Radiant Slab Tubing Leaks

Radiant Slab Tubing Leaks

Causes & repairs of leaky radiant heat tubing; f

ind & fix or move PEX tubing in slabs

- POST a QUESTION or COMMENT about the different types of tubing & fluids used with radiant heating systems

Radiant heat tubing leak location, access, & repair.

What causes leaks in tubing or piping used for radiant heat in floor slabs and what repair options make sense when the radiant heat system is leaking?

This article series discusses the suitability of various tubing materials for radiant heated concrete floor slabs, and choices of heat conducting fluids for radiant floors.

Our page top photograph shows polyethylene tubing being installed in a new concrete floor slab for radiant heat in a Two Harbors Minnesota building.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Radiant Floor Slab Tubing Leak Causes & Remedies

Reader Question: what can you tell me about Entran II leak-risk radiant heat tubing and how can I recognize it in a home?

Reader Question: what can you tell me about Entran II leak-risk radiant heat tubing and how can I recognize it in a home?

I have heard that Entran radiant heat tubing is a problem. Is that correct?

Reply: Entran II Radiant Heat Tubing Failure, Identification, Class Action Settlement

Early Entran™ Tubing marked Entran or Entran II is at risk of leakage and failure where it is installed, particularly if the tubing was subjected to high temperatures.

Entran-3 tubing does not have the same leak complaint history.

Our photo illustrates Entran-3 radiant heat tubing - not the leak-prone product discussed here.

Entran radiant heat tubing, produced by Goodyear Tire & Rubber and was distributed by Heatway Systems between 1989 and 1994 and has been estimated to have been installed in about 10,000 homes in the U.S. and possibly in Canada. Entran II tubing has been the subject of a class action lawsuit and settlement that we describe below.

Specifically Entran-II was a rubber tubing product installed for radiant heat floors. It was also installed in driveway or sidewalk snow and ice melting systems.

The defect of concern with Entran-II tubing is that a plasticizer added for flexibility was found to leach out of the rubber if it was exposed to high temperatures.

The loss of the plasticizer was associated with odor and smell complaints and ultimately with leaks in the tubing as with loss of plasticizer the tubing will crack.

We encountered this product first as part of an investigation into an odor complaint in a new home with radiant heat tubing stapled under hardwood floors.

The installer, hoping to "drive out" the odor, ran the heating system at higher-than-recommended operating temperatures, leading to a double fault: the flooring was damaged (gapping) from the excessive temperature and ultimately the tubing leaked.

In the trial testimony, as reported by various sources, there were defects in Goodyear's formulation of the tubing while Goodyear blamed Heatway for improper installation or faulty connectors. In 2000, Heatway Systems lost their legal battle with Goodyear Tire & Rubber Co. when the jury ruled in Goodyear's favor.

How to Identify Entran II Radiant Heat Floor Tubing (defective product)

You may identify Heatway Entran II tubing by noting its orange color and imprinted markings (given below) where you see radiant heat tubing at the supply and return radiant tubing manifolds that are usually close to the heating boiler.

- Entran II tubing is orange or "reddish-orange" color.

- Imprinted on Entran II tubing along its length will be some of the following text:

- Entran II by Heatway Systems

- Entran 2 Trace

- Entran 2 Wire

- Entran

- Nytrace

- Trace

- Twintran

- Tubing date code provided by Goodyear includes a manufacturing date, A letter A, B, C, D or Z along with other numeric datea

- Entran II Dimensions

- Outside Entran II Tubing diameter: 3/4" to 1"

- Inside Entran II Tubing diameter: 1/4" to 3/4"

Watch out: Don't mis-identify as Entran II other orange-colored tubing products that are not considered a defective product, such as tubing by Tayco as well as other Goodyear Entran tubing products like Entran III, Entran 3, or Entran EPDM.

Inspect The Condition of Radiant Floor Tubing

If the tubing was stapled-up beneath a wood floor and subfloor, by moving insulation (you may have to also remove ceiling coverings) you can also inspect the tubing and its condition.

If the tubing was stapled-up beneath a wood floor and subfloor, by moving insulation (you may have to also remove ceiling coverings) you can also inspect the tubing and its condition.

In our OPINION unless you already see visible leaks, cracks, or damage, it is not easy to determine the remaining life of the Heatway Entran-II tubing.

If the tubing was never subjected to high temperatures (which should have been the case with a properly installed and operated radiant heat floor system) the remaining life could be good.

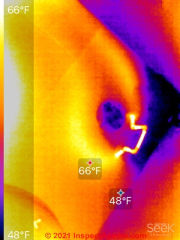

If you suspect that the tubing is already leaking (leaks may not be visible if tubing is embedded in a concrete slab) a pressure test or infra-red scanning and thermography can not only detect the leak but can detect where it is occurring.

Of course if the tubing has leaked in a finished ceiling you'll probably see water stains.

Class Action Settlement Offered Possible Financial Relief to Homeowners where Entran II Tubing Was Installed

In a class action lawsuit settlement, $324 million was set aside to pay building owners for claims related to defective Entran II tubing installed for radiant floor heating and driveway or sidewalk snow melting systems.

Only for homeowners who filed a claim prior to 19 November 2009, a financial settlement offered limited damage payments for homeowners in two categories, depending on the actual extent of leak damages that occurred due to Entran-II tubing.

The product names involved included Twintran, Nytrace, Entran II Trace, Entran II Wire, Entran 2, Entran 2 Trace, and Entran 2 Wire.

Details were at www.entraniisettlement.com or could be obtained by calling 800/254-9222. A follow-up check of these contacts in 2012 and again in 2023 lead nowhere.

Payment details varied depending on the type of Entran II installation (in-slab vs. staple-up jobs) and depending on the extent of leak damage to the buiding, claimants settlements were sometimes limited tojust 30% of the claimed damages amount.

Radiant Heat Tubing Leak Repairs or Modifications

Question: How to fix leaks in radiant heat tubing in a slab

Jan 1, 2017 Anonymous [by private email) wrote:

I have had radiant heat in a concrete slab for a little over 10 years now it was wonderful ,but six months ago it started leaking we found the leak and busted the concrete and found a pin hole in the hose. spliced the hose fix and check had no leak. in the last six months have had 3 other leaks, all in different places. had to replace the laminate floor twice.

