Brick Wall Damage Repair

Brick Wall Damage Repair

Repair Approaches for Bulged, Cracked, Loose, Spalled Brick Walls

- POST a QUESTION or COMMENT about the difference between a brick veneer wall & a structural brick wall & the significance of this difference when understanding cracks in brick buildings

Brick wall repair:

Brick wall repair methods for structural brick walls & brick veneer walls vary depending on the type of damage that is being addressed. Reinforcement or even reconstruction are required in cases of severe structural damage or unsafe buildings while other types of brick wall repair such as re-pointing or crack repair or lintel repair are often possible in-situ.

This article series explains types of damage to structural brick walls. We explain how to recognize, diagnose, & evaluate movement and cracks in brick walls and how to recognize brick wall bowing or bulging and cracking failures.

The article series includes identification of types of foundation cracks, crack patterns, differences in the meaning of cracks in brick structural walls or brick veneer walls and discusses cracks or movement as evidence of building movement.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Methods of Repair of Brick Walls on Buildings

Article Series Contents

Article Series Contents

- BRICK WALL REPAIR METHODS

- BRICK STRUCTURAL WALL REPAIRS

- BRICK VENEER WALL REPAIR METHODS including special repair connectors to secure a brick veneer

- BRICK VENEER WALL LEAKS in FLOOD PRONE AREAS - separate article

- BRICK VENEER WALL REPAIRS in FLOOD PRONE AREAS - separate article

- BRICK WALL TUCKPOINTING & RE-POINTING

- BRICK WALL LEAK REPAIRS - separate article

In our photo of an antique building in Hudson, NY (at left) those three "stars" shown above the three windows of the second floor are probably functioning as giant "washers" securing a front-to-back anchor that secures the front wall of this structure against bulging or movement, possibly also securing the floor structure inside as you can see in the sketch at left.

[Click to enlarge any image]

This article describing repair approaches for damaged brick walls is a companion

to BRICK VENEER WALL DAMAGE ASSESSMENT - that you should review if your brick veneer wall is cracked, leaning, falling, or broken

Note: The different Types of brick wall damage, notes on distinguishing between brick structural & veneer walls, & brick wall damage assessment: bulges, bowing, cracking, construction methods, support, spalling, effloresence, etc. are addressed beginning

at BRICK FOUNDATIONS & WALLS - home

Repairs / Reinforcement of Structural Brick Walls: Connectors, Special Fasteners

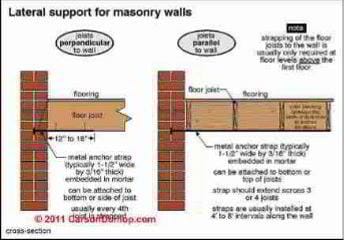

The drawing at below left, from Carson Dunlop Associates, shows how a structural brick wall may be reinforced laterally using a steel tie rod.

For repair of deteriorated brick wall mortar joints

see TUCKPOINTING BRICK & RE-POINTING

For detection & evaluation of thermal cracking or expansion cracks in brick walls of any type

see BRICK WALL THERMAL EXPANSION CRACKS which includes brick veneers and types of veneer damage.

Structural Brick Wall Ties & Rods Secure Walls Against Bulge, Lean, Collapse

Above: This brick building, located in Wappingers Falls, New York, illustrates structural connectors fastened through the building's side walls.

To stabilize and secure structural brick walls against leaning and bulging outwards, common for centuries has been the addition of exterior plates fastened through a brick wall and connected either to the building's interior frame or to the opposite wall (by a steel rod or bar).

Partial Re-Constrution of Structural Brick Walls

When the owners wanted the roof raised to gain habitable space over the rear wing of their home, the author [DF] needed to re-build the brick gable end of this historic structure, the Seneca Howland house located in Pleasant Valley, New York.

When improvement or repair to an existing brick structure is limited in scope it can be resonable and economical to re-build that wall section; had this wall re-construction project not been at the very top of the structure we'd have needed to add temporary support for any overhead brick structure, and engineering advice may have been required.

Also see SENECA HOWLAND HOUSE - links to various photos of this home as they appear at InspectApedia.com

Below: repairs to the brick walls at windows of this home in Beacon Hill, Boston, are common in a neighborhood of brick structures built upon unstable soil or settling soils along steep streets.

Below: extensive structural damage and repairs to a brick building in Brooklyn, New York confirm that at least for some valuable buildings these costly repairs were justified.

One would not undertake these extensive repairs without first having diagnosed the cause of building settlement and damage and without also having taken steps to stabilize the structure against further movement.

Re-Pointing or Tuckpointing Brick Walls

Brick walls that have lost mortar from the joints between bricks or brick courses may be repaired by re-pointing or "tuck pointing", a procedure that cleans and then replaces mortar that has been lost from joints.

