, formed in 1902 by the merger of 30 independent gypsum rock and plaster manufacturers, produced Pyrobar in 1903, a gypsum-based fireproof tile.

USG's first gypsum board product was Sackett Board described just above.

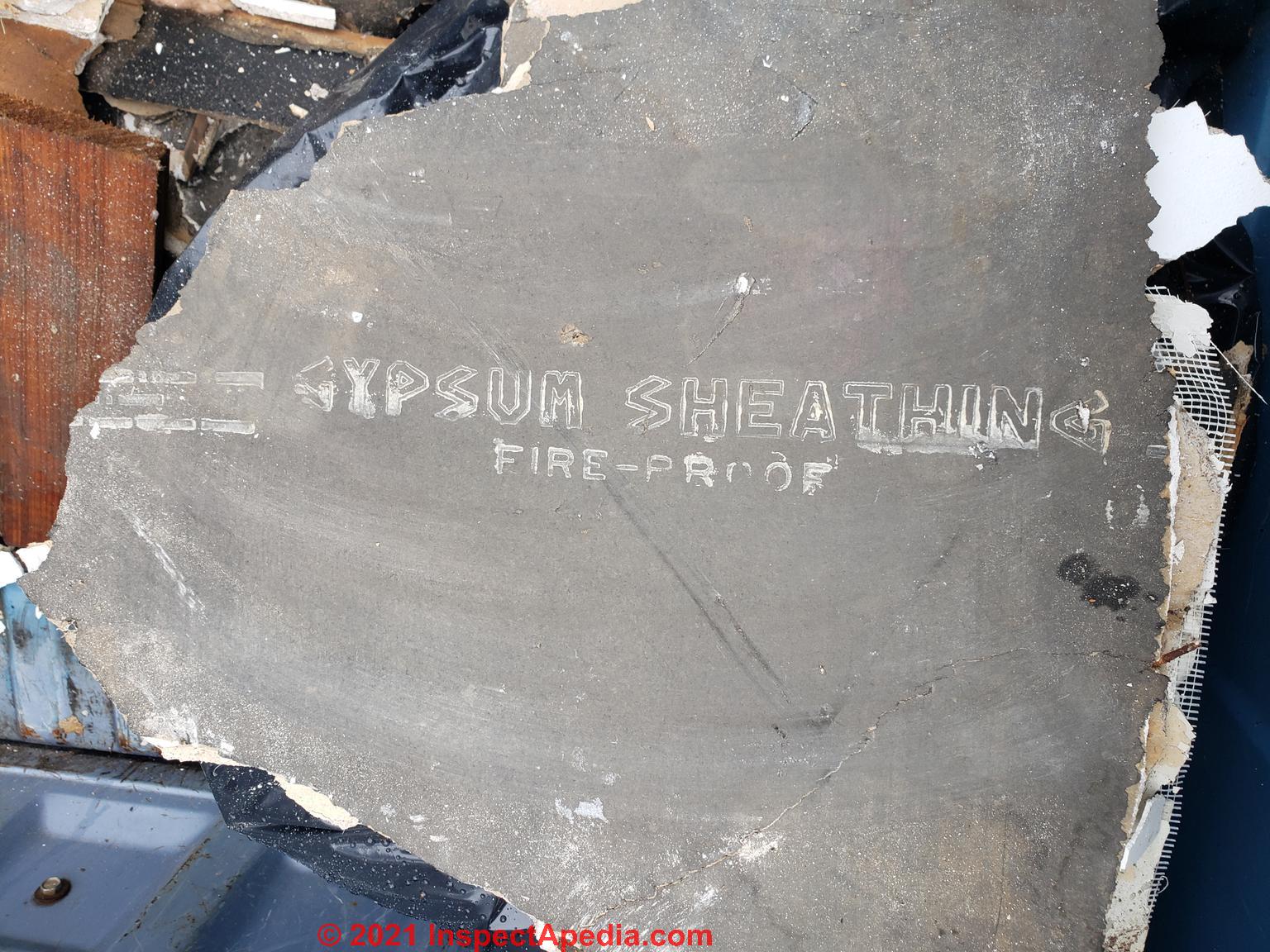

Below are photos of Certain-teed Products Corporation's Beaver Gypsum Lath, "Fire-Proof", including a nice edge view of "rock lath" or gypsum board used as a plaster base, courtesy of InspectApedia.com reader Z Headman & Zach, posted originally

at DRYWALL TYPE IDENTIFICATION STAMPS,

Solid gypsum board (above and below, without holes) was also used as a support for a plaster finish coat.

