Condensate Drains, Piping, Pumps

Condensate Drains, Piping, Pumps

Inspect & Repair HVAC Condensate Piping & Drains

- POST a QUESTION or COMMENT about recognizing defects in air conditioner and heat pump condensate drain line piping, connections, traps, or disposal destination

Air conditioner, heat pump & condensing boiler or furnace condensate handling & drainage defects:

This air conditioning repair article discusses the inspection, diagnosis, and repair of air conditioning condensate drainage systems, including condensate leaks, condensate piping, traps, drains, condensate pumps, and the detection and hazards of air conditioning, heat pump, or condensing boiler or furnace condensate piping, drains, & condensate leaks in buildings.

Condensate leak water health and safety concerns are also reviewed.

This document describes the inspection and repair of condensate handling systems for residential air conditioning systems (A/C systems) to inform home buyers, owners, and home inspectors of common cooling system defects.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

HVAC Condensate Drain Piping Installation

Condensate Disposal Codes & Installation Details

Condensate Disposal Codes & Installation Details

The following, adopted by the U.S. state of Tennessee, is adapted from the International Plumbing Code IPC (2012) and cited in detail below.

Section 314 Condensate Disposal

314.1 Fuel-Burning Appliances

Liquid combustion by-products of condensing appliances shall be collected and discharged to an approved plumbing fixture or disposal area in accordance with the manufacturer’s instructions.

Condensate piping shall be of approved corrosion-resistant material and shall not be smaller than the drain connection on the appliance.

Such piping shall maintain a horizontal slope in the direction of discharge of not less than one-eighth unit vertical in 12 units horizontal (1-percent slope).

314.2 Evaporators and Cooling Coils

Condensate drain systems shall be provided for equipment and appliances containing evaporators or cooling coils.

Condensate drain systems shall be designed, constructed and installed in accordance with Sections 314.2.1 through 314.2.4.

314.2.1 Condensate Disposal

Condensate from all cooling coils and evaporators shall be conveyed from the drain pan outlet to an approved place of disposal.

Such piping shall maintain a horizontal slope in the direction of discharge of not less than one-eighth unit vertical in 12 units horizontal (1-percent slope).

Condensate shall not discharge into a street, alley or other areas so as to cause a nuisance.

Examples of approved places for condensate disposal

Subject to approval of the local plumbing inspector, include

- Drainage into the sanitary waste piping system (as per UMC and IPC)

- Disposal into a trapped drain

- Disposal into a grassy area that does not drain across a sidewalk or driveay

- Disposal into a drywell where those are permitted in the jurisdiction - drywells are not approved in some jurisdictions

- Into a building foundation drain system (or sump pump system)

- Into a local drainage ditch

- Into a storm drain system, permitted in some areas, - considered not best practice because condensate, though not sewage, is considered a pollutant or potential pollutant (possibly containing legionella for example)

- Into a graywater disposal system, drywell, or seepage pit

- On to a roof surface - permitted in some jurisditions where the condensate is either removed by evaporation from the roof surface or is disposed of into the roof drainage system

Watch out: local conditions such as site contours and surface drainage, restrictions on avoidable drainage into a public sewer whose treatment plant is of limited capacity, and other factors mean that final approval of the disposal area for HVAC condensate is left to the local building authority.

802.1.5 Nonpotable clear-water waste.

Where devices and equipment such as process tanks, filters, drips and boilers discharge nonpotable water to the building drainage system, the

discharge shall be through an indirect waste pipe by means of an air break or an air gap.

802.3 Waste receptors.

Waste receptors shall be of an approved type. A removable strainer or basket shall cover the waste outlet of waste receptors.

Waste receptors shall be installed in ventilated spaces. Waste receptors shall not be installed in bathrooms, toilet rooms, plenums, crawl spaces, attics, interstitial spaces above ceilings and below floors or in any inaccessible or unventilated space such as a closet or storeroom.

Ready access shall be provided to waste receptors.