Our photo of a tuck-pointed structural brick wall (left) shows by the colored mortar that the mason attempted to match the color of older mortar in the wall.

The repairs done at below right look good.

But a different tuck pointing repair job (in the upper left portion of the photo where we are pointing to a damaged brick) has not fared as well, possibly due to a poor mortar choice and frost damage.

Definition of Tuck Pointing:

Tuck pointing is the filling in with fresh mortar of cut-out or defective mortar joints; in masonry this refers to the filling of joints in old (or damaged) masonry with fresh mortar. - Masonry Design Manual.

Tuck pointing, which may be performed on both structural and veneer brick walls (as well as on other types of masonry) is performed for several reasons

- To stabilize the brick foundation

or wall against movement. Our photo (left shows severe water and frost damage to the corner of a brick building, probably from roof spillage at the end of a gutter that was periodically clogged.

To stabilize these bricks against further movement and possibly more serious foundation damage, a mason would probably repair the corner using a combination of reconstruction of the most-loose (or missing) bricks, and tuck pointing the remaining open mortar joints. - To stop water entry

- For cosmetic reasons

Tips for Pointing, Tuck Pointing, or Re-Pointing Brick or other Masonry Walls

at left we show a bad brick wall repair, tuckpointed using a too-hard mortar mix for a loose brick mortar joint repair that also is not matched in the slightest to the original wall's mortar joint color, texture, nor tooling. This expedient repair invites further frost damage to the wall as well as to the brick surface.

at left we show a bad brick wall repair, tuckpointed using a too-hard mortar mix for a loose brick mortar joint repair that also is not matched in the slightest to the original wall's mortar joint color, texture, nor tooling. This expedient repair invites further frost damage to the wall as well as to the brick surface.

More photos of this wall are

at BRICK WALL FROST & WATER CRACKS, EFFLORESCENCE, SPALLING and

also

This wall was ultimately re-built over a substantial area damaged by water and frost.

So what is "tuckpointing"?

Working with a long narrow trowel whose width and shape are chosen to match the existing mortar joints, the mason first cleans the existing mortar joints of loose mortar and debris, then pushes fresh mortar into the open joints.

The mortar joint in the tuck pointed wall should tooled to match the existing mortar joints, and any mortar that has spilled onto the brick faces themselves should be cleaned before the new joints have fully hardened.

When I [DF] have done tuckpointing or re-pointing of brick walls I prepared (thanks to advice from Eddie Kondysar, a real mason) mortar of the proper color, texture, and hardness to closely-match the original building mortar.

After cleaning the very soft mortar from the bad brick joints I held my mud hawk against the wall surface at the bottom of the mortar joint and used the pointing trowel to push mortar into the joint, getting as little mortar as possible on the face of the bricks.

When the joint was filled to a proper depth I tooled the joint (flat, concave, angled in at the top of the joint, or special tooled or lined) using a trowel that matched the profile of the original brickwork.

When the mortar was set if there was a mess of mortar on the brick faces I used a bit of muriatic acid to clean the brick to leave a beautiful job.

Watch out: working with muriatic acid is dangerous and can burn you or put out your eyes. Use appropriate protective gear.

The most common errors we see in brick wall tuckpointing include

- Use of the wrong mortar for tuck pointing brick wall repairs

- Mortar that is not matched closely in original color

makes for a wall that is cosmetically unattractive. In our photo of a tuck-pointed brick wall (Wappingers Falls, New York) shows the effects of using a too-white mortar to "repair" the gable end wall of this home. - Mortar that is not properly matched in hardness

can cause serious spalling damage to a brick wall, especially in freezing climates. When the new mortar is too hard and too waterproof in comparison with the surrounding brick, moisture that penetrates the brick wall remains trapped behind the harder mortar.

In freezing weather the expanding strength of ice pops off surfaces of the softer bricks, damaging the wall further. - Using caulk or sealant where mortar should be applied:

when you apply a caulk or sealant to a brick or standstone (and some other stone) surface most likely you'll find that weathering of the softer stone, brownstone, or sandstone surface will cause the edges of the sealant or caulk to open up and pull away from the building surface.

See CAULKS & SEALANTS, EXTERIOR but use a properly-formulated mortar not caulk when re-pointing is needed on brick.

- Mortar that is not matched closely in original color

- Failure to adequately clean the brick faces

after new mortar is installed, leaving a "smear" of mortar on the brick surfaces - a cosmetic defect - Failure to clean the brick joints

before tuck pointing, resulting in short life for the tuckpointed "repair"

Methods of Repair of Brick Veneer Walls on Buildings

When a brick veneer wall's fasteners are found to be inadquate in original installation (by type, number, placement, or poor connection to the building's structure), or when a brick veneer wall is loose but deemed salvageable, there are special retrofit connectors that can be installed to secure the veneer to the building.