Often this material was applied in two-foot widths - a feature that the inspector may spot by noticing scalloped ceilings and walls or even cracks that appear regularly on 24" centers.

Below: rock lath / plasterboard lath / gypsum- lath (all synonyms) in a 1940's home in Poughkeepsie, New York. [Click to enlarge any image]

While cutting an opening in the home's interior wall to provide repair access to bath tub plumbing we could see the cross section of this material showing the thick plaster applied to the wall exterior. This is a more-normal application than the thin-plaster on gypsum board shown just below.

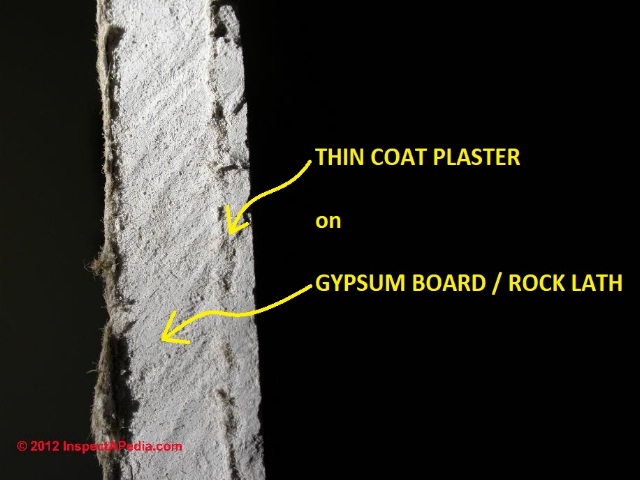

Below: very thin-coat plaster on more-recent gypsum board.

Our gyp-lath photo just above illustrates a simpler product installed on interior walls where no insulating layer was desired.

The gypsum-lath board (at left in the photo is made of gypsum covered on both sides by paper - there is no insulating board layer. You can see the very thin layer of finish-coat plaster on the right side of this gyp-lath board.

Question: What type of plaster ceiling do I have?

I've searched the internet and am trying to determine which type plaster ceiling I have in my master bedroom that collapsed. (see attached pictures) The insurance company has denied coverage and due to the Covid-19 pandemic the insurance company asked me to send them pictures.

The insurance company claims it is was a faulty installation and seem to be hanging their hat on one of the pictures showing a staple.

There are also pictures that show some nails. As an FYI, the home was built in 1962.

The 2 questions I have are:

- What type of plaster ceiling do I have?

- Were staples and nails used in plaster ceilings during the early 1960’s?

Thanks so much, Anonymous by private email 13 June 2020, Northridge CA

Moderator reply:

That's called a rock lath ceiling. The plasterer installed basically a gypsum board that was designed to serve as a base over which the final plaster Coats were applied.

Rock lath was a faster substitute for traditional wooden lath strips. I have not encountered rock lath nor other plaster board installed with staples.

I have found no prohibition of use of staples for fastening drywall nor plasterboard provided a staple with proper crown width and thickness is used, and some drywall installation instructions might include staples along with drywall nails and drywalls screws as acceptable fasteners, though staples are not a fastener I'd choose first for that purpose.

I prefer a larger fastener head and a more-secure fastener. The thin head of a staple is more-easily over-driven to create a weak connection between plasterboard or drywall and the building frame, and the thin legs of the staple have less withdrawal force than a drywall screw and probably less withdrawal force than a drywall nail.

The word "Staple" does not appear in USG's drywall installation instructions, not in CertainTeed's drywall instructions, nor in those from Lowes nor Home Depot, all of whom recommend use of drywall screws.

USG's Sheetrock™ installation instructions recommend:

Type W Bugle Head Screws attach singlelayer gypsum panels to wood framing. Screws provide greater holding power than wallboard nails, minimize popping and help prevent damage to the panels.

You're in Northridge where earthquake activity has shown itself thoroughly capable of loosening or damaging plaster ceilings and walls regardless of the type of fastener used.

See details

at EARTHQUAKE DAMAGE PHOTOS CA 1994 where we post photos of damage I inspected after the 1994 quake that decimated Northridge Meadows and other areas.

