Factory-built fireplace inspection procedures

Factory-built fireplace inspection procedures

Checklist for building inspectors

- POST a QUESTION or COMMENT about the installation, code compliance, safety & inspection of factory-built fireplaces, fireplace inserts, & zero-clearance fireplaces.

How to inspect factory-built fireplaces & fireplace inserts. This article provides a checklist useful for building or home inspectors who need to examine a factory-built fireplace and chimney.

Zero-clearance fireplaces are typically steel constructed fireplaces to burn wood or perhaps other fuels such as LP or natural gas in modern homes, usually connected to a metal chimney.

Our photo (left) shows a zero-clearance gas fireplace. Other zero clearance fireplaces burn wood or perhaps other fuels.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Factory-built fireplace inspection checklist

Following this example of hard-to-spot but unsafe factory-built fireplace installation fire hazards we provide a checklist for the inspection of factory-built fireplaces.

Watch out: we have found a few zero-clearance fireplaces improperly installed too close to combustibles.

[Click to enlarge any image]

The clearance to combustibles is not "zero" but one or more inches, depending on the materials, construction, and manufacturers' instructions.

The installer did not understand the purpose of steel clearance-assuring projections welded to the zero-clearance fireplace, and s/he had hammered them flat to "shoe-horn" the zero clearance fireplace into a too-small wood-framed rough opening.

The result was a serious building fire hazard and a building code violation as well.

Our photo of a zero-clearance fireplace from inside the framed opening (left) shows the clearance guards intact next to our ruler. But inspection showed chimney leaks onto this unit - evidenced by the rust and white stains that can ultimately damage the flue (at upper right) and the fireplace unit, making it unsafe.

Factory-built fireplace inspection checklist warning: This factory-built fireplace inspection checklist given below is a companion to our FIREPLACE INSPECTIONS article and our FIREPLACE INSPECTION PRE-FAB article

It is essential to also review and be familiar with the fireplace manufacturer's installation instructions and the homeowner should be familiar with the manufacturer's fireplace operation and maintenance instructions and recommendations.

This inspection checklist is also not a substitute for checks for compliance with local building and fire codes.

No checklist is ever a complete guide to building inspection or diagnosis since no checklist can contain every possible hazard or every clue that suggests a problem.

Therefore do not rely on this or any checklist to assure that your inspection of a chimney is complete. Instead, use this list to suggest additional topics that you otherwise may have omitted from your inspection.

The more detailed chimney inspection and repair articles at the links at Related Links and the citations below below suggest further, more-detailed chimney inspection points and procedures.

| Factory-Built Fireplace, Fireplace-Insert & "Zero-Clearance Fireplace" Defects & , Unsafe Conditions | |||

|---|---|---|---|

| Item # | OK? |

Factory-built Fireplace Hazard or Concern | Comment / More Detail |

Building ID & Location: __________________________________________ Date & Time: _________________________________________________ Inspector: ____________________________________________________ |

|||

|

|||

| 1 | Chimney cap and crown defects: Watch out: attaching anything other than the manufacturer's spark arrester to the chimney top cover and flashing violates the listing and the building code. |

CHIMNEY CAP & CROWN DEFINITIONS CHIMNEY SHROUD, Decorative CHIMNEY CHASE CONSTRUCTION |

|

| 2 | Chimney Chase: Chase termination adapters and sections may be described in separate instructions from those provided with the chimney & firebox. Inspect the chimney chase interior (it may be necessary to make or provide visual access, often feasible from inside the building attic). Check the chimney chase interior surfaces for signs of flue or metal chimney leaks, soot, smoke, or darkening of surfaces that may indicate overheating or an usafe chimney. if there has been a prior chimney fire in a metal flue the system should not be used again before it is replaced. Baird (1991) reported that "certain chase termination-adapter kits were improperly installed, ... leaving a gap in the metal chimney near the top of the chase". [4] |

||

Chimney Chase insulation Note: insulation may be required or prohibited as may fire-blocking within the chimney chase. See the separate chimney chase inspection article cited at right. |

|||

Chimney elbows, bends, angles where chimney elbows or angled runs are used, the weight of the chimney must be adequately supported above the elbows (by elbow support straps or by other means specified by the manufacturer). |

ANGLED CHIMNEYS | ||

| Chimney Installation air space / clearances: is the manufacturer-required air space or clearance provided between the chimney and any combustible materials at all locations? | |||

