Furnace Blower Fan Or Burner Cycles On/Off During the Heating Cycle

Furnace Blower Fan Or Burner Cycles On/Off During the Heating Cycle

Forced air heating furnace control diagnosis & repair for furnace short cycling

- POST a QUESTION or COMMENT about diagnosing furnace fan operating problems

Furnace diagnostic guide for heater cycling on/off:

This article describes what to check if the warm air heating blower fan cycles on and off after the call for heat has stopped, that is after the room thermostat has been satisfied.

Some conditions that cause unexpected furnace fan cycling on and off may be dangerous, risking overheating of the furnace heat exchanger which in turn risks cracks and even carbon monoxide leaks. So it is worth checking out this problem promptly.

This article series describes how to diagnose & fix just about any problem with forced air heating & cooling systems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Diagnose & Fix a Furnace Blower FAN that Cycles On/Off During the Heating Cycle

Discussed here: what to check if the forced warm air furnace blower keeps cycling on and off during the heating cycle - while the thermostat is continuously calling for heat.

Discussed here: what to check if the forced warm air furnace blower keeps cycling on and off during the heating cycle - while the thermostat is continuously calling for heat.

Synonyms: Forced warm air heat short cycling - furnace short cycling or rocking, or shutting off.

Where to buy replacement furnace limit switches, parts or repair parts.

Watch out: a return air inlet close to a gas heating furnace like the one shown in our photo may be unsafe, drawing combustion products or fatal carbon monoxide into the building air supply, shown in our photo at the start of this article.

See UNSAFE DUCT OPENINGS.

[Click to enlarge any image]

Why does the furnace keep turning on and off repeatedly during the heating cycle (the thermostat is calling for heat)?

Our furnace seems to turn off and then back on repeatedly during the heating cycle.

I've read that normally on a call for heat the burner should come on, then the blower, and both should keep running until the call for heat is satisfied.

What's going on? - Anonymous

Reply: Clarify: Three Different Furnace Short Cycling Problems

Thanks to reader Tim (2019/04/12) we have first to distinguish three different furnace burner or blower-fan on-off cycling problems:

CASE 1: furnace BURNER cycles ON-OFF during a call for heat, BLOWER remains ON - high limit rocking

CASE 2: furnace BLOWER FAN cycles ON-OFF while BURNER remains ON - blower short-cycling

CASE 3: furnace BLOWER FAN cycles ON-OFF AFTER a call for heat, BURNER remains OFF - residual heat purge problem

CASE 4: furnace BURNER and also BLOWER FAN both cycle ON-OFF DURING a CALL FOR HEAT - burner or fuel problem

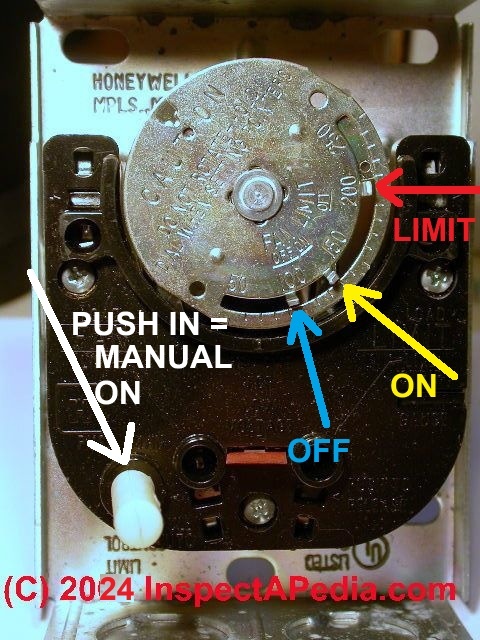

But first let's check the fan limit switch settings: normally we see

- FAN OFF at 90 °F - 110 °F - controls the cool-down or residual heat removal time at the end of a heat-on cycle

- FAN ON at 130 °F - turns the blower on to deliver heat once temperatures are high enough to avoid blowing cool air on occupants

- HI LIMIT at 200 °F - safety upper limit prevents overheat damage to the heat exchanger by turning off burner

Watch out: never set the high limit above its factory-setting higher unless the manufacturer so instructs

Details about these three settings are at FAN LIMIT CONTROL SETTINGS.

