How to Diagnose & Fix Leaks at Heating Boilers

How to Diagnose & Fix Leaks at Heating Boilers

Where do boiler leaks occur?

Which boiler leaks can be repaired?

- POST a QUESTION or COMMENT about diagnosing and fixing leaks on hot water heating systems & heating boilers

Heating boiler leak repairs:

Here we explain how to detect, diagnose, find, & evaluate leaks in or on hydronic heating boilers with focus on residential heating boilers, including leaks leading to loss of heat, heating boiler noises, leaks, odors, or smoke, and high heating costs.

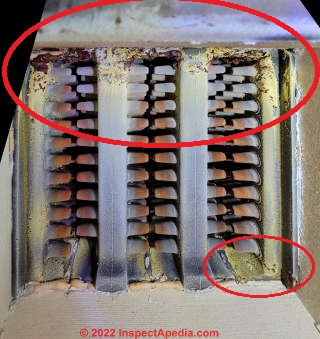

Our photograph at page top shows severe rust at the tankless coil on a steel heating boiler - the tankless coil itself is beyond repair but worse, this boiler itself may be beyond repair, as we will explain here.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Heating Boiler Leaks: cause, evaluation, repair or replacement

When a tankless coil-mounting surface on the boiler itself is severely rusted it may be impossible to get an adequate seal when bolting on a new hot water coil, making it necessary to replace the entire heating boiler.

More subtle, the mounting bolt holes in the body of the boiler itself may become so rusted that it's not possible to replace the leaky tankless coil or even to put a simple blind plate on the boiler to close that feature off. That, too, leads to the need to repalce the boiler.

See TANKLESS COIL / HOT WATER COIL LEAKS for more about this device.

It is important to recognize and accurately report the significance of rust like this on any heating boiler.

Even significant boiler water leaks at a tankless coil (left and at page top) may never show up on the building floor as a wet spot, leading an owner to ignore a condition that can lead to very expensive damage.

Article Contents

- HOW SERIOUS ARE BOILER CORROSION & LEAKS - how serious?

- BOILER LEAK EVALUATION DIAGNOSTIC QUESTIONS

- WHERE are BOILER LEAKS USUALLY FOUND?

How to Evaluate Heating Boiler Leaks & Corrosion

When observing evidence of leaks on a heating boiler, keep these points in mind:

- Even serious leaks may never show up as "wet" spots:

A boiler may be leaking but you may see no actual water: during the heating season the boiler may always be hot, causing small leaks on the boiler or on heating piping to simply evaporate.

But such leaks will usually be visually very evident: look for a build-up of corrosion, green or white or other colored mineral salts, or look for rust or water stains on the equipment.

Other boiler leaks can be very hard to see.

Below: white and yellow effloresence (mineral salts) left behind by a small to modest leak somewhere above on this 1990s Weil McLain gas boiler were found at the under-side of the heat exchanger during a careful boiler inspection and tune up job on this boiler in Two Harbors, Minnesota in 2022.

This evidence of boiler leakage was not, in the opinion of the boiler inspection technician, a reason to condemn the boiler, but it's a warning to look for and fix any leaks above. That boiler continued has continued in service to the present (July 2024).

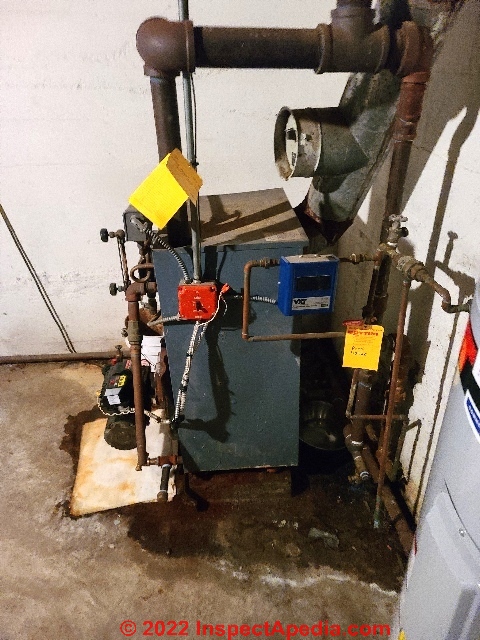

In contrast to the boiler above, the steam boiler below was found to be beyond repair.

- Surface rust,

light, superficial rusting, is generally repairable. Clean the area and fix the leak when the boiler is next serviced and monitor for any future leaks.