Chimney passage through building interior living space: is the chimney enclosed where it passes through occupied space in the building? Are any required fire-stopping materials (fire-sealant, fire stops) installed where the chimney passes through floors or ceilings in the building? |

|||

Chimney section connections, Baird (1991) reported that "... chimney sections are sometimes terminated at an elevation that does not allow for sufficient overlap of the various adapters and telescoping sections. This lap distance is specified by the manufacturer. If chimney offsets are used and not properly supported, the chimney is more likely to settle and open a gap in the flue.". [4] |

|||

| Chimney top clearances: is the top termination of the chimney at least 3-ft. above the roof surface & 2-ft above any component of any structure that is within 10-ft. horizontal distance? |

CHIMNEY HEIGHT & CLEARANCE CODE | ||

Chimney top housing, covering, shroud: have the chimney top housing or termination assembly been installed and secured following the manufacturer's instructions? Also see Decorative Shrouds in the checklist below. |

|||

Code compliance: Watch out: only the local building official has authority to declare an installation "legal" or "code-compliant". The local code official should not approve an installation or component if the manufacturer has not provided a listing (such as UL listing) for the the component as installed and used at a particular building or site. |

|||

Component Labels: Watch out: Baird (1991) points out that some component labels will not be visible after fireplace or chimney construction & installation are completed and must have been inspected at rough-in or other appropriate times. [4] |

|||

| Creosote or heavy soot in chimneys: a possible chimney fire hazard, especially at wood-burning fireplaces or woodstove flues |

|||

| Decorative shroud not listed: installation of a non-listed decorative chimney top shroud [4] | |||

Decorative shroud connected to wood: Watch out: If the decorative cap on your chimney is not listed and approved and correctly installed, have it removed, leaving the chimney flue top cap and spark arrestor installed. |

CHIMNEY SHROUD, Decorative | ||

Doors to the fireplace insert Add-on doors can make some fireplaces operate at a higher temperature than that for which the unit was designed. Baird (1991) reported that "... glass doors had been installed on a fireplace that had never been tested for use with glass doors". [4] |

|||

| Fireplace air circulating louvers & openings: are the air openings or louvers intended for circulating air around the fire-box clear of obstructions? | |||

| Fire clearances unsafe between metal flues or other types of chimneys and nearby combustibles. |

|||

Fireplace insert clearance to combustible materials Note: Baird (1991) reported that numerous fires occurred as a result of long-term effects of placing wood-framing too close to the opening of the fireplace. "A number of fires have occurred in a single development several years after prefabricated concrete tilt-up fireplaces were installed in violation of Section 3703 (h) of the Uniform Building Code™.".. [4] |

PYROLYSIS EXPLAINED | ||

| Fireplace inserts for wood or coal installed into an existing masonry flue without chimney inspection and if needed, re-lining. |

FIREPLACE INSERTS INSTALL, INSPECT, REPAIR | ||

Fireplace hearth extension: Are the thickness, depth, width of the hearth extension in compliance with both the manufacturer's installation requirements & building codes? Is the hearth extension also pre-fabricated and is it a listed accessory approved by the fireplace manufacturer? [Watch for wood trim that returns around a hearth extension and terminates in contact with the fire box.] |

|||

Fireplace insert add-ons: |

|||

| Fireplace instructions: the manufacturer's instructions for maintenance & use of the fireplace should be left where it will be available to building occupants. |

|||

Fireplace parts: Are all parts of the fireplace un-damaged & un-modified? Have fire clearance spacers been bent, cut, modified? Are there material intrusions into the fireplace space that violate the clearance distances intended by the spacers? Note: Baird (1991) reported that all of the fires associated with factory-built fireplaces that he studied (n=4) were related to installation errors.. [4] And in the article introductory text above we describe finding a fireplace insert whose welded-on extensions intended to assure adequate clearance from wood combustibles had been hammered-flat by the installer so that he could force the fireplace into a too-small wood-framed enclosure - DF. |

|||

Fireplace support: |

|||

Fireplace mantel & trim: Are there gaps or cracks between the trim and the fireplace? Are these gaps due to error or movement? Are the fireplace mantel and trim around the fireplace hearth front at the required distance from the fireplace hearth front opening as required by the manufacturer's instructions & local building code? |

|||

Fuel used in fireplace: Fuel quantity used in fireplace: Watch out: the author's NY home [DF] caught fire in 1969 as a result of the combination of an improperly-constructed masonry fireplace (wood damper support left in place, in contact with wood wall framing, burned through) and the use of a wax log. After the wax log had been ignited, visitors enjoyed poking at the log with a fireplace poker. The log fell apart, suddenly and greatly increasing the level of combustion and heat in the fireplace, setting the wall above the hearth on fire. |