CASE #1 (Common) Furnace BURNER Short-Cycling On and Off During a Call for Heat - High Limit Rocking

In this common situation the furnace heat source or BURNER goes OFF then back ON DURING the HEAT CYCLE while the blower FAN KEEPS RUNNING - that is while the thermostat is continuing to call for heat.

In this situation the temperature inside the supply plenum is becoming TOO HOT - that means that the plenum is at risk overheating - that can cause cracks or damage.

For safety the burner is turned off by the fan limit switch when the plenum temperature reaches or the HI LIMIT set on the limit control switch. The burner will stay off until things cool down.

In general when this problem occurs you should look for an air flow blockage, dirty air filter, dirty squirrel cage blower fan, loose fan belt, etc.

Formal Definition of Furnace Short Cycling (also called Shutting Off or Rocking on the High Limit)

Short Cycling is when the burner shuts off before a call for heat is met (thermostat setting is not reached).

The burner is shut off by the fan limit switch as a safety measure. The air handler will keep running.

The temperature in the plenum will go down and the burner will come on again, only to shut off again quickly.

This rocking back and forth on the HI LIMIT setting is bad for the furnace.

The heat exchanger is seeing temperatures it was not designed for, and may crack. It is also very inefficient and does not allow proper heat to be distributed to the living space. [1]

Watch out: a cracked leaky heating furnace plenum risks leaking fatal carbon monoxide into the building's occupied space. Someone could die.

Causes of Furnace BURNER Short Cycling or High Limit Rocking

For a furnace with adequate duct work this heat rise should fall in the range of 45 degrees to 70 degrees. Anything that causes overheating in the warm air supply plenum will cause furnace short cycling.

Common causes of heating furnace short cycling or rocking are listed here alphabetically. The most-common defects include a dirty air filter, damaged ductwork, and inadequate return air.

- Air filter defects: filter dirty, clogged, wrong type, too many layers of filtration, or even a filter that has collapsed and been sucked into the air handler or dworkwork can cause dangerous furnace overheating.

See details at DIRTY AIR FILTER PROBLEMS - Air handler defects ranging from a dirty air filter to dirty blower or wrong blower speed can prevent the furnace from producing enough heat rise across the heat exchanger, causing overheating and short cycling at the heating furnace. We'll give more specific examples below where we include links to specific diagnosis and repair articles for each of these problems.

Any defect that restricts air flow through the heating system supply or return ductwork can also cause unexpected furnace burner on and off cycling.

For example, belt-driven air handler fans, a too-loose or slipping or damaged drive belt can slow the blower and thus reduce air flow through the system.

And for direct-drive air handler blower fans, an incorrect jumper or dip switch setting on a control board may mean that the fan runs too slowly and air flow is inadequate.

Air leaks at the air handler (blower unit) may contribute to weak air flow.

Those details are

at BLOWER LEAKS, RUST & MOLD

- Dirty air handler blower fan: dirt accumulated on the blades of a typical air handler squirrel cage blower fan assembly can reduce air flow through the system by 30-40% or even more in some cases.

See details at BLOWER FAN ASSEMBLY CLEANING - Dirty air handler evaporator or cooling coil (or hydronic water to air heating coil) fins, clogged by dust, debris, mold will reduce air flow and can cause short cycling at the burner as it overheats the plenum.

See DIRTY COOLING COIL / EVAPORATOR COIL - Ductwork defects: if the heating air ducts are under-sized or are restricted by crimping or damage then the rate of air flow through the heating system is too low. Weak air flow leads to plenum overheating.

Diagnosis is at AIR FLOW TOO WEAK and

Measurement of air flow is

at AIR FLOW MEASUREMENT CFM

Here are pointers to diagnosis and repair of air flow problems traced to either supply ducts or return air ducts:

Inadequate return air / ducts: omission of proper return air ducts to deliver building air to the furnace return plenum; some systems take some or all return air from a cold basement or crawl space - expensive and potentially very dangerous if the return air can draw flue gases into building air.

