Fireplace & Hearth

Fireplace & Hearth

Rumford Fireplace Design Specifications, Fireplace Safety Inspections

Fireplace construction & repair

- POST a QUESTION or COMMENT about inspecting, diagnosing, & repairing fireplace damage from settlement, cracks, masonry movement

Fireplaces & hearths, construction, inspection and repair:

This article series provides information about masonry fireplaces, including inspection for damage/hazards (cracks and gaps that appear at masonry fireplaces due to chimney or fireplace settlement or movement), fireplace chimney sizing requirements, draft problems, chimney safety, creosote problems, inserts, and other topics.

Fireplace damage from chimney or fireplace settlement or movement may be a fire or gas hazard in a building Fireplace hearth size specifications; How to add support below a settling fireplace hearth.

Fireplace damper inspection, diagnosis, repair or replacement. Photo examples of cracks in on and around masonry fireplaces and a guide to their cause and remedy. Masonry fireplace chimney & flue size requirements & hearth dimension codes.

Our page top photo shows a lovely fireplace in a Church Hill restaurant on Stewart Island, New Zealand.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Masonry Fireplace Specifications, Safety Hazards, Recommendations

Article Series Contents

- FIREPLACE DESIGN SPECIFICATIONS, MASONRY

- FIREPLACE DAMPER DEFECTS, REPAIRS - separate article

- FIREPLACE FLUE SIZE SPECIFICATIONS - separate article

- FIREPLACE HEARTH DIMENSIONS & SUPPORT - separate article

- FIREPLACE DAMAGE & UNSAFE HEARTHS - separate article

- RUMFORD FIREPLACE DESIGN RULES

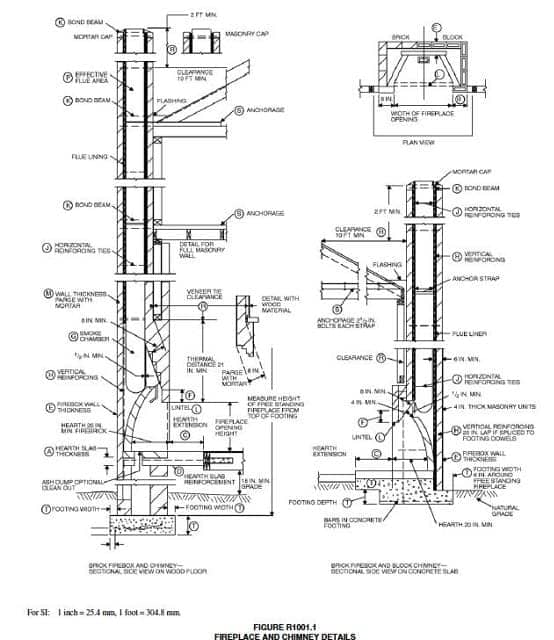

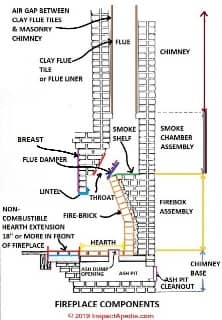

Our sketch shows the principal components of and terms used to describe a traditional masonry fireplace.

[Click to enlarge any image]

Fireplace Design Specifications Summary

Table R1001.1 |

|||

| Fireplace Component / Item | Illustration Key |

Requirements | Comments |

| Hearth slab thickness | A | 4" | |

| Hearth extension (each side of opening) |

B | 8″ fireplace opening < 6 square foot. 12″ fireplace opening ≥ 6 square foot. |

FIREPLACE HEARTH DIMENSIONS & SUPPORT |

| Hearth extension (front of opening) |

C | 16″ fireplace opening < 6 square foot. 20″ fireplace opening ≥ 6 square foot. |

|

| Hearth slab reinforcing | D | Reinforced to carry its own weight and all imposed loads. | FIREPLACE SAFETY: CRACKS, SETTLEMENT |

| Thickness of wall of firebox | E | 10″ solid brick or 8″ where a firebrick lining is used. Joints in firebrick 1/4″ maximum. |

|

| Distance from top of opening to throat | F | 8" | |

| Smoke chamber wall thickness Unlined walls |

G | 6" 8" |

|

| Chimney Vertical reinforcing b |

H | Four No. 4 full-length bars for chimney up to 40″ wide. Add two

No. 4 bars for each additional 40″ or fraction of width or each |

b. Not required in Seismic Design Category A, B or C. |

| Horizontal reinforcing | J | 1/4″ ties at 18″ and two ties at each bend in vertical steel. | CHIMNEY CRACK DETECTION & DIAGNOSIS |

| Bond beams | K | Not specified. | |

| Fireplace lintel | L | Noncombustible material. | |

| Chimney walls with flue lining | M | Solid masonry units or hollow masonry units grouted solid with at least 4 inch nominal thickness. |