|||

| 10 | Maintenance history: Note: The fireplace and chimney manufacturers recommend cleaning procedures and minimum inspection and cleaning interval. The actual required chimney cleaning interval will vary depending on the types fo fuel used, how the fireplace is used (combustion heat for example), and the amount of fireplace usage. |

||

Rusted or damaged chimney or fireplace components: Examples include a damper that has rusted through, a metal damper enclosure in the chimney throat rusted through, a metal fireplace insert rusted out at the chimney base. Watch out: damaged, leaky gas fireplace vents or flues or other fireplace components risk more than a building fire, also risking fatal carbon monoxide poisoning |

FIREPLACE INSERTS INSTALL, INSPECT, REPAIR FIREPLACE INSPECTIONS FLUE TILE DAMAGE in CHIMNEY |

||

Notes to the table above

Adapted from fireplace and chimney inspection safety sources including these documents

- MANUALS, GAS FIREPLACE LOG list of free downloads of manuals in PDF format

- [3] Wood Heating Alliance, "BUILDING INSPECTOR'S CHECKLIST FOR FACTORY BUILT FIREPLACES [PDF] " [PDF]

- [4] Baird, David J., C.B.O., "Factory-built Chimney Chase Fires: A case for More Detailed Inspection", Building Standards, March-April 1991, pp. 14-17.

- [5] Purdie, Roger K., "CHIMNEY FIRE SAFETY BULLETIN", Vista Fire Protection District, 2001, report of house fire related to the home's metal chimney. Contains advice for chimney * fire safety & sketches of approved and not-code-approved metal chimney tops, caps & crowns. [PDF]

- [12] Fire Inspector Guidebook, [BOOK] A Correlation of Fire Safety Requirements Contained in the 1987 BOCA National Codes, (newer edition available), Building Officials and Code Administrators International, Inc. (BOCA), Country Club HIlls, IL 60478 312-799-2300 4th ed. Note: this document is reissued every four years. Be sure to obtain the latest edition.

- [15] "Top Ten Chimney (and related) Problems Encountered by One Chimney Sweep," Hudson Valley ASHI education seminar, 3 January 2000, contributed by Bob Hansen, ASHI

Model Building Code, IRC 2009 on Factory-Built Fireplaces & Woodstoves

63. FACTORY-BUILT FIREPLACES AND WOOD STOVES. R1004, R1005 IRC 2009, 903.1 IMC 2009

R1004.1 General.

Factory-built fireplaces shall be listed and labeled and shall be installed in accordance with the

conditions of the listing. Factory-built fireplaces shall be tested in accordance with UL 127.

R1005.1 Listing.

Factory-built chimneys shall be listed and labeled and shall be installed and terminated in accordance with the manufacturer’s installation instructions.

Other relevant sections of this code are given at CHIMNEY HEIGHT & CLEARANCE CODE

Original source:

- Stevens WA, COMMONLY USED RESIDENTIAL BUILDING CODES, IRC 2009, [PDF] retrieved 2019/05/08 original source: http://www.co.stevens.wa.us/landservices/documents/MECHANICALSECTION.pdf

- Other sections of this mechnaical code are given at CHIMNEY HEIGHT & CLEARANCE CODE

Continue reading at FIREPLACE INSPECTION PRE-FAB or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FIREPLACES & HEARTHS - home

- BRACKET CHIMNEYS & GALLOWS BRACKETS

- CHIMNEY CLEANOUT DOORS

- CHIMNEY FIRE ACTION / PREVENTION

- CHIMNEY FLUE INSPECTION CAMERA

- CHIMNEY DRAFT & PERFORMANCE

- COMBUSTION AIR DEFECTS

- CREOSOTE DEPOSITS, FIRE HAZARD

- FIREPLACE CHIMNEY ROOF CLEARANCE

- FIREPLACE & WOODSTOVE CONTAMINANTS

- FIREPLACE DAMPER DEFECTS, REPAIRS

- FIREPLACE FLUE SIZE SPECIFICATIONS

- FIREPLACE HEARTH DIMENSIONS & SUPPORT

- FIREPLACE INSERTS INSTALL, INSPECT, REPAIR

- FIREPLACE INSPECTIONS

- FIREPLACE INSPECTION PRE-FAB

- FIREPLACE DAMAGE & UNSAFE HEARTHS

- GAS FIREPLACES & GAS LOGS - home

- GAS FIREPLACE VENT CLEARANCE REQUIREMENTS

- GAS FIREPLACE CERAMIC STAINS

- INACCESSIBLE CONNECTIONS FIREPLACE, WOODSTOVE

- RUMFORD FIREPLACE DESIGN RULES

- PYROLYSIS EXPLAINED

- WOOD BURNING FIREPLACE ROOF CLEARANCE

- GAS FIREPLACES & GAS LOGS

- ASBESTOS in UNUSUAL PLACES (gas fireplace logs)