Also see

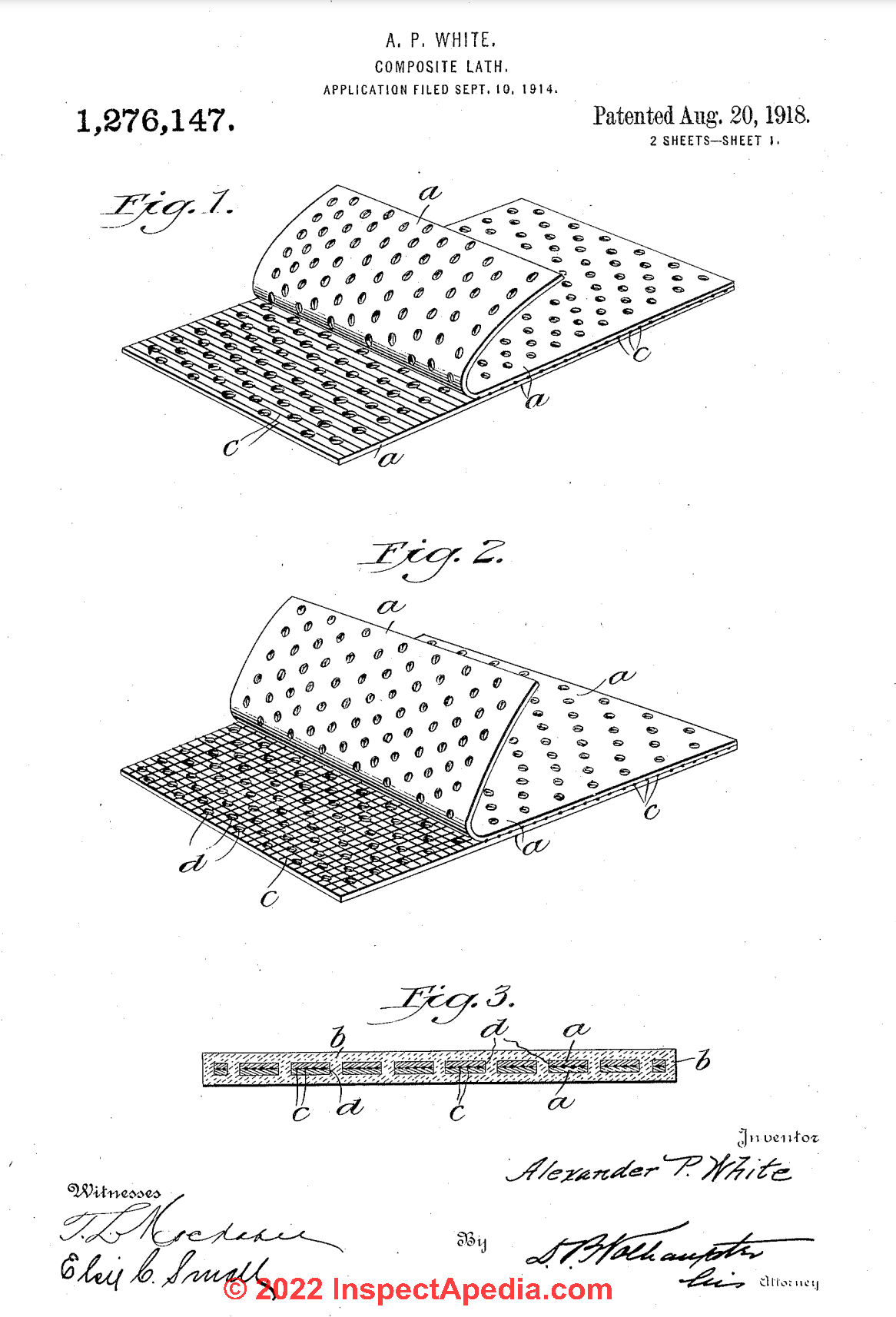

History of Invention of Gypsum Board, Perforated Board, Button Board as a Plaster Base or Plaster Lath System

Research: history of Rock Lath Gypsum or Plasterboard

Illustration: White's composite lath from 1918, cited below, was the earliest cited and patented perforated gypsum board used as an alternative to wood lath plaster walls or ceilings.

Illustration: White's composite lath from 1918, cited below, was the earliest cited and patented perforated gypsum board used as an alternative to wood lath plaster walls or ceilings.

Van Den Branden and Hartsell list ten gypsum board lath products, here we provide the full list

- Gypsum lath board - discussed above - see also SACKETT BOARD

- Long length insulating gypsum lath

- Veneer plaster gypsum lath

- Radiant heat gypsum lath plaster base

- Gypsum wallboards

- Gypsum backer boards

- Coreboard

- Gypsum studs

- Gypsum sound-deadening backer board

- Insulating lath board - discussed above

Patent disclosures give a general idea of the years of first popular use of gypsum board as a plaster lath base. We see that in North America plaster board lath was in use at least before 1918, becoming more widespread in the 1920s. Utzman in 1925 described "gypsum lumber" as a plaster base.