UNLINED FLUE INSPECTIONS |

| Distances between adjacent flues | - | See Section R1003.13. | FLUE SEPARATION REQUIREMENTS |

| Effective flue area (based on area of fireplace opening) | P | See Section R1003.15. | FIREPLACE FLUE SIZE vs OPENING DIMENSIONS |

| Clearances: Combustible material Mantel and trim Above roof |

R | See Sections R1001.11 and R1003.18. See Section R1001.11, Exception 4. |

CHIMNEY CLEARANCE & CONDITION SAFETY |

| Anchorage b Strap Number Embedment into chimney Fasten to Bolts |

S | 3/16″ × 1″ Two

12″ hooked around outer bar with 6″ extension. 4 joists |

b. Not required in Seismic Design Category A, B or C. |

| Footing Thickness Width |

T | 12″ min. 6″ each side of fireplace wall. |

Note that these are minimums. Soil conditions in some areas may require larger footings. |

Additional Recommendations [not in the ICC code notes - Ed.]: Chimney Flue Size Requirements Combustion air requirements Fireplace damper inspection & operation |

|

||

Notes to the fireplace design table above

Source: 2006 Virginia Residential Code that in turn excerpts from the 2006 ICC, Chapter 10, Chimneys and Fireplaces, Section R1001 Masonry Fireplaces, retrieved 2016/07/13, original source: http://www2.iccsafe.org/states/virginia/

Residential/PDFs/Chapter%2010_Chimneys%20and%20Fireplaces.pdf

See also RUMFORD FIREPLACE DESIGN RULES

For SI: 1 inch = 25.4 mm, 1 foot = 304.8 mm, 1 square foot = 0.0929m2.

This table provides a summary of major requirements for the construction of masonry chimneys and fireplaces.

Letter references are to Figure R1001.1, which shows examples of typical construction.

This table does not cover all requirements, nor does it cover all aspects of the indicated requirements. For the actual mandatory requirements of the code, see the indicated section of text.

Note a. The letters refer to Figure R1001.1. given just below [Click to enlarge any image]

Note b. Not required in Seismic Design Category A, B or C.

[Click to enlarge any image]

Fireplace Clearance to Combustibles - model building code citation

IRC Mechanical Code Section 65. CLEARANCE TO COMBUSTIBLES. Section R1001 IRC 2009

1001.11 Fireplace clearance.

All wood beams, joists, studs and other combustible material shall have a clearance of not less than 2 inches (51 mm) from the front faces and sides of masonry fireplaces and not less than 4 inches (102 mm) from the back faces of masonry fireplaces. The air space shall not be filled, except to provide fire blocking in accordance with Section R1003.13.

Exceptions:

1. Masonry fireplaces listed and labeled for use in contact with combustibles in accordance with UL127 and installed in accordance with the manufacturer's installation instructions are permitted to have combustible material in contact with their exterior surfaces.

2. When masonry fireplaces are part of masonry or concrete walls, combustible materials shall not be in contact with the masonry or concrete walls less than 12 inches (305 mm) from the inside surface of the nearest firebox lining.

3. Exposed combustible trim and the edges of sheathing materials such as wood siding, flooring and drywall shall

be permitted to abut the masonry fireplace side walls and hearth extension in accordance with Figure R1001.11, provided such combustible trim or sheathing is a minimum of 12 inches (305 mm) from the inside surface of the nearest firebox lining.

4. Exposed combustible mantels or trim may be placed directly on the masonry fireplace front surrounding the fireplace opening providing such combustible materials shall not be placed within 6 inches (152 mm) of a fireplace opening. Combustible material within 12 inches (305 mm) of the fireplace opening

IRC Mechanical Code Section 66. MASONRY CHIMNEY CLEARANCE: Section R1003.18 IRC 2009 and 67. MASONRY CHIMNEY HEIGHT AND SUPPORT. R1003 IRC 2009 are given

at CHIMNEY HEIGHT & CLEARANCE CODE

IRC Mechanical Code Section 68. SOLID FUEL BURNING APPLIANCES. Section R1006 IRC 2009

R1006.2 IRC 2009 Washington State Amendment. Solid fuel burning appliances and fireplaces.

