Structural Clay Tile & Terra Cotta

Structural Clay Tile & Terra Cotta

Hollow Clay Tile Wall Construction Identification, Inspection, Repair-clay tile unit masonry

- POST a QUESTION or COMMENT about clay masonry unit wall construction

This article describes structural walls built using hollow clay blocks or ceramic clay masonry units - synonyms: architectural terra cotta, building tile, hollow tile, hollow structural tile, structural clay tile, structural terra cotta, clay block, clay block-tile, building tile, and structural terra cotta tiles.

Page top photo: Garden Gate Florist and surrounding buildings built of hollow clay block with some brick infill, courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Clay Block Wall Construction: architectural terra cotta - hollow clay building tile

Clay has been used to construct buildings for thousands of years, typically as clay brick; the use of hollow clay tiles, like those shown here, to construct buildings is a more-recent building technology.

Clay has been used to construct buildings for thousands of years, typically as clay brick; the use of hollow clay tiles, like those shown here, to construct buildings is a more-recent building technology.

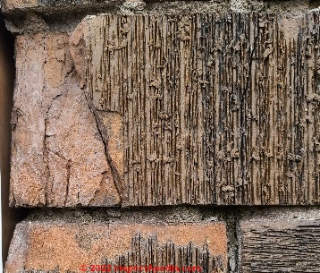

Structural clay or terra cotta tiles are made using natural clay (like the red tiles shown here) or from pulverized shale to form a gray structural tile.

The clay is extruded through a die to form hollow clay blocks that are then kiln-fired.

The ribbing on the sides of the hollow clay tiles in our photo provided a gripping surface that aided both in bonding structural clay tile courses and also in bonding plaster or stucco used to cover the tiles on the building interior or exterior.

This construction is also used as clay unit masonry infill walls for framed construction. (daPorto 2015).

Watch out: if you are preserving a structural terra cotta tile building, be sure to keep its exterior coating in good condition.

These hollow clay tiles are not hard-fired and do not usually have a glazed, weather-resistant surfaces. Exposed to rain and water the tiles will chip, scale, and deteriorate rapidly.

Hollow clay tiles or "blocks" are laid horizontally in a bed of mortar much like brick, concrete block, and stone masonry construction. But unlike their heavyweight clay brothers: bricks, hollow clay tiles are lighter and so both cheaper to transport to the building site and easier to lift into place on the job.

[Click to enlarge any image]

Hollow clay tiles made of terra cotta first saw widespread use in North America in the U.S. beginning in the 1850s and continued in popular use for about 100 years, disappearing from common use as architectural ornamentation in California as early as the 1930s (Dearborn 2010) and as a building construction material in North America by the 1950s.

Illustrated above and below, a textured-surface hollow clay block/brick structure in Two Harbors, Minnesota (October 2022), possibly dating from the 1960s, showing the effects of a combination of moisture and freezing climate.

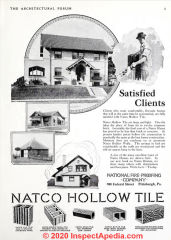

The popularity of hollow clay block or terra-cotta construction tiles during that interval can be traced in part to the fire-resistance and sound and heat-loss insulating properties of clay tile constructed buildings, (Wells 2007) but more broadly because in addition to being lightweight, one terra cotta hollow tile could be set in place providing the same volume as six to as many as a dozen fired-clay bricks: a hollow clay block building went up quickly and at less cost.

The Hollow Building Tile Association (Chicago 1920) described "Hollow Tile" as

The Hollow Building Tile Association (Chicago 1920) described "Hollow Tile" as

The most economical form of permanent construction.

Hollow Tile saves labor cost because rapidly and easily handled, besides giving lighter and better construction. The two or more air cells supply insulating air spaces in walls, floors, and partitions which resist the transmission of heat and cold, sound and dampness.

to afford the healthfulness and thorough comfort demanded of homes, and to reduce costs, build with Hollow Tile. To insure highest grade construction, specify MasTerTile -- tile made in accordance with the Association standards and identified for your protection.