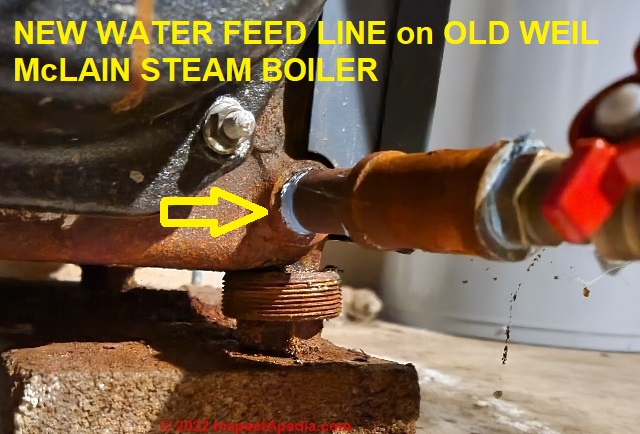

Below is a repair: installation of a new water feedline, on an old cast-iron boiler. The service technicians were able to remove an old rusty water feeder and install a new one.

Had the more-complete condition of the boiler been understood by the building owner at the time she might have opted to skip this water feed repair and replace this old Weil McLain steam boiler, because as we show later, within less than a year this boiler was leaking more than ever and on a more-complete inspection was found to be beyond further repair.

- Exfoliation, or thick flaking rust

on any boiler but particularly on a steel heating boiler is very serious, possibly not repairable, and risks loss of the boiler as well as sudden loss of heat in the building. The boiler shown at left might be repairable.

The boiler shown at page top was so badly rusted that simply replacing the coil and its mounting plate might not possible - the boiler might have been ruined by this unattended leak.

More examples of this problem are

at TANKLESS COILSWarning about corroded leaky heating system and plumbing parts: Don't Poke at Leaks and Corrosion on heating equipment.

Heating service technicians may be more daring, if they are prepared to immediately replace a ruined boiler or a catastrophic leaking part.

We watched a heating company rep poke his pencil right through a badly rusted boiler.But a home owner or home inspector should look but don't touch corroded leaky parts on a boiler.

Too often the mineral build up from corrosion is all that's holding back a serious leak that could, by chipping away the deposited gunk, result in a rapid leak so severe that the heating equipment has to be immediately shut down - not a good idea in freezing weather.

- Internal heating boiler leaks:

Some critical heating boiler leaks may be internal and not visible by simple inspection, such as a leak inside the boiler heat exchanger (photo at left) which may pass water into the combustion chamber.

A service technician or a skilled home inspector should be able to spot evidence of these leaks by inspecting for subtle clues (rust at the bottom of the boiler jacket) or by removing the boiler external covers (as in our photo). - Leaks related to temperature or pressure:

Some leaks occur only at peak operating temperature: e.g. at relief valve.

On some heating boilers such as some cast-iron units, leaks may occur between boiler sections when the system is cold - on these models some technicians prefer to keep a little heat in the boiler year-round to avoid this problem.

Leaks between boiler sections may be repairable but if left unattended can destroy the equipment. - Watch out: Leaks anywhere in the hot water heating system

can cause more than pressure loss in the heating system. Leaks can also allow air back into the heating system as it cools, leading to excess air, even abnormally high pressure (less common), or noisy heat piping or circulator pumps.

Diagnostic Questions Help Evaluate Water Leaks on Heating Boilers

Above and below: a leaking steam boiler at a Poughkeepsie,

New York Home in 2021. How bad were these leaks? Was this boiler repairable?

Was the boiler repairable?

1. Is the existing corrosion and rust so bad that there is a significant chance that trying to disassemble the parts will lead to a total failure and need to replace the whole boiler?

If not, give it a shot. With appropriate and due warnings.

Below: with the covers off of the Weil McLain steam boiler shown above, we see that the cast iron sections and the bolt holding them together are rusted nearly completely-through. This boiler was beyond repair.

When do we let the boiler alone and ignore the leak ? What's the cost? What are the risks?

2. If the parts are so corroded that a replacement of the whole boiler might be required, what's the cost of ignoring the problem until we see water on the floor?

Answer, as was experienced by the homeowner of the boiler we show in our photos.

2.a. The leaky corroded heating boiler is most-likely to fail when it's working the hardest, hottest, under longest periods of highest pressure: during the peak of the heating season on the coldest days of the year.

That's what this homeowner experienced. The result was a boiler that was so leaky and deteriorated what when the homeowner called for emergency service the heating tech took one quick look at the boiler and shut it down for safety, worrying that the whole unit could explode or burst or flood the home's basement. Deeming the unit unsafe he red-tagged it.

The homeowner was then without heat for several days until the heating service company could locate, obtain, and bring a new boiler to the site for a replacement job.

2.b.There was a further risk that the home's basement could be flooded by leakage - mitigated if the service company or homeowner were able to turn off the water supply to the now shut-down and red-tagged boiler.

There were additional costs as well. Because the boiler had to be replaced on an "emergency" basis, the boiler and its installation cost more than it might had it been replaced at a more-opportune time, such as mid-summer.

