Diagnostic Guide to Well Pump Problems

Diagnostic Guide to Well Pump Problems

- POST a QUESTION or COMMENT about how to figure out what's wrong with the well pump

This article provides a table of diagnostic checks and procedures for fixing well water pump problems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Editor/Publisher - See WHO ARE WE?

Well Pump Troubleshooting Diagnostic Guide

Things to Check if theWell Pump Will Not Start |

||

|---|---|---|

| Pump Trouble Cause | Diagnostic Procedure | Repair Procedure |

| Electrical Power is Off | Check that all service switches for the equipment are in the "on" position. Check for voltage at the pump motor or pump controls. If no voltage is found, check for voltage at the electric panel. If power is on to the building, check fuse or circuit breaker serving the electric motor that won't run. Check for local reset button on the motor (popped out = off ) Check for other power reset or power off buttons such as an access door compartment safety switch that turns off power to the equipment (found on A/C blower compartment doors) |

Turn on "off" switches. Replace bad fuse. Reset circuit breaker; if necessary replace bad circuit breaker. Let hot electric motor cool down, then push in its reset button. Be sure all safety interlock switches such as on compartment doors are depressed and that the doors are securely shut. Replace a bad safety switch. Replace bad or damaged electrical wiring that shorted and tripped the breaker. See ELECTRICAL POWER SWITCH FOR HEAT |

| Blown fuse, tripped breaker | Replace fuse or breaker - does the pump run and keep running normally? If the breaker keeps tripping most likely there is either a short circuit in the wiring or the pump motor is drawing abnormally high current |

Be sure proper breaker or fuse size in ampacity is installed - ELECTRIC PANEL INSPECTION |

| Low voltage to the pump | Check with VOM at the pressure control switch or at the pump wiring | Be sure the proper size of wire is used for the ampacity and length of circuit; Test for low voltage to the building. ELECTRIC MOTOR DIAGNOSTIC GUIDE |

| Loose or broken pump wire | Check wiring against the pump installation manual diagram, check all connections for tightness, shorts, burns, damage. A loose wire can cause intermittent pump or other electrical device failiures as well as a hard failure that means no power or blown fuses. |

Rewire or repair or replace wiring |

| Burned out pump motor | Check that the pump pressure control switch is trying to turn on the pump and that there is voltage at the pump wiring | Repair or replace the pump motor |

| Bad motor control switch | Check the control switch contacts for burning or wear. If the motor control is a well pump pressure control switch,check the pressure control switch settings - cut-in and cut-out; inspect for burned, pitted switch contacts or for dirt or wear. |

For water pumps, adjust or replace the pressure control switch. Temporary emergency repair by cleaning the switch contacts may be possible. |

| Bad pump pressure control switch | Check the tubing connecting the pressure switch to the pump housing for clogging | Clean or replace the tubing and be sure the connections are not leaky - an air leak will prevent the switch from sensing pressure properly |

| Bad water pump control switch tubing | Clogged or leaky tubing connecting a water pump pressure control switch to the water system results in failure to properly sense and respond to water pressure. Debris clogging can also occur in the bottom of the pressure control switch where it mounts or connects to the tubing.

|

Check and clear tubing blockage (blow air through tubing). Or install new tubing. Be sure tubing is proper diameter and type to seal properly with other fittings. Tighten tubing fittings to be sure there are no water or air leaks. Soap solution may help find air leaks in tubing fittings. Clear or replace clogged pressure control switch if the bottom sensor opening is clogged and cannot be cleared. |

| Bad pump impeller or impeller seal leak | Turn off electric power to pump, see if you can move the impeller or motor - if it won't turn it is jammed or damaged | Remove obstruction in impeller housing, inspect for and replace damaged impeller or frozen motor. |

| Bad pump motor starting capacitor | Use a VOM in ohms setting to check resistance across the capacitor. If the meter does not move (no current flows) the capacitor is "open". If there is zero resistance the capacitor is shorted. | Replace the starting capacitor |

| Pump motor shorted out, jammed, burned up | Fuse blows or breaker trips as soon as the pump tries to turn on. If the external wiring is ok (no short circuits) the motor is shorted internally | Replace the pump motor |

...

