PEX at Water Heaters & TPR valves

PEX at Water Heaters & TPR valves

Piping connection requirements, restrictions, codes

- POST a QUESTION or COMMENT about this PEX piping at water heating equipment & TPR valves

This article describes the requirements for copper or other metal piping to protect PEX piping from heat damage at a water heater.

We also discuss the use of PEX tubing for heating equipment discharge tube piping

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Proper vs Wrong PEX Plumbing Connections to a Water Heater

PEX Clearance Distances at Water Heaters

PEX Clearance Distances at Water Heaters

- Electric water heaters: Zurn PEX can be connected directly to residential electric water heaters used for domestic hot water (Zurn PEX uses brass adapters for this connection)

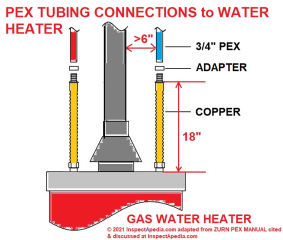

- Gas water heaters: 6" or more from exhaust flue

- Gas water heaters, power vented: 6" or more from metal blower housing except if blower housing itself is plastic (then direct-connection is permitted)

- QuickPort Manifold (Zurn): 18" or more from water heater outlet

- Tankless water heaters: 12" or more from exhaust piping (because this piping an reach 460° F.)

- TPR Discharge tube: PEX is permitted but check with the TPR valve and heater manufacturer to be sure that the diameter restriction from PEX fittings is acceptable

- source: (Zurn 2010) cited below

Reader question:

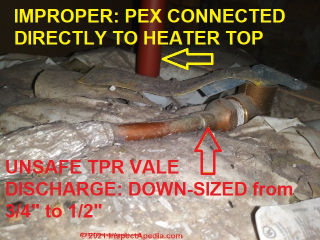

Something I didn't mention, but which shows on the picture of the water heater which I sent earlier and illustrated at WATER HEATER SAFETY, are the two hot and cold PEX lines leading directly to the top of the tank.

If the T&P valve is still functional, I understand it won't open before it gets hotter or up to a higher pressure than is good for PEX .

So with this configuration is a failure at the top of the tank before the water can vent through its proper channel (the T&P valve) unheard of? - Anonymous by private email 2021/07/01

Moderator reply:

PEX water piping should not be connected directly to a gas or oil fired or tankless water heater; in two photos we can see red or blue PEX piping to the top of the water heater.

But your water heater is electric. According to Zurn (cited below) this is a permitted connection if the installation uses Zurn PEX and Zurn PEX fittings.

Really? Other codes and PEX guidelines do not explicitly permit this connection and are more general, requiring at least 18" of copper isolating PEX from the water heater - see our citation below.

For gas or oil fired heaters there are additional clearance distances required between PEX plumbing and the flue vent connector because that too is an area where high temperatures might be found.

There are other similar code citations discussing how PEX can be connected to all types of water heaters: tank type, instantaneous, and tankless coils, but this one from the Uniform Plumbing Code can suffice:

604.11.2 Water Heater Connections. PEX shall not be installed within the first 18 inches (457 mm) of piping connected to a water heater.

cited in

- HUD, PPFA, DESIGN GUIDE for RESIDENTIAL PEX WATER SUPPLY PLUMBING SYSTEMS [PDF] (2006) HUD, U.S. Department of Housing & Urban Development, Plastics Pipe Institute, Inc (PPI) 105 Decker Court Suite 825 Irving, TX 75062 www.plasticpipe.org and Plastic Pipe and Fittings Association (PPFA) 800 Roosevelt Road, Bldg. C, Ste. 312 Glen Ellyn, IL 60137 www.ppfahome.org and Partnership for Advancing Technology in Housing 451 7th Street, SW Washington, DC 20410 www.pathnet.org and NAHB Research Center, Inc. 400 Prince George’s Boulevard Upper Marlboro, MD 20774 www.nahbrc.org retrieved 2019/09/20 or\iginal source: https://www.huduser.gov/portal/publications/pex_design_guide.pdf

You will find this same detail cited in other PEX plumbing manuals and codes and you'll find it mentioned in quite a few water heater installation manuals.

Watch out: This is but one more of multiple safety questions about this particular heater that suggest that its installation appears not to have been inspected / approved by a building official, or if it was, that official didn't do her job properly.

The risk is a plumbing leak; in the worst case, a burst hot water pipe could scald someone nearby.

But the risk of burst piping is partially mitigated, as you can read in the following excerpt from the same HUD document.

In the event of a water heating system malfunction, PEX piping is designed to accommodate short-term conditions of 48 hours at 210ºF (99ºC) and 150 psi (1034 kPa) until repairs can be made. The most commonly used safety relief valve (T&P) activates (opens) at either of these temperature or pressure conditions.

All PEX piping has been tested to withstand T&P activation for 30 days to ensure that safety requirements are met.

As such, PEX systems DO NOT require the use of a special T&P valve.