Solid fuel burning appliances and fireplaces shall be provided with tight fitting metal or ceramic glass doors, and:

1. A source from outside the structure of primary combustion air, connected to the appliance as per manufacturer’s specification. The air inlet shall originate at a point below the fire box. The duct shall be 4 inches or greater in diameter, not to exceed 20 feet in length, and be installed as per manufacturer’s instructions;

or

2. The appliance and manufacturer’s recommended combustion air supply, as an installed unit, shall be certified by an independent testing laboratory to have passed Test No. 11-Negative Pressure Test, Section 12.3, of ULC S627- M1984 “Space Heaters for Use with Solid Fuels,” modified as follows:

Negative pressure of 8 Pascal shall be initially established with the chamber sealed and the air supply, if not directly connected to the appliance, closed off.

The air supply if not directly connected to the appliance, shall then be opened.

The maximum allowable air exchange rate from chamber leakage and intentional air supply for the unit (appliance with combustion air supply) in the test chamber is 3.5 air changes per hour, or 28 cfm (cubic feet of air per minute), which ever is less.

Exception:

Combustion air may be supplied to the room in which the solid fuel burning appliance is located in lieu of direct ducting, provided the one of the following conditions is met:

1. The solid fuel burning appliance is part of a central heating plant and installed in an unconditioned space on conformance with the International Mechanical Code; or

2. The solid fuel burning appliance is installed in existing construction directly on a concrete floor or surrounded by masonry materials as in a fireplace.

The combustion air terminus shall be located as close to the solid fuel burning appliance as possible and shall be provided with a barometric damper or equivalent.

The combustion air source shall be specified by the manufacturer or no less than 4 inches in diameter or the equivalent in area or as approved.

R1006.3 Clearance.

Unlisted combustion air ducts shall be installed with a minimum 1-inch (25 mm) clearance to combustibles for all parts of the duct within 5 feet (1524 mm) of the duct outlet.

R1006.4 Passageway.

The combustion air passageway shall be a minimum of 6 square inches (3870 mm2) and not more than 55 square inches (0.035 m2), except that combustion air systems for listed fireplaces shall be constructed according to the fireplace manufacturer’s instructions.

R1006.5 Outlet.

Locating the exterior air outlet in the back or sides of the firebox chamber or within 24 inches (610 mm) of the firebox opening on or near the floor is permitted. The outlet shall be closable and designed to prevent burning material from dropping into concealed combustible spaces.

Original source:

- Stevens WA, COMMONLY USED RESIDENTIAL BUILDING CODES, IRC 2009, [PDF] retrieved 2019/05/08 original source: http://www.co.stevens.wa.us/landservices/documents/MECHANICALSECTION.pdf

- Other sections of this mechanical code are given

at CHIMNEY HEIGHT & CLEARANCE CODE

Masonry Fireplace Chimney & Flue Size Requirements

This information is now found in a separate article

at FIREPLACE FLUE SIZE SPECIFICATIONS

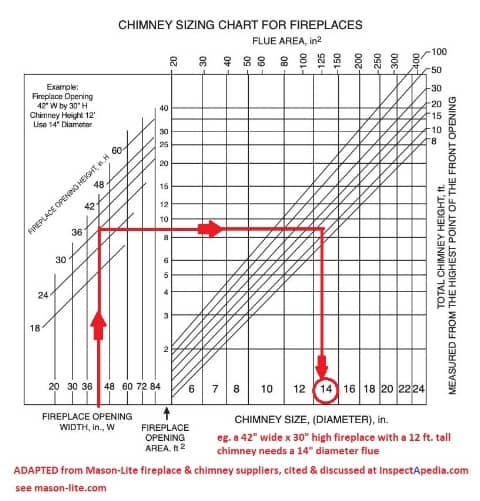

According to the Masonry Institute of America, the required flue size for masonry fireplaces (burning wood) is basically a function of the area of the fireplace opening.

Typical standards require a cross-section area of the fireplace flue or chimney/vent to be equal to 1/10 of the area of the fireplace opening itself, for a conventional wood-burning installation and without considering the effects of a glass fire-door.

The FHA requires using a 1/8 ratio instead of 1/10 for chimneys that are less than 15 feet high and the 1/10 ratio for chimneys that are 15 feet or more tall. [9]

Fireplace Hearth Size Requirements: Hearth Dimensions

This topic is now found in a separate article:

see FIREPLACE HEARTH DIMENSIONS & SUPPORT

Above, an antique fireplace used for cooking, Brinstone Farm, St. Weonards, U.K. To the left of the fireplace you can see a clay-cover over a huge built-in cauldron that was used to heat water, or perhaps when the farm was at full staff, soup.

