Replace a Blown Fuse

Replace a Blown Fuse

5 Steps to replace a blown or burn-out fuse, fuse types, fuse sizes

- POST a QUESTION or COMMENT about how to inspect main fuses and main circuit breakers

What to do if a fuse blows in your electrical panel:

Here we describe the types of fuses found in fused electrical panels, the causes of blown fuses, the right fuse size selection, and fuse replacement.

This article series discusses safety hazards at residential electrical panels using fuses or circuit breakers. While we recommend that a professional inspector check these devices in some circumstances s/he should not do so, and extra care is always needed.

These articles suggest safety procedures for the electrical inspector, home inspector, or other professionals who examine residential electrical systems.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Testing Main Circuit Breakers or Main Fuses in Electrical Panels

Watch out: Fatal Shock Hazard Warning: Inspecting electrical components and systems risks death by electrocution as well as serious burns or other injuries to the inspector or to others. Do not attempt these tasks unless you are properly trained and equipped.

Watch out: Fatal Shock Hazard Warning: Inspecting electrical components and systems risks death by electrocution as well as serious burns or other injuries to the inspector or to others. Do not attempt these tasks unless you are properly trained and equipped.

How to Replace a Blown Fuse

So the lights have gone out, or some of your wall receptacles have died - a fuse has blown.

How do we restore power to the dead circuit?

[Click to enlarge any image]

This article is about replacing a blown fuse. If your electrical panel uses circuit-breakers (toggle switches) instead of fuses,

see ELECTRICITY TURN ON AFTER BREAKER TRIP.

Watch out: Consider safety for yourself and other building occupants first. Look at the fuse box and look at the floor before touching anything.

If you are standing in water don't touch electrical equipment.

If you see arcing, burns, smoke, fire at the electrical panel, don't touch it. Instead it's time to get people out of the building and call emergency services.

You can improve your safety by avoiding touching the electrical box at all if you are not familar with electrical wiring and safety procedures, by wearing heavy rubber gloves, by avoiding touching any electrical wires or connections in the electrical box, by noticing if the elecrical ground rod and ground wiring are missing from your property, and by reviewing these two articles:

and also

ELECTRICAL PANEL INSPECTION SAFETY - more detail about working safely around electrical panels and fuse boxes.

Watch out: when electrical connections or bare wires or metal bus bars are exposed inside a fuse box or panel, if you touch one of these you will be shocked, injured, possibly killed.

Article Contents

- IDENTIFY the TYPES of FUSES PRESENT

- IDENTIFY WHICH FUSE HAS BLOWN

- CHOOSE the RIGHT REPLACEMENT FUSE

- REMOVE & REPLACE the BLOWN FUSE

- RESTORE POWER & CHECK for TROUBLE

Watch out: Many fuse boxes or fuse panels have a hinged cover that can be opened to provide access to the fuses. If there is safety cover that remains in place when you open the fuse box door, leave it in place.

Without removing the internal panel safety cover, but by opening the hinged electrical panel access door of a larger fuse panel, homeowners can access the main fuses, as well as individual circuit fuses.

However any smaller fuse boxes like the one in our photo at the top of this page and some of the fuse panels shown in this article have a single hinged cover that opens to expose all wiring and fuses together.

In our fuse box photo above, the box uses a combination of a main fuse pull-out at the top of the panel - this removes all electrical power to the building, three 240-Volt fuse block pull-outs, and twelve screw-in type plug fuses.

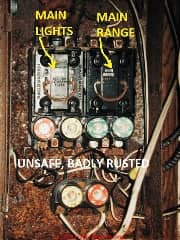

We also noticed rust along the bottom of this panel, raising a possibility of internal damage that is not visible until your electrician opens the panel to examine its interior.

Step 1: Identify Fuse Types in the Fuse Box

First: if you know what caused a fuse to blow, such as something you just plugged-in, or that bank of six electric heaters in the sitting room, turn off and un-plug those devices.

First: if you know what caused a fuse to blow, such as something you just plugged-in, or that bank of six electric heaters in the sitting room, turn off and un-plug those devices.

With a flashlight if needed, let's go take a look in the fuse box to find and replace the blown fuse.