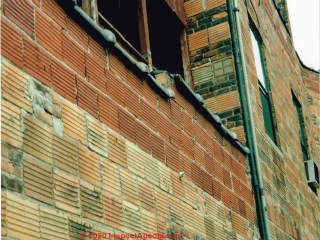

In the U.S. hollow clay block construction was used in skyscrapers of the 1920s such as the ten story Fyfe Store Building in Detroit, shown here constructed using hollow clay tiles produced by the Atlanta Terra Cotta Company and shipped to Detroit from the company's Pennsylvania factory.

The decline of popularity of structural clay tile is tracked by the availability of other inexpensive building materials that are less fragile (concrete block or Concrete Masonry Units CMUs) along with a history of structural damage in earthquake zones.

Our photo above shows where you may structural clay tile construction in a building attic or below, where there has been partial demolition of interior wall coverings.

Photos of block clay construction shown here are provided courtesy of Carson Dunlop Associates, a Toronto home inspection, report writing, and eduction firm.

We pose that the many building inspectors and owners are unaware that hollow clay tiles were used in construction principally because the tiles are usually covered by finish materials both inside and on the building exterior.

- THE HAND BOOK OF HOLLOW TILE CONSTRUCTION [PDF] is offered without charge to architects and engineers engaged in large building projects. - Architectural Forum October 1920.

Where hollow clay tile construction has not fared well has been in earthquake zones ( Doğangün 2008) where this frequently un reinforced masonry construction collapsed during earthquakes.

Clay tile has also been used in the construction of interior partition walls.

Where covered directly with plaster it is considered a medium or average suction masonry base - discussed

at PLASTER TYPES & METHODS in BUILDINGS

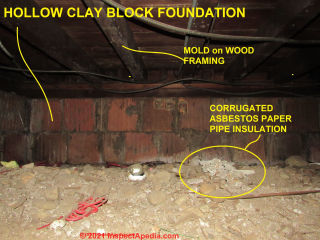

Hollow Clay Tile / Block Used as Building Foundation

These photos of clay block foundation walls in a New York crawl space are provided courtesy of NY Home Inspector DovBer Kahn.

Above: click to enlarge this clay block foundation photo to see additional details that include mold contamination on the floor framing overhead and corrugated asbestos paper pipe insulation fragments on the crawl area floor.

Both of these may indicate that some costly cleanup is needed this space.

Below: details of the same clay block foundation.

Above in this clay block foundation wall we see breaks in the hollow clay blocks that may have been intended to serve as a crawl area vent - now blocked.

Dov Ber Kahn, a home inspector in Rockland County, NY has contributed photographs of various building features. Mr. Kahn is a licensed home inspector in New York and New Jersey, and can be reached at Website: Kahnbhomeinspectors, Tel: 845-445-8234, Email: kdovber@googlemail.com

References & Research on the History & Use of Clay Tile Unit Masonry Construction

- Almesfer, Nasser, Dmytro Y. Dizhur, Ronald Lumantarna, and Jason M. Ingham. "Material properties of existing unreinforced clay brick masonry buildings in New Zealand." Bulletin of the New Zealand Society for Earthquake Engineering 47, no. 2 (2014): 75-96.

- The ARCHITECTURAL FORUM [PDF] October 1920, source of hollow clay tile advertisement shown above.

- Asteris, Panagiotis G., M. P. Chronopoulos, C. Z. Chrysostomou, H. Varum, V. Plevris, Nicholas Kyriakides, and V. Silva. "Seismic vulnerability assessment of historical masonry structural systems." Engineering Structures 62 (2014): 118-134.

- Bennett, Richard M., Kurt A. Boyd, and Roger D. Flanagan. "Compressive properties of structural clay tile prisms." Journal of Structural Engineering 123, no. 7 (1997): 920-926.