See UNSAFE DUCT OPENINGS

A seat-of-the-pants test we perform while the air handler is running is to open the air handler door or cover to expose the blower fan and then release it.

If the door SLAMS shut the system was running at a vacuum and return air is inadequate; or if opening the door causes the furnace to stop short cycling or shutting off that may be the same diagnosis.

See UNDERSIZED RETURN DUCTS

and

see RETURN AIR REGISTERS & DUCTS

Watch out: most modern air handlers include a safety interlock on the air handler door - the switch will turn off the furnace if you open the door with equipment running. This is because it's easy to lose a finger or be even more seriously injured by opening the air handler when equipment is running.

See RETURN AIR, INCREASE for details on other ways to fix this problem.

See RETURN AIR, HVAC for a list of ways you can improve return air flow rate and quantity or volume.

Inadequate supply air ducts: warm air supply ducts that are too small, bent, constricted, leaky or perhaps have become disconnected in a hidden space such as an attic or crawl area.

See SUPPLY DUCT AIR LEAKS and

Some rules of thumb on heating air duct requirements are given

at SUPPLY DUCTS & REGISTERS

Leaky duct work can also contribute to inadequate or weak air flow through the heat exchanger.

See AIR LEAKS in RETURN DUCTS

and AIR LEAKs in SUPPLY DUCTS

- Electrical connection defects: a loose or corroded electrical wire bringing power to the burner OR at the limit switch or fan control board can cause intermittent burner operation

- Fan limit switch defective: a defective or consumer-damaged fan limit switch may fail to operate normally and in fact may be unsafe - a switch that permits the furnace to overheat can crack the heat exchanger, causing both costly damage and potentially fatal carbon monoxide leaks into building air.

FAN LIMIT SWITCH describes how this control is installed, tested, diagnosed & adjusted.

Warnings include avoiding bending or forcing the control which then pushes it out of calibration. - Furnace pressure switch tubing leak: a furnace that is cycling on-off can be caused by a leak in pressure switch tubing.

Thanks to reader Mark who commented (March 2015

at MOBILE HOME HEATING SYSTEMS

that a furnace that cycles on and off may be caused by pressure switch tubing that has a leak. - Gas burner problems: short cycling or high limit rocking in a gas fueled furnace may be due to excessive gas pressure, in turn caused by improper gas pressure regulation: if the gas regulator delivers gas at a pressure higher than antcipated by the furnace design engineers the burner puts out too much heat, the plenum overheats during the heating cycle because the blower fan and moving air cannot remove heat fast-enough.

The result is that the furnace overheats and shuts off on high limit until the moving air cools the plenum back down. - Improper fan limit switch settings or a damaged or defective control.

If the Fan-Limit switch FAN-ON setting is too high then the heat exchanger may be too hot by the time the blower fan turns on.

With the high FAN-ON setting combined with added heat from continued burner operation, on some furnaces the fan cannot cool down the heat exchanger sufficiently to avoid reaching the FAN-OFF limit so the limit reaches FAN-OFF and the burner turns OFF. Try dropping the FAN-ON setting. - Thanks to reader Tim for this observation 2019-04-29

- Oil burner nozzle over-sized: a too-large nozzle (or a change that upped the oil burner fuel unit output pressure) may have increased the oil burner firing rate over that the furnace is designed-for.

Check the nozzle size and fuel unit pressure against the furnace manufacturer's recommendations and allowable firing range on the furnace data tag.

See OIL BURNER ELECTRODES

Oil fired heater BTU output estimating tip: If there is no data tag on the furnace or you can't find the oil burner output BTUH you can guess it as follows:

Multiply the oil burner nozzle size (firing rate in gallons per hour) x 138,200 (BTUs per gallon of No. 2 heating oil) x an efficiency estimate (use .75 for older furnaces and .80 for newer furnaces if you don't have a recent efficiency measurement). - Over-sized furnace for the heating load? - usually this just gives too-short on-cycles, an inefficient way to heat the home; in a cooling system an over-sized A/C unit will have short on cycles that lead to failure to adequately dehumidify the building.