The fuse that has blown may in your main electrical panel or it may be in a sub-panel fed from the main (and located elsewhere in the building). Usually the main panel or service panel and sub panels will be located close together.

Note where the electrical wires come to your building - as inside the main panel will usually be close to that same aera.

Specialty sub panels for air conditioners and heating equipment as well as water pumps may be installed close to that equipment.

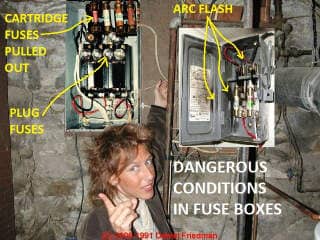

There are two types of fuses found in fuse panels or boxes: larger ampacity cartridge fuses and smaller ampacity plug fuses.

Cartridge fuses are longer cylindrical devices that snap into a clip at either end. Cartridge fuses are used in fuse panels as the main fuse as well as to protect high-amperage circuits such as the 240 Volt circuits supplying an electric range, clothes dryer, or air conditioner circuit.

In my photo the cartridge fuse pull-outs have been removed and placed in the bottom of the panel to pose for this image.

Plug fuses, also called Edison-base fuses or S-type fuses depending on the diameter of the screw-in end of the fuse. Plug fuses are short, round threaded base fuses that screw into position in the fuse box.

In our photo just above the cover has been opened and the inspector (me) has pulled out the two pull-out fuse carriers that each held a pair of cartridge fuses.

Watch out: Our photo above shows, circled in white, bare live wire ends that have lost their twist-on connector.

Touching these live wires or allowing them to touch any metal component inside this fuse box is very dangerous. The missing twist-on connector needs to be replaced, and its omission may signal work by an un-trained worker who may have left other unsafe conditions.

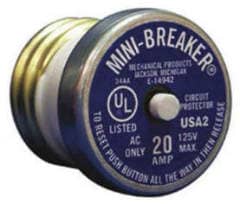

Mini-Breaker Edison-Base Plug Fuses are newer devices that provide a miniature circuit breaker but screw into the opening originally designed for a conventional fuse.

If a mini-breaker fuse is used in your fuse panel and if it is the fuse (breaker) has blown (in this case "tripped"), you should not need to do more than the following:

If a mini-breaker fuse is used in your fuse panel and if it is the fuse (breaker) has blown (in this case "tripped"), you should not need to do more than the following:

- Identify that there are one or more mini-fuses in your panel - see our photo here of a 20A Mini-Breaker® from Mechanical Products Co.

- Notice that the center button on the mini-fuse has popped-out.

- Wait about 5 minutes to let the fuse cool down.

- Push the center button fully in, then release it.

- If the button stays in then the mini-breaker has been re-set.

- Watch out: if after re-set the button immediately pops back out, or if the button won't stay re-set, then the electrical circuit is unsafe and should be left off to reduce the risk of a shock or fire.

You'll need to call for help from a licensed electrician.

Assuming that your fuse panel uses real fuses, not mini-breakers, we continue below.

Step 2: Identify Which Fuse has Blown

A plug-fuse: Look at the exposed face of the fuses in the electrical panel.

A plug type fuse that is blown will usually be obvious as its clear mica face will be scorched black by the arc flash that occurred when the fuse's internal metal components melted or burned - thus opening (turning off) the electrical circuit that the fuse was intended to protect.

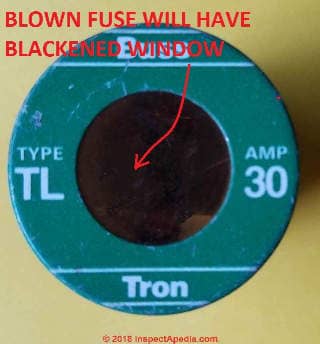

In our photos above the first TL-30 fuse has a blackened window - this fuse has blown. In the second photo of the same fuse type you can see into the window and spot the copper strip that is still intact - this fuse is good.

You might also know which plug fuse is blown by having observed the circuit in the building that has lost power.

If someone was thoughtful enough to label the fuses in the fuse panel, writing down what circuits are protected by each fuse, you will read the fuse number or position in the fuse panel of the fuse that protects the circuit that has lost power.

