Plastic Piping Leak Causes & Symptoms

Plastic Piping Leak Causes & Symptoms

Cause, cure, prevention of plastic pipe leaks in water supply or drain piping

- POST a QUESTION or COMMENT about the causes of leaks in plastic piping in buildings

Leaks in plastic water supply or drain piping:

This article series describes the causes of damaged or leaky buried plastic water pipe & resulting poor water pressure, poor water flow, or water leaks in water piping between a well or municipal water service main & the building.

We include links to in-depth reports of pipe leaks occurring at various types & brands of plastic water supply piping & building drain piping and we provide a catalog of the most frequent causes of damaged or leaky plastic piping at buildings.

Knowing just what kind of leak is occurring in a building helps pinpoint the problem and also helps specify the necessary plumbing repair. The articles at this website will answer most questions about diagnosing and repairing pumps, wells, water supply systems, and building piping.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

What Causes Leaks in Plastic Piping?

Article Series Contents

Article Series Contents

- PLASTIC PIPE LEAK CAUSES

- DAMAGE CAUSES in PLASTIC PIPING - why do plastic pipes leak?

- JM Eagle® DEFECTIVE PVC PolyVinyl Chloride PIPING LAWSUIT - separate article about JM Eagle plastic piping leaks, explosions, whistleblower lawsuit

- Kitek® PLASTIC PIPE LEAKS, CLASS ACTION SETTLEMENT - separate article about Kitec aluminum-core PEX piping leaks, litigation, failure causes, research

- PlumbPex® PEX PIPE LEAKS, CLASS ACTION SETTLEMENT

- PLASTIC PIPE PRESSURE LIMITS

- WATER MAIN BREAKS & LEAKS

- PEX BRASS CONNECTOR LEAKS - separate article explains meringue dezincification leaks at brass pipe fittings

Causes of Damage, Leaks, or Crimps in Buried Plastic Water Piping

- Brass connector leaks in pressurized plastic piping

See PEX BRASS CONNECTOR LEAKS - Burying plastic piping with soil containing sharp rocks can lead to later puncture and leaks

- Defective plastic piping: see these reports of plastic pipe failures:

JM Eagle® DEFECTIVE PVC PolyVinyl Chloride PIPING LAWSUIT - separate article

and

Kitek® PLASTIC PIPE LEAKS, CLASS ACTION SETTLEMENT - separate article

and

PlumbPex® PEX PIPE LEAKS, CLASS ACTION SETTLEMENT - in this article - Driving over piping that is not properly bedded in sand or not buried at a safe depth can cause leaks or crimps in piping. Even if the buried water pipe is not leaking, if it has been crimped or crushed water pressure and flow into the building will be reduced.

- Freezing pipe damage: while plastic pipes can tolerate limited freezing better than some metal pipes, nevertheless a water supply or drain pipe that remains water-filled and exposed to freezing can crack or burst.

See WATER PIPE FREEZE-UP POINTS

also

See FREEZE-PROOF PIPES for advice on preventing freeze damage to supply or drain piping - Gluing errors: Improper gluing procedures when assembling plastic supply or drain piping. Failure to properly prepare the pipe, misapplication of primer and glue, or failure to respect both gluing procedures and set and cure times specified by the pipe cement manufacturer, failure to allow for high or low temperatures during pipe assembly and gluing, failure to allow for high humidity during plastic pipe installation and gluing all cause significant risks of a future pipe leak or failure.

See PVC & CPVC PIPE INSTALLATION STEPS

and

see PVC & CPVC PIPE GLUING SET & CURE TIMES - Overheating plastic piping during joint fitting can chemically change the plastic, making it brittle and crack prone near the connector

- Over tightening metal connector parts such as hose clamps can (rarely) crack or crimp a pipe or fittings as cited earlier.

- Plastic connector leaks in plastic piping occur if the stainless steel (or equivalent) clamp is insufficiently tightened or is not properly positioned when making the connection between plastic connectors and ABS well piping or equivalent piping; other damage can occur if the clamp is over-tightened on over-heated ABS tubing and less often if the connector itself is cracked or damaged.

See details at PIPE / HOSE CLAMP LEAK REPAIR - Plastic well (or water main) piping damage during installation: What caused the well piping leak that we describe above? My soil is 18"-24" black topsoil, then sandy, silty clay soil.

No rocks or sharp objects were found. We were careful digging around the line. We checked about 10 foot of line, but only found leaks near the fitting at the casing.

After removing the leaking section, I cleaned it up for further investigation. It appears to me the pinholes were a result of careless installation work.

