No Heat Diagnosis & Repair

No Heat Diagnosis & Repair

for Oil or Gas Fired Hot Water Heating Boilers

- POST a QUESTION or COMMENT about how to fix a heating boiler that is not working - how to diagnose the loss of heat in a building when the heat source is an oil or gas fired boiler

Heating boiler problem diagnosis and repair guide - no heat or loss of heat calls:

We give a step by step procedure that will let ytou recognize & diagnose no-heat problems with residential heating boilers, including loss of heat, heating boiler noises, leaks, odors, or smoke, and high heating costs.

This article explains the diagnosis and correction of no heat for water or hydronic or hot water or radiator or baseboard hot water heating systems.

We give help in troubleshooting heating systems using the common fuels: heating oil or LP gas (propane) or natural gas.

This article series answers questions about all types of heating systems, advising on troubleshooting, inspection, diagnosis, and repairs. We describe how to inspect, troubleshoot and repair heating and air conditioning systems to inform home owners, buyers, and home inspectors of common heating system defects.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Diagnose a "no heat" problem: steps the occupant or owner can take before calling repair

If your building is heated by a hot water boiler or "hydronic heating system, this page will step through the diagnostic and repair steps to fix a "no heat" problem.

Article Contents

- HEATING BOILER PROBLEM TYPES

- IS YOUR HEATER TURNED ON? - Check this first.

- NO HEAT? STEP BY STEP DIAGNOSIS

- OTHER CONTROLS that MAY TURN OFF THE HEATER

- BURNER RUNS but WITH TROUBLE SIGNS

- BURNER RUNS but NOISY or SOOTY

- BURNER RUNS but NO HEAT is DELIVERED

If your heat is by forced warm air, it's not a boiler, it's a furnace. For furnace no-heat troubleshooting please

Not sure what kind of heat you have?

If you don't know whether your heat is provided by a furnace (hot air) or boiler (hot water), or whether your fuel is oil, gas, or electric,

and whether your heat is hot water, steam, or warm air,

see HEATING SYSTEM TYPES.

Note: some hybrid or mixed heating systems combine both hot water and hot air to heat a building, such as water to air systems which use a heating boiler (oil, gas, or electric) to heat water which circulates through (and inside of) a heat exchanger (that looks like a car radiator) . - also described at the heating systems types page given just above.

Photo above: the red electrical power switch found near your heating boiler or sometimes at the top of a basement stairway is one of the first things to check. Make sure that electrical power to your boiler is "ON". In our photo the switch is in the "OFF" position!

Types of Defects and Problems with Hot Water Heating Boilers - Hydronic Heating Systems, Loss of Heat, Noises, Leaks

What sort of defects should you look for when inspecting a heating system?

What sort of defects should you look for when inspecting a heating system?

- LOSS OF HEAT in your BUILDING? - boiler or furnace won't operate,

or system operates but heat is not produced in the living area - we outline a step by step diagnostic procedure for "no heat" conditions just below. - Improper Heating System Function:

NOISES ODORS SOOT, unreliability, inadequate heat distribution - Unsafe conditions on the heating system

- Missing Heating System Components: safety controls, operating aids

- Unreliable heating systems or heating systems at or near the end of their useful life

- Improper Heating System Construction/Installation

- Heating System Damage: leaks, mechanical damage

- Clues of potential other heating system defects:

LEAKS CORROSION STAINS, abnormal temperature

or pressure,

HIGH HEATING BILLS - No domestic hot water for washing and bathing? This is not usually a home heating system problem, but if your hot water is made by a tankless coil and a gas or oil fired heating boiler, the problem could be with the heating boiler itself. If your water heater is not working, find your water heater type

at WATER HEATERS. - Need to know the parts of your boiler and how it works?

at BOILER COMPONENTS & PARTS

andat BOILER OPERATING STEPS we describe the parts and operating sequence of hot water heating systems.

Step by Step Diagnosis of Loss of Heat for Hot Water Heating Systems = hydronic heating systems

If the heating boiler oil burner or gas burner is not turning on at all check the causes listed on this page.

We'll take you through photo-illustrated step by step things to do when you have no heat and you need to determine what's wrong. First let's review these simple "no heat" concepts .

NO HEAT: BURNER OFF, SAFETY NOT TRIPPED: - Oil or gas burner has stopped, no safety switch is tripped

1. Is the thermostat calling for heat?

check that the room thermostat setting is at least 5 degrees above the actual room temperature.

See THERMOSTATS.