When a brick veneer wall's fasteners are found to be inadquate in original installation (by type, number, placement, or poor connection to the building's structure), or when a brick veneer wall is loose but deemed salvageable, there are special retrofit connectors that can be installed to secure the veneer to the building.

Typically the retrofit brick veneer connector is installed through holes drilled in the mortar joints, connected to the structure, and the hole repaired or sealed.

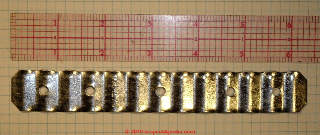

Shown here: the traditional and exquisitely-simple brick veneer wall tie: a corrugated galvanized steel strap that is nailed to the building's structural wall and bent outwards at a 90-degree angle to place the tie's strap into successive mortar joints as the veneer wall is built.

Metal wall ties such as the one shown have been used in the construction of load-bearing masonry walls in England and in North America since the 1850s.

These metal wall ties, used in brick and stone masonry wall construction served three purposes. All improvements and modifications to this very simple original wall tie must meet all of these objectives (and perhaps others).

- To provide a strong structural connection

between the brick veneer and the struture - thus avoiding a precarious wall and its collapse - To accommodate movement and differences in movement

between the masonry or brick veneer and the structure to which it is attached; such movements occur due to changes in temperature and humdity in different building materials. If such movement is not accomodated the veneer wall will simply break away from the structure to which it is attached. - To transfer lateral loads

between the veneer wall and its supporting structure.

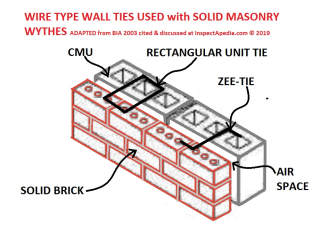

Besides the flat corrugated metal wall tie shown here, the two most-common other unit ties used in masonry construction were a rectangular tie and a "Z" shaped tie shown below.

Corrugated ties are typically used in low-rise, residential veneer over wood frame construction and are not recommended for construction incorporating brick veneer over steel studs, masonry-backed cavity walls, multi-wythe walls or grouted masonry walls. (BIA 2003)

Repair of Brick Veneer Walls

Brick veneer walls that are not so loose, damaged, dangerous as to prohibit repair, can be secured to the structure using a variety of wall ties described here.

The brick veneer wall shown in our photos (below) was rebuilt after a partial collapse. You can see some of the original veneer bricks on the ground.

...

...

- Add fasteners for a brick veneer wall that is loose:

Other loose brick veneer walls that are not bulged or badly damaged but are poorly supported on the building structure can sometimes be repaired using special fasteners (e.g. Fero Engineered Masonry Connectors cited below) that mount through mortar joints and connect to the building structure behind. - Brick veneer wall drainage repairs: a brick veneer wall that is not draining properly may be repairable by adding drainage openings or clearing blocked drain openings.

See BRICK WALL DRAINAGE WEEP HOLES - Re-construction

of all or part of the brick veneer wall: a brick veneer wall that is extensively damaged, bulged, loose and collapsing will probably need to be removed and rebuilt. - Thermal expansion cracks in brick veneer walls:

for detection & evaluation of thermal cracking or expansion cracks in brick walls of both structural & veneer design, also

see BRICK WALL THERMAL EXPANSION CRACKS which includes brick veneers and types of veneer damage.

Brick Wall Construction References, Repair Fasteners, Bolts, Wall Ties

Here we provide links to industry experts, research on brick wall and brick veneer wall construction and repair products including restoration ties & connectors for masonry wall or veneer repairs,

- Ambrico, American Brick Company, (Produces EZ-Wall® Engineered Thin Brick System), 12901 Stephens Road, Warren MI 48089Tel: 866-663-6898, Website: http://www.ambrico.com/ Email: info@ambrico.com

- ARF, ''Flexural Strength of Cavity Walls”, ARF Project B870, Armour Research Foundation, Chicago, Illinois, March 1963.

- Armour, ”Investigation of Masonry Wall Ties”, ARF Project B870-2 (Revised), Armour Research Foundation, Chicago, Illinois, December 1962

- Avongard FOUNDATION CRACK MONITOR PROGRESS CHART [PDF] for structural crack monitoring

Provides a worksheet that allows easy logging of dates and amounts of movement in a crack being monitored using the Avongard Crack Monitor slide. - Brown, R.H. and Elling, R.E., ''Lateral Load Distribution in Cavity Walls”, Proceedings of the Fifth International Brick Masonry Conference, Washington, D.C., October 1979.

- Bortz, S.A., “Investigation of Continuous Metal Ties as a Replacement for Brick Ties in Masonry Walls”, Summary Report ARF 6620, Armour Research Foundation, Chicago, Illinois, June 1960.