See details at FURNACE OVERSIZE PROBLEMS - Thermostat wiring or device defects: check for loose thermostat wires, debris-clogging of a thermostat's bimetallic spring or thermocouple (and clean them)

See THERMOSTATS, HEATING / COOLING - Thermocouple defective, or dirty thermistor on gas fired equipment: Short cycling or unexplained on-off cycling of heating equipment has also been traced (by one reader) to a dirty or failing thermocouple (possibly the reader meant a dirty thermistor).

See THERMISTORS

Or see THERMOCOUPLE REPAIR / REPLACEMENT

This condition was reported in the FAQs by a reader commenting

at HEAT ANTICIPATOR Adjustment

The amount of supply and return ductwork a hot air heating system has can affects the actual efficiency of the heating system, as well as the life expectancy of the furnace itself.

If there isn’t enough duct work to deliver the heat the furnace produces, obviously clients are cold, operating costs go up, efficiency goes down, and eventually a premature crack in the heat exchanger will result (the furnace can’t get rid of the heat and it stresses out the metal in the heat exchanger). [1]

Watch out: while the Vermont government publication that we quote above explains that short cycling can crack the furnace heat exchanger, we need to understand that that means: a cracked heat exchanger is unsafe because it may leak combustion gases or fatal carbon monoxide into a building. Besides leading to an expensive furnace repair or replacement, a cracked-heat exchanger is dangerous.

Watch out: This return air opening boosts the total air output of the system but it is an improper and unsafe design.

In addition to this return air problem given above check this short list, then take a look at the furnace short cycling diagnostic discussion and examples that follow.

CASE #2: Furnace BLOWER FAN Short-Cycling On and Off DURING a Call for Heat - BLOWER Short Cycling

The furnace air handler blower FAN goes OFF and then back ON during the heating cycle while the thermostat continues all the time to call for heat, and the BURNER KEEPS RUNNING.

In this uncommon furnace cycling case, most likely the blower fan is moving so much air or at such a high velocity or is seeing return air that is so cold that the temperature in the supply plenum falls BELOW the FAN -ON temperature.

In that case the FAN LIMIT SWITCH TURNS OFF the FAN to avoid blowing cold air onto the building occupants. This is the same feature that keeps the fan from turning on before the plenum temperature is sufficiently high: a situation that occurs at the start of a call for heat.

Causes of Furnace BLOWER FAN Short-Cycling During a Call for Heat

That happens most-often when

- The fan speed is too high, perhaps on a control board the speed is set too high for the system design or the wrong pulley size has been installed on a belt-driven blower fan

- The furnace burner is not adjusted properly - weak flame, inadequate combustion air (dangerous), dirty gas orifices, oil burner in need of service, burnt-out electrical heating elements - depending on furnace type

- The heat exchanger is dirty or blocked - not enough heat transfer out into building air

- Very cold air entering the system - blower on: poor return air design picking up more fresh cold air and not enough return air from the building can cool down the plenum below the FAN ON temperature.

This may be due to improper location (even an unsafe one) of a main or additional cold-air return.

I've seen systems that were picking up 100% new cold air in a crawl space - no conditioned building air was returning to the furnace - that 's the most-expensive heating design possible and could be unsafe. - Poor electrical connections: a loose or corroded electrical wire bringing power to the blower fan motor OR at the limit switch or fan control board can cause intermittent fan operation

- A defective fan limit control switch

Watch out: a number of writers (previously including this page) confuse BLOWER cycling on and off during a call for heat - being discussed as CASE #2 here, and BURNER cycling on and off during heat - discussed at CASE 1

Read people's explanations with care: the overheating in the plenum that causes CASE 1 will shut off the burner, not the fan.