2. No electrical power:

check that all of the switches that power on the oil or gas burner are in the "on" position.

Check heating circuit fuses & circuit breakers, not just the wall switch. We discuss this in detail at

IS IT TURNED ON?

3. Is there fuel in the oil tank or LP gas tank?

Check your oil tank or LP gas tank tank gauge.

Out of heating oil?

If the marker in your oil tank gauge reads 1/8 full or less, or is at the bottom or out of sight you are probably out of oil. If your oil tank is buried, and if you do not have an indoor (remote) fuel level gauge, the oil level is checked in the tank by removing the tank filler pipe cap and using a long (clean) stick (or in emergency a clean string and weight) to measure the depth of heating oil in the tank.

Remember that a problem with the oil piping, oil filter, or fuel unit can also cause no oil to be delivered to the oil burner even if plenty of oil is in the tank.

See OIL BURNER FUEL UNIT for some helpful diagnostics

and

also OIL & GAS PIPING.

Out of LP liquid propane gas?

Check the gauge on your propane tank. If the reading is 10% or less you are out of fuel.

If your boiler is fueled by piped-in natural gas from a utility company, check that the company hasn't turned off your gas supply at the gas meter - something that might happen if you didn't pay a gas bill or if the gas company thought your building's gas system was unsafe.

4. Electric motor problem at the burner or blower fan:

Check that an electric motor (for the oil burner, gas burner, or blower assembly) reset switch may have tripped. See our notes above about electric motors, and

See RESET SWITCH, ELECTRIC MOTOR.

5. Aquastat or cad cell control or relay trouble:

NO HEAT: BURNER HAS TURNED OFF ON SAFETY: Oil or gas burner has stopped, the safety switch is "off" or "tripped"

If you are not sure how to find and check the safety control reset buttons on your heating system, we describe these controls in more detail just a bit further on in this article.

The burner on your heating boiler, furnace, or water heater has shut down, if a red "reset button" has popped up on the burner primary control or on an electric motor that operates the system. This condition is called "Safety Off".

Watch out: Before re-setting the safety switch or button, it's a good idea check the following five common causes of loss of heat leading to a Safety Off condition. Photos and details follow these short paragraphs.

How to press the heating system reset button:

If you do not see anything wrong, you can try re-setting the heating system: press and hold the red reset button down for 3 seconds and release it. If the heating system has electricity it will try to re-start.

Watch out: If the system does not keep running smoothly don't keep pressing the reset button - that could flood the combustion chamber with unburned fuel, causing a dangerous puff-back.

Just press the reset button once. If the heating system starts and runs ok, you still should request a service call, but you can have heat while you're waiting.

Other heating boiler control troubles like humming or buzzing? If you hear or have ever heard buzzing from any heating system control that includes a relay switch, watch out for a control cover that is in contact with a relay switch in the unit.

If the cover is lightly touching the relay switch the control may simply buzz when the relay is trying to move.

But a too-tight control cover can also prevent a relay from operating, leading to loss of heat. Simply pulling off the cover to let the relay move freely can immediately discover and "fix" this problem.

Details and illustrations including diagnosing buzzing relays are

at HEATING SYSTEM NOISE DIAGNOSIS.

1. Heating fuel failures:

If your heating system is out of oil in the oil tank, has a clogged oil filter, clogged oil nozzle, oil line has been bent, crimped, clogged, clogged oil pump strainer (fuel unit strainer), or inability of the fuel unit to pump oil (broken motor shaft, missing internal bypass plug on a two line oil tank system, an air leak in the oil inlet line, or a leaky foot valve in the oil tank causing loss of oil prime).

If the oil tank is outdoors in freezing weather the oil in the tank or in an oil line may have become waxy or jelled. That will prevent fuel from reaching the oil burner and your system will shut down. You'll have no heat.

2. Oil burner motor failure:

the electric motor that runs the oil burner may itself have gone off on reset.

Some causes of electric motor failure: one pipe oil system with the bypass plug installed in the fuel unit (oil pump) causing excessive pressure and stalling the motor; centrifugal motor switch sticking (try banging on the motor once); motor condenser burned out; motor stator or internal windings burned or shorted; motor bearing failure.