And Hicks, also in 1922, described plaster board with recesses or depressions to adapt gypsum board for use as a plaster base.

Gypsum Board & GypRoc plaster base patent research & history

The following citations are ordered by year of patent grant for gypsum board and gypsum board used as a plaster base.

- White, A.P., COMPOSITE LATH [PDF] U.S. Patent 1,276,147, issued August 20, 1918

Excerpts:

Improvements in Composite Laths, of which the following is a specification. This invention relates to a novel building material to be used chiefly for lathing, and its object is to provide an improved and side thereof. cheaper article of this nature that can be readily handled and transported, and which possesses strength without great weight.

This invention relates to a novel building material to be used chiefly for lathing, and its object is to provide an improved and cheaper article of this nature that can be readily handled and transported, and which possesses strength without great weight.

A special object of the invention is to provide a composite lath construction having novel means for strengthening the product in combination with an artificial stone body element, while at the same time imparting thereto improved facility for absorbing and assimilating excess moisture in such a manner as to hold the body of the lath to proper form and condition during the setting of the plaster, thereby insuring the drying of the latter with an even surface, both on Walls and ceilings. - Emerson, Joseph W. "Gypsum wall board." U.S. Patent 1,439,954, issued December 26, 1922.

- Hicks, William D. "Lath." U.S. Patent 1,430,080, issued September 26, 1922.

Patent excerpt: This invention relates to a lath and .particularly pertains to a composition lath. It is the object of this invention to provide a lath in the form of a wall board adapted to be manufactured in comparatively large sheets and so formed as to possess considerable rigidity and not bend in handling and so reinforced as not to be readily bro en.

Another object is to provide a rigid composition slab or board having recesses or depressions on its outer face adapted to receive and form a key for plaster, and in which the recesses or depressions are so formed and arranged as not to materially weaken the board.

... to provide a combined wall board and lath to adapt it for use in forming either a smooth wall surface in itself or as a lath to receive a finish' coating of plastic material. - Brookby, Harry E. "Composition wall board and method of making the same." U.S. Patent 1,428,827, issued September 12, 1922.

- Brookby, Harry E. "Process of making plaster board." U.S. Patent 1,511,500, issued October 14, 1924.

Patent disclosure excerpts:

This invention relates to improvements in building materials and more particularly to 'a light weight wallboard or plaster board, and is an improvement of the invention set forth in my prior Patent No. 1,428,827, dated September 12-, 1922.

Fabricated plaster board for some time i has been used as a substitute for the customary wooden lath in buildings and plaster wallboard as a substitute for both wooden lath and plaster.

The fabricated boards of this character formed of a plaster body protected by fibrous cover sheets when used as wallboard or a substitute for both lath and plaster are usually of a larger size than the plaster board or substitute for the lath alone and on account of the weight of the plaster body and increased size. usually 48 inches wide, of an inch thick and from to 10 feet in length, are both cumbersome and heavy.

It is an object of this invention to provide a light. weight body for plaster wallboard with all the favorable characteristics and structural requirements of the present plaster wallboard but which will be easier to i handle in shipment and in application .upon the building, wall or ceiling, and which while not detracting from the strength of the board will greatly reduce the cost of transportation. - Utzman, Clarence W. "Wall construction." U.S. Patent 1,559,134, issued October 27, 1925.

Excerpt: ... body having a fibrous-"covering" bonding, the gypsum boards contemplated in this invention may both be sawed and fitted in the same manner as their wooden construction here before mentioned a ... This invention contemplates the use of gypsum lumber [for the backing of' wall-. board the nature of which' board will permit the accomplishment of the above described objects. - John, Schumacher. "Method of making plaster-board lath." U.S. Patent 1,589,569, issued June 22, 1926.

- MacDonald, Marylee. OLD HOUSE RESTORATION: PLASTER [PDF] (1984) Old House Restoration OHR1 (2004). Building Research Council, School of Architecture, Univ. Illinois Urbana Champaign

- Buttress, George A. "Lath board." U.S. Patent 1,694,640, issued December 11, 1928.

Excerpt: This invention particularly pertains to aIl lath of the type embodying a panel consisting of a layer of plaster interposed between fibrous facing sheets. - SACKETT BOARD - early history of plaster board products used as a plaster base to supplant or replace wood lath systems.