Diagnose Case 2: Blower Short Cycling

Watch the dial on the furnace FAN LIMIT CONTROL switch during a heating cycle. If you see the dial rotate to the FAN ON point you should then hear the blower fan start up.

Keep watching. If the dial rotates back towards cooler temperatures a bit that's normal, but the blower should keep running until the thermostat says it has been satisfied.

IF instead the dial continues to rotate towards lower temperatures until it drops below the FAN ON setting,

THEN something is causing the plenum temperature to get so low that the limit switch should TURN THE FAN OFF - that's to avoid blowing cold air on occupants.

An example of burner-on short cycling or high limit rocking is discussed in the reader Q&A given later on this page at

EXAMPLE of CASE-1 LIMIT ROCKING with the burner staying on and the fan going on and off

CASE 3: Furnace BLOWER Fan Short Cycles On and Off at the END of a CALL FOR HEAT - BURNER REMAINS OFF - Residual Heat Purge problem

The furnace blower fan cycles on and off AFTER the call for heat has been satisfied and AFTER the BURNER has TURNED OFF.

Usually this is a problem of residual heat in the furnace heat exchanger rising into and re-heating the plenum air, causing the fan limit switch to turn the fan back on to try to cool down the system by extending the heat exchanger temperature purge cycle time.

Some causes of this trouble include:

- Fan speed too high: at the end of heat cycle during purge cycle so much air moves through the heat exchanger and supply plenum that the air therein is cooled enough to turn off the blower; but residual heat in the heat exchanger re-heats the plenum air and turns the fan back on

- Very cold air entering the system - blower off: a similar but less common cold air problem can occur just after the furnace burner has shut down, during the heat purge interval.

Abnormally cold incoming air temperature enters the heat exchanger while the blower is still running but the burner has shut down - this is the heat purge cycle that occurs after the thermostat has stopped calling for heat.

The incoming cold air (with burner off) may cool down the supply plenum so rapidly that the fan limit switch, working properly, turns the blower OFF before enough heat has been extracted from the steel or cast iron of the heat exchanger itself.

If this is happening, rising heat and air (by convection) from the still-hot heat exchanger into the supply plenum may warm the plenum again and turn the blower fan back ON in an effort to cool down the system to a safe "turn off" temperature.

In this case the blower will remain off but the fan turns on and off one or more times after the thermostat has stopped calling for heat.

Blower fan short cycling on and off too frequently during the heating cycle is often traced to this problem.

Why would we have "abnormally low incoming air temperature" at a furnace?

We've seen this problem at buildings with improper HVAC duct design, in particular where some or all of the return air to the furnace is being taken from an opening right at the furnace such as a unit located in a cold basement or crawl space(see our photo, above left).

Sometimes in an effort to improve the total airflow delivered by a furnace a technician will cut an opening in the return ducts in an unheated basement or crawl area. - Improper fan limit switch settings or a damaged or defective control

Details about this problem are

at FURNACE FAN CYCLES AFTER HEAT

CASE 4: (uncommon) furnace BURNER and also BLOWER FAN both Cycling ON-OFF DURING a CALL FOR HEAT

Special thanks to reader Goeffrey for pointing out this problem: similar to Case #1, HI-Limit rocking, the burner turns off during a call for heat but the blower fan also turns off before the call for heat is satisfied, then both turn back on - cycling repeatedly.

Causes of both burner & blower fan cycling off & on during a call for heat.

- Burner or fuel or burner ignition defect: an ignition or combustion defect can cause the burner to turn off not under the control of the fan limit switch but because of another external defect such as a bad igniter (gas burners) or bad thermocouple (gas burners)

When the burner cuts off on its own before the call for heat is satisfied, the blower will continue to run until the plenum temperature drops below the FAN ON temperature.

As the call for heat continues, depending on the furnace burner type and its controls, the burner will attempt to re-ignite itself. On systems whose burner can re-ignite successfully, the burner will thenturn on and as plenum temperature increases the blower fan will turn on again as well.