Try re-starting the motor -

see RESET SWITCH, ELECTRIC MOTOR

3. Oil burner or gas burner ignition failure

For oil burners: the oil burner's ignition transformer terminals are loose; the electrodes on the burner nozzle are dirty or not set to the proper gap;

the oil is contaminated and is hard to ignite; the ignition transformer has become weak or has burned out (look for tar oozing out of the ignition transformer container);

the oil burner nozzle is clogged preventing oil from contacting the ignition spark arc; the ignition electrode(s) are grounded on the air tube of the burner;

4. Faulty heating system control operation

the safety sensor that checks that a good oil burner flame has been established is not working; a stack relay spring or cad cell eye may be dirty with soot; the stack temperature may be too low for the stack relay (boiler is under-fired); the oil burner has been cycling on and off to frequently (a problem with the thermostat).

Tip: Look for loose electrical connections

before deciding that a control or switch has failed, confirm that the system has electrical power, all switches are on, and that a wiring connection has not come loose.

On a recent no-heat call we were embarrassed to learn from Bob, the service tech, that the problem was most likely that somebody (who me?) may have accidentally knocked loose the electrical connector at the oil delay valve (aka "quick stop valve").

The connector may still appear to be in place but may have been pushed slightly back or askew. The result is that on a call for heat the oil burner motor will run but the burner will never ignite. Details about loose connector diagnosis & cures for the quick stop valve or oil delay valve or the PD Timer are

at OIL LINE QUICK STOP VALVES.

Other common loose electrical connections might be at wiring to any heating control or at the oil burner itself.

5. Irregular heating boiler stack temperatures

Improper temperature (too low or too high) in the exhaust flue can cause oil burner draft and temperature or control problems. Downdrafts (missing chimney cap), insufficient draft due to chimney problems, or fluctuating oil burner flame may be at fault. Also

see CHIMNEY INSPECTION DIAGNOSIS REPAIR.

-- some of this material is paraphrased from Audel.

Is your Heating System Turned On?

Has someone left one of the heating system electrical power switches OFF?

Has someone left one of the heating system electrical power switches OFF?

Before you switch it back on consider that there are two different situations:

- First - the system may be off because its unsafe - as we'll explain just below.

- Second- the system may be perfectly safe but was switched off for service, or by mistake - as we explain after our safety warnings.

Unsafe Heating Equipment Deliberately Switched Off

Watch out: SAFETY WARNING: If a heating system oil burner has been deliberately "shut down" and you don't know when or by whom this step was taken, beware of turning the heating system back on without an inspection and safety check by an expert technician.

A heating service technician who sees what she or he considers a dangerous condition at your heater may leave the system turned OFF for safety.

In this case the technician should connect a red tag to the heater at a conspicuous location, explaining the action. The technician should also notify the building occupants and owners of this condition and suggest what to do next.

Watch out: leaving electrical power and heat off in a building in freezing conditions may also be unsafe for occupants and can risk frozen pipes and subsequent water damage. So taking steps to have the system repaired and restored to safe operation may be urgent.

Case report: disabling an unsafe boiler: the choice may be beween no-heat and dead people

The author has turned off and red tagged unsafe heating systems in just these conditions. I found a gas boiler venting all of its combustion products right into an occupied building, risking unsafe or even fatal carbon monoxide poisoning of building occupants. I learned that previous service techs had red-tagged the boiler and left it turned off and notified the owner. But the building owner had repeatedly simply ripped off the red tag and switched the boiler back on, putting his tenants in real danger.

At oil burner school we were taught that if a heating system causes a fire or worse, injuries or deaths, the last professional to look at or touch the system was likely to be held responsible. The instructor called this the "last man in problem" to which we noted that our business partner in heating service was Carol Schnierer who was certainly a woman. So it might be the last woman in problem too.

Knowing that the owner was going to turn the boiler back on when I left and that occupants could be in mortal danger, I actually removed an electrical part from the boiler and tossed it into the woods behind the building, then added my red tag and notified the owner and occupants of the unsafe heater and that I was leaving it OFF until it could be repaired. The owner was furious and I didnt' get paid, but I also was able to sleep that night without worrying about dead people.

My friend Steve Vermilye, a New Paltz home inspector, did the same thing at another property. Steve was sued for loss of heat. In court he told the judge:

"Your honor, I had a choice: no heat and risk of frozen pipes on the one hand, or dead people on the other hand. Which choice does your honor think I should have made?"

The judge considered for just a moment, then threw the case out of court. Steve smiled as he told me about it.

When You can Turn the Boiler Back On

In other circumstances than the unsafe condition we described just above, a heater may have been turned off and left off by mistake or in conditions where all that's needed may be to turn its power switch back on.

So find and check all of the switches that send power to your boiler or furnace or electric heater.