Benjamin Thompson - Count Rumford & the Rumford Fireplace Design, Specifications, Proportions

Count Rumford, nee Benjamin Thompson, was born in Woburn Massachusetts in 1753. As a colonial Tory but as a loyalist he fled the colonies in 1776, returning to Britain during the American Revolution.

Count Rumford, nee Benjamin Thompson, was born in Woburn Massachusetts in 1753. As a colonial Tory but as a loyalist he fled the colonies in 1776, returning to Britain during the American Revolution.

There Count Rumford was sent to Bavaria where he developed the measurements on the perfect fireplace design. His title "Count" was given to Thompson by the Bavarian government in recognition of his work there on the perfection of an efficient woodburning fireplace design.

[Click to enlarge any image]

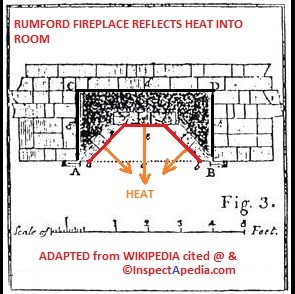

The Count Rumford fireplace proportions specify the height to width of the fireplace opening (as a ratio), the angle of the fireplace sides from front to back, the fireplace throat dimensions, and the requisite chimney dimensions.

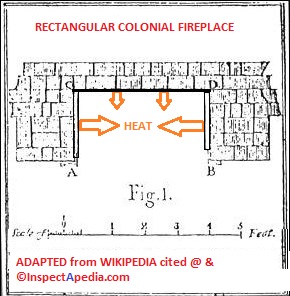

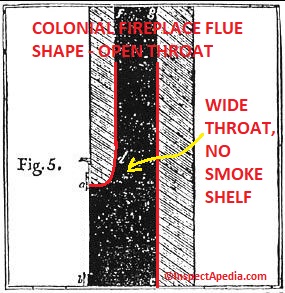

Rumford's design was an enormous change from the traditional huge European and early Colonial fireplaces in the New World. Those earlier fireplaces, to provide space for cooking and to heat the building where they were installed, were built shallow, with very wide openings.

Colonial pre-Rumford fireplaces consumed such a stunning amount of wood that in the Colonies by the late 1700s most forests had been cut down and consumed.

His work was documented in The Complete Works of Count Rumford (1798) or in some citations, The Collected Works of Count Rumford.

In some historic homes in North America, historians and preservationists report that by 1800 masons often undertook the re-lining of those huge Colonial fireplaces to change their dimensions to something closer to the Rumford (1753 - 1814) design.

More understandable was the relining of the fireplaces to Rumford proportions around 1800. It was common practice in Connecticut

and spread rapidly throughout the state once this more efficient design was published by Benjamin Thompson, an English physicist

known as Count Rumford. - US NPS,

Later it was Benjamin Franklin's invention of the Franklin Stove that moved the fire out of the wall and into open air indoors, providing a still greater improvement in the efficiency with which wood was burned for heat and for cooking. That improvement was significant even though our modern and very efficient airtight woodstoves were more than 100 years in the future.

Rumford, studying the movement of or flow of heat and air in fireplaces, found the optimal fireplace dimensions by trial and error - not having the engineering toolbox nor even a smartphone calculator for help.

In his era Rumford would have been considered thus an empirical philosopher. Some texts assert that it was Rumford who discovered that heat was transferred by three means: conduction, convection, or radiation. (MIA 1995)

10 Principles of Rumford Fireplace Design

Frustrating for a beginning mason or fireplace builder is the difficulty of finding, among websites and articles offering information about Thompson / Rumford's work, the actual fireplace dimensions and proportions developed by that empirical scientist. You will find that data here and in some of the references we cite below. Here I paraphrase or re-word original text for clarity.

- Fireplace fire-box materials:

Choose flat faced stone or fire-brick to better reflect heat into the room. Do not use rough fieldstone (as was previously common).

- Fireplace fire-box shape:(above)

slant the sides of the firebox on an angle to reflect heat into the room rather than back into the firebox. Square or even improperly-sloped firebox-sides reflected heat inside the firebox rather than out into occupied space.

Illustrations above, excerpted from Wikipedia's entry on Rumford, shows the general shape and proportions of fireplaces before & after Rumford's (Thompson's) empirical fireplace design work. - Wikipedia 10/17/2019

Notice that if the fire-box side angles are any closer to 90° than shown in the second sketch above, the angle will no longer direct heat out into the room.

Above: this fireplace, located in Venice in the Palacio Brandolin-Rota, includes sides that are not fully angled to reflect heat into the room, and I suspect that the opening is also a bit too tall. The fireplace back is set dead vertical.