- COMBUSTION AIR REQUIREMENTS

- DEFECTS LIST - HEAT SPACE & FIREPLACE, GAS

- FIREPLACE INSPECTION PRE-FAB

- GAS FIREPLACE VENT CLEARANCE REQUIREMENTS

- GAS FIREPLACE / LOG MANUALS

- GAZCO STOVAX Gas Fires,

- THERMOCOUPLE REPAIR / REPLACEMENT

- WOOD STOVE OPERATION & SAFETY

Suggested citation for this web page

FIREPLACE INSPECTION PRE-FAB at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to CHIMNEYS & FLUES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [3] Wood Heating Alliance, "BUILDING INSPECTOR'S CHECKLIST FOR FACTORY BUILT FIREPLACES [PDF] ", appearing in Baird, David J., C.B.O., "Factory-built Chimney Chase Fires: A case for More Detailed Inspection", Building Standards, March-April 1991, pp. 14-17. Note: The Fireplace Institute (FI) and the Wood Energy Institute (WEI) united to form the Wood Heating Alliance in 1980. The name was then changed again in 1983 to the Hearth Products Association (HPA) a non-profit organization, in order to better reflect the diversity and range of products and services within the industry. The name was changed once more to, Hearth Patio and Barbecue Association (HPBA) in 2001. Pacific HPBA, 2304 Huntington Dr., Suite 218, San Marino, CA 91108

(626) 237-1200 or (888) 332-2472

Fax: (626) 237-0721- info@hpbapacific.org, Website: http://hpbapacific.org/

Fireplace Safety Tips - Barbecue Safety Tips from the HPBA - see http://hpbapacific.org/pdfs/safetytips.pdf - [4] Baird, David J., C.B.O., "Factory-built Chimney Chase Fires: A case for More Detailed Inspection", Building Standards, March-April 1991, pp. 14-17.

- [6] Residential Masonry Fireplace and Chimney Handbook, James E. Amrhein, S.E., MIA, Masonry Institute of America, 2d. Ed., 1995, ISBN 0-940116-29-4. The MIA is in Los Angeles, CA 213-388-0472. This manual reflects the 1994 Uniform Building Code, Energy Conservation Requirements of California, and the U.S. Department of Housing and Urban Development - HUD. The complete UBC is available from the International Conference of Building Officials (ICBO), Whittier CA 310-699-0541.

- [7] NFPA 211 - Standards for Chimneys & Fireplaces, NFPA 211: Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, 2006 Edition (older editions and standards are found at the same bookstore)

- [9] NFPA # 54-7.1 1992 - Specific to venting of equipment with fan-assisted combustion systems.

- [10] GAMA - Gas Appliance Manufacturers' Association has prepared venting tables for Category I draft hood equipped central furnaces as well as fan-assisted combustion system central furnaces.

- [11] National Fuel Gas Code, an American National Standard, 4th ed. 1988 (newer edition is available) Secretariats, American Gas Association (AGA), 1515 Wilson Blvd., Arlington VA22209, and National Fire Protection Association (NFPA), Batterymarch Park, Quincy MA 02269. ANSI Z223.1-1988 - NFPA 54-1988. WARNING: be sure to check clearances and other safety guidelines in the latest edition of these standards.

- [12] Fire Inspector Guidebook, A Correlation of Fire Safety Requirements Contained in the 1987 BOCA National Codes, (newer edition available), Building Officials and Code Administrators International, Inc. (BOCA), Country Club HIlls, IL 60478 312-799-2300 4th ed. Note: this document is reissued every four years. Be sure to obtain the latest edition.

- [13] Uniform Mechanical Code - UMC 1991, Sec 913 (a.) Masonry Chimneys, refers to Chapters 23, 29, and 37 of the Building Code.