I shut the valves and blowed out the lines, but the floor is now too cold for my wife. was wondering if it would be possible to install a smaller hose inside the7/8 PEX hose with maybe a1/2 inch hose? i have two zones with open system ,app 190 ft total - Anonymous 2017/01/02

Reply: options for re-lining or repairing leaky radiant heat tubing in a slab?

Interesting idea and not one I've seen before. There are pipe relining systems for larger diameters, principally for drains. I worry that your piping re liner won't push past connectors even if otherwise you could shove it through the tubing.

There are other relining options such as using a cured in place piping repair (CIPP) or an internal coating, epoxy or something else.

CIPP is described at TRENCHLESS PIPE REPAIRS where we also list some vendors of that system.

NuFlow provides an expoxy relining system: http://www.nuflowtechnologies.com/products/epoxy-lining/ intended for re-lining by coating copper or galvanized pipe. I'm not sure it's rated for plastic piping (assuming that's what you have) in part because plastic flexes. But you might ask the company how their system would work on flexible tubing encased in a concrete floor.

Special product seals leaks in radiant heat tubing

Reader Question: We may have a leak in the plastic lines in the basement floor. Not sure what material the lines are, but they're grey and the house is 30 years old. Is there a "stop leak" type of product that might work for this application?

I was hoping not to open the floor up. I did find a product from C-Tec called CT1 that claims to seal plastic pipe. Even has a video, but anything can claim to work. Ever hear of them? - Anonymous by private email 2018/02/27

Moderator Reply:

The leak fixes I've found for various plastic pipes are externally-applied patches or repairs, clamp-ons or epoxies.

I looked at C-tec, fhttp://www.ct1ltd.com/ - I don't see a product that would be successfully run through PEX type plastic tubing or water pipes to seal it; You should talk directly with the company - let me know what you're told.

[As of 2018/04/11 we were unable to load any of this company's web pages. You may have success contacting the company directly - Ed.]

If your plastic lines are a heating system you'd also be worried that the sealant goops up control valves or other components.

- C-Tec N.I Limited - Head Office. Unit 6. Ashtree Enterprise Park Newry Co Down Northern Ireland BT34 1BY. T:028 3083 4892. F:028 3026 4444. Email: info@ct1ltd.com

Reader follow-up:

I still have to do some testing to determine if the pressure loss is truly in one of the basement floor loops. The carpet has a small stain, but not damp. Still winter here, so testing may have to wait. Found a couple products last night, and I’ll call them today.

It looks like they’ve had success with Poly B in a closed loop system. The only issue may be the heat

. The system runs at 180F+ @ 30psi, but never over 200F. The relief valve limits pressure to 30psi, so the system runs just below that. I would think that a geothermal system handles pretty hot water, although I’m not sure the temp.

I did another test last night with the make up water shut off, and after 6 hrs, the system didn’t lose any pressure. I’ll continue testing this weekend.

Karen at Hood Chemical in Milton Ontario assisted in this research. She reported:

FINALLY they called me back. They said they have had no issued with Poly-B products. $ 60 for 8 oz bottle, not including shipping.

It is marketed as GEO LOOP and FIX A LEAK, it is the same product.

- Hood Chemical, FIX A LEAK [PDF] product data sheet, Hood Chemical, 295 Alliance Rd. Unit #14, Milton, Ontario L9T 4W8 tel: 905-876-0707 800-567-9791 Fax: 905-876-0695 Website: www.hoodchemical.com

- Hood Chemical, GEO LOOP LEAK SEAL & CONDITIONER INSTRUCTIONS [PDF]

- Special thanks to Karen ( karen@hoodchemical.com ) at Hood Chemical for assistance with investigating the usability of Fix A Leak in radiant heat flooring tubing.

How to find, cut, move radiant heat tubing to permit moving a toilet

I am planning a remodel of my bathroom, and changing the position of the shower and toilet. As a result, I will need to go through my hydronic radiant slab to get to the plumbing below.

I am finding it difficult to track down literature on this process. Im not sure if I’ll need to cut my hydronic tubing or if its possible to chip away the concrete and move the tubing out of the way.

Does your website cover this topic at all? Ive tried searching with no luck.

- by private email - in Arizona

Reply: proceed carefully including by hand when cutting concrete slab to find radiant heat tubing

I have in fact run into exactly this problem myself and have taken some photographs but I haven't published the details.

What I did was to chip carefully and slowly into the slab until I found the tubing and then I carefully broke the concrete around it taken care not to damage the tubing.

If you clear a big enough area you should be able to push it to one side and leave it uncut Which is far better than risking leaks later on.

I look forward to seeing photos of your own job and that may allow me to offer further suggestions.

Reader follow-up:

When you did this, did you just cut the insulation out below the slab and cut a piece to fit back in after plumbing changes were made?

Seems quite involved!

I want to follow up on my previous situation "the unknown history of a radiant slab". We've been in our house now going on 4 months, and the gas bills are starting to roll in. With two 20 year old water heaters, I'm seeing gas bills around $100. Not too bad, but the wife wants it warmer.

We go to bed with it at 70º and wake it up to it at 65. I've been eyeing boiler system and fancy hot water heaters to lower those bills.

That bathroom I want to remodel? Frigid. My toddler's room? Also frigid.