Do US Gypsum Solid ROCK LATH or Partitions Made Using ROCK LATH Contain Asbestos?

Bottom line: even if the rock lath product itself didn't contain asbestos (undertain) a partition made using USG ROCK LATH and built between 1920 and 1969 (and possibly later) should be treated as presumed to contain asbestos because of the construction specifications that include asbestos-containing RED TOP Plater for completing such walls.

Supporting Research:

- USG 2" SOLID ROCKLATH & PLASTER PARTITION SPECIFICATIONS [PDF] - specifications & installation details from US Gypsum's 1952 Technical Specifications Book.

Note: this document describes the constituents of USG 2" Solid Rocklath and Plaster Partition construction as using ROCKLATH 1/2" from USG, USG's RED TOP gypsum plaster, and an aggregate made of sand and perlite. Perlite Perlite itself is a non-fibrous non-asbestos-containing material which has an R-value of about 2.7 per inch and would not be expected to contain asbestos. Asbestos is not mentioned in this document.

Watch out: that does NOT mean that asbestos won't be found in building partition walls built using USG Rock Lath products. The partition specifications above include a description of how USG RockLath would be used, specifying the use of RED TOP plaster made by USG. That product did contain asbestos.

- US GYPSUM SHEETROCK ASBESTOS in this article we point out that USG's RED TOP Gypsum Plaster produced between 1920 and ca. 1958 is reported to have contained asbestos and UAF USG RedTop™ Firecode™ plaster made between 1962 and 1969 contained asbestos, probably at a higher asbestos content level.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

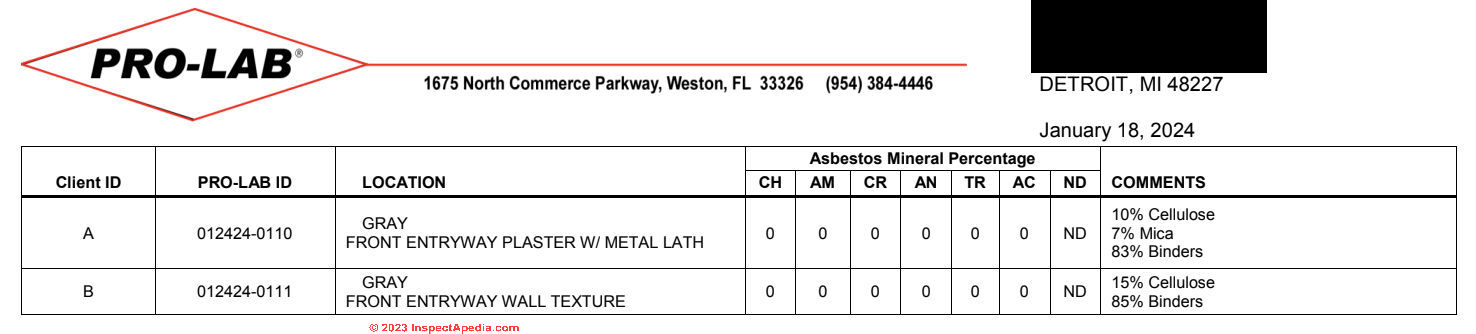

On 2024-01-31 by Harold - asbestos test result for the rock lath in 1942 Detroit home: asbestos not detected

Hello, I just demolished a front entryway in my 1942-built Detroit home.

We think it had this entryway and a dining room added on in the late 60s.

Anyway, I had the rock lath that was covering the walls and ceiling lab tested for asbestos and wanted to share those results with you. It looks like we are in the clear here.

...

...

On 2024-01-31 by InspectApedia Publisher - asbestos test result for the rock lath in 1942 Detroit home

@Harold,

Thank you for taking the time and trouble to share this asbestos test result for the rock lath in your Detroit home. That information will indeed be helpful to other readers and so we'll be sure to keep the report and photos with this article.

Readers should keep in mind that sampling any gypsum board or rock-lath for asbestos is never an exhaustive test if, over the life of the building, someone may have made wall repairs or modifications using joint compound that could have contained asbestos even if the original wallboard did not.

Still, a representative sample of the wall board itself is a reasonable place to test for asbestos if you need to demolish or remove the material.

Thanks again, Harold.

On 2023-12-22 by Heather What type of walls are in this 1953 Cape Cod Style Home in Ohio?