- Brick Development Association, The Building Centre, 26 Store Street, London, WC1E 7BT, England, U.K., Tel: 020 7323 7030, Website: http://www.brick.org.uk Email: brick@brick.org.uk

- Brick Industry Association, 1850 Centennial Park Drive, Suite 301, Reston, VA 20191

Phone: 703.620.0010 Fax: 703.620.3928. Website: http://www.gobrick.com/

WALL TIES for BRICK MASONRY [PDF] (2003) Brick Industry Association 1850 Centennial Park Drive, Reston, Virginia 20191 | www.gobrick.com | 703-620-0010 - this BIA technical note includes a brief history of the use of wall ties or anchors and fastners in brick masonry construction and describes the function and use of wall ties.

Excerpt:

The use of metal ties in brick masonry dates back to loadbearing masonry walls in the 1850's. Historically, the size, spacing and type of ties have been entirely empirical. Over time, ties of various sizes, configurations and adjustability have been developed for loadbearing masonry, cavity walls and brick veneer construction.

These ties are used to connect multiple wythes of masonry, often of different materials; anchor masonry veneer to backing systems other than masonry; and connect composite masonry walls. This Technical Notes addresses the selection, specification and installation of wall tie systems for use in brick masonry construction.

Information and recommendations are included which address tie configuration, detailing, specifications, structural performance and corrosion resistance.

THIN BRICK VENEER CONSTRUCTION [PDF] (2014) op. cit.

How to use thin brick in adhered veneer systems. Methods of thin brick construction discussed include thick set, thin set, modular panels, and prefabricated panels consisting of architectural precast concret, tilt-up concrete, and wood or steel stud frame panels. Properties of the finished constructionb and comparison to other systems are presented. - BRICK WALL DRAIN, FLASHING, VENT SOURCES [Web article] retrofit or new brick veneer wall drain systems

- Canada Masonry Centre, 360 Superior Blvd., Mississauga ON Canada L5T 2N7. Tel: (905) 564-6622. Offers the CMCA Textbook of Canadian Masonry. Website: http://www.canadamasonrycentre.com/

- Eschenasy, Dan, P.E., FACADE CONDITIONS, Illustrated Glossary of Visual Symptoms [PDF] Mr. Eschenasy is chief structural engineer for the New York CIty Department of Buildings. This excellent glossary is among the most-complete catalogs of masorny building damage visual inspection clues that we have found. Retrived 2019/10/11 original source: https://www1.nyc.gov/assets/buildings/images/content/misc/FacadePresentation.pdf

This is a presentation is described by its introduction:

This glossary is intended to be used only as an educational tool by those interested in visual inspections of facade conditions. The glossary does not include any guide as to the impact of the various listed conditions on the public safety or buildings’ structural stability.

Watch out: [Emphasis ours - Ed.] Such determination needs to be the result of the qualified inspector’s professional consideration based on a specific examination of the façade where all visual symptoms are assessed based on their location, prevalence and in their relationship to the façade system.

Such determination shall comply with all New York City Construction Code requirements and prescriptions. The visual symptoms listed in the Glossary refer to types of facades common in New York City high and mid rise buildings. The glossary is by no means exhaustive, but hopefully it describes most of the typical façade problems encountered in New York City.

As this manual refers to façade conditions only, the roofing conditions are not included, but one should note that their impact on the proper performance of the facade can be significant.

Following a visual inspection, the evaluation of a façade’s condition should take into account all of the visual distress symptoms, together with consideration of other building components as well as with the building’s structural, thermal insulation and HVAC systems and fire protection systems. In many cases the source of a façade defect cannot be established without probing.

While the glossary associates causes to symptoms, the reader needs to be aware that many other causes, or a combination thereof, can produce the types of distress presented. It remains the responsibility of the professional performing the inspection to provide the proper diagnosis. This glossary is the result of discussions with an ad-hoc round table of façade inspection professionals who contributed with some of the text, pictures and reviews.

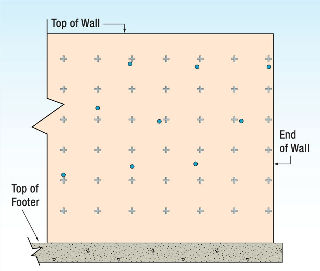

Below: Insufficient number of brick veneer wall ties led to the collapse of brick veneer walls as described by FEMA in the document cited below.

The first brick veneer wall tie illustration above notes that

What the FEMA document (below) does not detail is how long these improperly-constructed brick veneer walls stood before the veneer collapse and what exact loading conditions precipitated the collapse: presumably wind loading, wind-blown rain, or other stresses that occurred either over time or as a single event. The document describes the wall ties at a house under construction in Ocean Springs Mississippi observed after Hurricane Katrina.

Important was the FEMA inspectors' observation that the wall included only nine masoanry ties (the blue dots) while to comply with required standards 42 such ties (the + marks) would have been required. |

The second illustration of a home where a brick veneer wall collapsed is in the same document and was originally reported in the 2007 report FEMA 549 Hurricane Katrina cited just below.