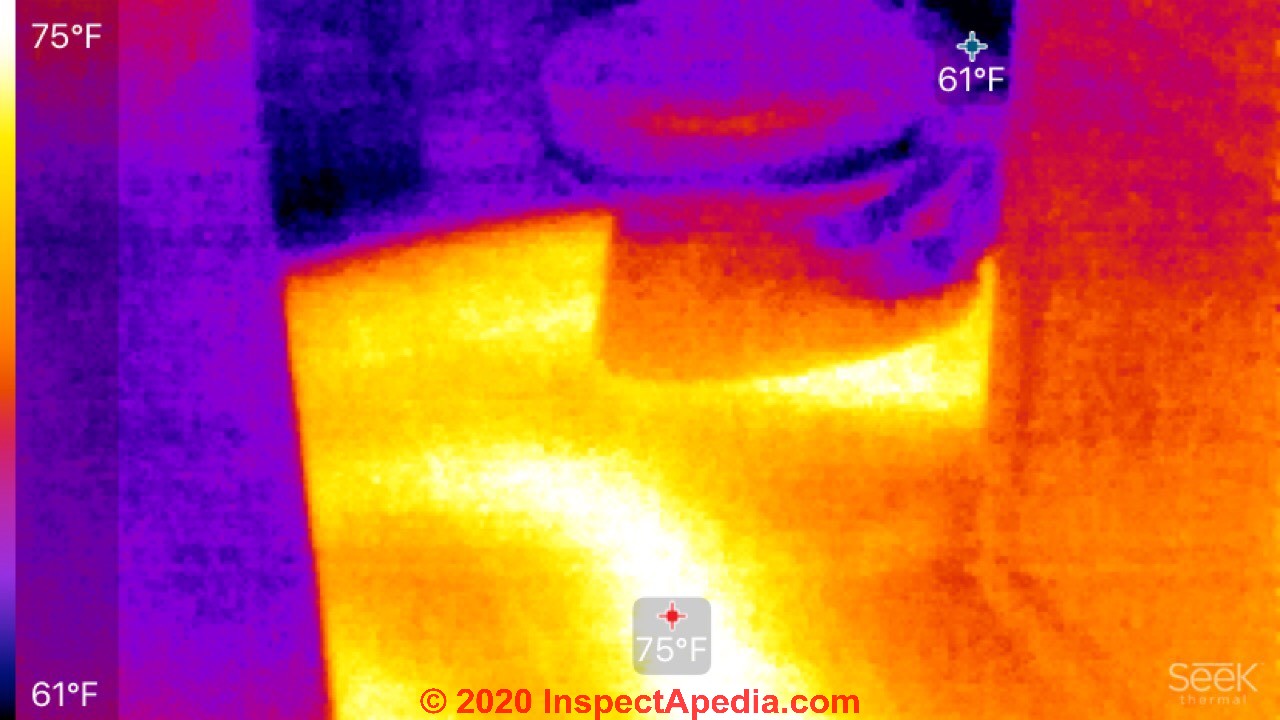

I recently got a cheap thermal camera and started scoping things out. One obvious culprit is the perimeter wall - it's uninsulated, above grade and in someplaces nearly 6' tall. Just so happens that the most exposed spot is my daughter's room outside wall. 4' of uninsulated foundation, and she's on the corner of the house. The thermal camera also picked up some big sections of outside walls that are losing heat.

Bringing it all back around - the remodel of the bathroom might also tell me what's happening under the slab as well. If its uninsulated, I wonder what is more cost effect - above-grade perimeter insulation, or insulating the slab from the conditioned space and installing a gas fired furnace?

Moderator reply:

Our Plumbing modification was abandoned over a code issue. But if I had had to continue I would have snipped the wire mesh that we uncovered in the course of breaking up the concrete and then excavated to whatever depth I needed to install what was required.

In our case it would have been a bathroom drain system that would have gone down through the slab and out below a footing. The object was to work carefully enough that we can preserve the radiant tubing lines and not have to put in connectors that risk a leak down the road.

For scanning and making thermal images to pinpoint the location of the PEX tubing that provides heat in your radiant slab

see THERMAL IMAGING, THERMOGRAPHY

Following up on this, how have you progressed?

Did you try insulating the accessible heat loss points like the above grade perimeter?

Reader follow-up:

Feb 10, 2020, 5:03 PM

No movement yet. Lots of back and forth with my wife about “do we really want to do this?”

No matter what we come up with, it always ends in the desire to move the toilet, and to move it at all is going to require getting under that slab.

Currently my only Plan-B would be to try a side approach - break the slab in the area without radiant PEX, dig under the slab (6” tops) to get access to the toilet flange and plumbing, then use a flowable fill when putting it all back together.

I know where the PEX line is at least.

The cabinet in the foreground on the right doesnt have any tubing under it so it could be a decent access point - its also where the toilet will be moved to.

I’ll let you know when we get moving on it!

Moderator reply:

Thanks for the update, I look forward to hearing how this progresses - photos and notes may help others with similar problems.

Also your thermographic photo is particularly helpful; I'd like to see more of these and perhaps to plug a couple of such images into our articles on thermography and on radiant heat slab troubleshooting and repair.

Reader follow-up: best way to expose, without damage, Pex in Slab?

Im back to working on my bathroom remodel project and getting closer to the key element of the project: replacing a toilet flange with a shower trap, and adding a new toilet drain line.

Luckily, I think only one of my hydronic lines in the slab will be disturbed by this work.

Have you heard much about the best way to expose, without damage, Pex in Slab?

I know where the line is (within 6”), but Im not sure how to get to it.

Uphonor recommends cutting a relief line, then working towards the line with a chisel (manual, air, rotary hammer?) to expose it.

They also have no concerns with approved Pex repair options. Id prefer not to need to repair the line, haha!

Any suggestions on method and tools to expose pex in slab?

Moderator reply: power tools then hand tools to expose PEX tubing in a concrete slab

I recently chopped open a slab to expose some PEX lines and I was able to get down to it without damaging the pics. But of course once it's exposed it's not at all difficult to patch in a section if you need to you could even use shark bites.

I use the combination of a jackhammer for the initial work but very quickly switch to a rotary impact drill. I took care of course. You drill into the floor slab near the tubing.

Watch out: when nearing the PEX or similar radiant heat tubing in a slab slow down and work by hand so as not to damage the tubing unnecessarily.

It's pretty durable. You can chop pretty close to it without breaking it.

Reader follow-up:

I talked with Uphonor and they suggested not using power tools to expose the Pex if I wanted to avoid damage.

They prefer the “get close then use manual tools to expose it.”

Moderator reply:

I agree with proceeding carefully.

Once I got close enough to be good to see where the tubing was exactly I use a Pneumatic hammer drill to break up the surrounding material. There are photos of that process at InspectApedia.com

I have to add though that working for several days with a hammer drill.

And then by hand with a cold chisel and mallet - just about killed my wrist and hand.

Reader comment:

Is there any way to better show the process of how you got down to the tubing without damaging it?

Another thing Ive been thinking about is how a poorly installed in-slab hydronic system might be able to be converted to a Warm Board setup. It might be ugly until all floors are the same height but it would prevent someone with an expensive boiler setup from losing all those costs. Any thoughts on that?

Moderator reply: steps in removing concrete to move or remove PEX tubing in a radiant heat floor slab

The sequence wont' fit your case exactly but in essence

1. a worker used an electric jackhammer

to break up most of the concrete floor over the work area. We knew the approximate depth of tubing in the slab from photos taken when the radiant-heat slab was first built.