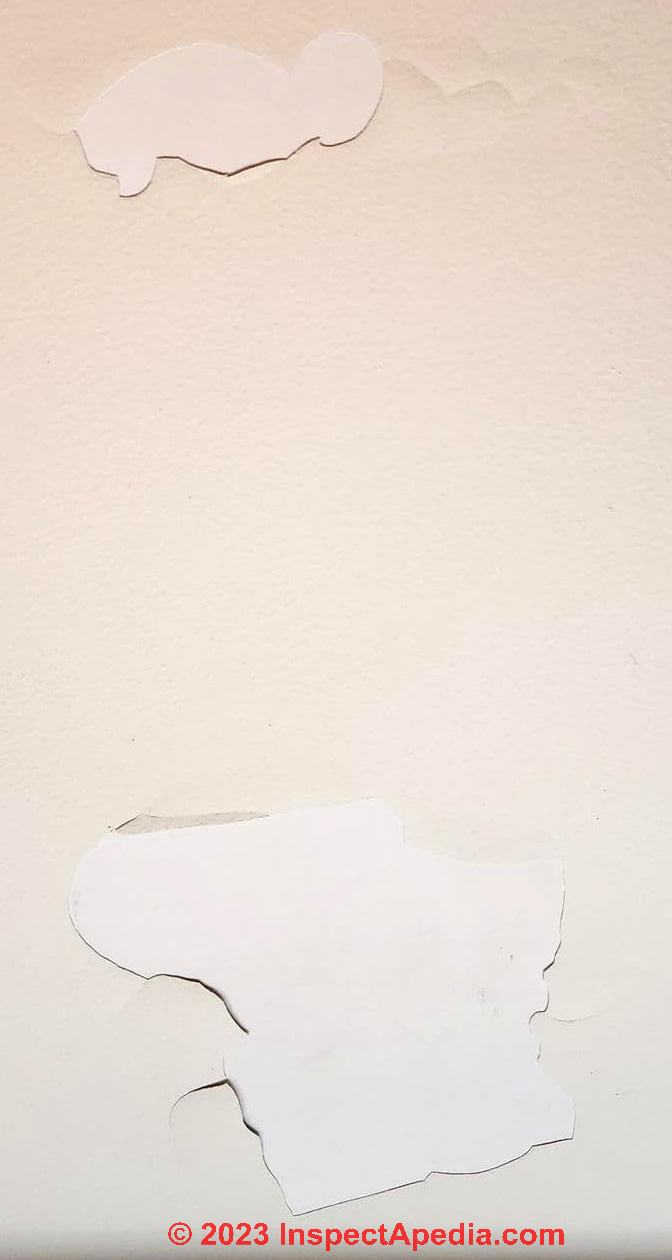

How can I determine the type of walls and the cause and how to fix ? Home built in 1953 in Ohio. This is ceiling in dining room.

Thank you very much.

Previous owners had a water issue. We put new roof on. So many of these areas in the dining and kitchen.

Picture of outside the bathtub where tiles are falling off. I don't know how to fix this or what this is.

The upstairs was added on in 1975. Home was built in 1953. I hope you can help me identify this problem. I have no idea how to address this.

I have a capecod 1953 home in Ohio. Several areas have peeling paint. I cant find on any search what type of walls I have. There was an upstairs added on in 1975.

The original bathroom down stairs has thick tile and I noticed while cleaning it was pushing in.. so I popped the tile out. Now I've got another real problem.

Seems there is nothing behind this wall. I stuck my camera in the hole and took this picture. This is a picture looking inside the wall inside the shower. Can you help ?

Thank you.

On 2023-12-22 by InspectApedia Publisher - peeling paint and loose bathroom tiles in 1953 Ohio home

@Heather,

I'll make some brief comments for what I can see in each of your photos..

Here it looks like there's peeling paint or poor adhesion of the more recent paint layers. That could be poor surface prep such as painting over loose or damaged surface materials or over a chalked surface.Area of prior water damage and peeling paint has been painted over. It looks as if some of the surface that was painted should have been scraped to remove loose material and sanded and feathered in so it's not to leave the lines that you see.

If you're confident that there are no ongoing leaks this is strictly a cosmetic problem.For that photo showing loose ceramic tiles, I'm sorry to say that most likely to repair this wall you need to remove all of the loose tile and possibly replace some plaster on expanded metal lath (I think I might evidence of that in your wall cavity photo)

Or remove the wall section entirely and install cement backer board before re-tiling.