A cartridge fuse that is blown might or might not be be visually obvious depending on the cartridge fuse brand and model.

Some cartridge fuses such as Eaton / Cooper / Bussman FRN-R cartridge Fuses are sold with an easy ID™ window that shows a deformed line if the fuse is blown .

Other blown cartridge fuses will look ugly: discolored, deformed, corroded.

Once removed from the fuse block or panel it's also easy to test a cartridge fuse provided you are trained in safe use of simple electrical test tools:

Simply use a voltmeter (VOM) or digital multimeter (DMM) in Ohms mode to test the fuse for continuity. If the fuse is good it will show zero resistance. If the fuse has blown it will show infinite resistance.

See GUIDE to ELECTRICAL TEST EQUIPMENT - neon tester to check for live voltage, continuity tester to check for bad cartridge fuses

Like plug fuses, you might also know which plug fuse is blown by having observed the circuit in the building that has lost power.

And as I noted just above, if the panel fuses have been mapped and written down on a label in or next to the panel, you will read the cartridge fuse position in the fuse panel of the fuse that protects the circuit that has lost power.

In some fuse panels the cartridge fuse pull-outs might also be labeled or even embossed right into the fuse block with the words MAIN or RANGE.

Step 3: Choose the Replacement Fuse Size Ampacity & Type

We need to identify the type and size of blown fuse so that it can be replaced with a new fuse of the proper type.

Watch out: never try to install a fuse that is rated higher (in amps - that is a bigger number) than the fuse that has blown. Doing so is unsafe because you're allowing more current to flow on the circuit that the wires are designed to carry. The result is overheating wires and a risk of a building fire.

However in an emergency, if you don't have the right sized fuse, it is safe to install a fuse of lower ampacity.

For example, to keep the lights on you can screw in an Edison-base 15A fuse for temporary use where an Edison-base 20A fuse was used previously. Just don't go the other way.

Plug Type Fuse Sizes

Plug fuses like the ones in the photo above show their type and ampacity or size both by color convention - the color of the fuse top - and by printing on the fuse that will give the amps rating and fuse type on the fuse top surface.

Residential plug fuses will be as shown from left to right:

- 15-Amp (blue),

- 20-Amp (yellow), or

- 30-Amp (green) fuses,

each protecting a single 120-Volt circuit.

Plug Fuse Base Types: Edison Base vs. Type S-Fuses

Plug fuses are sold in two base diameters: traditional (larger-diameter) Edison-base fuse plugs, and smaller-diameter S-Fuses.

Edison base fuses: Larger-diameter screw-in base fuses (at the right in my photo) are called Edison base fuses and fit into older fuse boxes.

Type-S fuses (at the left in my photo) use a smaller-diameter, finer-threaded base and screw into a socket adapter that has already been screwed into the Edison-base-sized fuse socket in the fuse panel.

Each Type-S fuse base diameter is unique to the fuse's amps rating, and once a type-S fuse adapter has been screwed into the original Edison-fuse size socket in the fuse panel, the adapter can't be removed.

The Type-S fuse can, however, be un-screwed from the adapter when the fuse has blown and needs to be replaced.

S-type fuses are also called rejection-base fuses or tamper-proof fuses because they will reject or prohibit the screwing-in of the wrong-sized fuse.

S-fuse adapter is to prevent the user from installing a fuse of larger size (Amps-rating) than is proper for the circuit. You will see that you can't fit a 20-A or 30-A S-type fuse into a 15-A S-type fuse socket.

These fuses are not very pretty, as they've been bouncing around in my electrical toolbox for three decades, kept at hand for an emergency need that has not arisen.

More Plug Fuse Types: Type T, Type TL, Type W

Type T-fuses are a time delay fuse that are also called "slow-blow" fuses.

Type T time delay fuses, shown above as a 15-Amp fuse, are designed to avoid blowing the fuse during the brief current-draw surge that occurs when some motors first turn-on.

[Click to enlarge any image]

An example use of a time delay fuse is on an air conditioner circuit whose compressor draws high current when the motor first starts. Water pumps and some other circuits also use time delay Type T fuses.