- FEMA, EXTERIOR CLADDING COMPONENTS AND BEST PRACTICES [PDF] U.S. FEMA, Federal Emergency Management Association, retrieved 2019/10/11 original source: https://www.fema.gov/media-library-data/20130726-1707-25045-0913/chapter9.pdf

Excerpt: Brick Veneer.

The current masonry code referenced in the IBC and IRC is ACI 530-08/ASCE 5- 08/TMS 402-08, 2008 Building Code Requirements for Masonry Structures. This code provides both prescriptive and performance-based requirements. Brick-veneer construction in residential applications tends to follow prescriptive requirements.

Brick veneer is addressed by the IRC with prescriptive minimum requirements for sizing and spacing of masonry ties. In high-wind areas (where more than 30 pounds per square foot of pressure is applied to the brick), each tie is not permitted to support more than 2 square feet of wall area.

The ICC-600 provides design requirements that vary with design wind speed. At greater speeds, ties are required to be designated as a percentage of the tributary area that would be used at lower wind speeds. Figures 9-10 and 9-11 illustrate how brick veneers failed during Hurricane Katrina, due to improper design and construction of the wall covering.

Appendix E of FEMA Hurricane Katrina Recovery Advisory (Attachment of Brick Veneer in High-Wind Regions) provides recommended practices for brick-veneer attachment. This advisory was based upon observations from hurricanes Ivan and Katrina. - FEMA, HURRICANE KATRINA in the GULF COAST (FEMA 549) [PDF] (July 2006) Mitigation Assessment Team Report, Building Performance Observations, Recommendations, and Technical Guidance, U.S. FEMA, op. cit., retrieved 2019/10/11 original source: https://www.fema.gov/media-library-data/20130726-1520-20490-4067/549_cvr_toc.pdf

Excerpt: The conclusions and recommendations of this Report are intended to provide decision-makers with information and technical guidance that can be used to reduce future hurricane damage. - Fero Engineered Masonry Connectors & Accessories, FERO Corporation, 15305 - 117th Ave., Edmonton, Alberta T5M 3X4

Canada, Tel: (780) 455-5098. Website: http://www.canadamasonrycentre.com/

Fero produces Fastj-Fero shelf angle supports for brick veneers, brick veneer fasteners, concrete block backup CMU block shear connectors, steel stud backup connectors, rubble veneer fasteners, thin stone veneer connectors, wood stud backup connectors fo rpoured concrete, and the FAST bracket.

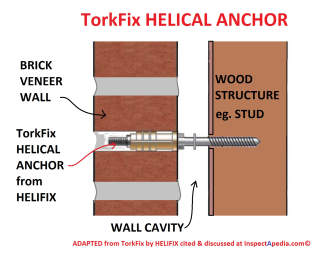

- Helifix, TorkFix RETROFIT MECHANICAL ANCHOR [PDF] Helifix, Division of Halfen USA Inc.

4965 Eisenhauer Rd, Suite 101

Windcrest, TX. 78218

Tel: 888-992-9989 Email: sales@helifix.comWebsite: https://www.helifix.com

In the U.K. Contact: Helix Fixings 102 Hillside Crescent, Cheshunt, Hertfordshire, EN8 8PJ 08082 813739 (uk) 011 44 8082 813739(usa) sales@helixfixings.co.uk

TorkFix anchors can connect a masonry veneer to structural members of structural types including masonry (brick-to-brick/concrete block/cmu), wood and steel. These anchors canalso be used to anchor veneer panels to structures.

Website excerpts:

TorkFix mechanical repair anchors are a well proven method of stabilizing masonry veneer walls which have become detached from the inner supporting structure due to wall tie failure or omission at the time of construction.

Suitable for tying masonry veneers to inner wythes of brick, concrete block, wood or steel stud, TorkFix retrofit anchors provide structural stability and resist wind pressure forces.

Brick to Wood Installation of a TorkFix anchor:

1. Drill a 7/16” hole through the outer wythe, either through the solid brick or mortar joint.

2. Screw the threaded end of Setting Tool 1 onto the outer end of the anchor, insert into the hole and screw the anchor into the wood stud to a minimum depth of 11/4“.

3. Fit hexagon of Setting Tool 2 over the end nut and turn until the outer shell has expanded and is tight. Apply the torque wrench to the end of Setting Tool 2 (1/4“ square) to check the torque (36-54lbf-ins). Make good the hole and seal the surface with color-matched mastic or mortar.