Things to Check if thePump Motor Starts but Overheats - Trips Reset Buttonor Pump Blows a Fuse or Trips Circuit Breaker |

||

| See ELECTRIC MOTOR OVERLOAD RESET SWITCH for how to find and reset this button | ||

| Pump Trouble Cause | Diagnostic Procedure | Repair Procedure |

|---|---|---|

| Bad line voltage | Use a VOM to check the voltage level at the pressure control switch | If voltage is too low, check voltage at the electrical panel and check that the proper size wiring was used for the ampacity and length of run and that there are no partial shorts or damaged wires or connectors |

| Incorrect motor wiring | Check the actual electrical wiring against the motor wiring diagram or the installation manual for the equipment | Reconnect wiring properly |

| Motor is too hot due to surroundings - inadequate ventilation | Check the air temperature where the motor is located. If the air temperature is over 100 degF, the pump may be too hot and its thermal overload switch tripping because of the environment, not a pump problem. | Install adequate ventilation, or if needed, shading, or relocate the motor/equipment to a cool location |

| Pump operates too long at low water pressure | If the well recovery rate is too poor and the pump is operating at low water pressure, possibly because a tailpiece is installed to prevent air injection and pump burnup, the pump may be overheating. | Install a valve on the water discharge line and reduce water flow to increase water pressure inside the pump itself. |

...

What to do if theWell pump runs continuously or Pump runs too often |

||

| Pump Trouble Cause | Diagnostic Procedure | Repair Procedure |

|---|---|---|

| If the Well Pump Motor Runs Too Often | If the pump runs too often the cause may be a control problem, water tank problem, piping problem, or a well problem. | See INTERMITTENT CYCLING WATER PUMPS if the pump runs at odd times for no apparent reason. See SHORT CYCLING WATER PUMP and also |

| If the Well Pump Motor Keeps Running & Won't Stop | If the pump won't turn off the cause may be a damaged pump control, a plumbing or fixture leak, or a well problem. | Watch out: If the pump motor won't shut off you should turn off electrical power to the pump to avoid damaging it, then diagnose the problem. |

...

Other well pump troublesWater pump noise |

||

| If the Well Pump is too Noisy | If the well or water pump has gotten quite noisy the cause may be a worn pump bearing or damage to the pump impeller. | Review our list of common sources of water pump noise before replacing anyhing. |

Notes to the tables above

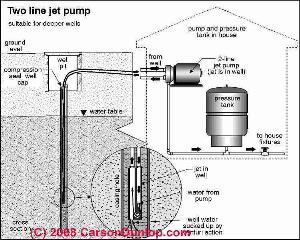

Some of the well pump troubleshooting suggestions in this list can be found at the Betta-Flo Jet Pump Installation Manualfrom the National Pump Co. Page top illustration courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

Also see our other diagnostic guides for water pumps, wells, motors, in table form:

- WATER PUMP SHORT CYCLING DIAGNOSIS TABLE - table format.

- SHORT CYCLING WATER PUMP - text.

- WATER PRESSURE PROBLEM DIAGNOSIS TABLE - table format.

- WATER PRESSURE LOSS DIAGNOSIS & REPAIR - text.

- WATER PUMP DIAGNOSTIC TABLE - table format.

- WATER PUMP REPAIR GUIDE - home - text

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-03-21 by BOBBY w CARLISLE - well takes too long to recover

i am dealing with a slow recovering water well .iam going to clean the screen at bottom of casing with a well brush

;then pump out with trash pump what is chances that i will increase amount of water capacity coming into the well i will keep brushing and pumping till it cleans the deber and open up the wter fin on screen

On 2020-03-21 by (mod) - dealing with a slow recovering water well

Bobby

Cleaning the well screen makes plenty of sense as does removing debris from the well bottom.

That might be sufficient to improve water flow.

What we can't know from just your question is whether or not the actual flow rate - the rate at which water flows INTO the well bore has itself diminished.

But well flow rate can be measured, and there are other methods to increase well flow rate.

See details at

WELL FLOW RATE

and at

WELL YIELD IMPROVEMENT

On 2019-03-30 by Andrea- fuse blows when we turn on the pump

We have replaced the points, the pump, and the pump control box, but it still blows the fuse every time we put one in. We have no water because of the blown fuse. Please someone help us. Oh and we also rewired.

On 2019-03-30 - by (mod)

Andrea

Usually when the pump circuit blows a fuse or breaker I suspect that either there is a wiring short OR there is a pump that is damaged/ruined/jammed and drawing high current.