The pipe exterior surface had cuts and nicks where the pinholes were. What people may not know is that HDPE pipe needs to be slightly heated to fit over the fitting.

If it's overheated it could change the integrity of the pipe. The previous installer may have overheated and nicked the pipe with the clamps or a screwdriver. Maybe they didn't know the pipe needed heat and used brute force with pliers or channel locks to slip it over the fitting. - Pressure limits exceeded: excessive water pressure can burst plastic water pipes.

See details at PLASTIC PIPE PRESSURE LIMITS - Temperature limits exceeded. For PVC the maximum operating temperature is PVC of 140°F / 60°C.

Pipe burst pressures are reduced as temperatures of the pipe increase. - Under heating plastic piping during heat-activated joint fitting can cause the pipe to crack when it is forced over a fitting or connector

- Under-tightening metal connector parts such as hose clamps often leads to immediate or near-term leaks in the well piping connector. That was the problem that caused the leak in our photograph just above.

- Water hammer: because water hammer causes brief but significant pressure increases in a piping system, water hammer may cause damage or ultimately a burst pipe or broken pipe joint.

See WATER HAMMER NOISE DIAGNOSE & CURE - CONTACT us to suggest other leak causes in plastic well piping

Inspect your plastic piping connections carefully with the well piping under full pressure before burying the water piping.

Defective PVC Polyvinyl Chloride Pipe Production, Leaks, Explosions, & Whistle Blower Lawsuit - JM Eagle

JM Eagle® DEFECTIVE PVC PolyVinyl Chloride PIPING LAWSUIT

Excerpt:

JM Eagle produces roughly 60 percent of plastic water piping sold in the U.S. and also distributes its products in Canada and Mexico and describes itself as

JM Eagle is the leading manufacturer of PVC and PE plastic pipe.... JM Eagle recently announced a 50-year warranty on its products*. Plastic-pipe products from JM Eagle will maintain their performance for the next 50 years or the company will replace them.

Early in 2010 New York Times reported that John Hendrix has accused PVC piping manufacturer JM Eagle of falsifying PVC pipe quality testing results, covering up the discovery that pipes that should last 50 years are failing as early as in one year, risking costly leaks and dangerous explosions.

In a review of news reports through March 2015, the failure rate and extent of failure of JM Eagle's PVC piping raised some troubling questions about the actual extent of and occurrence of damage.

See JM Eagle® DEFECTIVE PVC PolyVinyl Chloride PIPING LAWSUIT for details.

Kitec® PEX Plastic Pipe Fitting Leaks

Details of this topic have moved to a separate article.

Details of this topic have moved to a separate article.

See Kite® PLASTIC PIPE LEAKS, CLASS ACTION SETTLEMENT

Excerpts are below.

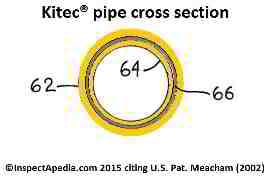

Kitec PEX plastic piping was / is a composite tubing produced by IPEX and consisting of an aluminum tubing laminated between two layers of polyethylene or PEX of various compositions described by several U.S. Patents cited below.

Kitex® tubing was sold in Canada and the United States (and possibly other countries) for a wide range of applications including pressurized potable water piping and heating water piping for radiant heat floor systems.

Meacham's figure above, edited for clarity by InspectApedia, shows a cross-section of the three concentric sections of Kitec tubing. Flexible outer and inner layers 62 and 64 in the illustration are made of resilient and flexible non-metallic portions coating the exterior and interior of a thin-walled flexible metallic pipe-66.

The Kitec piping system included both the flexible tubing collection of brass plumbing fittings & connectors intended for use with PEX type plastic piping. Kitec, also in some sources spelled Kyetec is a brand of brass plumbing fitting that was recalled in 2005 by its manufacturer, IPEX, due to its tendency to quickly corrode.

Plumb-PEX Plumbing System Class Action Settlement - PEX piping leaks

In March 2012 the U.S. District Court for the District of Minnesota court-ordered homeowner notification program was scheduled to begin.

People who own or previously owned a building where Plumb-PEX plumbing components were installed are notified of a proposed class action settlement involving Radiant Technology, Inc. and Uponor, Inc who sold Plumb-PEX insert fittings and stainless steel PEX tubing clamps.