Examples of condensate disposal places that are NOT approved or may not be approved

- Into the plumbing stack vent pipe (e.g. in a building attic), is not recommended and is prohibited by building code in some jurisdictions.

- Onto or into a crawl space floor, dirt or otherwise, onto the soil under a mobile home or trailer

- Onto a sidewalk or driveway, driveway or any other area where it creates a nuisance

- Onto any surface where people walk and thus where there may be a slip or fall hazard or where people may track unsanitary bacteria/laden condensate into occupied spaces

- Into a plumbing fixture such as a sink or drain where likely to come into human contact or food preparation

- Immediately adjacent to a building foundation - where there is risk of creating a building water entry problem or where a low area may cause ponding

- Immediately onto a roof surface (this is permitted in some jurisdictions)

- Where sewer gases or fumes may enter the condensate piping system, building, or mechanical equiment

- Into a storm drain system, permitted in some areas, - considered not best practice

- See more at CONDENSATE DISPOSAL, IMPROPER

314.2.2 Drain Pipe Materials and Sizes

Components of the condensate disposal system shall be cast iron, galvanized steel, copper, cross-linked polyethylene, polybutylene, polyethylene, ABS, CPVC or PVC pipe or tubing. All components shall be selected for the pressure and temperature rating of the installation.

Joints and connections shall be made in accordance with the applicable provisions of Chapter 7 relative to the material type. Condensate waste and drain line size shall be not less than 3/4-inch (19 mm) internal diameter and shall not decrease in size from the drain pan connection to the place of condensate disposal.

Where the drain pipes from more than one unit are manifolded together for condensate drainage, the pipe or tubing shall be sized in accordance with Table 314.2.2.

Table 314.2.2 Minimnum Condensate Pipe DiameterCondensate Drain Sizing |

|

| Equipment Capacity | Minimum Condensate Pipe Diameter |

| Up to 20 tons of refrigeration | 3/4 inch |

| Over 20 tons to 40 tons of refrigeration | 1 inch |

| Over 40 tons to 90 tons of refrigeration | 1 1/4 inch |

| Over 90 tons to 125 tons of refrigeration | 1 1/2 inch |

| Over 125 tons to 250 tons of refrigeration | 2 inch |

Notes to the table above:

This is adapted from the 2012 IPC as adopted by the state of Tennessee.

For SI: 1 inch = 25.4 mm, 1 ton of capacity = 3.517 kW.

Watch out: assure that condensate drain piping is adequately-supported so as to maintain proper slope (1/8" / ft). Horizontal (maintain 1/8" per ft slope) runs of plastic pipe such as widely-used PVC should be supported every 4 ft. and vertical runs should be supported every 10 ft.

314.2.3 Auxiliary and Secondary Drain Systems

In addition to the requirements of Section 314.2.1, where damage to any building components could occur as a result of overflow from the equipment primary condensate removal system, one of the following auxiliary protection methods shall be provided for each cooling coil or fuel-fired appliance that produces condensate:

1. An auxiliary drain pan with a separate drain shall be provided under the coils on which condensation will occur.

The auxiliary pan drain shall discharge to a conspicuous point of disposal to alert occupants in the event of a stoppage of the primary drain. The pan shall have a depth of not less than 11/2 inches (38 mm), shall be not less than 3 inches (76 mm) larger than the unit or the coil dimensions in width and length and shall be constructed of corrosion-resistant material.

Galvanized sheet metal pans shall have a thickness of not less than 0.0236-inch (0.6010 mm) (No. 24 gage) galvanized sheet metal. Nonmetallic pans shall have a thickness of not less than 0.0625 inch (1.6 mm).

2. A separate overflow drain line shall be connected to the drain pan provided with the equipment. Such overflow drain shall discharge to a conspicuous point of disposal to alert occupants in the event of a stoppage of the primary drain. The overflow drain line shall connect to the drain pan at a higher level than the primary drain connection.

3. An auxiliary drain pan without a separate drain line shall be provided under the coils on which condensate will occur. Such pan shall be equipped with a water-level detection device conforming to UL 508 that will shut off the equipment served prior to overflow of the pan. The auxiliary drain pan shall be constructed in accordance with Item 1 of this section.