Our first photo, above showed how the cast-iron sides of the boiler were rusted through.

Our second failed leaky boiler photo below shows that a heavy steel pipe (the condensate return port) on the boiler's bottom-back was rusted so thin that not only was it leaking, but it was easily broken away by simple hand pressure when the repair crew came to the job.

This boiler was beyond repair by the time the homeowner called for repair service.

Sometimes a leaky gasket at a tankless coil can be replaced by removing the coil, cleaning the surfaces, and installing a new gasket + sealer.

Our photo above, of the same failed leaky boiler whose cast iron sides were rusted through (above) shows that the steel pipe for the condensate return at the boiler's bottom-back was rusted so thin that not only was it leaking, but it was easily broken away by simple hand pressure when the repair crew came to the job.

The condensate line return pipe and port leak, the main cause of water on the floor at this oil fired steam boiler, were rusted through - again, beyond repair.

5 Key Questions about Rust on a Heating Boiler or Water Heater

When you see thick exfoliating rust and corrosion on a heating boiler or calorifier, even before there's water on the floor, there are some critical questions to answer:

- Where is the rust?

Only on the part to be removed or also on the mating surfaces of the boiler? - How bad is the rust?

Is it surface rust - the parts can probably be removed successfully, or is there thick exfoliating flaking rust - the parts may meet with disaster on trying to execute the repair - What are the surrounding conditions?

Is the current weather very cold? Can the building and its occupants be without heat for a time?

What are the potential costs and risks of a more-serious leak or of a loss of heat that may occur if the repair is deferred? - Can we wait & would it be better to wait for warmer weather to perform the repair?

Bottom line: if you can fix a leak in time to avoid destroying the boiler, it's worth giving that a shot.

A Catalog of Common Heating System Leak Points - Where to Watch for Heating System Leaks

Note: the following catalog of common places where you may find leaks on a hot water heating system boiler or its components is arranged alphabetically. Some of these leaks, such as at TPR valves, are dangerous and require urgent attention or even system shut-down.

Note: the following catalog of common places where you may find leaks on a hot water heating system boiler or its components is arranged alphabetically. Some of these leaks, such as at TPR valves, are dangerous and require urgent attention or even system shut-down.

- Air bleeder vent valve leaks - leaks can occur at automatic air bleeder valves or air vents wherever these vents are installed on hot water heating systems including at baseboards, expansion tanks, air scoops, or radiators.

See AIR BLEEDER VALVES used to purge air from hot water heating piping, baseboards, radiators, and from the boiler itself.

and

see AIR SCOOPS SEPARATORS PURGERS - these devices use an automatic air purger or air bleeder valve and may leak at fittings or at the valve itself.

and

see EXPANSION TANK AIR VALVE LEAKS - Baseboard or baseboard piping leaks:

Do not usually cause direct corrosion or rust damage to the boiler but may damage the building and may, by causing excessive replacement of makeup water in the boiler, may contribute to boiler corrosion or scaling and clogging. - Boiler control setting-caused leaks:

Leaks due to improperly-set boiler controls - temperature set too high - can show up as leaks at the TPR valve.

see BOILER LIMIT SWITCHES - Boiler control valve leaks, boiler drains, zone service valves, zone drain valves, & radiator control valves -

see LEAKS at BASEBOARD, CONVECTOR, RADIATOR - Bolt opening leaks - suspect hidden damage - can occur at any bolt connection that connects boiler compnents. For example

see TANKLESS COIL / HOT WATER COIL LEAKS for an example of severely rusted coil mounting bolts that are probably beyond repair - Boiler section leaks between cast iron boiler sections of a cast iron boiler, possibly occurring where the push nipples or seals join the water passages of individual cast iron boiler sections together. A photo showing cast iron boiler sections is just above

at HEATING BOILER LEAKS, INTERNAL. - Boiler crack or split leaks in a cast iron boiler section, also leaks at a crack, split, or rust perforation of a steel boiler.

- Circulating pump mounting flange leaks -

see CIRCULATOR PUMP LEAKS . Our photo (left) shows a closeup of an active leak at a heating system circulator pump. - Expansion tank / compression tank leaks due to water-logged expansion tanks - occur when the expansion tank has lost its air charge.

See EXPANSION TANKS - Frozen, burst piping leaks

or in extreme cases, frozen and burst heating boilers themselves. Freezing pipes produce very distinctive types of damage such as splits or separation at solder joints.

See also ANTIFREEZE for BOILERS - Tankless Coil mounting plate - see rust stains below and around plate.

See TANKLESS COIL / HOT WATER COIL LEAKS

and TANKLESS COILS for a guide to diagnosing, evaluating, and repairing leaks at the tankless coil.