- Borchelt, J. Gregg. "History of Anchored Masonry Veneer." In Brick and Block Masonry, Proceedings of the Eighth International Brick and Block Masonry Conference, pp. 1496-1506. 1988.

Abstract:

Anchored masonry veneer construction accounts for the 1argest percentage use of c1ay and concrete brick masonry in North America. The design of this construction method evolved in an empirical manner.

Little testing had been undertaken until a number of veneer applications suffered failure. This paper traces the development of anchored masonry veneer from its beginning to the testing done to date.

Current design recommendations for anchored masonry veneer supported by various backings are given. - Da Porto, Francesca, Giovanni Guidi, Massimo Dalla Benetta, and N. Verlato. COMBINED in-plane/out-of-plane BEHAVIOUR of REINFORCED AND STRENGTHENED INFILL MASONRY WALLS [PDF] In Proceedings of the 12th Canadian Masonry Symposium, pp. 2-5. 2013.

Abstract excerpts:

This work presents experimental test results obtained on clay unit masonry infill walls for framed structures.

The main aim of the tests is characterizing the out-of-plane behaviour of infill walls made with different types of masonry, under various levels of damage caused by in-plane deformation of the frame.

Tests were carried out on one-bay, real scale reinforced concrete frames, by imposing in-plane cyclic displacements at the frame top beam until reaching pre- determined drift levels. ...

The results of seven tested frames are presented and discussed. One frame is a reference bare RC structure, without any infill wall. Four frames have thick (300 mm) clay unit masonry infill walls.

Two of these specimens are made of unreinforced masonry, the other two are made of reinforced masonry, having both horizontal and vertical reinforcement.

The remaining two frames have thin (120 mm) clay unit masonry infill walls with plaster layer, one of them is strengthened by means of a special quadriaxial net made by hybrid glass fibres, that is casted in an extra fibre-reinforced plaster layer.

Above: architectural terra cotta ornamentation on the Cumberland Hotel in Cumberland MD, from Architectural Forum magazine, October 1920.

- Dearborn, Valerie Jean. THE RISE AND FALL OF AN ART FORM: ARCHITECTURAL TERRA COTTA ON CALIFORNIA'S COAST FROM THE EARLY 1900S TO 1930S. [PDF] California State University, Dominguez Hills, 2010.

- Dhanasekar, Manicka, and Mlinder Kumar. PARAMETRIC STUDIES ON THE STRENGTH AND STIFFNESS OF REINFORCED CLAY BLOCK MASONRY [PDF] In Proc. of the 10th International Brick and Block Masonry Conference, pp. 97-106. 1994.

Abstract:

This paper contains the results of the tests on fifty one four high stack bonded clay block masonry prisms with and without grout and reinforcement. The compressive strength and elastic properties are included.

Effect of strength and workability of grout, percentage of longitudinal steel reinforcement and the presence of lateral tie stirrups on the strength and stiffness of masonry is discussed.

The experimental results are compared with the predictions of the Australian Masonry Standard and some general and specific conclusions derived. - Doğangün, A., A. Ural, and R. Livaoğlu. SEISMIC PERFORMANCE of MASONRY BUILDINGS during recent EARTHQUAKES in Turkey [PDF] In The 14thWorld Conference on Earthquake Engineering October, pp. 12-17. 2008.

- Ezzatfar, Pourang, Barış Binici, Özgür Kurç, Erdem Canbay, Haluk Sucuoğlu, and Güney Özcebe. "Application of mesh reinforced mortar for performance enhancement of hollow clay tile infill walls." In Seismic evaluation and rehabilitation of structures, pp. 171-186. Springer, Cham, 2014.

- HAND BOOK of HOLLOW TILE CONSTRUCTION [PDF] Hollow Building Tile Association (Chicago 1922)

Excerpts:

Hollow building tile is an incombustible product of burned clay or shale of high structural value, which may be divided into five grades of ware, each of which is more or less particularly adapted to certain requirements, and all of whih may be sued for certain other purposes.