4. A water-level detection device conforming to UL 508 shall be provided that will shut off the equipment served in the event that the primary drain is blocked. The device shall be installed in the primary drain line, the overflow drain line, or in the equipment-supplied drain pan, located at a point higher than the primary drain line connection and below the overflow rim of such pan.

Exception: Fuel-fired appliances that automatically shut down operation in the event of a stoppage in the condensate drainage system.

314.2.3.1 Water-Level Monitoring Devices

On down-flow units and all other coils that do not have a secondary drain or provisions to install a secondary or auxiliary drain pan, a water-level monitoring device shall be installed inside the primary drain pan.

This device shall shut off the equipment served in the event that the primary drain becomes restricted. Devices installed in the drain line shall not be permitted.

314.2.3.2 Appliance, Equipment and Insulation in Auxiliary Drain Pans

Where appliances, equipment or insulation are subject to water damage when auxiliary drain pans fill such portions of the appliances, equipment and insulation shall be installed above the flood level rim of the pan.

Supports located inside of the pan to support the appliance or equipment shall be water resistant and approved.

Watch out: if you vent a condensate drain line the top level of the vent opening must be above the opening of the secondary condensate drain pan overflow opening, thus above any possible high condensate water level in the system. Otherwise condensate can spill out of the vent into the building.

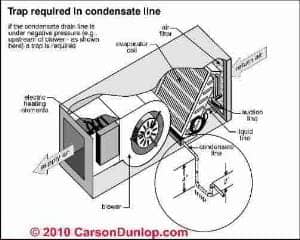

314.2.4 Traps Required on Condensate Drains

Condensate drains shall be trapped as required by the equipment or appliance manufacturer.

Condensate drains shall be trapped as required by the equipment or appliance manufacturer.

Notes:

IMC 307.2.4.1 permits ductless A/C systems (or heat pumps) to have either a check valve OR a trap in the condensate drain line (check valves may not approved by all manufactuerers)

IMC 307.2.5 requires that condensate assemblies shall be installed so that the drain system can be cleared of blockages without having to cut the drain.

See details at CONDENSATE DRAIN CLEAN & DE-CLOG

Photo: an EZTRAP installed on an air conditioner, showing the red caps that are opened to clean the condensate drain line using a brush provided by the manufacturer, Rectorseal.

Other models from Rectorseal include an integral overflow safety switch.

Watch out: connecting a condensate drain directly to an existing building plumbing drain risks both siphoning out of the water from the condensate trap and possible back-drafting of dangerous sewer gases from the building drain and sewer or septic system back up into the air handler, duct system, and building air.

Some designs including some EZTRAP and other HVAC condensate trap products provide a vent in the condensate drain line, located AFTER (downstream from) the trap, to prevent siphoning out of the condensate line trap.

We discuss condensate drain trap issues and solutions further

Insulation on HVAC Condensate Piping

The model building, mechanical, plumbing codes do not address an insulation requirement on condensate drain lines.

However it is good practice to provide insulation of sufficient R-value on condensate drain piping in areas where building temperatures and/or ambient humidity levels present a risk of condensate drain line freezing or of condensation forming on the exterior of drain piping.

Condensate on the condensate drain line can lead to mold growth or or building damage on nearby building materials.

Freezing condensate drain lines risk burst piping, leaks into the building, or shut-down of or condensate backup at the HVAC equipment.

I'm avoiding quoting a specific R-value requirement for condensate drain piping as that's dependent on the location of the equipment and local climate conditions. R-2 may be sufficient to prevent condensation forming on an AC condensate drain in Miami Florida but insufficient to prevent freezing on equipment in Duluth Minnesota.