Also

Pipe fittings at face of coil plate - look for mineral salts and rust stains since small leaks will evaporate without leaving visible water or wet areas

See TANKLESS COIL / HOT WATER COIL LEAKS for photos of this type of leak stain - Piping leaks at poorly-soldered copper pipe fittings on finned copper baseboard heating systems -

see LEAK TYPES, WATER SUPPLY or DRAIN PIPES - Piping leaks due to frozen and burst piping or in extreme cases, frozen and burst heating boilers themselves.

See FIND & FIX WATER PIPE FREEZE-UP POINTS - Radiator control valve leaks

or leaks between radiator sections don't directly damage the boiler but can damage the building and by causing constant make-up water feed to the boiler, may contribute to boiler corrosion or scale problems. - Temperature / Pressure Relief Valve TPR Valve Leaks:

This leak may be very dangerous as corrosion from water passing through the valve may prevent its safe operation in an emergency.

The boiler pressure/temperature relief valve may be leaking because the system pressure or temperature is too high - it's working properly; or the relief valve may be leaking because its internal gasket has failed or because it has become jammed partly open by corrosion and mineral debris build-up.

Prompt expert inspection and repair are needed. Watch for leaks below the valve's mouth or discharge pipe (a pipe should extend from the relief valve to a few inches from the floor) or watch for corrosion at the tip of the discharge pipe. Gently feel inside the tip of this pipe to see if it's wet.

Watch out: DO NOT TRY TO TEST or open or operate the relief valve itself.

Watch out: a dripping or frequently spilling T&P valve is dangerous because those very leaks can eventually cause the valve to clog and then to fail to open when it should.

See RELIEF VALVE LEAKS

Watch out: never try to fix a leaky temperature / pressure relief valve by using a boiler leak-stop product - you are risking

BLEVE EXPLOSIONS - Zone valve leaks - occur at the piping connections or at the connection of the zone valve head or motor and controls to the zone valve body.

See ZONE VALVES, HEATING

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2013-03-13 - by (mod) -

You don't say how hot water is being made.You might try looking at the simple diagnostic "no hot water" steps at

HOT WATER PRESSURE LOSS

When you tell me a bit more about your hot water system I can help with diagnostic suggestions. But without the fuel and type of heater we're shooting too wildly to be useful.

On 2013-03-13 by Kiy

Hot water is not coming through with pressure or heat but cold water working fine.

Boiler seems to be working correctly after checked flow through other outlet so it seems the problem might be in the way the water is feeding back in the house. How can we check where the problem is and what might it be?

On 2012-05-12 by Anonymous

The carpet is wet--dis colored and warm

Could the return water pipe be leaking from the baseboard heater?

On 2012-04-27 - by (mod) -

SMS, some header tubes can be welded, particularly if it's really a crack and without signficant rust damage;There are also expoxy repair compounds for boilers, though I have not had much success with them. More often the header is replaced.

Mike: putting too much water into a steam boiler can send it up into the steam piping, blocking the movement of steam, leading to cold radiators. If you didn't over-do it, the normal water consumption would have brought the level back down in a few days.

Jim Miller:

Sounds as if there were additives in your heating system, perhaps antifreeze. The leaky pipe needs to be replaced.

On 2012-01-19 by SMS

How to rectify the boiler header tube crack

On 2012-01-16 by Mike

Bryant model 234-55... Have to just water in everyday...before was about every 3-4 days. So I filled with water and went past the glass tube, to see what would happen..well water runs out of the boiler somewhere but cannot see from where.

On 2011-10-23 by Jim Miller

I live in a apartment and the heating pipe is leaking a GREEN LIQUID - What is it and how may it be fixed? - Should I worry? - It has already ruined my Color Printer

...

Continue reading at BOILER LEAKS, HOW TO LOCATE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see BOILER LEAKS CORROSION STAIN FAQs - questions & answers posted originally on this page.

Or see these

Boiler Leak Articles

- AIR BLEED VALVE LEAK REPAIR

- BOILER LEAKS CORROSION STAINS

- CIRCULATOR PUMP LEAKS

- EXPANSION TANK AIR VALVE LEAKS

- LEAKS at BASEBOARD, CONVECTOR, RADIATOR

- RELIEF VALVE LEAKS

Suggested citation for this web page

BOILER LEAKS CORROSION STAINS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about diagnosing and fixing leaks on hot water heating systems & heating boilers

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "The Fight Against Corrosion - A Study of the Nature of Corrosion and its Problems in Water Services and Heating Systems", Daniel Davies, Research and Development Services, Stansted Mountfichet, Essex, England, World Plumbing Conference-IV, "Plumbing and the World Environment, Compendium of Workshop Papers, October 3-6, 1996, Hyatt Regency Chicago, Chicago, IL", [personal correspondence, DJF - Author, July 2011]

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.