On 2018-08-29 by (mod) - flexible connections to water heater connect also to PEX tubing

Wade,

Wade,

I suspect the flexible copper connectors shown in your photo are UL listed or otherwise listed for connecting the appliance or for connecting two of them. However your installation makes me nervous about an increased risk of a catastrophic plumbing leak.

I see

- flexible plastic water pipes connected to flexible copper connector at the water heater (which is proper) but without any visible support. Allowing pipes to wiggle about invites damage and leaks.

- no shut-off valve on the cold water in to the water heater

- what looks like a gas fired water heater flue vent connector that is touching or very close to combustible wood framing

- possibly the same vent connector passing through what looks like foil faced foam (combustible) insulation under the roof. Give me a photo of the labeling on the insulation and I can research clearance requirements further.

On 2018-08-29 by Wade Vanastros

Dual water heaters that are piped in a series with Brasscraft 3/4 FIP iron pipe x connected to PEX tubing.

Can i use the same material (3/4 Fip)to pipe the same water heaters in parallel? Or do I need to sorer [sic] actual copper pipe?

Thank you

Codes, Standards, Instructions for PEX Piping Connections at Water Heaters

- ASTM F876 - Standard Specification for Crosslinked Polyethylene (PEX) Tubing - available at https://www.astm.org/f0876-22ae01.html

Abstract:

This specification covers crosslinked polyethylene (PEX) tubing that is outside diameter controlled, made in standard thermoplastic tubing dimension ratios, and pressure rated for water at three temperatures. This specification covers one PEX tubing material in one standard dimension ratio and having pressure ratings for water of three temperatures.

The pressure ratings decrease as the temperature is increased. PEX tubing shall be made from polyethylene compounds which have been crosslinked by peroxides, Azo compounds, or silane compounds in extrusion, or by electron beam after extrusion, or by other means such that the tubing meets the performance requirements.

The following tests shall be performed: dimensions and tolerances; density; sustained pressure test; burst pressure; environmental stress cracking test; degree of crosslinking; stabilizer functionality; and oxidative stability in potable chlorinated water applications. - ASTM F877 - Standard Specification For Crosslinked Polyethylene (PEX) Hot- And Cold-Water Distribution Systems - available from https://webstore.ansi.org/

Excerpt:

This specification covers requirements, test methods, and marking requirements for system components when tested with nominal SDR9 crosslinked polyethylene tubing as a system.

Systems are intended for 100 psi (0.69 MPa) water service up to and including a maximum working temperature of 180 °F (82 °C). Requirements and test methods are included for materials, workmanship, dimensions and tolerances, burst pressure, sustained pressure, excessive temperature and pressure, and thermo-cycling tests.

The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water distribution systems or other applications such as municipal water service lines, radiant panel heating systems, hydronic baseboard heating systems, snow and ice melting systems, and building services pipe. - Canada: CAN/CSA B137.5:20 Crosslinked polyethylene (PEX) tubing systems for pressure applications

available at https://www.csagroup.org/store/product/2427341/

Excerpt:

Scope 1.1 This Standard specifies requirements for crosslinked polyethylene (PEX) tubing systems that comprise tubing and fittings.

Tubing covered by this Standard is made in Standard Dimensional Ratio 9 (SDR 9).

Systems are pressure rated at three temperatures: 1105 kPa at 23 °C, 690 kPa at 82 °C, and 550 kPa at 93 °C, with a maximum working pressure of 690 kPa at 82 °C.

Systems are intended for use in potable water distribution systems or other applications, including municipal water service lines, reclaimed water distribution, radiant panel heating and cooling systems, hydronic baseboard heating systems, snow and ice melting heating systems, building services piping, compressed air distribution, and ground source geothermal systems, provided that the PEX tubing systems covered herein comply with the applicable code requirements. Residential and commercial systems are included.

and

Appendix A-7.2.5.7(1) ACCEPTABLE SOLUTIONS, PART 7 - PLUMBING SYSTEMS [PDF] - original source: https://free.bcpublications.ca/civix/document/id/public/bcbc2006/building_b_p7_7.2 - PEX PIPING INFORMATION [web page]

- US UPC 604.11.2 Water Heater Connections -

Excerpt:

PEX shall not be installed within the first 18 inches (457 mm) of piping connected to a water heater. - Plastic Pipe & Fittings Assoc. PEX INSTALLATION HANDBOOK [PDF] (2016) Plastic Pipe & Fittings Assoc. , Plastic Pipe and Fittings Association

800 Roosevelt Road

Building C, Suite 312

Glen Ellyn, IL 60137

www.ppfahome.org

Cross-linked Polyethylene (PEX) Hot- and Cold-Water Distribution systems And Service Lines

Excerpts:

Do not use in applications where the temperature of the water could exceed 180 °F at 100 psi unless specifically approved in the code, e.g., water heater relief line. See manufacturer’s recommendations for higher operating temperatures at lower pressures.