Check local switches at the boiler, wall mounted boiler switches at the stairwell down to the basement or utility room or in other areas, and check the circuit breakers or fuses in the electrical panel.

If your heating system is a heat pump, check the service switch outside at the compressor/condenser unit to be sure it is "on".

Also some heating sytems have multiple components with individual power switches.

Make sure that electrical power is on for all of the heating system components.

Is the heating boiler turned on? Is there electric power to all of the heating system components such as an oil burner at the boiler and power to the circulator pumps?

I Didn't Know What the Red Switch Was, so I Just Turned it OFF to be Safe!

Watch out: as we illustrate above and below, there may be more than one heating boiler or furnace power On-Off switch.

Often there is a service switch right at the heater, and another at the top of the basement stairway or elsewhere in the living space.

The upstairs heater on-off switch is there so that in an emergency the building occupants don't have to go down into a basement (or crawl space or other hard-to-access area) to turn off the heat.

The heating system On-Off switch shown here was "hidden" in a closet in an older New York home.

At one time the door shown led to a stairway down to a basement under the home - the location of the heating boiler.

Later renovations eliminated the stairs to the basement, converting the stairway into a small closet (photo above).

The basement could still be accessed but only by an outdoor basement entry stairs. But the boiler on-off switch remained in the "closet".

Nancy and Edna, as new homeowners didn't know what this red switch did, and one of them, thinking it "did nothing" thought it would be safer to turn the switch to its "OFF" position, so she did so.

Our friend Nancy didn't understand what the red "ON-OFF" switch was in a closet in her living room - a space that earlier in the life of the house had been an entry to the home's basement. (Photos above and below)

Seeing an uknown switch in the ON position (photo above) she simply flipped it off.

When winter came and the house got cold, Nancy called her heating service company to "fix the boiler".

The service tech found that the boiler had no power, found the old on-off switch and simply turned it back on for the occupants.

Watch out: emember to check all of the On-Off switches for your heater - there are often at least two, sometimes more. See details

at HEAT ON-OFF SWITCH LOCATIONS - hidden? extra?

and

at OTHER CONTROLS that MAY TURN OFF THE HEATER

and

and

at FURNACE CONTROLS & SWITCHES

and

at STEAM HEATING SYSTEMS & CONTROLS

Watch out: on forced warm air systems check the air handler blower door interlock switches:

Has someone left an inspection or furnace access door open on the furnace? Or has an interlock switch itself been knocked loose?

(Modern furnaces have a switch which forces the furnace to turn off if the inspection door is opened - to avoid injury to someone working on the blower assembly.)

Be sure the access covers are properly-closed, seated, and latched and that the switches themselves are secured in place.

Check All of the Controls that Can Turn Off Your Heater

If you already checked the power switches for your heater then continue below.

Otherwise see IS YOUR HEATER TURNED ON? - Check this first.

- Oil Burner safety reset switch is OFF or TRIPPED

the heating or air conditioning system may have been turned off on reset - see our "off on reset" and other advice

at CAD CELL RELAY SWITCH (modern equipment).

LP and natural gas fired heating equipment and water heaters also have safety controls including temperature limit controls and gas spillage sensors (see list of reset switches below).

For gas heat, turn off electrical power to the gas fired heater using the service switch. Wait two minutes and turn the electricity back on.

See ELECTRICAL POWER SWITCH FOR HEAT. This will reset most gas heating equipment.

For oil heat: are you sure there is no safety or reset button tripped?

Where are all the heating system reset buttons? If you are looking for the main reset button on heating equipment you'll want to

see:

AQUASTAT CONTROL FUNCTIONS

CAD CELL RELAY SWITCH (hot water boilers and some water heaters),

STACK RELAY SWITCH On older oil fired boilers and furnaces,

FLUE GAS SPILL SWITCH TRIPPING & RESET (gas fired equipment),

and

LOW WATER CUTOFF CONTROLS On steam heating systems.

At ELECTRIC MOTOR OVERLOAD RESET SWITCH we discuss the thermal overload switch and reset button that is found on many electric motors including those operating air conditioning fans, heating system oil burners, and furnace blowers and motors.

A Stack relay switch may be installed on the flue vent connector and may be in the "safety - off" position. To identify and reset this control see STACK RELAY SWITCH. Stack relays are found on older oil fired furnaces and boilers.

- Heating fuel supply - check again:

if it is a gas furnace, is the gas turned on? If your gas is from bottled or LP gas, is the tank empty? If it is an oil fired heating furnace, check the gauge on the oil tank. Are you out of oil?