If the circuit protected by a Type T fuse continues to draw excessive current beyond a few seconds, the soldered spring-loaded link inside the fuse continues to melt and the spring pulls the fuse apart, opening or turning off the circuit.

Type T-fuses use a larger-diameter Edison screw-in base.

Inside the Type T Fuse:

The time delay mechanism in a Type T fuse will usually appear to include a spring that is used to pull apart or open the fuse when its fusible link melts.

Type TL Fuses are another form of Type T time delay fuse but TL fuses, shown above in a 30-A model, use a different internal design.

Like a Type T fuse, the TL fuse permits a brief circuit overload such as when a motor is starting. Typically a Type TL fuse uses a large solder blob that acts as a heat sink but finally melts to open the fuse after a delay.

The duration of the time delay is controlled by the dimensions of the solder link that is to melt. At higher current flow rates the solder link heats more-rapidly so the fuse will blow sooner, and at very high current flow rates such as a dead short, the solder link will melt almost instantly.

In my photo above you can see the internal parts of a Type TL slow-blow or time-delay fuse.

The red arrow under the word "SINK" points to the solder that acts as a heat sink to slow the melting of the narrow copper fusible link, giving a time delay before the fuse will blow. But with a high current flow the narrow copper strip (with a small hole in its center) will melt almost immediately, regardless of the nearby solder heat sink.

The mica covers are a safety feature on fuses that form a shield to prevent melted copper and solder from spraying out of the fuse when the fuse blows.

Type SL fuses work like Type TL fuses but use the smaller-diameter Type-S fuse base to prevent tampering.

Both Type SL and Type TL fuses are considered medium-duty time delay fuses.

Inside the Type TL Fuse:

Inside a TL fuse you'll see that the time delay mechanism is in essence a large rectangular blob of solder.

Instead of a spring-loaded fuse-blow mechanism seen inside of type T and Type S fuses, a Type TL fuse uses a larger piece of solder that can absorb and dissipate some heat from the circuit before the solder melts and the fuse "blows".

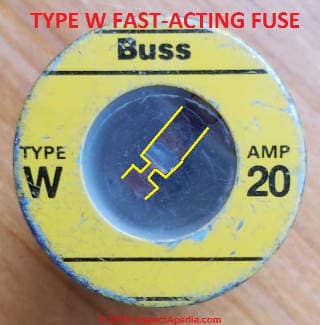

Type W Fuses are an Edison-base screw-in fuse that is a quick-blow or "fast-acting" fuse.

Type W fuses, shown above in a 20-Amp fuse, use no time-delay feature at all. Instead the fuse is designed to blow very quickly if there is an over-current on the electrical circuit the fuse is intended to protect.

A fast-acting or quick-blow fuse can open the electrical circuit in as little as 0.004 seconds if the fuse is exposed to a short circuit.

If you look into the window of a Type W fuse you'll see that the copper strip inside the fuse has a very narrow section (outlined in yellow in my photo) that will heat up and melt rapidly when an over-current occurs.

Type W fuses belong on lighting circuits, receptacle circuits, and on other electrical circuits that do not feed high-current electric motors, air conditioners, or water pump motors.

Cartridge Type Fuses

Cartridge fuses are available in an enormous range of ampacities but in a residential fuse panel the cartridge fuses in use will usually be a higher amperage rating than most of the plug fuses in an electrical fuse panel, and are usually used in (and replaced in) pairs to protect a higher-current 240-Volt circuit.

The amps rating of a cartridge fuse will be printed on the fuse label and will also be determined by the fuse diameter.

Watch out: I've made all of these cartridge fuse images the same size. In reality each fuse will be quite different in physical dimensions. Higher-ampacity fuses will be larger in size than smaller amp-rated cartridge fuses.

Notice that cartridge fuses are provided in two different designs: a round-end fuse that clips into receiving half-round clips in the fuse panel and copper spade-tipped fuses like the 70-A Eaton cartridge fuse shown above. In some fuse designs the copper tip can be removed depending on the panel into which it is to be inserted.

In my photo above of this horrible, badly rusted fuse panel, the two bakelite fuse blocks are printed in white indicating MAIN LIGHTS and MAIN RANGE.