Condensate Drain Codes & Code Sources

- BUILDING CODE DOWNLOADS

- CONDENSATE DISPOSAL REQUIREMENTS, California Building Code (2013) [PDF] retrieved 2017/07/17, original source: http://buildingincalifornia.com/wp-content/uploads/2014/01/CondensateDisposalReq.pdf

- HVAC CODES

- PLUMBING CODE of TENNESSEE 2012, CHAPTER 3 GENERAL REGULATIONS International Plumbing Code 2012, Adapted from Tennessee Building Code adoption of the 2012 IPC, retrieved 2019/07/30, original source https://up.codes/viewer/tennessee/ipc-2012/chapter/3/general-regulations#314

How to Inspect the Air Conditioner Condensate Drain System

Improper handling of air conditioning system condensate is one of the most commonly reported set of A/C system defects. Condensate problems can lead to leaks into the building, costly mold or insect damage, or even to complete A/C or heat pump system shutdown.

Perhaps we see lots of air conditioning condensate leaks and related problems in part because these defects are easily observed visually, and perhaps also because some A/C installers do not follow basic plumbing and building code requirements for handling the discharge of the condensate produced when an air conditioning system is operating.

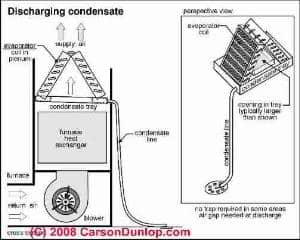

Sketch courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ]. [Click to enlarge any image]

Condensate leaks or discharge errors (such as the drips into the dog bowl and cooking pot in this attic) present several risks of ugly surprises in buildings.

Here are some inspection tips that can avoid a condensate leak or even a costly mold problem in the air conditioning system air handler, duct work, or in the building itself:

1. Find how & where condensate discharge has been carried for final disposal

Details about improper condensate disposal are

Details about improper condensate disposal are

at CONDENSATE DISPOSAL, IMPROPER

Here are some of the condensate drainage disposal piping arrangements we've found in various buildings:

- A flexible plastic condensate drain line may be routed through building walls, ceilings, floors, at some installations such as split system wall-mounted air conditioners and heat pumps.

at SPLIT SYSTEM AIR CONDITIONERS & HEAT PUMPS we describe the routing, slope, and protection from damage for in-wall condensate drain lines.

Our photo (left) shows the condensate drain termination for a roof-mounted split system air conditioner - the white plastic condensate drain exits the building wall and is carried to the roof surface next to the roof-mounted inverter or compressor/condenser unit for the cooling system. - A plastic line draining outside to an approved drain destination -

See CONDENSATE DRAINS, CODES - A floor drain

- To a sump pit

- To a hole in the floor - to where? Properly, a floor drain, not simply spilling through a floor into a crawl area, dirt floor, or under a mobile home

- A reservoir lift pump which pipes condensate to: (a properly connected building drain; something else). The condensate pump exit line is taken to the house main waste line. See details

at CONDENSATE PUMPS - Problems with condensate drains themselves are detailed

at CONDENSATE DRAINS, CODES - Onto a roof surface: improper;

Condensate drains or swamp cooler leaks or drains directly onto a roof surface may leave algae, mold,

or WHITE STAINS on ROOFS and may damage the roof surface

2. Check for a clogged A/C condensate drain line trap

One of the most common causes of air conditioning or heat pump condensate leakage and overflow is a clogged condensate drain line trap. And if the secondary or emergency condensate handling system is absent or defective, the result can be costly leak damage to the equipment or to the building.

Carson Dunlop Associates' sketch (left) illustrates the requirement for a trap on the A/C condensate primary drain line.

3. Look out for a missing condensate overflow pan or drip tray:

If there is no overflow pan under the air handler, especially in units installed on upper building floors or in an attic, when the condensate drain clogs or the condensate pump fails you can expect to have leaks into the building and possibly costly mold or water damage.

See CONDENSATE DRIP TRAY DEFECTS for details.

4. Look out for an improper condensate overflow pan drain connection

A condensate pan should have its own independent drain to an approved location. Otherwise, for example if it shares the main condensate drain pipe, you have not gained much protection. An alternative to a drain on a condensate overflow pan is the installation of

a FLOAT SWITCH on CONDENSATE TRAY that will turn off the system if water is detected.