See OIL TANK GAUGES.

Still no heat? Once you have assured that you have heating fuel and that electrical power is turned on to the heating unit, if you still don't have heat check these controls:

- Thermostat

is in the "off" position or is set to a temperature that does not call for heating (or cooling)

See FAN AUTO ON THERMOSTAT SWITCH for details about what turns the blower fan on and off. - Flue gas spill switch

If your heating boiler is gas-fired (natural gas or "bottled" LP gas), a flue gas spillage switch may have shut the system down after sensing possibly dangerous flue gases (that can contain fatal carbon monoxide).

See FLUE GAS SPILL SWITCH TRIPPING & RESET. This switch will not normally be found on oil fired heating equipment.

- Is there fuel for the boiler ?

check the oil tank gauge

(see OIL TANK GAUGES for tips on how to find, read,and test the oil tank gauge. If the heating boiler is fired by natural or LP gas and not oil, check that no one has shut the gas supply valves.

If the oil tank gauge says there is more than 1/4 of a tank

of oil, you might want to pull the gauge plastic cap and press down on the gauge indicator - check to see if it was stuck indicating oil when the tank is in fact empty.

If you're out of oil or gas

call your oil or gas company and request an emergency delivery. For oil systems, usually the delivery person will also need to enter the building to bleed air from the oil lines in order to get the oil burner operating again. For gas fired heating equipment the driver may want all gas appliances turned off in the building during delivery. - Oil burner motor coupling

another cause of an oil burner starting to run but never igniting at all may be a broken or slipping coupling (or a frozen coupling) between the oil burner motor and the fuel unit. In this case the burner starts in response to a call for heat, but there will be no ignition whatsoever because no oil is being delivered to the nozzle assembly. - Other reasons for no oil flow to the oil burner include:

- an oil safety valve that has been "closed"

(someone turned it the wrong way), - an oil delay valve or quick stop valve that has lost electrical power

- discussed earlier on this page - low oil or no oil in the heating oil tank

(the tank may not be completely empty but oil may be below the oil pickup line if the oil lines are exiting at the top of the tank), - a clogged oil filter or fuel unit strainer.

If the oil filter is clogging the oil burner may re-start after the system has been off for a time, but in minutes after the burner ignites the flame may begin to stumble or even go out as the fuel unit has trouble sucking oil through the filter. An inspection of the oil filter for sludge and crud clogging the filter can diagnose this problem.

While it's out, just replace the filter. - a clogged oil burner nozzle,

- an air leak in the heating oil supply piping,

or a crimp or clog or restriction in the oil piping. - If you recently ran out of oil

and then got a delivery, and if your system uses a single oil line between tank and burner, the line or fuel unit may be air bound and needs to be bled. [8]

- an oil safety valve that has been "closed"

- Is the thermostat calling for heat?

and is the temperature at the thermostat lower than the thermostat setting? - Does the oil burner start but then shut off? Is the system "off on reset"?

if so the red "reset" button will have popped up on the oil burner control (or possibly on an electric motor operating the oil burner) and the system has an operating problem and needs service. It may be possible to re-start an oil burner that has turned itself off by pressing the red reset button ONCE.

If the heating boiler or furnace re-starts and runs acceptably, you can have heat while waiting for the service technician but the system still needs inspection, service, and possibly other repairs before it can operate safely and reliably.

If you push the reset button and the burner does not start and keep running for five minutes or more, DO NOT try again as you may flood the system with oil and make restarting difficult and dangerous. - Is the oil burner motor itself off on reset?

See MOTOR OVERLOAD RESET SWITCH.

Oil Burner Runs but with Problems

Oil Burner Operating Problems: rough, noisy, smoky, smelly

The heating burner operates but not properly.

See OIL BURNER NOISE SMOKE ODORS

Next let's check each cause of no heat in detail; if your system uses warm air heat instead of water or steam, review the check-items just below before going

to HEATING LOSS DIAGNOSIS-FURNACES.

Diagnose Soot or Noises during Heating System & Oil Burner Operation

For full details of this topic be sure to

see OIL BURNER NOISE SMOKE ODORS.

- Noises during oil burner startup

a "bang" or puffback which blows soot into the room through the barometric damper or through other equipment openings: the oil pump may not be shutting down properly at the end of an oil burn cycle, leaking incompletely burned oil into the combustion chamber.