The cartridge fuse diameter will in most cases prevent you from inserting an over-sized fuse into the fuse clip.

Notes to the table above

Cartridge Fuse Type Notes

CDN Type D / PON Type P cartridge fuses are Canadian CSA certified for applications where the potential short circuit current is relatively low.

FRN-R & FRS-R cartridge fuses are heavy duty time delay fuses used for motor protection while providing a time delay that avoids blowing the fuse during the brief period of high current draw while a motor is starting.

Dual-element cartridge fuses include a fast-blow feature that opens the circuit as quickly as 0.004 seconds when the fuse is exposed to a short circuit.

NON & NOS type cartridge fuses are general purpose fast-blow fuses used in lighting circuits, main panel protection, and for circuits that do not include large electric motors or inductive loads. 1 to 60A NON / NOS are UL listed as Class K5 - IR: 50kA, while 70A-600A fuses are UL listed as Class H - IR: 10kA.

PON Type P are one-time fuses sold in the 16-60A range

Midge Cartridge Fuses are small sized (1 1/2" long x 13/32" in diameter) sold in a range of amps and volts ratings, typically used as supplemental protection in sub panels protecting heating or air conditioning equipment. Midget cartridge fuses include the following

Midget Class CC - rejection versions used for both branch circuit wiring and supplemental device protection

Midget FNM time delay cartridge fuses

Midget FNQ time delay fuses

Midget KTK fast acting (quick blow) cartridge fuses

Midget G Class SC Fast-acting rejecting fuses, 1/2A to 6A SC - rejecting designs prevent installing a fuse size larger (in Amps) than the circuit should use.

Midget G Class SC Rejecting Fuses, Time Delay combinations used in residential, mobile home, & industrial applications, available from 7A to 60A in capacity.

Step-4 Remove & Replace the Blown Fuse

Step 4-a: Replacing a Blown Plug Fuse

Choose a matching replacement fuse of the same type and ampacity.

Un-screw the plug fuse by turning it counter-clockwise ("lefty-loosie" as my daughter Mara says).

Screw in the replacement fuse by turning it in clockwise ("rightie-tightie").

Step 4-b: Replacing a Blown or Faulty Cartridge Fuse

Pull the Main Fuse?

Pull the Main Fuse?

Should you ever pull the main fuse or switch off the main circuit breaker in the electrical panel?

Really? Absolutely: in an emergency if you suspect that an electrical fire is at risk or if someone is being shocked, don't waste time trying to guess which circuit is at fault. In my OPINION it is safe to simply and quickly turn off ALL electrical power.

I recognize that this may be inconvenient (in the dark let's hope you grabbed a flashlight) but I prefer inconvenience to a building fire or an electrocution.

Special hazards are faced when pulling a main fuse block (or any fuse block) even though this is a device intended for emergency use by a homeowner.

Using the fuse block handle, pull the fuse block straight out of the fuse panel.

Watch out: if the cartridge fuses are not removed by pulling out a fuse block like the ones in our photo above, you'll need to use an insulated cartridge pulling tool, usually a plastic clip, to remove the cartridge fuse.

Do not try to grab the fuse directly with your fingers because you may touch live electrical contacts - the shock could kill you.

Using a fuse puller to remove individual cartridge fuses: if there is not a fuse puller already at hand near your fuse panel, stop by your local hardware store or electrical supplier and buy one now, before the emergency.

Shown here: a Cooper Bussman cartridge fuse puller, BP-FP-2 shown here sells for about $10. U.S. There are many other similar cartridge-fuse pulling tools of varying designs, all made of non-conductive materials to help prevent electric shock (or worse).

Shown here: a Cooper Bussman cartridge fuse puller, BP-FP-2 shown here sells for about $10. U.S. There are many other similar cartridge-fuse pulling tools of varying designs, all made of non-conductive materials to help prevent electric shock (or worse).

The new replacement cartridge fuse is pushed into the spring clips that held the two ends of the fuse that was removed.

Replace the fuse block by taking care to align it properly and push it back in.

Watch out: take care to push the fuse block squarely into its opening or it may not seat and the electrical system could be unsafe or fail to provide power.