4. Fit Setting Tool 2 over the end nut and turn until the outer shell has expanded and is tight (36-54lbf-ins). Fit the torque wrench to the end of Setting Tool 2 (1/4“ square) and check the torque, as before. Make good the hole and seal the surface with color-matched mastic or mortar. - Installation now complete

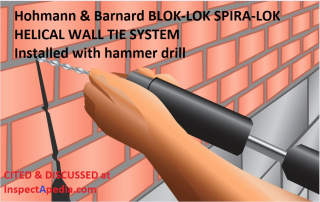

Above: Hohmann & Barnard's SPIRA-LOK helical wall tie system - a stainless steel wall tie installed into a pre-drilled pilot hole using a hammer drill.

- Hohmann & Barnard, SPIRA-LOK HELICAL WALL TIE SYSTEM [PDF] Hohmann & Barnard, 12 Ashbridge Circle

Woodbridge, Ontario L4L 3R5

Telephone: (905) 266-2277

Fax: (905) 266-2272

www.blok-lok.com

sales@blok-lok.com

U.S.A: 1-800-561-3026 retrieved 2019/10/11, original source:

Hohmann & Barnard, Inc, produces a huge range of strucural ties and anchors, including many other products for masonry repair and restoration, stone anchors, rebar ositioners, [Wing Nut 2-Seal™ Tie, wing nut veneer anchor seals air barriers], Offices in 8 U.S. cities, including H&B New York 30 Rasons Court, Hauppauge, NY 11788 (P) 631-234-0600, (F) 631-234-0683, Toll: 800-645-0616, Website: www.h-b.com - KPFF, WSCPA, DESIGN GUIDE for STRUCTURAL BRICK VENEER [PDF] (2004) KPFF Consulting Engineers, fdor Western States Clay Products Association, retrieved 2019/10/11 original source: https://www.interstatebrick.com/sites/default/files/library/design-guide-structural-brick-veneer-wscpa.pdf

- Mack, Roberty C., FAIA & John P. Speweik, REPOINTING MORTAR JOINTS IN HISTORIC MASONRY BUILDINGS [PDF] (1998) U.S. National Park Service, Technical Preservation Services, retrieved 2022/10/02 original source: https://www.nps.gov/tps/how-to-preserve/briefs/2-repoint-mortar-joints.htm

- Masonry Design Manual, [Book at Amazon] James E. Amrhein & Walter L. Dickey, Civil & Structural Engineers, Masonry Industry Advancement Committee, Masonry Institute of America, ASIN B0006XMFZE

Watch out: this manual may include opinions and recommendations that are obsolete or even very dangerous. For example p. I-4 expresses the opinion that "buckling is not a serious condition in masonry ..." contrary to the direct experience of masonry experts who report cases of catastrophic building collapses. - Masonry Design for Engineers and Architects , M. Hatzinikolas, Y. Korany, Canadian Masonry (2005), ISBN-10: 0978006100, ISBN-13: 978-0978006105

- Masonry Structures: Behavior and Design, [Book at Amazon] Robert G. Drysdale, Ahmid A. Hamid, Lawrie R. Baker, The Masonry Society; 2nd edition (1999), ISBN-10: 1929081014, ISBN-13: 978-1929081011

- Masonry, Engineered: Using the Canadian Code, [Book at Amazon] J. I. Gainville, Cantext publications (1983), ASIN: B0007C37PG

- Masonry, Non-reinforced masonry design tables, [Book at Amazon] Hans J. Schultz, National Concrete Producers Association and the Canadian Masonry Contractors Association (1976), ASIN: B0007C2LQM

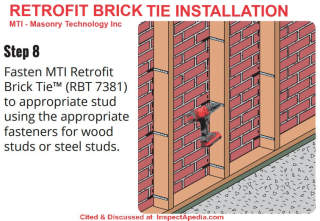

- MTI, RETROFIT BRICK TIE INSTALLATION GUIDE [PDF] [Illustrated above] Masonry Technology, Inc., PO Box 214

24235 Electric Street

Cresco, Iowa 52136 USA Tel: 1-800-879-3348 Email: info@mtidry.com Web: mtidry.com

Manufacturer's comment [from private email rec'd. 2023/09/05]

The Retrofit Brick Tie™ allows the brick veneer to be anchored to the stud framing from the interior. This system is designed to be used with MTI's Retrofit Weep™ system. The MTI Retrofit Brick Tie™ system is an inexpensive alternative solution for a restoration project.

Applications- The Reattachment of Common Brick Veneers to Existing Stud Backup Walls

- Residential Applications

- Commercial Applications

- Flood Damage

- Interior Fire Damage

- Historical Restoration

- All Brick Veneer Restoration Projects When the Removal and Replacement of the Brick Veneer is Not Feasible

These solutions will be reasonable options when existing brick veneer removal and replacement in a restoration project is not feasible. The Stainless Steel Retrofit Brick Tie™ allows the brick veneer to be anchored to the existing stud framing from the interior.

Illustrated in detail just below - Ed.