RADIANT HEAT MISTAKES has a couple of those images of the original work and further on the page, the tubing after I had exposed it completely - down to the pink foam on which the tubing was (improperly) pinned.

PEX tubing is really quite strong. The original jackhammering was done by a subcontractor - I was not in the building when he did that work - and I don't think he was being particularly careful at the time. But he got right down to some tubing without breaking it, though I found some of the tubing surface had been roughed up a bit.

2. Because the tubing at this project was pinned to thick styrofoam insulation,

its underside was somewhat cushioned against impact from above.

That styrofoam also meant that we could use a small mallet to break up concrete between tubing runs and just lift it out.

If your tubing is actually encased in cement I am so sorry to say your job is tougher than mine (and mine was horrible). You'll need to work very carefully to get down close to the tubing and then work by hand to expose it.

3. In areas where there was thick concrete remaining

that I needed to remove, AND knowing within a couple of inches where the tubing was (as it was exposed in some areas already) I used a heavy-duty electric impact/hammer-drill and an large bit (I think it was 3/8") to drill successive holes until it was easy to break out concrete exactly where I needed to do so.

For your case if you know how the tubing was laid out originally if you can get close to one bit of tubing you can know where to drill or hammer and then drill to expose more of it, follow it, as needed.

Thanks for the Warmboard idea - I'm not familiar with that system but will take a look at it.

https://www.warmboard.com

is what I found. If you have a different source let me know. - Mod. 2020/11/25

Reader follow-up:

I got into my slab, and of course, hit a line. My Rotary/Demo Hammer was seemingly working intermittently (my first time using one) and I was getting aggressive and sure enough, I found the limits of PEX tubing.

So now I've got the water to the system turned off, because I cannot for the life of me figure out how to stop the flow of water to that loop. I don't know if I have the wrong loop on the manifold or what. The good news, I can probably heat my whole house on the rest of the operational loops, the downside is, I can't figure out how to turn JUST that loop.

Do you know how the Uphonor/Wirsbo valves work?

Do I remove them to shut of the water, or turn them the whole way in? - Anon 2020/12/30

Moderator reply:

There should be a turnkey at the inlet valve to that zone, but that's not enough anyway; so don't worry if you can't find it

I would in an emergency crimp or bend the pipe or tape it or even use a C-clamp to pinch the ends shut.

Figure that you are going to simply cut in a patch with two Sharkbite PEX connectors at the end of the chopping job.

Don't worry it's pretty easy to repair.

Crimp it off for now. - Mod 2020/12/30

Reader follow-up: steps to identify the PEX radiant heat tubing loop to be cut & moved

I do not appear to have turn key on the individual loops. Just a single one for the entire system before the hot water heater, and one on the outlet (cold) side after the valves.

See attached pictures.

Above: radiant heat slab ontrols, heat source, and piping entering the wall and floor.

Below: damaged PEX tubing as we chopped into the concrete slab to gain access.

I've resorted to pulling off the valves one by one to see if I can find that specific loop. My first try failed, and because my toddler just started throwing up I dont have an extra set of eyes to watch the flow of water on the rest quite yet.

My demolition hammer is being wierd and pretty slow, so I wasnt able to clear enough of the slab around the puncture to crimp it. The multiple holes are evidence of the frustration of a tool that isnt working properly. - Anon 2020/12/30

Moderator reply:

Well if it makes you feel any better I went through bad hammer drill before I bought a much better heavy duty Milwaukee model. The first one which seems like a great deal on Amazon gave up the ghost after just an hour of use.

If you can make a reasonable cut across the damaged PEX it might be possible to stuff a makeshift cork into each of the open ends.

Toddlers take top priority.

Reader follow-up: tips for removing concrete to get at PEX tubing: repair leaks or move PEX lines

Went one night without heat but luckily the house was pretty warm already so house temp only dropped into mid-60s. Still burns me that I couldnt isolate the Master Bed/Bath and keep running water to the rest of the house.

A set of shark bite fittings has created a temporary “work” loop so I can keep going through the slab without losing heat.

I almost wonder if I’m going to repair this section “properly” with Uphonor ProPex fittings, if Im better to remove the whole problematic loop around my existing toilet flange, and when I relay the concrete (which will be under the new shower) to either make additional loops for more heat, or just leave it out all together.

My master bath is cold. Combination of two outside walls (exterior and garage), less than ideal insulation, and only 1/3rd of the floor actually containing hydronic lines that are not particularly tight loops.

Maybe one solution for this is to add loops, but doing it in the floor is problematic. Ive heard of people taking radiant heat lines, running them out of the concrete and into towel warmers or hydronic wall heaters. This is perhaps a better option for my situation.

As far as the slab work goes - what are your thought on working around/under rebar? Remove it without worry, or try to undermine it if at all possible?

Oh one more thing - Im using a 7.4lb impact force Baurer Rotary Hammer. Ive also got a little pneumatic air hammer/chisel. The Baurer was giving me problems due to IBM - “idiot behind machine”. I think its got a safety that prevents it from hammering when pressure is not applied to the bit. So everytime I lifted up and kept the trigger pulled, it was would enter this safety mode. I found that if I lifted it, I should let go of the trigger, reset it on the target, then press again. That seemed to work more reliably.

Here’s what I determined about tools for slab work around hydronic lines (something to add to your website perhaps)

Tool Recommendations for Concrete Slab Work Around Hydronic or Radiant Floor Heat Lines

- Bigger is only better if

you dont care about having to patch or repair lines. Or you know EXACTLY where they are.

Moderator comment: yes smaller is safer, but we spent days using a small impact drill at the start of one concrete removal job and found the job sped up by a factor of 10 when we switched to a more-powerful impact drill. - Watch out: While PEX lines are tough, a big tool can damage them easily, especially with a direct hit.

- A pneumatic air hammer

is light but powerful if you’ve got the 10+ gal 4+cfm to run it. Mine was nice to have as I got closer to the lines. Its more of precision tool. - Bull point bits are the quickest

way to get through concrete, find and puncture hydronic lines. - Baurer is 7.4lbs impact

and almost a little small to quickly go through the slab, but too big to comfortably work closely around the PEX hydronic lines. - A good combination of tools for this job

would be something small (pnuematic air hammer or 3.4lb impact rotary hammer) and something big (12lbs or bigger demolition hammer or small jackhammer.) - Watch out: Scoring cut lines with a saw has gotta be tricky - my hydronic lines were about 1.5” down, but I’d still be very nervous running a saw over them, even if I set it to 3/4”.