Some fuse blocks have an ON-OFF position. In the "OFF" position the block will re-insert into its opening very easily - and without making any electrical contact. Insert such fuse blocks with the letters "ON" facing up or towards the pointer arrow molded into the fuse panel receiver.

What Could Go Wrong When Pulling a Fuse Block?

At one inspection the author pulled the main fuse block in a 60-Amp panel, only to have the pullout block disintegrate in his hand.

The failure left one fuse in place and one half out of the panel.

A new panel was needed as the service and equipment were obsolete, not because the fuse pullout needed replacement. But we pose that it may be difficult to find a replacement fuse pull-out for some older fuse panels.

If I had not pulled the fuse shown at lower right in this photo, something interesting would have been missed.

Is that smaller fuse unsafe? No, installing a smaller fuse means that the overcurrent device will open the circuit under less current flow.

What about the other wiring in the panel? There is an unsafe open splice at the right side of the panel.

Are some of the edison-base fuses oversized? Can't tell for sure from the photo. In older fuse panels people are too often tempted to get around a frequent problem with blown fuses by installing an over-sized fuse - this is an unsafe action and is a fire hazard. Be sure that fuses in the panel are matched properly to the wire size.

Step 5 Watch What Happens After Replacing a Fuse

Watch out: if the new fuse blows again then there is an unsafe condition on the electrical circuit.

In that case do not keep replacing fuses. Doing so risks a building fire, property loss, injury or worse.

Leave the circuit off.

If there are multiple appliances connected to the circuit whose fuse is blowing, unplug everything on the circuit.

Look for signs of overheating or damaged equipment such as frayed power cords, discolored or melted wall plugs, burning odors

Leave such equipment un-plugged until it has been repaired

Try replacing the fuse again.

Watch out: if the fuse for a circuit blows when nothing is connected to it the problem is in the wiring of the circuit itself. The circuit is unsafe and should be left off. Call a licensed electrician for repair assistance.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: Can a type TL 30 amp Edison fuse be used in place of a type W 30 amp Edison fuse?

2021/01/25 Jeff said:

2021/01/25 Jeff said:

Can a type TL 30 amp Edison fuse be used in place of a type W 30 amp Edison fuse

Moderator reply:

Jeff

Yes but: I include a warning below.

A type TL screw-in fuse is one made to delay blowing immediately on sensing an overcurrent.

A Type W screw in fuse is made to blow very quickly on sensing an overccurrent.

Both fuses will protect the electrical circuit they are powering.

From a fire protection sense, a fast-blowing fuse is always "safer" - but if your circuit is powering certain equipment causes a **normal** high but brief current surge at start-up, such as an air-conditioning compressor, then you may find that using a Type W fuse results in nuisance fuse-blowing.

On 2020-03-22 - by (mod) - If the circuit breakers keep tripping

Moma

Moma

If the circuit breakers keep tripping then we know that the fault is not the breaker but rather the circuit: it is either overloaded or short circuited and is unsafe and should be left off until the wire, wire connections, or most-likely, the heater itself is repaired.

On an electric water heater, one of the failures that can occur is a burnt-up and short circuited heater element.

Details are at ELECTRIC WATER HEATER REPAIR GUIDE https://inspectapedia.com/plumbing/Electric_Water_Heater_Repair.php

On 2020-03-22 by Moma

My fuse keeps tripping and both are connected to my (old) water heater (14B & 16A) . I’ve already replaced them both once with 2 singles and then again with a double .

Still keeps flipping onto mid - So now I’ve flipped it off -

Any suggestions??

On 2020-03-15 - by (mod) - how to determine the correct size or rating for your fuses

John

You can determine the correct size or rating for your fuses by noting the wire size of the circuit it is protecting. For example a number 14 copper wire would be requiring a 15 amp fuse. In the article index you will find other articles in this series on wire sizes versus ampacity.

On 2020-03-15 by John

S-Type Fuse Identification

Hi. I have an S-type fuse that is operable, but have no spares. Markings are completely unreadable. I'd like to obtain a replacement. Any way I can determine it's rating/specifications so I buy one that will fit? Thanks.