It's not uncommon to find tile damage on wall damage like this in a bathroom wall covered with ceramic tile. Don't kid yourself to think that the ceramic tile covering is waterproof. It's not. Particularly we get leaks of the grout joints.On 2023-12-23 by Heather

@InspectApedia Publisher, Thank you so much for all your replies. I have been on your site countless times and it is a wealth of information.

I’m wondering if the cause of this room could be condensation?Ever since I had a new ac unit put in, this dining room gets condensation on the windows and the paint is also bubbled up above the vent where the cold air comes out. I did a dehumidifier and it helped some.

All this causes me a great deal of anxiety. My dad passed away and he was my go to guy and now I just don’t know how to handle these issues.

The walls are hard.. can’t push a nail into them. Under the painting that is coming off , it is chalky in some areas. We used a primer but guess that didn’t work as I see the primer stuck to the bottom of the paint we applied.

On 2023-12-22 by InspectApedia Publisher - history of leaks and water damage require wall repairs

@Heather,

Again, just be sure you have no plumbing or other building leaks going on.

I see what looks like a history of leaks and water damage, what looks like peeling paper from the back of gypsum board or rock left.

And that right in your photo that nubbled surface could be plaster on expanded metal lath.

It wouldn't be a surprise in an older home to find a combination of wall materials.Continuing, gypsum board is soft. You could easily push a small diameter nail into it whereas plaster walls are much harder and you wouldn't be able to do that.

For a plaster or plastered-over wall like that that I think I see in your photo you would remove all loose material. Then for a more-durable repair, use a fiberglass mesh tape over any cracks before re-surfacing with plaster or joint compound.

On 2023-12-23 by Heather

@InspectApedia Publisher, Hmm… looking grim

Thank you for taking your time to help me. I really appreciate it !On 2023-12-23 by Heather

@InspectApedia Publisher, Thank you again ! I actually kinda liked the original look as odd as some may think that is. Would it be possible to reuse these tiles ? The whole bathroom has these in it. Liked the originality.

The home was a foreclosure and we put a lot of time and money into it and it’s sad to me. This is the whole bathroom which I really would like to keep but not sure if that possible. That has been fixed where the four tiles are missing in the photo.

On 2023-12-23 by InspectApedia DF - can I use original tiles in my bathroom renovation

@Heather,

An older and high quality bathroom tile job involved setting tiles in cement on plaster or metal lath - which might be your bathroom's case. Those can be re-built using the same method if you find an experienced tile setter who knows the method.

Most modern tile setters prefer using a cement board as a backer as it's quicker, less labor, more profitable.

About re-using ceramic tile, it's probably not economically reasonable to plan to do so.

1. I think you'll find that most of the tile that comes off of the wall on its own will have some cement adhered back surface. Unless that adhesive is very soft (such that it can be easily scraped off completely to leave a smooth tile back surface) you can't remove it without breaking at least some of the tiles.

2. For tiles that remain bonded to the wall those are almost impossible to remove without breaking many of them.

3. About the best you can do is to have a worker carefully remove all loose and damaged wall material down to a horizontal line around the bathroom, then replace damaged wall backer with sufficient thickness or shimming to bring the new tile surface out flush with what remains of the original.

Then for your finished wall, you can usually buy tile that matches or is very close to the original tile size and color. Bring a sample of old tile to your tile supplier.

On 2023-07-13 by Martha - A doctor said just spray vinegar on my moldy cement lath - OK?

Okay tear out cement lath that is paper backed! I heard vinegar then bleach from a Doctor…any experience w/ that?

On 2023-07-13 by InspectApedia Publisher - Vinegar or bleach are never a cure for mold

@Martha,

Vinegar or bleach used as a solee remedy are never a cproper ure for mold and

Leave toxic spores or residue even if the spores are "dead".

Sprays and disinfectants don't cure the underlying cause - water or moisture somewhere.Remove the mold (clean the surfaces) and fix the leaks.

On 2023-07-11 by Martha - How do I get rid of mold in this rock lath wall: cut into the wall? Spray it?

Have a 1930’s brick cape cod built in Lansing Mi. Noticed bedroom ceiling has the 2 ft joints, as you mention in one of your posts! In attic walls I can see what looks like old fashioned cement lath wrapped in paper skin. No anchoring holes.

Have a 1930’s brick cape cod built in Lansing Mi. Noticed bedroom ceiling has the 2 ft joints, as you mention in one of your posts! In attic walls I can see what looks like old fashioned cement lath wrapped in paper skin. No anchoring holes.