- Sanford Contracting, Inc., (produces thin masonry veneers and engineered brick panels), Sanford Contracting Inc., 1400 Iron Horse Industrial Park, North Billerica, Massachusetts 01862-1612, Tel: 978-663-0200 Web: http://www.sanfordcontracting.com/ Email: tsanford@SanfordContracting.com

- Tamlyn building products, Tom Tamlyn, President, 13623 Pike Rd., Stafford TX 77477, Tel: 800-334-1676. Web: http://www.tamlyn.com

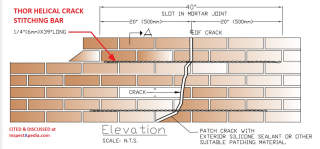

Above: Thor Helical's Wall Tie and Helical Crack Stitching Bar, excerpts from the company's documentation given below.

- Thor Helical USA, 340 West Passaic St.

Rochelle Park, NJ 07662

Tel:(201) 880-8819

Email:amelia@thorhelicalusa.comTel: 001-201-880-8819Website: https://thorhelicalusa.com - documents below retrieved 2019/10/11 from the company's website.

Thor Helical, provides a range of repair devices for masonry construction including strap ties, helical wall ties or pins, horizontal masonry reinforcing bars for crack stitching, and related products.

Thor STRAP TIES [PDF] documentation, Retrofit wall ties and lateral restraints for masonry.

Drawing for THOR STRAP TIES [PDF]

...

Thor HELICAL WALL TIES [PDF] documentation, used to replace damaged, corroded, or missing wall ties in cavity brick walls. Retrofit wall ties and lateral restraints for masonry

Drawing for Thor HELICAL WALL TIES [PDF]

...

Thor MASONRY REINFORCING BARS for Crack Stitching [PDF] documentation, Reinforcement bars and Grout for repair to stabilize cracked bricks, concrete blocks and other masonry construction.

Drawing for Thor Helical CRACK STITCHING BAR [PDF]

...

Drawing for Thor GROUT TIES [PDF]

Excerpt from the company's website:

Wall Ties are hammer-driven into small pilot holes the remedial ties corkscrew into brick, block and concrete to deliver a mechanical fix that grips the wall on each side of the cavity.

Unlike conventional ties having expanding mechanisms, that delivers point-loading when tightened to the substrate, the threaded interlock connection of the self-tapping helical wall tie exerts no expansive stress into the brickwork and will not loosen with vibration.

...

Continue reading at BRICK WALL LEAK REPAIRS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BRICK FOUNDATIONS & WALLS - home

- BRICK STRUCTURAL WALLS LOOSE, BULGED

- BRICK WALL THERMAL EXPANSION CRACKS

- BRICK WALL WOOD NAILER INSERTS

- BRICK VENEER WALL AIR LEAKS

- BRICK VENEER WALL DAMAGE ASSESSMENT

- BRICK VENEER WALL FLOOD DAMAGE REPAIR

- BRICK VENEER WALL FLOOD REPAIR CODES & STANDARDS

- BRICK VENEER WALL LEAKS in FLOOD PRONE AREAS

- BRICK VENEER WALL LOOSE, BULGED

- BRICK VENEER WALL REPAIRS in FLOOD PRONE AREAS

- BRICK WALL DRAINAGE WEEP HOLES - home

- BRICK WALL FROST & WATER CRACKS, EFFLORESCENCE, SPALLING

- BRICK WALL INSULATION RETROFIT

- BRICK WALL LEAK REPAIRS

- BRICK WALL REPAIR METHODS

- BRICK WALL THERMAL EXPANSION CRACKS

- BRICK WALL WOOD NAILER INSERTS

- CHIMNEY BRICK / BLOCK SPALLING

- CONCRETE or MASONRY DAMAGE TESTS

- MASONRY FACADE / WALL, LINTEL & BROWNSTONE DAMAGE

Suggested citation for this web page

BRICK WALL REPAIR METHODS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to Alan Carson, Carson Dunlop, Associates, Toronto, for technical critique and some of the foundation inspection photographs cited in these articles

- "Concrete Slab Finishes and the Use of the F-number System", Matthew Stuart, P.E., S.E., F.ASCE, online course at www.pdhonline.org/courses/s130/s130.htm

- Sal Alfano - Editor, Journal of Light Construction*

- Terry Carson - ASHI

- Mark Cramer - ASHI

- JD Grewell, ASHI

- Duncan Hannay - ASHI, P.E. *

- Bob Klewitz, M.S.C.E., P.E. - ASHI

- Ken Kruger, P.E., AIA - ASHI

- Aaron Kuertz aaronk@appliedtechnologies.com, with Applied Technologies regarding polyurethane foam sealant as other foundation crack repair product - 05/30/2007