- [14] New York 1984 Uniform Fire Prevention and Building Code, Article 10, Heating, Ventilating, and Air Conditioning Requirements

- New York 1979 Uniform Fire Prevention & Building Code, The "requirement" for 8" of solid masonry OR for use of a flue liner was listed in the One and Two Family Dwelling Code for New York, in 1979, in Chapter 9, Chimneys and Fireplaces, New York 1979 Building and Fire Prevention Code:

- [15] "Top Ten Chimney (and related) Problems Encountered by One Chimney Sweep," Hudson Valley ASHI education seminar, 3 January 2000, contributed by Bob Hansen, ASHI

- [16] Chimney Inspection Checklist, Carson Dunlop, Associates, Toronto, Ontario

- [17] "Rooftop View Turns to Darkness," Martine Costello, Josh Kovner, New Haven Register, 12 May 1992 p. 11: Catherine Murphy was sunning on a building roof when a chimney collapsed; she fell into and was trapped inside the chimney until rescued by emergency workers.

- [18] "Chimneys and Vents," Mark J. Reinmiller, P.E., ASHI Technical Journal, Vol. 1 No. 2 July 1991 p. 34-38.

- [31] Brick Institute of America - Flashing Chimneys

Brick Institute of America - Proper Chimney Crowns

Brick Institute of America - Moisture Resistance of Brick - [32] American Gas Association - New Vent Sizing Tables

- [33] Chimney Safety Institute of America - Chimney Fires: Causes, Effects, Evaluation

- [34] National Chimney Sweep Guild - Yellow Pages of Suppliers

- [35] "Building Codes that Regulate Decorative Chimney Shrouds", provided by Stephen Werner [5], [copy on file as Chimney_Decorative_Shroud_Regs.pdf] cites:

- International Mechanical Code IMC (2000), M74-98 806.6, ratified 9.98, model building code for the United States,

806.6 Decorative Shrouds. Decorative shrouds shall not be installed at the termination of factory-built chimneys, except where such shrouds are listed and labeled for use with the specific factory-built chimney system and are installed in accordance with section 304.1. Reason: Decorative shrouds have been the cause of roof and chase fires - International Residential Code (IRC) (2000), R1002.2 ratified 9/99, 1000.2 Decorative Shrouds. Decorative shrouds shall not be installed at the termination of factory-built chimneys, except where such shrouds are listed and labeled for use with the specific factory-built chimney system and are installed in accordance with the manufacturers installation instructions. Reason: Decorative shrouds often allow for the creation of temperatures in excess of those permitted in UL 103 and UL 127. Decorative shrouds have been the cause of chase top fires ...

- International Fire Code (IFC) (2000), IFC 603.6.3, 603.6.3 Decorative Shrouds. Decorative shrouds installed at the termination of factory-built chimneys shall be removed, except where such shrouds are listed and labeled for use with the specific factory-built chimney system and are installed in accordance with the manufacturers installation instructions. Reason: Decorative shrouds have been the cause of dozens of chase fires. As a non-listed part to a listed assembly, their use should not have been allowed in the first place.

- International Mechanical Code IMC (2000), M74-98 806.6, ratified 9.98, model building code for the United States,

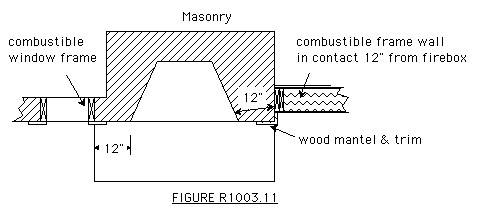

- [36] International Residential Code IRC R100.11 - Fireplace Clearance:

International Residential Code was recently amended:-

R1001.11 Fireplace clearance. Combustible material shall have a clearance of not less than 2 inches (51 mm) from the front faces and sides of masonry fireplaces and not less than 4 inches (102 mm) from the back faces of masonry fireplaces. The air space shall not be filled, except to provide fire blocking in accordance with Section R1003.12.

Exceptions:1. Masonry fireplaces listed and labeled for use in contact with combustibles in accordance with UL 127, and installed in accordance with the manufacturer's installation instructions, are permitted to have combustible material in contact with their exterior surfaces.

2. Combustible materials, including framing, wood siding, flooring and trim, shall be permitted to abut the sides and hearth extensions, but not the backs, of masonry fireplaces, in accordance with FIGURE R1003.12, provided such combustible materials are a minimum of 12 inches (306 mm) from the inside surface of the nearest firebox lining.

3. Exposed combustible mantels or trim may be placed directly on the masonry fireplace front surrounding the fireplace opening provided such combustible materials shall not be placed within 6 inches (153 mm) of a fireplace opening. Combustible material within 12 inches (305 mm) of the fireplace opening shall not project more than 1/8 inch (3.2 mm) for each 1-inch (25 mm) distance from such opening

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.