In kitchen I have clean water damage from a loosened toilet tank inlet connection in 2nd fl bath directly above. This leaked onto some original inch thick ceramic bath floor tile, I assume into kitchen soffit (though haven’t opened soffit ) & along back wall of upper kitchen cabinets.

A hall way is on back side of cabinet wall. Only evidence of water damage is some peeling paint on wood cabinets.

I have run fans nonstop for a week. Saw some cracks on thin coat of plaster that appeared to have been covered up w/ spackle primer & paint after my house fire of 1999, possibly bowed out.

So chiseled off thin coat. That revealed a very cement grey substrate. Can’t tell if there was a paper coating on it. But worried about possible mold behind it or up in soffit.

Trying to locate a prong type tool to ell me off soffit is damp… water may have only run along back cabinet wall as no water damage on soffit visible.

Cement area exposed feels damp.

Should I cut into it to see if damp behind it? There is no mold smell. I have a very good nose…should I make a small hole in soffit & squirt some beach in there. Just in case?

Do the same with the back wall of cabin net…I am concerned if put plaster directly on grey substrate, or should I put some green board on 1st? Then prime & paint…

On 2023-07-12 by InspectApedia Publisher - any paper covered wallboard that gets wet is mold friendly

@Martha,

Unfortunately when we wet any paper covered wallboard, whether its gypsum- based or plaster- or something similar, the paper is mold friendly. So the minimum I'd do in this case is cutting out the water-stained drywall, clean the exposed surfaces, and when it's all dry you can complete the repair and repainting.

Spraying bleach won't be helpful - even "dead" mold spores can be toxic.

On 2020-08-15 by Jeffrey Does this fireproof gypsym ceiling board contain asbestos?

Gypsum Sheathing Fire-Proof Board

In Ceiling, coated with another layer of Plaster

Does this contain Asbestos?

On 2020-08-15 - by (mod) - asbestos in Fireproof Gypsum Sheathing Plaster Based Ceiling?

Possibly, depending on when it was made.

See ASBESTOS in DRYWALL

and see PLASTER ASBESTOS CONTENT

On 2019-01-30 by Kerry - Perforated gypsum board lath in a Colorado Home: paint keeps peeling.

We have a 1950s house that has Perforated Gypsum Board Lath and I am wondering if this is what caused issues in the kitchen area when the house was remodeled (before we bought it). The paint on the ceiling in the kitchen keeps peeling.

We think that there might have been a leak from the roof years ago from the looks of the staining now visible when the ceiling peeled. We just put a new roof on so that is not a problem any longer. However we don't know how to deal with the ceiling in there.

It keeps peeling. Are there any suggestions on it? I think the guys we bought the house from may have taken the texture off, but then painted it with a bad choice of type of paint. Any suggestions on dealing with this? This is also happening in the bathroom.

Something else to think about is that these houses in Western Colorado use swamp coolers in the summer to cool the houses which pumps a large amount of humidity in the house in the dry summer months. This might be part of the problem as well but I don't think so.

If you have any ideas I would love to hear them!

IMAGE LOST by older version of Clark Van Oyen’s useful Comments code - now fixed. Please re-post the image if you can. Sorry. M

On 2019-01-30 - by (mod) - issues in 1950s house that has Perforated Gypsum Board Lath

Kerry

I would get help from a home inspector who has equipment to measure moisture - we want to be SURE that there is no ongoing leakage nor that wet plaster or gypsum board was left where it might harbor a nasty mold reservoir.

I agree that inadequate surface prep such as leaving dust or debris can lead to paint failure, but your photo looks to me like peeling paint around a water stain.

If the problem with peeling paint were inherent in the properties of perforated gypsum board lath used as a plaster base you would not see such a localized peeling problem.

Bottom line: look for a recent or recurrent or seasonal leak.

Keep me posted, as what you find will help other readers.

...

Continue reading at PLASTER TYPES & METHODS in BUILDINGS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- PERLITE INSULATION

- PLASTER TYPES & METHODS in BUILDINGS

- PLASTER DUST EXPOSURE HEALTH HAZARDS

- PLASTER INGREDIENTS, MIX, PROPERTIES

- PLASTER, LOOSE FALL HAZARDS

- PLASTER REPAIR METHODS

- PLASTER TYPE IDENTIFICATION

- SHEATHING, GYPSUM BOARD

- US GYPSUM SHEETROCK ASBESTOS

Suggested citation for this web page

GYPSUM BOARD ROCK LATH SYSTEMS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- ASTM C 841 Metal Lath or gypsum lath installation

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.