Diagnostic example

(Jan 13, 2020) Geoffrey said:

I replaced my Fan Limit Control Switch to address the 3rd scenario of the blower cycling back on w/o the burner for just a minute or two after a heating cycle. This fixed that problem. I now have noticed another problem which does not meet the criteria of any of the 3 examples.

The issue is similar to the High Limit Rocking case #1, except when the burner shuts off prior to satisfying the thermostats set temperate ( call for heat), the blower shuts off as well. The burner then immediately relights, the blower comes back on, and the system runs until the call for heat is satisfied by the house reaching the temp called for on the thermostat.

This "shut down" which is the burner and the blower usually occurs about 10 minutes or so after the thermostat is turned on or up. Once the system turns back on after the burner immediately relights, it will run as long as needed depending on how high the thermostat is set.

It never shuts off either burner or blower again until the heating cycle is complete and it is supposed to shut them off.

Because this "second run" is often a lot longer than the initial 5-10 I don't think it is because of getting too hot, or else why would it be able to then immediately relight and run for twice as long or longer with no problem? Any ideas?? Thanks!

Moderator said: watch the fan limit control dial

Let's try this. Watch The Fan limit switch when the furnace is behaving in the way that you described and make a note of where the temperature dial is rotating and what points it reaches. That might help us figure out what's actually happening here.

- If the burner stops before the fan stops then

1.a. If the fan limit dial is reaching the upper limit of the control and then turning off the burner then the system is overheating

1.b. If the fan limit dial is not reaching the upper limit of the control but the burner stops, then there is a problem with the burner operation itself such as an ignition failure, a fuel supply failure, or possibly flue gas spillage at a draft hood. - If the fan stops before the burner stops

then see CASE 2:

Reader follow-up: problem traced to bad ignition controller

Turned out to be the Ignition control. It progressed to where it would have trouble lighting sometimes when the thermostat called for heat. I tried this route because I knew the part was old and it seemed to me that if the issue was with the ignition, or burner turning off then right back on, it might work.

So far so good. It seems to operate normally and burner lights right away when thermostat calls for heat, and stays lit until thermostat satisfied. Fan limit switch is working fine too now, and turns fan on/off when it is supposed to.

...

...

Continue reading at FAN LIMIT SWITCH or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see FURNACE FAN CYCLES DURING HEAT FAQs - questions and answers posted originally on this page.

Or see these

Recommended Articles

- AIR HANDLER / BLOWER UNITS - home

- BLOWER FAN ASSEMBLY CLEANING

- BLOWER FAN CONTINUOUS OPERATION

- BLOWER FAN CYCLES ON INTERMITTENTLY

- BLOWER FAN OPERATION & TESTING - home

- BLOWER FAN SPEED SETTINGS - how to set the air handler fan speed

- FAN, AIR HANDLER BLOWER UNIT

- FAN LIMIT SWITCH - home

- FAN ON AUTO MAN THERMOSTAT SWITCH

- FURNACE OVERSIZE PROBLEMS

- UNDERSIZED RETURN DUCTS - not enough return air

Suggested citation for this web page

FURNACE FAN CYCLES DURING HEAT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING FURNACES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Comments

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Jeff Wilcox, "Evaluating Duct Work, How to Evaluate Furnace Duct Work & Cure Short Cycling or Inadequate Ductwork Problems" Vermont Department for Children and Families, Office of Economic Opportunity, - dcf.vermont.gov/sites/dcf/files/pdf/oeo/WAPManual/AppendixI.pdf retrieved 12/5/2013. Geoff Wilcox Vermont Office of Economic Opportunity Weatherization Assistance Program Waterbury, VT (802) 769-8376 Geoff.wilcox@state.vt.us Reference Material for the original article came from: 1. Saturn Mechanical Systems Field Guide 2. Bacharach (Rudy Leatherman)

- [2] Emerson Climate Technologies, "White-Rodgers History", retrieved 12/7/2013, original source: http://www.emersonclimate.com/en-us/ Brands/White_Rodgers/Pages/White-Rodgers-History.aspx

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.