5. Look for corrosion or water stains on floor surfaces around the equipment

Check the condensate drip pan and at bottom of the "A frame" cooling coil, indicating that the drain may need cleaning and more important, indicating that the condensate is leaking out of the equipment or drains and not being carried to an acceptable disposal point.

Links below continue with detailed discussions of condensate handling components, defects, cleaning, maintenance, and repairs.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-11-28 - by (mod) -

"ever done" - sure if we include serious errors,

But 'ever done properly' ? No. It is never ever proper to just dump AC condensate into a wall cavity.

On 2020-11-28 by Anonymous

Thanks,

Yes that is what i meant..

Wanted to know if it was ever done this way.

In my situation.Just a way to remove water, its always mud wet around the outside unit where it drains.

On 2020-11-28 - by (mod) -

Joe,

If I understand your question correctly you want to know if it makes sense to drain the condensate from an indoor air handler outside to the compressor condenser unit where it's blowing through the condenser coil fins in order to be evaporated. I doubt that that would harm the unit but it seems to me impractical, and unnecessary.

On 2020-11-27 by Joc

Just wondering if this is ever done?

(Not a heat pump system)

Air Handler & Evaporator are in attic, Compressor Unit is in backyard..

Can the condensate water drain outside venturi through the Compressor Coil fins atomizing to outside air?

On 2020-07-23 by Rick

I want to get rid of the condensate from my AC/heat pump. Currently the drain line exits exterior wall and line runs 2-3 feet from house. Water runs onto sidewalk. Can I dig hole 3-4 feet deep and place rock in hole and drain water into rock?

On 2019-07-20 by Val

The threaded fitting on the main condensate drain port have broken. (The threads where the drain line attaches to the AC unit located in ther attic to. route the water outside) The fitting allows the 3/4 in PVC drain line to attach top the unit

The drain line now leaks at that attach point.

How would I fix this?

On 2019-06-07 - by (mod) -

The term failing an inspection sounds a little questionable to me. I didn't think that home inspections - if that's what transpired - passed or failed. Maybe someone's just speaking carelessly. There's no plumbing code that I have found that requires insulation on the condensate drain line. Why don't you go back to whoever the expert is who failed the system and ask them to give you an authoritative citation

that would be very helpful and I'd be very grateful to see it.

On 2019-06-07 by AircoTech

Do condensate line need to be insulated by code ?

On 2019-03-26 - by (mod) -

Ted I think so but frankly from just the text I can't be sure we correctly understand the situation, the distances, slopes, etc. involved.

On 2019-03-25 by ted

moved condensate lines which were dumping into a concrete pit and couldn't drain. ran one line directly into an already installed p trap. had to put line trap in second unit line downstream on exit downsteam. will that work ok?

On 2018-10-01 - by (mod) -

OM

Man I wish I could promise what a local code inspector will do. I can't, and she's the final legal authority on code compliance.

But in general, IF the piping capacity is sufficient and there are no missing traps I'd figure the inspector will be ok with that.

On 2018-10-01 by O.M.

Will multiple package units hook up on the same Condensation pipe Pass inspection

Question: how and when do we inspect the condensate drain?

I can't find a description of the method for inspecting the drain pipe leading out from the drain pan under the condenser coils.

I can't find a description of the method for inspecting the drain pipe leading out from the drain pan under the condenser coils.

I have been told that this pipe commonly blocks up and causes problems and that inspecting it is a part of a HVAC maintenance program. Would you describe for me, or maybe add to your site, how often and how this drain line should be inspected and maintained?

- R.B. Chattanooga, TN.,

Reply: check for a clogged condensate drain line trap, crimps in the line, or clogs in the line; check that the line is routed to a proper destination

The condensate drain line, trap, and evidence of blockage, leaks, overflow, or improper piping should be part of annual air conditioning system service, or should be performed immediately if there is evidence of a condensate spill or leak

. It only takes a quick look by an experienced service technician to see trouble. Here are some signs of trouble that a visual inspection of the condensate drain system might pick at an inspection:

- Visual inspection for obvious debris at opening to the condensate drain, inside the air handler

- Visual inspection for evidence of condensate overflowing out of or backing up in the air handler [photo] when it should be passing out the drain - such as is shown in our photo at left.