Those components may have leaked, or may leak, causing building damage. The defendants denied all claims of the lawsuit but have agreed to settle the case. [14][15]

Plumb-PEX Settlement Details

RTI Plumb-PEX Plumbing System fittings and components including

- ASTM Standard F1807 brass insert fittings

- Stainless steel clamps used with the installation of these components

- Installed on or after 15 May 1999

- Where a leak in the system [using those components] occurred or

- Where water flow differential of 50% is found between hot and cold water supply lines feeding one or more fixtures

or

- People or "entities" whose structure has already suffered a qualifying leak and have already paid for repairs

Plumb-PEX Settlement Provisions

The settlement reimburses for property damage caused by a qualifying leak in the Plumb-PEX installation, and it provides for possible repair or replacement of the RTI Plumb-PEX installation in structures suffering two or more "qualifying" leaks.

Plumb-Pex Class Action Settlement Deadline

Watch out: If you are eligible for a claim under the Plumb-PEX settlement, you must file your claim within 18 months of the notification date of 22 March 2012

Leaks in Municipal Water Service Piping

In 2015 JM Eagle, a large plastic pipe producer posted this remark on the company's Facebook page:

In 2015 JM Eagle, a large plastic pipe producer posted this remark on the company's Facebook page:

Cold weather dramatically increases the chance of a break as pipes expand and contract with temperature changes. On average, 400 to 500 water main breaks occur each year in [Washington D.C.] - JM Eagle on Facebook, retrieved 22 March 2015, original source: https://www.facebook.com/JMEaglePipe

Photo at left: the report cited above at Facebook.

[Click to enlarge any image]

As Carson Dunlop's Home Reference Book points out,

Plastic water service piping may be polybutylene (PB), polyethylene (PE), cross-linked and Tubing Tubing Tubing Tubing Tubing Tubing Tubing polyethylene (PEX), polyvinyl chloride (PVC) or chlorinated polyvinyl chloride (CPVC).

Most plastic piping is buried at least 18 inches deep. [In freezing climates water piping is buried below the frost line, a depth that can exceed 8 feet in some areas.] Exposed piping may be subject to mechanical damage and deterioration from sunlight.

Since the supply line from the street cannot be seen, no comment is offered during a home inspection. If there is a leak, it may go undetected for some time. In some cases, water can be heard running outside the basement wall.

Water accumulating in the basement or a wet spot on the lawn is often the first indication. Leaks may be caused by building settlement, excavation, poor connections, faulty valves or a flaw in the pipe itself.

The underground water service line from the property line to the house is owned by the homeowner. Beyond the property line, the pipe is the responsibility of the city. A leak in the pipe requires excavation, and it is often difficult to know whether the leak is on the city’s or the homeowner’s side.

The city is usually contacted and they excavate their section of the pipe, correcting the problem if they discover it. If no problem is found, the homeowner is left to correct the problem on his or her own.

In some cases, the homeowner must pay for the city’s work if the city pipe is not at fault. Some municipalities use sophisticated leak detection equipment.

While the comments below originally described the cause of a leak in plastic well piping, the same conditions can cause a leak in buried municipal water supply piping between the building and the street.

As Carson Dunlop's Home Reference Book points out,

Poor water pressure in the house may be the result of a partially closed or obstructed valve in the street. It may also be because of blockage, such as a stone or other foreign body in the pipe. New piping may be crimped during installation or become pinched under a rock during back-filling operations. This can also cause low water pressure.

Plastic Pipe Pressure Limits

There are multiple sources for operating pressure and burst pressure limits for plastic pipe and plastic pipe components. We find that they give similar but not identical results, and some manufacturers promise significantly higher pressure limits for specialty-versions of plastic piping.

In the plastic pipe system pressure limits table below, we're using a combination of sources cited below the table.

Plastic Pipe Pressure Limits |

Maximum Pressure -

psi |

|||

| Operating Pressure |

Burst Pressure |

Operating Pressure |

Burst Pressure |

|

| PVC Polyvinyl Chloride | Schedule 40 |

Schedule 80 |

||

| 1/2" | 360 psi | 1910 psi | 510 psi | 2720 psi |

| 3/4" | 288 | 1540 | 414 | 2200 |

| 1" | 270 | 1440 | 378 | 2020 |

| 1 1/2" | 198 | 1060 | 282 | 1510 |

| 2" | 168 | 890 | 240 | 1290 |

| 2 1/2" | 180 | 870 | 250 | 1360 |

| CPVC Pipe Operating Pressure Limits | ||||

| CPVC Pipe to 80°F | 400 psi | |||

| CPVC Pipe at 180°F | 100 psi | |||

| PEX Operating Pressure | ||||

| PEX Pipe at 73°F, | 160 psi | |||

| PEX at 180°F | 100 psi | |||

| PEX at 200°F. | 80 | |||

| PB Polybutylene Operating Pressure | ||||

| PB at 68°F - 20°C | 232 psi 1600 kPa |

|||

| PB at 140F - 60°C | 152 psi 1050 kPa |

|||

| PB at 203F - 95°C | 72 psi 490 kPa |

|||

Notes to the table above

-

Watch out: The safe operating pressure limit of any plastic piping system is actually the operating pressure limit of the lowest-rated component in the piping system - as that's where a pressure-related failure might be expected to occur.