That oil ignites at startup causing a potentially dangerous puffback. Immediate service and repair are needed. - Soot and black marks

in the living area can sometimes indicate an unsafe or poorly-functioning heating system but these marks can also be normal in some buildings depending on other conditions. Details about soot tracking are

at THERMAL TRACKING.

Watch out: Safety warning about soot: Sooting can occur with both gas fired and oil fired systems.

Soot coming from a gas fired heater is probably indicating a very dangerous condition risking carbon monoxide poisoning. If a gas fired appliance is producing soot, it should be turned off and Immediate service is needed.

See COMBUSTION AIR DEFECTS

and

also SOOT on OIL FIRED HEATING EQUIPMENT

and GAS FIRED WATER HEATERS for safety warnings about soot at heating appliances. - Noises during oil burner startup

a "rumbling" sound (which usually continues all during operation" or a "stumbling" sound in the combustion chamber probably indicates that the system needs inspection and cleaning very soon. Some noise is normal however, but the normal sounds tend to be more smooth and continuous.

See OIL BURNER CHOKING SOUND

See OIL BURNER RUMBLING NOISE - Noises during oil burner shut-down

a stumbling or rumbling after the oil burner motor has stopped, indicate that oil is continuing to leak into the combustion chamber and risks a dangerous puffback - see "Noises during oil burner startup" above. Immediate service is recommended.

See OIL BURNER SOOT & PUFFBACKS - Noises of shrieks or grinding coming from the electric motor or oil pump

On the oil burner mean that immediate service is needed - probably a bearing is failing.

See OIL BURNER SQUEALING HIGH PITCHED SOUNDS - Startup problems:

noises and clues of puff back: if you see flapping at the barometric damper or if you see or hear vibrations in the system, or if you see black soot on or near heating equipment the system may be unsafe and prompt service is needed - Noises from radiators or heating baseboards: clanking pipes

or sharp snapping noises may be heard as a normal consequence of expansion of metals during the heating cycle.

These noises can often be eliminated or reduced by careful routing of piping and by allowing room around heating pipes for expansion, but probably not eliminated in the case of hot water baseboards.

Bubbling or rumbling noises

in hot water heating piping can be caused by air in the heating lines. If the amount of air becomes excessive the system may be unable to circulate hot water and extra steps to bleed unwanted air will be required.

See OIL BURNER GURGLING

Hissing sounds

such as air escaping from radiators or other piping where air bleeder valves are installed are normal but should be brief and uncommon.

If you constantly hear air hissing from radiator bleed valves double check that you understand what kind of heat you have - hissing from bleeder valves on steam heat radiators as heat is coming up in the building is normal.

Heating Boiler Runs but No Heat is Delivered

- Boilers-Hydronic Heat: Is hot water water circulating?

- Check the hot water circulator:

Test to see if the circulator is operating Feeling the hot water distribution piping (Watch out it should be HOT!).

Feeling the piping can indicate if circulator is running or not -- a quick change in temperature means the circulator works; slow change in temperature may occur if the circulator does not work but hot water is circulating by convection.

See CIRCULATOR PUMPS & RELAYS for articles that help diagnose a circulator pump that won't start or won't stop or is noisy or leaking - Check for a bad zone valve or bad circulator pump relay.

If the building has more than one heating zone it probably uses either multiple circulator pumps, each of which is operated by a circulator relay switch that is in turn operated by a wall thermostat, or it uses multiple zone valves, each of which is operated by a thermostat.

A bad circulator motor or pump, a bad circulator relay (or even a circulator relay cover that is pressed against and jamming the relay switch), or a stuck zone valve (common on some models) will prevent heating water from circulating in that zone while other zones may work fine.

See ZONE VALVES, HEATING for diagnosis of zone valves that don't open or don't close when they should - Check hot water baseboards:

if some baseboards are hot and others cold, are they all on the same heating zone? If not, are all of the thermostats turned up?

If some heating baseboards are hot and others cold and we're sure that they're on the same zone, then the system is probably air-blocked.

See AIR-BOUND HEATING SYSTEMS to diagnose and fix air-blocked heat piping, baseboards, or radiators.

A heating circulator pump is capable of pushing water around in the loop of heating baseboard but is often not capable of overcoming a section of baseboard that contains a large bubble of air.

It's necessary to remove such air blocks. If air blocking has been recurrent a previous owner may have installed air bleeders at strategic points. The bleeder can be opened slightly and carefully, to permit air to escape.

As soon as water starts coming out of an air bleeder valve it can be closed.