All it would take if a line to be a little shallow and your into a repair job. - My Seek Thermal Compact sensor

for iPhone [photo above] has been indispensable in getting some idea of where lines run and their routing to and from the manifold. It is not, however great when standing directly over a section of floor trying ti determine where to cut, drill or chise first. If I did it again, I might spend more money for the widest field of view (mine is only 36deg) and the most sensitive sensor.

The Seek Shot Pro has a 57 degree field of view and a more sensitive 360x270 sensor. As a DIYer a thermal camera is pretty handy for all sorts of jobs. See attached image for an example of this lack of fidelity at close range (standing on a stool with camera almost against the ceiling).

Thanks for the help, I’ll keep you updated as I go. - Anon, 2021/01/21

Moderator reply:

Thank you for the discussion and update; ultimately we may add a list of your tips for other readers facing similar in concrete pex heat issues.

I don't hesitate to use a sawzall with metal cutting bit to snip out re-bar that's in the way in a small area like a bath;

In an area of unstable soils, earthquakes, or in a large floor I might be more cautious about cutting too many re-bars across a section - say 10 ft. or more;

I was skeptical about Sharkbites vs. the Uphonor fittings that require far more costly tools and procedures.

I read various reviews and comments and have so far had no issues with sharkbites - in a 10 year old installation in NY nor in our PEX water lines in MN.

Epoxy Water Pipe Relining Systems

- Nu Flow North America, 1313 Boundary Road, Oshawa, ON L1J6Z7 Tel: +1 (905) 433-5510

Watch out: there is some question of the efficacy of re-lining pipes. Questions include

- One cannot inspect the pipe interior to see where the lining material adhered or didn't adhere so you could be spending a wasted sum with an unpredictable life far less than the typically-claimed 60 years

- Adhesion of these liners may not work at all on plastic piping such as PEX

- If the pipe is already corroded, thinned or leaking, then the "repair" is itself very thin at that location - that is there's only the liner, no pipe material. Under pressure and temperature such a repair may be short-lived.

Research on Epoxy Water Pipe Relining System Effectiveness & Life

- Robles, Dan, "What the Insurance Industry Needs to Know about Epoxy Water Pipe Liner", (2013), retrieved 2017/01/02, web article, original source: http://insurancethoughtleadership.com/what-the-insurance-industry-needs-to-know-about-epoxy-water-pipe-liner/

and in that article citations of - Impact of an Epoxy Pipe Lining Material on Distribution System Water Quality by Ryan Price and supervised by Andrea M. Dietrich, PhD., Chair, Environmental Engineering, Virginia Polytechnic Institute.

http://harrisonwest.net/wp-content/uploads/2012/10/THESIS_Revised1.pdf - PUBLIC WORKS TECHNICAL BULLETIN 420-49-35 15 June 2001 IN-SITU EPOXY COATING FOR METALLIC PIPE; Department of The Army; U.S. Army Corp or Engineers.

http://harrisonwest.net/wp-content/uploads/2012/10/Military-Application-Epoxy-Standard.pdf - Layman's Guide to Epoxy Paint / Coating Failures.

http://www.epoxyproducts.com/fail4u.html - ASTM F2831 – 12: Standard Practice for Internal Non Structural Epoxy Barrier Coating Material Used In Rehabilitation of Metallic Pressurized Piping Systems.

2014 Pipe Relining Guide - http://www.trenchlessonline.com/pdfs/2014-pipe-relining-guide.pdf

If you can, send me photos of the floor, the tubing, the opening you cut, the hole you found, and the repair. That will let me comment in a way that at least *sounds* smarter. <g>

Other questions about change in heat transfer through a double-thickness of pipe make assessment of the effectiveness tricky too. You might think about increasing water velocity and temperature but that, in turn, risks exceeding the temperature rating of the tubing.

Finally, where did the leaks occur? What can we say about cause? Were pinholes in the tubing or in brass connectors?

If leaks are being found at the connectors used in your radiant heat piping,

Research on Radiant Heat Tubing or Slab Leaks & Litigation

- [18] Chemax, "Cross-Linked Polyethylene Tubing and Water Contamination", retrieved 2/17/2013, original source: http://www.chemaxx.com/polytube1.htm [copy on file as [Water Contamination chemical investigation.pdf]

- Contractor Magazine, Entran TUBING BATTLE ENDS WITH A WHIMPER [PDF] (2004), Contractor Magazine, - retrieved 2023/04/06, original source: contractormag.com/radiant/article/20873481/entran-tubing-battle-ends-with-a-whimper

- [28] Contractor Magazine, "California approves PEX for plumbing — again- Contractor Magazine.pdf", retrieved 2/18/2013, original source: http://contractormag.com/news/ california-pex-plumbing-1234 [copy on file as California approves PEX for plumbing — again- Contractor Magazine.pdf]

- [26] GreenBuilding Advisor, HOW SAFE is PEX TUBING [PDF] retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ blogs/dept/qa-spotlight /how-safe-pex-tubing Web: GreenBuildingAdvisor.com

- [25] GreenBuildingAdvisor.com, PEX vs COPPER [PDF], retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ community/forum/green-products-and-materials/ 16256/pex-vs-copper

- Friedman, Daniel J., "Polybutylene Piping: Time Bomb?" Daniel Friedman, Journal of Light Construction, August 1996 [Technical Q&A].

- HollandHart, GOODYEAR TIRE & RUBBER COMPANY SETTLES WITH NEW MEXICO PLAINTIFF IN ENTRAN CASE, [PDF] (2003) HollandHart LLP,, Web: hollandhart.com - retrieved 2023/04/06, original source: hollandhart.com/the-goodyear-tire-rubber-company-settles-with-new-mexico-plaintiff-in-entran-case

- [27] Hunter, Lauren, "California’s PEX Battle Continues", Remodeling Magazine, June 2010, Website: Builderonline.com, "x", retrieved 2/18/2013, original souirce: http://www.builderonline.com/legislation/californias-pex-battle-continues.aspx [copy on file as California’s PEX Battle Continues - Plumbing, Legal Issues, Legislation - Builder Magazine.pd]

- [19] Ingun Skjevrak, Anne Due, Karl Olav Gjerstad, Hallgeir Herikstad "Volatile organic components migrating from plastic pipes (HDPE, PEX and PVC) into drinking water", Water Research Volume 37, Issue 8, April 2003, Pages 1912–1920

Abstract:

High-density polyethylene pipes (HDPE), crossbonded polyethylene pipes (PEX) and polyvinyl chloride (PVC) pipes for drinking water were tested with respect to migration of volatile organic components (VOC) to water.