In that scenario a well expert would hook up an ammeter and COM to the wiring to do some simple tests to see what happens when you try to turn on the pump, as well as tests for shorted wires and tests for circuit resistance that can indicate a failed motor or winding.

You may also want to see the motor testsat ELECTRIC MOTOR DIAGNOSTIC GUIDE

HOWEVER from just your brief note you've replaced pump, pressure control switch, and "control box" - I'm not sure exactly what you've got - an above ground jet pump or an in-well submersible pump.

You also "re-wired" but I don't know how much of the circuit was addressed.

It sounds as if there's either a wiring error or damaged wires that are shorting together or shorting to ground.

Hire an electrician to follow the pump circuit from the breaker onwards (starting by making sure the breaker itself is not defective and that it's the right size)

(Oct 10, 2017) Maurice said: - your water well has seized up!

What is meant by the term...your water well has seized up! Just what does that mean? Please give me an answer.

On 2019-02-04 - by (mod) - What is meant by the term...your water well has seized up!

Maurice,

that is not a phrase that I have seen and descriptions of water well problems. I suspect that whoever said that meant that the well pump motor is seized or frozen or not working.

On 2019-01-12 by Geoff - murky water after installing new expansion tank

New well expansion tank in basement. Water clarity suddenly very bad

On 2019-01-13 by (mod) -

Geoff:

I'd have the water tested if, after putting some cloudy water into a glass and letting it sit for a few minutes it doesn't clear up - thus ruling out air bubbles. Sometimes plumbing work on an existing system stirs up crud that was in pipes previously.

On 2019-01-08 by Michael - pump hums and trips circuit breaker

Once I flip the switch I get good water pressure and the switch kicks on and off a few times then it makes a humming noise and the water stops running and then my breaker flips.

On 2019-01-08 - by (mod) -

Watch out: Sounds to me like a failing pump motor drawing high current and tripping the breaker. I'd leave it off (sorry) and call your pump service company for repair. (There could of course be different causes).

On 2018-11-06 by Vicki Green - water pump tripped the breaker twice in the last two weeks.

Our water pump tripped the breaker twice in the last two weeks. Seems like it may have happened at nite. The only water running then would be the water softener we rent from Culligan.

On 2018-11-06 - by (mod) -

Vicki

Speculating: when the water softener is in regen cycle it can run for quite some time through multiple phases of backwash and regen, using a lot of water. Details are at WATER SOFTENER REGENERATION CYCLE DURATION https://inspectapedia.com/plumbing/Water_Softener_Cycle_Time.php

That water use could be dropping the water level in the well or simply running the pump a long time either causing a marginal, near end of life motor, to overheat and seize-up, drawing high current, tripping a breaker.

So your well water flow rate may be poor or your pump is at end of life, or both .

...

Continue reading at WATER PUMP REPAIR GUIDE - topic home, which offers an example of diagnosis of loss of water pressure, loss of water, and analyzes the actual repair cost, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see WATER PUMP DIAGNOSTIC TABLE FAQs - questions & answers posted originally at this article

Or see these

Recommended Articles

- WATER PUMP DIAGNOSTIC TABLE - you are on this page

- WATER PUMP REPAIR GUIDE - home

- WELL FLOW TEST PROCEDURE - well runs out of water entirely

- WELL YIELD IMPROVEMENT - increase the yield (flow rate) of your well

- WELL WATER PRESSURE DIAGNOSIS - improve water pressure or flow rate

Suggested citation for this web page

WATER PUMP DIAGNOSTIC TABLE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- DEEP WELL JET PUMPS PDF, Government of Alberta, Agriculture and Rural Development, toll free in Alberta at 310-FARM web search 07/24/2010, original source: http://www1.agric.gov.ab.ca/$department/deptdocs.nsf/all/agdex639

- Betta-Flo JET PUMP INSTALLATION MANUAL [PDF], National Pump Co., LLC., includes helpful well pump troubleshooting tips as well as basic jet pump installation details. Web search 07/24/2010, original source: http://www.nationalpumpcompany.com/Documents/OIM/Betta%20Flo%20IOM%20Jet%20Pump.pdf

- Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

Water Supply & Drain Piping, Wells, Pumps, Water Supply Equipment

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Life Expectancy of Water Pumps - Well Pumps: how long should a water pump last? What affects pump life?

- Life Expectancy of Wells & Water Tanks how long should a water well and its components last?

- Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.