Automatic air purge devices are available and are usually installed right at the heating boiler but sometimes additional ones are needed at higher levels in the building. - Check hot water radiators or convectors:

if some radiators or wall convectors are hot and others are cold, and provided that the individual feed valves located at each of these devices is open (turned counterclockwise) the radiator or convector may be air blocked. Usually an individual air bleed valve is located on each of these devices. - Check the Oil Heating Equipment Safety Controls and Switches -

see FIRE SAFETY CONTROLS for photos and details - On gas fired heaters check for flue gas spillage at the heater or for a bad flue gas spillage switch:

If your furnace is gas-fired, a flue gas spillage switch may have shut the system down after sensing possibly dangerous flue gases (that can contain fatal carbon monoxide).

See FLUE GAS SPILL SWITCH TRIPPING & RESET for details. - On oil fired boilers or furnaces check for a bad automatic draft damper switch

If the draft damper does not open in response to a thermostat's call for heat the heating appliance will not start.

Heating Equipment Malfunctions & Their Implications

This information is now

at BOILER OPERATING PROBLEMS and

at DIAGNOSE & FIX FURNACE PROBLEMS and

at FURNACE DIAGNOSTIC CHECKS, GAS

How to Evaluate Heating Boiler Leaks & Corrosion

This discussion is now found at BOILER LEAKS CORROSION STAINS

How to Recognize & Diagnose Inadequate Combustion Air for Oil-Fired Heating Systems

This topic is now discussed at INADEQUATE COMBUSTION AIR

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-09-23 by Tony - heating baseboards don't get hot

I had a Navida Tankless water heater installed for hot water only, the big water tank was removed from my oil burning system for the baseboard heaters,

Now my baseboard heaters are not getting hot, the boiler is at 180 and the hot water seams to be going out back the baseboards are not hot, and the return lines are cold,

Was the hot water tank needed to still run the baseboard heaters ?

On 2020-09-23 - by (mod)

Tony

It's possible that the settings on your aquastat are incorrect.In the ARTICLE INDEX you will see an AQUASTAT SETTINGS article on what the proper settings are.

If your control is set, for example, with the LO too close to or above the HI then the circulator pump won't run and hot water won't be sent to the baseboards.

On 2020-05-14 by JERRY - very smoky oil burner flame

boiler will purge , ignition is immediate after purge ,fires thru trial period very smoky, goes to hard lockout after trial period

Has new nozzle , cleaned boiler, new cad cell , cleaned screen on pump.air settings the same as it has always run

any ideas on what is causing failure

On 2020-05-15 - by (mod) -

Jerry,

That smoky flame tells us the oil burner is out if adjustment and so locking out is normal.

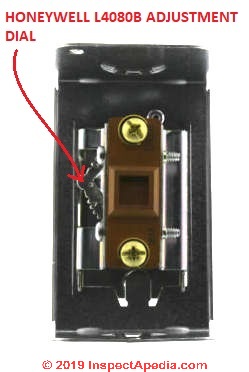

On 2020-02-21 by John - How do I set dial and locking arm on Honeywell L4080B 1212 Aquastat?

How do I set dial and locking arm on Honeywell L4080B 1212 Aquastat?

How do I set dial and locking arm on Honeywell L4080B 1212 Aquastat?

This is a Two stage HI B 85/50 Hydrotherm boiler.

Boiler will not go from hi fire to low fire after return water reaches its maximum setting.

Please advise

On 2020-02-21 2 - by (mod) - here are the Honeywell L4080B 1212 Aquastat instructions as a free PDF download

Also can you post a photo of your boiler and another of its data tag (one image per comment) ? I don't have a Hydrotherm HI B 85/50 boiler manual nor can I find that exact boiler name.

I'm looking into the question in more-detail John and will report back.

If you don't have it, the manual for your aquastat is at

i HONEYWELL L4080B AQUASTAT MANUAL [PDF]that also covers the HONEYWELL L8080A AQUASTAT MANUAL [PDF]

Honeywell's own website provides no literature for the L4080 / L8080 nor does the company list a replacement, though the L4080 - series and L8080- series aquastats are certainly listed as a available by many supply houses.

Also the Honeywell L7224U might suit.

But to the point of your question, I don't see that the L4080 has within itself specific provision for dual fire-level boilers.

The L4040B aquastat is a simple high limit aquastat controller with a single adjustable set-point using an internal dial inside the aquastat.

On 2020-01-21 by Mike - only 1 of the 2 boiler pipes gets hot

There’s 2 pipes coming out of burner one gets hot the other staying cold and burner runs for a few minutes and shuts off.