- Visual inspection for condensate backup or spillage such as presence of condensate in an overflow pan

- Tripping off of the float switch in the overflow pan if you have one

- Some condensate drains have a removable cap on the trap to inspect in and clean the trap - traps are usually where blockages occur

- Visual inspection of the entire drain line to see its routing - and to assure it's taken to a proper destination.

Our photo at the top of this section above shows a crimped condensate drain pump line [photo] - we were a bit worried that with even the slightest additional movement in this soft flexible plastic tube (connecting the condensate pump to a nearby laundry drain) would prevent the pump from working properly. - Failure of any condensate to come out of the exposed end of the condensate drain line when the A/C system has been running during hot, humid weather

- If a condensate pump is installed, overflow of condensate out of the pump housing

Check out the articles listed below for more detail about each type of condensate drain system defect.

Reader Question: our wall-mounted split system air conditioner leaks condensate down the interior wall

We noticed water stains and wet spots on the wall below our wall-mounted split system air conditioner. But condensate is also coming out of the drain line on the roof. What might be wrong? - Ed.

Reply: Common defects that cause leaks or blockages in wall-mounted air conditioner condensate drains

Check the following sources of condensation leaks at or near a wall-mounted air conditioner::

Check the following sources of condensation leaks at or near a wall-mounted air conditioner::

If the wall mounted air conditioner is not level, condensate may collect in its internal drain pan but may overflow the (relatively shallow) condensate pan edges before reaching the condensate drain opening.

Check the unit for level, and watch out: the plastic cover may not be dead straight - it's the unit itself that should be level for the condensate drain pan to work properly.

The photo showing flexible air conditioner condensate piping is explained

at SPLIT SYSTEM AIR CONDITIONERS & HEAT PUMPS.

That white line is the condensate drain headed from the wall-mounted unit (not shown) to outdoors.

- Check for lint or crud blocking the opening to the condensate drain line inside the unit.

- Check for a blocked or clogged condensate drain line as it passes through the building wall to the building exterior.

- Check for punctures in the condensate drain line anywhere in its route but especially high on the wall near the unit where you see the leaks or wet spots

- Check for missing insulation on the refrigeration lines inside the wall-mounted unit.

We describe this SNAFU at Interior Leaks On & In Wall Below a Split System Air Conditioner Wall-Mounted Unit

...

Continue reading at CONDENSATE LEAKS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see CONDENSATE HANDLING FAQs - questions and answers posted originally on this page

Or see these

HVAC Condensate Articles

- CONDENSATE HANDLING, HVAC

- CONDENSATE LEAKS

- CONDENSATE PUMPS

- CONDENSATE DISPOSAL, IMPROPER

- CONDENSATE DRAINS, CODES

- CONDENSATE DRAIN CLEAN & DE-CLOG

- CONDENSATE DRAIN INSULATION REQUIREMENTS

- CONDENSATE DRAIN PROBLEMS

- CONDENSATE DRIP TRAY DEFECTS

- CONDENSATE PAN SWITCH LOCKOUT

- Legionella BACTERIA & HVAC EQUIPMENT

- CONDENSING BOILER/FURNACE CONDENSATE DRAIN

- HARTFORD LOOP

- Legionella BACTERIA & HVAC EQUIPMENT

- SPLIT SYSTEM AC CONDENSATE LEAK REPAIR

- CONDENSING BOILER/FURNACE CONDENSATE DRAIN

Suggested citation for this web page

CONDENSATE HANDLING at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to Areader RB in Chattanooga TN for discussing inspection procedures and inspection frequency for air conditioning condensate drain line systems - October 2010

- Complete List of Air Conditioning & Heat Pump Design, Inspection, Repair Books at the InspectAPedia Bookstore.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.