It would be misleading to rate the plastic piping system's pressure limits on just the pipe itself.

For example, in a 1/2" PVC Schedule 40 pipe system operating at 73 °F, using flanges, the 1/2" PVC flange has an operating pressure rating of just 150 psi, unions have a pressure rating of 235 psi, threaded fittings are rated at 300 psi, socket fittings are rated at 300 psi, and the pipe itself is rated at 600 psi.

Because socket type fittings are in our opinion most common, the plastic pipe system pressure limits table below shows pressure limits based on the socket fitting limits.

-

Watch out: Exceeding the manufacturer's recommended pressure limits can cause piping to burst, leading to costly building damage, mold contamination, flooding, and in more-rare cases, even personal injury.

ASTM D2466 - 06 Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 40 - ASTM D2467-04e1 Standard Specification for Poly(Vinyl Chloride) (PVC) Plastic Pipe Fittings, Schedule 80

- ASTM D2846 - CPVC Plastic Hot and Cold Water Distribution Tubes

- ASTM F441 — Standard Specification for Chlorinated Poly(Vinyl Chloride) (CPVC) Plastic Pipe, Schedules 40 and 80;

- Charlotte Pipe, PLASTIC PIPE PRESSURE & TEMPERATURE RELATIONSHIP [PDF] Charlotte Pipe & Foundry Co., Charlotte, North Carolina, USA, Web: https://www.charlottepipe.com/ retrieved 2022/07/30, original source: https://www.charlottepipe.com/TechTools/Content/temp_derating_calc_info.pdf

- PPFA, CPVC PIPING SYSTEMS INSTALLATION HANDBOOK: CPVC HOT & COLD WATER PIPING [PDF] Plastic Pipe and Fittings Association 800 Roosevelt Road Building C, Suite 312 Glen Ellyn, Illinois 60137 www.ppfahome.org

Website excerpt (https://www.ppfahome.org/page/CPVC) 2022/07/29:

CPVC piping which is suitable for hot and cold water distribution has a 400 psi pressure rating at room temperature, and a 100 psi pressure rating at 180°F. - Plastic pipe operating pressures are decreased as the pipe or its contents reach the maximum operating temperature

CPVC maximum operating pressure derates from 400psi at 80°F down to 100 psi at 180°F

PVC maximum operating pressures decrease as the temperature approaches the maximum of 140°F / 60°C - PBPSA, A REVIEW OF THE PERFORMANCE OF POLYBUTENE PRESSURE PIPING SYSTEMS [PDF] PBSA, Polybutene Piping Systems Association, Email: pbpsa@posteo.de Website: pbpsa.com - retrieved 2022/07/30, original source: https://www.pbpsa.com/uploads/files/resources/pbpsa-brochure-en.pdf

- Plastic pipe fitting designs vary and may have different maximum operating pressures and temperatures by fitting brand and features.

For example, Corzan CPVC is rated at 4000 psi at 72°F (23°C) as listed in PPI TR-4, and 1000 psi at 180°F (82.2°C) as listed in PPI TR-4, but note that that's for the pipe. With socket fittings Corzan's CPVC operating pressures and temperatures are substantially less.

Details are at CPVC & PVC PLASTIC PIPING - PEX: Temperature and pressure ratings for PEX, according to Zurn Manufacturing's engineering specifications is 160 PSI at 73°F, 100 PSI at 180°F, and 80 PSI at 200°F.

- PEX TUBING TECHNICAL SPECIFICATIONS [PDF] PEX Universe.com (Sales of PEX tubing) Tel: 800-818-3201 original source: https://www.pexuniverse.com/pex-tubing-technical-specs

- Thanks to InspectApedia reader Jaggz for suggesting this additional cause of plastic pipe leaks. 2022/07/29

...

Continue reading at PEX BRASS CONNECTOR LEAKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see PLASTIC PIPE LEAK CAUSE FAQs - questions & answers about pipe leaks posted originally at the end of this page.