- Bob Peterson, Magnum Piering - 800-771-7437 - FL*

- Arlene Puentes, ASHI, October Home Inspections - (845) 216-7833 - Kingston NY

- Greg Robi, Magnum Piering - 800-822-7437 - National*

- Dave Rathbun, P.E. - Geotech Engineering - 904-622-2424 FL*

- Ed Seaquist, P.E., SIE Assoc. - 301-269-1450 - National

- Dave Wickersheimer, P.E. R.A. - IL, professor, school of structures division, UIUC - University of Illinois at Urbana-Champaign School of Architecture. Professor Wickersheimer specializes in structural failure investigation and repair for wood and masonry construction. * Mr. Wickersheimer's engineering consulting service can be contacted at HDC Wickersheimer Engineering Services. (3/2010)

- *These reviewers have not returned comment 6/95

- Masonry structures: The Masonry House, Home Inspection of a Masonry Building & Systems, Stephen Showalter (director, actor), DVD, Quoting:

Movie Guide Experienced home inspectors and new home inspectors alike are sure to learn invaluable tips in this release designed to take viewers step-by-step through the home inspection process. In addition to being the former president of the National Association of Home Inspectors (NAHI), a longstanding member of the NAHI, the American Society of Home Inspectors (ASHI), and the Environmental Standard Organization (IESO), host Stephen Showalter has performed over 8000 building inspections - including environmental assessments. Now, the founder of a national home inspection school and inspection training curriculum shares his extensive experience in the inspection industry with everyday viewers looking to learn more about the process of evaluating homes. Topics covered in this release include: evaluation of masonry walls; detection of spalling from rebar failure; inspection of air conditioning systems; grounds and landscaping; electric systems and panel; plumbing supply and distribution; plumbing fixtures; electric furnaces; appliances; evaluation of electric water heaters; and safety techniques. Jason Buchanan --Jason Buchanan, All Movie Review - Building Failures, Diagnosis & Avoidance, 2d Ed., W.H. Ransom, E.& F. Spon, New York, 1987 ISBN 0-419-14270-3

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Diagnosing & Repairing House Structure Problems, Edgar O. Seaquist, McGraw Hill, 1980 ISBN 0-07-056013-7 (obsolete, incomplete, missing most diagnosis steps, but very good reading; out of print but used copies are available at Amazon.com, and reprints are available from some inspection tool suppliers). Ed Seaquist was among the first speakers invited to a series of educational conferences organized by D Friedman for ASHI, the American Society of Home Inspectors, where the topic of inspecting the in-service condition of building structures was first addressed.

- Domestic Building Surveys, Andrew R. Williams, Kindle book, Amazon.com

- Defects and Deterioration in Buildings: A Practical Guide to the Science and Technology of Material Failure, Barry Richardson, Spon Press; 2d Ed (2001), ISBN-10: 041925210X, ISBN-13: 978-0419252108. Quoting:

A professional reference designed to assist surveyors, engineers, architects and contractors in diagnosing existing problems and avoiding them in new buildings. Fully revised and updated, this edition, in new clearer format, covers developments in building defects, and problems such as sick building syndrome. Well liked for its mixture of theory and practice the new edition will complement Hinks and Cook's student textbook on defects at the practitioner level. - Guide to Domestic Building Surveys, Jack Bower, Butterworth Architecture, London, 1988, ISBN 0-408-50000 X

- "Avoiding Foundation Failures," Robert Marshall, Journal of Light Construction, July, 1996 (Highly recommend this article-DF)

- "A Foundation for Unstable Soils," Harris Hyman, P.E., Journal of Light Construction, May 1995

- "Backfilling Basics," Buck Bartley, Journal of Light Construction, October 1994

- Historic Preservation Technology: A Primer, Robert A. Young, Wiley (March 21, 2008) ISBN-10: 0471788368 ISBN-13: 978-0471788362

- Masonry structures: The Masonry House, Home Inspection of a Masonry Building & Systems, Stephen Showalter (director, actor), DVD, Quoting:

Movie Guide Experienced home inspectors and new home inspectors alike are sure to learn invaluable tips in this release designed to take viewers step-by-step through the home inspection process. In addition to being the former president of the National Association of Home Inspectors (NAHI), a longstanding member of the NAHI, the American Society of Home Inspectors (ASHI), and the Environmental Standard Organization (IESO), host Stephen Showalter has performed over 8000 building inspections - including environmental assessments.

Now, the founder of a national home inspection school and inspection training curriculum shares his extensive experience in the inspection industry with everyday viewers looking to learn more about the process of evaluating homes. Topics covered in this release include: evaluation of masonry walls; detection of spalling from rebar failure; inspection of air conditioning systems; grounds and landscaping; electric systems and panel; plumbi ng supply and distribution; plumbing fixtures; electric furnaces; appliances; evaluation of electric water heaters; and safety techniques. Jason Buchanan --Jason Buchanan, All Movie Review - MOISTURE CONTROL in WALLS [PDF] U.S. Department of Energy

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.