1. Very hard burned or vitreous

[especially suitd for foundations or other work in contact with the earth or for exterior walls without stucco or other covering]

2. Standard Hard Burned

[ standard for loadbearing tile for exterior walls and other similar work where walls are to be stuccoed or veneered with brick, stone or other covering]

3. Ordinary Medium Burned

[major portion of hollow tile manufactured for fireproofing and interior construction]

4. Soft Tile

[underburned dense tile first cousin to salmon brick and about which no more need be said (for interior work in some locales), and a full porous tile made with the addition of sawdust to produce a tile that can be nailed into]

5. Salt-Glazed Tile

[a dense tile of fire clay or shale that is glazed in burning ... suitable to resist moisture and frost, for foundations] - Levine, Jeffrey S. & Donna Ann Harris, STABILIZATION & REPAIR of a HISTORIC TERRA COTTA CORNICE [PDF] Preservation Tech Notes, Masonry No. 2, U.S. Department of Interior, National Park Service, preservation assistance division - retrieved 2022/10/07, original source: https://www.nps.gov/tps/how-to-preserve/tech-notes/Tech-Notes-Masonry02.pdf

Excerpt:

Visual inspection of the terra cotta revealed four common types of deterioration: spalls, glaze crazing, cracking, and open mortar joints. In addition , sounding the terra cotta 'units with a wooden mallet indicated that roughly 10% of the terra cotta units had cracked internal webs.

Deterioration resulting in loss of material appeared with less frequency and was found principally at the outer scroll of the brackets ... and at the scalloped fascia .....

Water infiltration through holes in the cornice's roof membrane was determined to be the primary reason for much of the terra cotta deterioration. - Mack, Robert C., FAIA & Anne E. Grimmer, ASSESSING CLEANING AND WATER-REPELLENT TREATMENTS FOR HISTORIC MASONRY BUILDINGS [PDF] (2000) U.S. National Park Service, Technical Preservation Services, retrieved 2022/10/02 original source: https://www.nps.gov/tps/how-to-preserve/briefs/1-cleaning-water-repellent.htm

Excerpt: Inappropriate cleaning and coating treatments are a major cause of damage to historic masonry buildings. While either or both treatments may be appropriate in some cases, they can be very destructive to historic masonry if they are not selected carefully.

Historic masonry, as considered here, includes stone, brick, architectural terra cotta, cast stone, concrete and concrete block. It is frequently cleaned because cleaning is equated with improvement. Cleaning may sometimes be followed by the application of a water-repellent coating.

However, unless these procedures are carried out under the guidance and supervision of an architectural conservator, they may result in irrevocable damage to the historic resource. - Naumann, K. "Building acoustics–calculation of sound insulation in buildings with single leaf clay unit masonry." In Brick and Block Masonry-From Historical to Sustainable Masonry: Proceedings of the 17th International Brick/Block Masonry Conference (17thIB2MaC 2020), July 5-8, 2020, Kraków, Poland, p. 238. CRC Press, 2020.

- Plummer, Harry Custer, and Edwin F. Wanner. Principles of tile engineering: handbook of design. Structural Clay Products Institute, 1947.

- Flanagan, Roger D. Behavior of structural clay tile infilled frames. No. Y/EN-5110. Oak Ridge National Lab., TN (United States), 1994.

- Strozs, Maris, and G. Sahmenko. USE OF STRAW-CLAY MATERIAL IN WALLS [PDF] In 3rd international Civil Engineering conference, building materials, vol. 1, pp. 84-90. 2011.

Abstract:

The research aims to investigate the use of straw–clay material in wall construction, its load bearing and heat insulation properties. The main objective of this study is to get optimal straw–clay construction material, which could be used in load bearing external wall constructions of one–storey houses.

The effectiveness of different kinds of straw and clay proportions in construction materials is determined by compression and thermal conductivity tests.

To show the effectiveness of straw–clay material in load bearing external walls, a specific model of a one–storey house in the finite element analysis program Ansys is created.