The odour of water in contact with plastic pipes was assessed according to the quantitative threshold odour number (TON) concept. A major migrating component from HDPE pipes was 2,4-di-tert-butyl-phenol (2,4-DTBP) which is a known degradation product from antioxidants such as Irgafos 168®.

In addition, a range of esters, aldehydes, ketones, aromatic hydrocarbons and terpenoids were identified as migration products from HDPE pipes. Water in contact with HDPE pipes was assessed with respect to TON, and values ⩾4 were determined for five out of seven brands of HDPE pipes. The total amount of VOC released to water during three successive test periods were fairly constant for the HDPE pipes.

Corresponding migration tests carried out for PEX pipes showed that VOC migrated in significant amounts into the test water, and TON ⩾5 of the test water were observed in all tests. Several of the migrated VOC were not identified.

Oxygenates predominated the identified VOC in the test water from PEX pipes. Migration tests of PVC pipes revealed few volatile migrants in the test samples and no significant odour of the test water. - [3] PB (polybutylene with mechanical fittings) Piping leaks: especially in mobile homes and in the U.S. South, for example trailers and double-wides throughout Florida that were piped with this material - per M Cramer.

- Plumbing & Mechanical Engineer, HEATWAY LOSES ENTRAN II LAWSUIT TO GOODYEAR [PDF] (2000) Plumbing & Mechanical Engineer Magazine,

Main Office

2401 W. Big Beaver Rd., Suite 700

Troy, MI 48084 USA, Tel: 248-362-3700 - Email: pmengineer@omeda.com,retrieved 2023/04/06, original source: pmengineer.com/articles/86862-heatway-loses-entran-ii-lawsuit-to-goodyear

Excerpts:

... an expert witness from the Naval Research Laboratory pointed out that Goodyear used inadequate antioxidants, inappropriate volatile plasticizers and cheap clay fillers in making the hose.

A second expert witness testified that Goodyear's failure to properly test the Entran II product for radiant heat purposes led to the problems.

Meanwhile, mechanical contractors from Colorado and Alaska testified that they had employed exactly the same installation methods when installing Heatway's other radiant brands-yet only experienced problems with Entran II hose.

Goodyear argued that the failures were due to Heatway's radiant system design, as well as problems with installation and maintenance by contractors.

It said that field inspections showed that leaks were caused by the wrong type of hose connectors and that the hose was damaged by highly acidic fluid.

In addition, Goodyear said it had been using the same 20-year-old formula to make hose for other applications, such as air and water hose, without any problems. - Polybutylene Plumbing Failures: Spencer Class settlement, Web: spencerclass.com, 10% of replacement cost/damages, only for acetal (plastic) fittings

- US DOE, RADIANT HEATING SYSTEMS [PDF], U.S. DOE

- US DOE, SCALING and CORROSION in SOLAR WATER HEATING SYSTEMS [PDF], U.S. DOE

- [22] Andrew J. Whelton, Andrea M. Dietrich, and Daniel L. Gallagher. (2011) Impact of Chlorinated Water Exposure on Contaminant Transport and Surface and Bulk Properties of High-Density Polyethylene and Cross-Linked Polyethylene Potable Water Pipes. Journal of Environmental Engineering 137:7, 559-568

Online publication date: 1-Jul-2011.

Abstract:

The aim of this work was to determine if the aging of polyethylene (HDPE, PEX-A and PEX-B) water pipes by exposure to chlorinated water altered polar and nonpolar contaminant diffusivity and solubility by analyzing new, laboratory-aged, and exhumed water-distribution system polyethylene (PE) pipes.

After 141 days of aging in pH 6.5 water with 45 mg/L free chlorine, the surface chemistry and bulk properties of PEX-A pipe were unaffected.

Carbonyl bonds (σ=1,713 cm−1) were detected on the surfaces of HDPE and PEX-B pipe, and these oxygenated surfaces became more hydrophilic, resulting in statistically significant increases in diffusion rates.

All 10 contaminant and four pipe material combinations had diffusivity increases on average of 50% for polar contaminants and 5% for nonpolar contaminants.

Contaminant solubility was slightly increased for aged PEX-A and slightly decreased for PEX-B pipes. Toluene and trichloromethane diffusivity and solubility values for 7- to 25-year-old buried water utility pipes were similar to values for new and laboratory-aged HDPE-based materials.

Because chlorinated water exposure alters how polar contaminants interact with aged PE pipes, results of this work should be considered in future health risk assessments, water quality modeling, pipe performance, and service-life considerations. - [20] Andrew J. Whelton, Ph.D., M.ASCE; Andrea M. Dietrich, Ph.D., Aff.ASCE; and Daniel L. Gallagher, Ph.D., P.E., M.ASCE, ”Contaminant Diffusion, Solubility, and Material Property Differences between HDPE and PEX Potable Water Pipes.” J. Environ. Eng., 136(2), 227–237.

doi: 10.1061/(ASCE)EE.1943-7870.0000147

Abstract:

the objectives of this work were to identify differences between the composition, bulk properties, contaminant diffusivity and solubility for new high-density polyethylene (HDPE) pipe and crosslinked polyethylene (PEX) pipe, as well as determine which contaminant and polymer properties are useful for predicting contaminant fate in water pipe.

Variations in PE pipe density (0.9371–0.9547 g/cm3) , crystallinity (69–72%), crosslinking (60 and 76%), and oxidative induction time (33 to >295 min .) were detected.

While numerically these differences seem minor, results show that slight material differences have a notable effect on contaminant diffusivity and solubility. Nonpolar contaminant diffusivity and solubility were best predicted by bulk density. Polar contaminants were more soluble and diffused faster through PEX than HDPE pipes because PEX pipes contained a greater amount of oxygen.