Do not install PEX tubing downstream of any instantaneous, point-of-use or immersed coil water heater where the output is uncontrolled or temperature can exceed 180 °F. Contact manufacturer for recommended metallic transition fittings.

PEX tubing may be connected directly to residential eledctric tank or tankless (instantaneous) water heaters, if the local code and manufacturer’s instructions allow. When connecting PEX tube to gas tank or tankless water heaters, the tube must be kept at least 6 inches away from the exhaust vent of the heater. Flexible metal water heater connectors may be needed in some instances. - RELIANCE 40 Gallon Short Energy Efficient Liquid Propane Water Heater MODEL 6 40 LBFS- 6 Year Warranty

Excerpt: For homes with plastic pipe, use threaded connectors suitable for the specific type of plastic pipe used: CPVC or PEX (cross-linked polyethylene). Do not use PVC pipe. - Zurn, ZURN PEX PLUMBING INSTALLATION GUIDE [PDF] (2010), ZURN PEX®, Inc.

Highway 11 EAST,

Commerce, TX, U.S.A. 75428

USA, Tel: 1-800-872-7277 Web: www.zurn.com

Canada: ZURN Industries Ltd., 3544 Nashua Drive, Mississauga, Ontario, Canada L4V 1L2 Tel: 905-405-8272 retrieved 2021/07/01 original source: https://api.ferguson.com/dar-step-service/Query?ASSET_ID=927224&USE_TYPE=INSTALLATION&PRODUCT_ID=3784258

Excerpts:

ASTM F 877 is the standard that specifies the performance requirements for a PEX system, tube and fittings together. It has requirements for Minimum Burst at 73°F and 180°F, Sustained Pressure Test (1000 hours) at 73°F and 180°F, Thermocycling at 100 psi and Excessive Temperature and Pressure for 30 days to simulate a water heater malfunction. The Zurn PEX systems meet the requirements of ASTM F 877.

ASTM F 1807 is the standard for brass or copper insert and crimp fittings. This standard specifies acceptable materials for these fitting and specifies the dimensions for the insert or barbed portion of the fittings. It also gives the dimensions and the material specifications for the copper crimp rings and the finished crimp dimensions.

These fittings, when tested with PEX tube have to meet the performance requirements for PEX systems as required in ASTM F 877. Zurn PEX brass insert fittings and copper crimp rings meet the requirements of ASTM F 1807.

ASTM F 2159 is the standard for plastic insert and crimp fittings. This standard specifies the acceptable materials and dimensions for the fittings. It also has some test requirements for evaluating the quality of the molding process that was used to make the fittings.

These fittings, when tested with PEX tube have to meet the performance requirements for PEX systems as required in ASTM F 877. Zurn PEX plastic insert fittings meet the requirements of ASTM F 2159.

Other ASTM Fitting Standards

ASTM F 1960 is the standard for “Cold Expansion Fittings” as sold by Wirsbo/Uponor. Zurn PEX tube can be used with these fittings so the standard number is included in the print string on our tube but the system is not covered by the Zurn PEX warranty.

ASTM F 2080 is the standard for “Cold Expansion Fittings with Metal Compression Sleeves” as sold by Rehau. Zurn PEX tube can be used with these fittings so the standard number is included in the print string on our tube but the system is not covered by the Zurn PEX warranty.

ASTM F 2098 is the standard for a “Stainless Steel Clamp” to be used in place of a copper crimp ring for brass or copper insert fittings meeting the requirements of F 1807 or plastic insert fittings meeting the requirements of ASTM F 2159. Zurn PEX does sell rings meeting the requirements of this standard and they are covered by a special, limited time warranty.

Detailed Description of the Test Requirements of ASTM F 877 for PEX Plumbing Systems

Burst Test at Room Temperature and 180°F In this test, sample assemblies are subjected to a constantly increasing pressure until something fails. The minimum acceptable pressure depends on the size of the tube, but it is a minimum of 620 psi at room temperature and 275 psi at 180°F. The pressure is increased at a rate that will cause failure in about 1 minute.

The significance of this test is that it demonstrates that the short term strength of the connection exceeds the strength of the tube

...

Continue reading at WATER HEATER SAFETY, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recomended Articles

- HOT WATER ANTI-SCALD REGULATIONS

- Legionella BACTERIA in WATER HEATERS

- PEX CONNECTIONS to WATER HEATERS

- PEX PIPING INFORMATION

- PIPING in BUILDINGS, CLOGS, LEAKS, TYPES - home

- PLASTIC PIPE LEAK CAUSES

- PLASTIC PIPING ABS CPVC PB PEX PPR PVC - home

- RELIEF VALVE, WATER HEATER

- WATER HEATER SAFETY

- WATER SUPPLY PIPE DIAMETER vs FLOW - PEX ID is smaller than Copper Pipe ID

Suggested citation for this web page

PEX CONNECTIONS to WATER HEATERS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.