As a result of this study it is determined that straw–clay block construction material in right proportions can be used in one–storey house load bearing external walls with sufficient compressive strength and thermal resistance. - Tiller, Teel Patterson, THE PRESERVATION OF HISTORIC

GLAZED ARCHITECTURAL TERRA-COTTA [PDF] (1979) Preservation Brief No. 7, U.S. National Park Service, Technical Preservation Services, retrieved 2022/10/02 original source: https://www.nps.gov/tps/how-to-preserve/briefs/7-terra-cotta.htm

Excerpt:

Glazed architectural terra-cotta was significant in the development of important architectural idioms in this country—specifically, the "Chicago School," the High Rise and the Historic or Beaux Arts styles.

In fact, glazed architectural terra-cotta is one of the most prevalent masonry building materials found in the urban environment today.

Popular between the late 19th century and the 1930s, glazed architectural terra-cotta offered a modular, varied and relatively inexpensive approach to wall and floor construction. It was particularly adaptable to vigorous and rich ornamental detailing.

However, with changing vogues in materials and architectural styles and rising production costs, glazed architectural terra-cotta fell into disfavor and disuse by the mid 20th century. - Tumialan, J. Gustavo, Nestore Galati, and Antonio Nanni. "Field assessment of unreinforced masonry walls strengthened with fiber reinforced polymer laminates." Journal of Structural engineering 129, no. 8 (2003): 1047-1056.

- Woolson Ira H. et als, RECOMMENDED MINIMUM REQUIREMENTS for MASONRY WALL CONSTRUCTION [PDF] (1924), U.S. Bureau of Standards, US Department of Commerce, Report of Building Code Committee, June 26, 1924, Ira H. Woolson, Dir., Edwin H. Brown, William K. Hatt, Albert Kahn, Rudolph P. Miller, John A Newlin, Joseph R. Worcester, Frank P. Cartwright, Bureau of Standards, Washington D.C. (price 15 cents).

- U.S. GSA, STABILIZING 2-WYTHE TILE WALLS USING ADHESIVE FOAM FILLER [PDF] U.S. General Services Administration, retrieved 2020/12/15

Excerpt:

This procedure includes guidance on stabilizing two-wythe clay tile walls with a light weight rigid adhesive filler in the cavity between the wythes for seismic retrofit.

Note: this procedure should be executed by a specialist trained in masonry stabilization and is recommended for use in very limited applications.

The filler material shall adhere to clay tile and have strength and rigidity properties so that the tile-foam composite will respond to earthquake shaking as a wall of thickness equal to the existing out-to-out dimensions of the two-wythe wall. - Wells, Jeremy C. "History of Structural Hollow Clay Tile in the United States." Construction History 22 (2007): 27-46.

...

Continue reading at CONCRETE, MASONRY BLOCKS, & BRICKS, WORKING WITH, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BLOCK FOUNDATION & WALL DEFECTS - home

- BLOCK FOUNDATION BACKFILL DAMAGE

- BRICK FOUNDATIONS & WALLS

- BULGE or LEAN MEASUREMENTS

- BULGED vs. LEANING FOUNDATIONS

- DIAGONAL CRACKS in BLOCK FOUNDATIONS, WALLS

- CHIMNEY REPAIRS, TOP & CLAY FLUE TILE

- CLAY HOLLOW TILE CONSTRUCTION - Structural clay tile, terra cotta, building tiles

- CLAY TILE / PAVER TILE FLOORING

- CLAY TILE ROOFING - home

- CONCRETE or MASONRY DAMAGE TESTS

- CONCRETE, MASONRY BLOCKS, & BRICKS, WORKING WITH

- FOUNDATION FAILURES in CLAY SOIL

- HORIZONTAL FOUNDATION CRACKS

- VERTICAL CRACKS in BLOCK WALLS

Suggested citation for this web page

CLAY HOLLOW TILE CONSTRUCTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.