On 2019-07-15 - by (mod) - a fuse panel cover is needed

Yes a cover is required and would have been present at the original installation.

Yes a cover is required and would have been present at the original installation.

It appears to me that the cover is still there and that it has been latched into the up and open position.

On 2019-07-15 by Anonymous

Is a dead front cover required for this cartridge type fuse box like it is required for panel with circuit breakers. I tend to think that as they are old that is they way they were installed without one. I would assume that they expect anyone opening this would pull the main switch to turn off the power before tampering with the panel. . It's difficult to get a clear answer on this but it you know I would appreciate your insight. Thanks

On 2019-02-16 - by (mod) - repair damaged fuse base

It would be helpful to see a sharp photo of the conditions about which you are asking. But I suspect that it's quite likely that a licensed electrician could repair the fuse socket that you described using standard readily available Hardware.

On 2019-02-15 by john

If the screw in base for the fuse becomes damaged how do you replace it and where do yoy find a replacement part?

On 2018-12-25 - by (mod) - take care not to cause a fire: do not over-fuse

Kevin

In a residential fuser panel the screw-in type edison base fuses are intended to be able to be safely replaced by the homeowner by un-screwing the blown fuse and screwing in a replacement OF THE SAME VALUE

That is if the blown fuse is 15 Amp replace it with a 15 Amp fuse. Never install a higher amp fuse as the risk is an electrical fire.

Cartridge type fuses can also be replaced by the homeowner when the fuse is is in a pullout block. The block is removed from the panel by its handle, the cartridge pulled out and replaced.

Other cartridge type fuses that are not in a carrier that is removed from the panel must be pulled and replaced using a special non-conductive plastic fuse puller.

Watch out: never put your fingers, hands, or a tool inside the fuse panel - touching an electrical contact can kill you.

On 2018-12-25 by Kevin

Can I fix the blown fuse?

...

Continue reading at CIRCUIT BREAKER MAIN or FUSE TEST or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BLOWN FUSE REPLACEMENT

- CIRCUIT BREAKER MAIN or FUSE TEST

- CIRCUIT BREAKER RESET STEPS

- ELECTRICAL CIRCUIT ID, MAP & LABEL - figure out which fuses protect which circuits and make a map or guide

- ELECTRICAL PANEL INSPECTION SAFETY

- ELECTRICAL INSPECTOR SAFETY PROCEDURES - important basic safety procedures, clothing, and equipment for home inspectors and electrical inspectors

- ELECTRICAL TOOLS BASIC

- ELECTRICITY TURN ON AFTER BREAKER TRIP

- GUIDE to ELECTRICAL TEST EQUIPMENT - neon tester to check for live voltage, continuity tester to check for bad cartridge fuses

- OLD HOUSE ELECTRICAL SYSTEMS

- SAFETY for ELECTRICAL INSPECTORS - home

Suggested citation for this web page

BLOWN FUSE REPLACEMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about how to inspect main fuses and main circuit breakers.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Jim Simmons: Personal communication, J. Simmons to Daniel Friedman, 9/19/2008. Photographs contributed to this website by Jim P. Simmons, Licensed Electrician, 360-705-4225 Mr. Electric, Licensed Master Electrician, Olympia, Washington Contact Jim P. Simmons, Licensed Master Electrician, Mr. Electric, 1320 Dayton Street SE

Olympia, WA 98501, Ph 360-705-4225, Fx 360-705-0130 mrelectricwa@gmail.com - Kenneth Kruger: Original author of the sidebar on testing VOM DMM condition: Kenneth Kruger, R.A., P.E. AIA ASCE, is an ASHI Member and ASHI Director in Cambridge, MA. He provided basis for this article penned by DJ Friedman.

- "How to Use DMM's Safely," Leonard Ogden, CEE News, 888 Seventh Ave., New York, NY 10106, Dec 1990 p.10.

- Dr. Jess Aronstein, consulting engineer, Poughkeepsie NY, 1991 protune@aol.com

- Rex Cauldwell, master electrician and contributor to the Journal of Light ConstructionOn electrical topics

- New York State Central Hudson Gas and Electric Company, G&E/1-2/85 consumer safety pamphlet

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.