On 2020-01-22 - by (mod) -

Mike

Is the boiler's burner shutting off because it's reaching the hi limit, because the thermostat is satisfied, or because of an operating problem?

About the line that doesn't get hot, in the INDEX to RELATED ARTICLES found at the end of this article see AIRBOUND HEATING SYSTEM for troubleshooting and repairAlso look for a circulator that's not coming on or a valve closed in the heating line.

On 2019-12-19 by jimmy45 - our baseboards get warm but not hot enough and house takes a long time to get up to temperature

Our home is a late 60's pre-built with 1150 square feet. We have a Weil-mclain CG 11 hot water boiler, Taco sentry zone valve on the supply side, and I think the issue is with the zone valve.

We use 10% LP on a 500 gal. tank a week. When the thermostat calls, the zone valve closes, the boiler fires, as does the circulator.

The baseboards get warm to the touch, but not 180 degree hot. Once the heat is reached, the boiler stops as does the circulator, and the zone valve opens.

We have our thermo set at 65, it turns out around 63 degrees, and shuts of around 66. It takes close to an hour to raise 3 degrees.

Is this much LP normal?

How has no damage occurred with the circulator running and the zone valve closed?

Thank you for your time

On 2019-12-19 b (mod) - Weil-mclain CG 11 hot water boiler gas usage rate

Jimmy

First: perhaps you mis-typed but you said

The baseboards get warm to the touch, but not 180 degree hot. Once the heat is reached, the boiler stops as does the circulator, and the zone valve opens.

That's not right. The zone valve OPENS to let hot water circulate to the baseboards and CLOSES at the end of a call for heat to that zone.So if your zone valve is really working backwards that would explain why it takes forever to heat your home.

When the zone valve is CLOSED but the boiler and circulator are running, NO hot water circulates through that heating zone - it won't get warm.

Then when the boiler and circulator STOP if the zone valve OPENS then the remaining hot water in the boiler will circulate slowly by convection and your house will slowly get some but not enough heat.

Finally: I can't guess how much LP gas use is normal for your home because the amount of fuel needed and heat output needed to warm a home varies significantly by the home's rate of heat loss (how well a home is insulated, how much air leakage there is, how much glass there is, how much opening and closing of windows and doors occurs, etc).

But there are some sanity checks that one can make.

1. Look at the heating boiler's data tag where you'll see the input BTUh consumption rate of your boiler.

At GAS BTUH, CUBIC FEET & ENERGY we give all of the ways to convert between cubic feet or other measures of LPG and btus. You can thus start by seeing the rate per hour (of "on" time) at which your boiler consumes fuel.

You'll need to watch or measure or count hours-on for your boiler.

2. Have your heating service tech be sure that the boiler is properly tuned and adjusted. If your boiler's HI limit is set to 180degF that does NOT mean that the baseboard pipes will ever see that temperature; there is heat loss enroute;

However your tech might agree to push up the HI to 190 or closer to 200F (not above that or the TPR valve will open); the thermal conductivity of baseboard is exponentially greater at higher temperatures so you'll see a bit more efficient heat transfer into the occupied space.

3. InspectApedia offers a number of articles on cutting heating cost by finding where the waste or leaks are.

Two articles I like are

ENERGY SAVINGS PRIORITIES

and

HEATING COST SAVINGS METHODS

3. There are plenty of additional heat savings articles recommended at those pages I just cited.

...

Continue reading at BOILER OPERATING PROBLEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see BOILER REPAIR DIAGNOSTIC FAQs - questions & answers posted originally at this page.

Or see this

Article Series Contents

- BOILERS, HEATING

- BOILER OPERATING PROBLEMS

- HEATING SYSTEM TYPES if you don't know what type of heating system you have

- OIL BURNER INSPECTION & REPAIR

- OIL BURNER NOISE SMOKE ODORS - home

- GAS BURNER FLAME & NOISE DEFECTS

- GAS BURNER SOOT CAUSE & CURE

- GAS BURNER PILOT LIGHT PROCEDURE

- RADIATORS for ROOM HEAT - topic home, for cold radiator or baseboard diagnosis and repair

Suggested citation for this web page

DIAGNOSE & FIX HEATING PROBLEMS-BOILER at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- Thanks to Bottini Fuel service manager Ron Thomas for discussing aquastat functions, low limit controls, oil burner short cycling causes, and boiler maintenance, reliability, and service contracts 4/13/2010. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.