For all materials, dipole moment and Log Kow were good predictors of contaminant fate and molecular volume was only useful for predicting diffusivity and solubility values for haloalkane and nonpolar aromatic contaminants. - [14] Zurn Pex Plumbing

Products Liability Litigation, United States Court of Appeals

FOR THE EIGHTH CIRCUIT, No. 10-2267, Filed 6 July 2011,

Quoting:

Minnesota homeowners brought this action1 against Zurn Pex, Inc. and Zurn Industries, Inc (Zurn) alleging that brass fittings used in the company's cross linked polyethylene (PEX) plumbing systems are inherently defective.

In pretrial motions the homeowners sought class certification for their consumer protection, warranty, and negligence claims, and Zurn moved to strike the testimony of two of the homeowners’ experts.

After denying Zurn's motion to strike the expert testimony, the district court2 granted the homeowner requests for class certification for their warranty and negligence claims, but denied it for their consumer protection claims. Zurn appeals from the district court's certification order. We affirm.

Web search 4/12/12, original source: www.ca8.uscourts.gov/opndir/11/07/102267P.pdf

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2019-12-20 by Mod - How do you FIND the leak in radiant slab tubing?

An easy way to spot leaks in radiant slab tubing IF your heat source is working, is to heat up the tubing (and its fluid) and then use a thermal or IR scanner across the building's floors.

At RADIANT HEAT SLAB TUBING LOCATION & REPAIR you can read details of the steps involved in finding, exposing, and then repairing or moving a section of radiant heat tubing in a concrete floor slab.

On 2019-12-20 by Jay - FIND the leak in radiant slab tubing

How do you FIND the leak in radiant slab tubing?

On 2018-07-27 6 - by (mod) - avoid earthquake damage in a concrete slab with radiant heat tubing

Great question. I'm uncertain that it's possible with tubing itself to avoid earthquake damage in a concrete slab, since even a flexible tubing, once set in concrete, is likely to be damaged if the concrete heaves and cracks.

Great question. I'm uncertain that it's possible with tubing itself to avoid earthquake damage in a concrete slab, since even a flexible tubing, once set in concrete, is likely to be damaged if the concrete heaves and cracks.

BUT if you use the level of reinforcement that you see in New Zealand new floor slabs after their recent earthquakes you will minimize damage.

In NZ the builders use a larger size re-bar at a closer spacing and with plenty of wire ties, compared to what we see in -- well you didn't give your country and city.

This is an article on beams but it'll give some idea and resources

- Brooke, Nicholas James, and J. M. Ingham. THE EFFECT OF REINFORCEMENT STRENGTH ON THE OVERSTRENGTH FACTOR FOR REINFORCED CONCRETE BEAMS [PDF] In Proceedings of the 9th Pacific Conference on Earthquake Engineering, Building an Earthquake-Resilient Society, Auckland, New Zealand. 2011.

In some images I'll post here you will see the use of heavy re-bar and extensive tying during foundation and slab construction in Christchurch when I took these photos in September 2014.

Here is a closer detail. This was of course the foundation at the perimeter of the slab;

On 2018-07-27 by Daryl Prindle

What suggestions do you have for limiting earthquake issues with Pex in a slab? I haven't poured it yet. 16' x 24'

On 2018-02-28 - by (mod) - a product that would be successfully run through PEX type plastic tubing or water pipes to seal it;

I looked at www.ct1ltd.com - I don't see a product that would be successfully run through PEX type plastic tubing or water pipes to seal it;

If your plastic lines are a heating system you'd also be worried that the sealant goops up control valves or other components.

Keep me posted, I'll also look further, and perhaps other readers will have a suggestion.

On 2018-02-28 by Possible floor leak

We may have a leak in the plastic lines in the basement floor. Not sure what material the lines are, but they're grey and the house is 30 years old. Is there a "stop leak" type of product that might work for this application? - anonymous by private email

follow-up email:

I was hoping not to open the floor up. I did find a product from C-Tec called CT1 that claims to seal plastic pipe. Even has a video, but anything can claim to work. Ever hear of them?

...

Continue reading at RADIANT SLAB TUBING & FLUID CHOICES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Radiant Heating System Articles

- CIPP PIPE LINING REPAIRS

- PEX BRASS CONNECTOR LEAKS

- PEX CONNECTIONS to WATER HEATERS

- PEX PIPING INFORMATION

- PLASTIC PIPING ABS CPVC PB PEX PPR PVC

- PLASTIC PIPE LEAK CAUSES

- RADIANT HEAT - home

- CARPETING IMPACT on RADIANT HEAT FLOOR

- DRIVEWAY & WALK DE-ICING SYSTEMS

- RADIANT HEAT AIR BOUND

- RADIANT HEAT CONTROLS

- RADIANT HEAT DEFECTS LIST

- RADIANT HEAT DESIGN & INSTALLATION MANUALS

- RADIANT HEAT INSTALLATION

- RADIANT HEAT MISTAKES

- RADIANT HEAT TEMPERATURES

- RADIANT HEAT TEMPERATURE CONTROL / MIXING VALVES

- RADIANT HEAT TEMPERATURE NIGHT SETBACK

- RADIANT SLAB FLOORING CHOICES

- RADIANT SLAB TROUBLESHOOTING

- RADIANT SLAB TUBING & FLUID CHOICES

- RADIANT SLAB TUBING LEAKS

- SLAB INSULATION, RADIANT / PASSIVE SOLAR

- THIN FILM RADIANT HEATING SYSTEMS for Ceilings & Floors

- WOOD FLOOR RADIANT HEAT

- WOOD FLOOR RADIANT HEAT DAMAGE

- THERMAL IMAGING, THERMOGRAPHY

Suggested citation for this web page

RADIANT SLAB TUBING LEAKS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to RADIANT HEAT

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Solar Age Magazine was the official publication of the American Solar Energy Society. The contemporary solar energy magazine associated with the Society is Solar Today.

"Established in 1954, the nonprofit American Solar Energy Society (ASES) is the nation's leading association of solar professionals & advocates. Our mission is to inspire an era of energy innovation and speed the transition to a sustainable energy economy. We advance education, research and policy. Leading for more than 50 years.