Or see these

Recommended Articles

- LEAK TYPES, WATER SUPPLY or DRAIN PIPES

- PIPE / HOSE CLAMP LEAK REPAIR

- PIPING in BUILDINGS, CLOGS, LEAKS, TYPES - home

- PLASTIC PIPE LEAK CAUSES

- PLASTIC PIPING ABS CPVC PB PEX PPR PVC - home

- PLASTIC PIPE PRESSURE LIMITS

- PLASTIC PLEXVENT ULTRAVENT RECALL

- PLUMBING SYSTEM PRESSURE TESTS

- LEAK CAUSES in WATER PIPING

- LEAK TYPES, WATER SUPPLY or DRAIN PIPES for help in finding leaks by understanding different types of leakage and when it occurs

- LEAKY PIPE REPAIRS

- RADIANT SLAB TUBING LEAKS

- WELL PIPING LEAK DIAGNOSIS iIf your building water supply is provided by a private well

Suggested citation for this web page

PLASTIC PIPE LEAK CAUSES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "New Electric Heat Tapes Help Prevent Fires," US Consumer Product Safety Commission (CPSC) #00936

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- "Freezeproof Your House," Mike McClintock, Rodale's New Shelter, p. 30, October 1985 (approximate date)

- "How to Winterize Your Pipes," Mike McClintock, Homeowners How-To Magazine, p. 59-62, Nov-Dec 1979.

- "PVC pipe extruder JM Eagle hit with whistleblower lawsuit", Plastics News, 11 Feb 2010, web search 11/19/2010, original source: http://plasticsnews.com/headlines2.html?id=17829

- "A Trail of Broken Pipes, In Lawsuit, Fired Worker Cites Defective Plastic", Mary williams Walsh, The New York Times, 12 Feb 2010, pp. B1, B5

- "Facing Suit, Pipe Maker Extends Guarantee", Mary Williams Walsh, The The New York Times, 5 April 2010.

- "JM Eagle PVC Pipe Lawsuit Information", law suit and class action information sponsored by law firm of audet & Partners, LLP. - web search 11/19/2010, original source: http://jm-eagle-lawsuit.com/jm-eagle-pvc-pipe-lawsuit/tag/lawsuit/

- JM Eagle Corporation, Global Headquarters, 5200 West Century Boulevard, Los Angeles, California 90045, Phone: (800) 621-4404

Quoting

JM Eagle is the complete manufacturer of PVC and PE plastic pipe. With greater strength, capacity and geographic reach than ever before, our resources provide an unmatched capability for new products, new materials, new applications and new processes. We consistently produce the highest quality plastic pipe in the industry and are committed to ensuring ongoing product excellence. - JM Eagle 50-Year warranty - web search 11/19/2010, original source: http://www.jmeagle.com/warranty/ Quoting from that source:

April 5, 2010, Dear Valued Customer:

At JM Eagle, we have always stood behind the quality of our plastic pipe as our commitment to serving you. Now we are taking that commitment a step further with the introduction of our 50-year warranty on the design of our innovative engineered thermal plastic-pipe products.* This means you can trust JM Eagle pipe to maintain its performance for the next 50 years or we will replace it.** No other manufacturer makes this claim.

The warranty covers issues associated with new verifiable manufacturing defects on pipe. The warranty also covers plastic-pipe products sold and installed since JM Manufacturing’s inception, manufactured by JM Eagle or JMM. It does not cover products made by other manufacturers acquired by JM Eagle at later date or products manufactured by PW Eagle prior to the 2007 merger.

Plastic pipe is the safe, long-lasting and stable solution for a modern infrastructure. Millions of miles of plastic pipe have been installed throughout the country. It outlasts any other material. It complies to strict industry standards that confirm its strength, durability and longevity. And it keeps the water flowing without bursts, flooding or disruptions.

Plastic pipe from JM Eagle is of the highest quality. It has always met—and will continue to meet—the standards of the American Water Works Association, and it has always been—and will continue to be—certified by NSF International and Underwriters Laboratories.

We are excited to bring this warranty to you, for the betterment of your business and the industry as a whole. We hope that you will continue to choose plastic pipe, and choose it from the only plastic-pipe manufacturer that stands behind its quality with a 50-year warranty, JM Eagle.

Information on this Web site tells you more about our warranty, our products and our commitment to serving you with quality plastic pipe. We hope you find it helpful as we continue our long and fruitful partnership.

Sincerely,

Neal Gordon Vice President of Marketing, JM Eagle

* Plastic pipe certified to AWWA for water distribution and transmission and force sewer mains.

** See warranty for full details - [3] Kitec Plumbing System Settlement Website, web search 08/05/2011, original source: www.kitecsettlement.com.

- Thanks to reader Dan Babb for discussing well piping leaks, July 2010

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.