ASES leads national efforts to increase the use of solar energy, energy efficiency and other sustainable technologies in the U.S. We publish the award-winning SOLAR TODAY magazine, organize and present the ASES National Solar Conference and lead the ASES National Solar Tour – the largest grassroots solar event in the world." - Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - J. Boucher, "Radiant Subfloor Panels," Journal of Light Construction, (18:7), pp. 75-81, April 2000.

- Portland Cement Association: www.concretethinker.com/Papers.aspx?DocId=8 indicates that

- tubing for radiant heat in a concrete slab is installed UP TO two inches below the surface of the slab

- the slab is insulated from the ground at all sides to direct heat upwards to the living space [this is our preferred design for a cold northern climate] - Radiant Panel Association,

P.O. Box 717,

1433 West 29th Street,

Loveland, CO 80539

Phone: (970) 613-0100 or (800) 660-7187, Email: Email: info@rpa-info.com, Website: rpa-info.com

www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=1 offers design guidelines at http://www.radiantpanelassociation.org/i4a/pages/index.cfm?pageid=115 including these insulation R-value and coverage details:

Application#, Minimum R-Value, and Insulation Coverage

The following insulation alternatives are given for Slab on Grade construction:

Alternate #1 [(Ti-To)x0.125)=R-value, with coverage from perimeter to below frost line ["Ti-To" means we calculate the necessary R-value as (Ratio of indoor to outdoor temperature) x 0.125]

Alternate #2 R-value=5, with coverage 4' horizontal or vertical at perimeter

Alternate #3 R-value=5, with coverage under entire slab and slab edge [this is our preferred design for a cold northern climate]

The Radiant Panel Association offers education and publications in radiant heat design. See radiantpanelassociation.org - R. Groff, "Mixing Forced-Air and Boiler Heat," Fine Home Building, (No. 85) pp. 86-87, January 1994.

- Heatway Corporation, "Radiant Heat Installation", Heatway Corporation, 3131 W. Chestnut Expwy, Springfield MO 65802, Tel: 417-864-8161

- Hydronic Radiant Heating Division,

The Hydronics Institute,

P.O. Box 218,.

Berkeley Heights, NJ 07922

Phone: (908) 464-8200 - Dan Holohan, Hydronic Radiant Heating: A Practical Guide for the Nonengineer Installer, 1998. Dan Holohan Associates, Inc., 63 North Oakdale Avenue, Bethpage, NY, 11714; Phone: (800) 853-8882; $20.00.

- J. Siegenthaler, Modern Hydronic Heating, Delmar Publishers. 1995. Available from Delmar/Thomson Learning, Order Fulfillment, P.O. Box 6904, Florence, KY 41022; Tel: 800-347-7707. ISBN: 0-8273-6595-0.

- J. Siegenthaler, "Hydronic Radiant Heat for Wood-Framed Floors,"The Journal of Light Construction, (11:11) pp. 34-37, August 1993.

- J. Siegenthaler, "Radiant Slab Techniques,"The Journal of Light Construction, (10:11) pp. 21-24, August 1992.

- J. Siegenthaler, "Radiant Slab on a Tight Budget," The Journal of Light Construction, (13:10) pp. 47-50, July 1995

- Olsen, B. & Lidelt, D., Existing Knowledge on Possibilities and Limitations of Radiant Floor Cooling- #4014, , 1996. Part of the January 25-29, 1997 ASHRAE Winter Meeting Technical Program. American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE), 1791 Tullie Circle NE, Atlanta, GA 30329; Phone: (800) 527-4723; website: www.ashrae.org

- J. Truini, "Adding Radiant-Floor Heating," Home Mechanix, (91:792) pp. 56-61, Feb 1995.

- N. Nisson, "Can Radiant Floor Cooling Succeed Despite Design Limitation?"Energy Design Update, (17:5) pp. 5-8, May 1997.

- "Canadian Study Details the Impact of Carpets on Radiant Floor Heating," Energy Design Update, (18:11) pp. 12-13, November 1998.

- B. Kaercher, Jr. , "Electric-Radiant Floors,"Fine Home Building, (No. 75) pp. 68-72, June/July 1992.

- Heatway, Goodyear Square Off in Court Over Radiant System Failures," Energy Design Update, (18:10) pp. 2-4, October 1998.

- Ohio Jury Says Goodyear’s Entran 2 Hosing Was Not Defective," Energy Design Update, (20:4) pp. 5-7, April 2000.

- C. Wardell,"Radiant Floor Systems,"Custom Builder, (10:6) pp. 26-30, Sept/Oct 1995..

- Takagi radiant heat systems:

Takagi offers pre-assembled radiant heating system installation packages including for do-it-yourself'ers, and including systems that combine radiant heat flooring with domestic hot water production using a gas-fired tankless water heater.

See takagi.com for more information. "

The T-KJr model (gas inputs up to 140,000 BTU per hour) is the smallest unit in the Takagi line-up. The T-KJr is perfect for light residential (i.e. small apartment units) and radiant heating applications."

Also see TANKLESS WATER HEATERS [web article] - The Passive Solar Design and Construction Handbook, Steven Winter Associates (Author), Michael J. Crosbie (Editor), Wiley & Sons, ISBN 978-047118382 or 0471183083

- SOLAR WATER HEATING SYSTEM MAINTENANCE & REPAIR [PDF] , U.S. DOE

- [7] PB Technology Center (information about PB Pipes) Tel: 800-338-7732, also see the 1990 PB Pipe recommendations published by the Polybutylene Product Line Committee of the Plastic Pipe and Fittings Association.

- [12] Zurn Manufacturing, Web: zurn.com , Zurn Pex, Inc., Highway 11 East, Commerce, TX 75428, Tel: (903) 886-2580

provides information about installing and using PEX piping including Type b PEX through their website. Quoting from the company's website

Zurn was founded in 1900 in Erie, PA. It originally manufactured a patented backwater valve, and it now manufactures and distributes one of the largest plumbing products packages in the world!

Zurn includes: the Specification Drainage Operation, AquaFlush flush valves, AquaSense sensor-operated plumbing products, AquaSpec commercial faucets, Wilkins, Zurn Light Commercial, Flo-Thru, the Chemical Drainage Systems, Zurn PEX Plumbing Systems and Zurn Radiant Heat. - [13] Zurn PEX PLUMBING DESIGN AND APPLICATION GUIDE(PDF) - web search 12/23/2010, original source zurn.com/operations/pexrh/pdfs/installation/PEXDesApplGuide.pdf

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.