- Fireplace back slope:

Rumford's original fireplace back was straight and plumb. Some fireplace backs slope gently forward towards the top or are kept vertical for a height equal to the fireplace depth, then sloping or curving forward to the top of the back.

As Rumford put it: The best fireplace is not deep and squatty but shallow and high with slanted sides and back.

Beginning in the 1800s masons began giving a slope to the fireplace back, sloping the upper back forward towards the room. Rumford approved this fireplace design improvement.

That slope allowed the firebox to be deeper (12-inches or 305 mm) than it might otherwise have been (just 8-inches or 203 mm).

Modern fireplaces are generally deeper than these dimensions, permitting a bigger prettier fire but in fact radiating less heat into the room.

- Fireplace fire-box depth:

fireplace depth should be between 1/3 and 1/2 the width of the fireplace opening.

Example: a 36-inch-wide (914 mm) fireplace opening built to Rumford's specifications would sport a depth between 12" (305mm) and 18" (457mm).

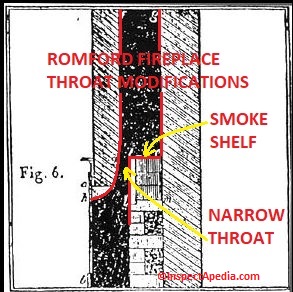

- Rounded, narrow throat.

The narrowed throat above the fireplace itself forms the entry to the bottom of the chimney and gives velocity to the draft; the smoke-shelf prevents chimney downdrafts from slapping into the fire and blowing ash or embers out into the room.

A Rumford fireplace throat will be around 4" (102mm) deep. The width of the throat will be the same as the width of the fire-back. The throat is always in front of the smoke shelf, not behind it.

A typical throat height from top of the fireplace itself to bottom of the chimney flue (or level with the smoke shelf) is 8-10".

The ratio of throat area to the fireplace opening is important and is approximately 1/20 th of the area of the fireplace opening.

Example: a 36" x 36" wide fireplace opening has an area of 1,295 sq .in.

1,295 / 20 = 64.8 - so the throat area for a 36" fireplace opening ought to be close to 65 sq .in.

Rumford found that rounding or curving the throat front or face improved draft and avoided eddies of smoke in this narrow venturi formed at the bottom of the chimney flue.

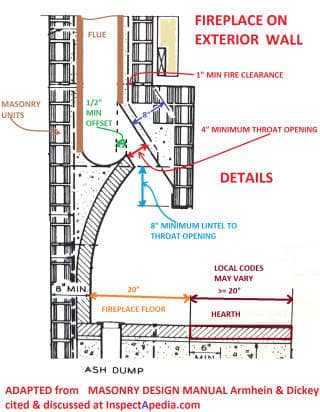

The fireplace lintel or bottom of the fireplace breast should give at least 8-inches distance between the lintel bottom and the opening to the fireplace throat. (Amrhein 1972).

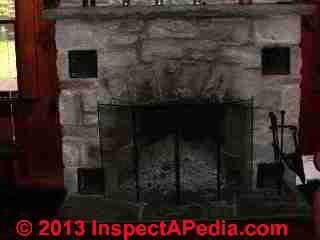

Above: when I see heavy smoke and soot stains above the fireplace lintel or opening I suspect there is a draft problem such as a fireplace opening size too tall an opening area too large for the size of the chimney flue, or a too-short chimney. Simply adding a listed chimney cap might improve the performance of this fireplace by stopping downdrafts.

- Fireplace opening width & height:

The fireplace opening is roughly square, with the fireplace opening width about the same as the opening height.

Watch out: a fireplace opening that is much taller than it is wide will smoke like crazy, sending smoke into the room rather than up the chimney. - Fireplace flue size:

Generally the flue size in effective square inches of venting area (a flue cross-section) should be 1/10 the size of the fireplace opening. An unlined flue should have an effective area no less than 1/8 of the fireplace opening area. (Amrhein 1972).

Example: our 36" x 36" square fireplace opening cited above gave us 1,295 sq .in. of fireplace opening size.

Our flue for that fireplace needs to give 1,295 / 10 = 130 sq .in. of venting area (this is actually a teeny fireplace - most will be larger).

The chimney height must clear the building roof by 2 feet as detailed at

CHIMNEY HEIGHT & CLEARANCE CODE and should also be 2-3 feet above nearby obstructions.

Below we cite sources giving detail of fireplace flue sizing.

Photo above: firemen on the roof of the author's home in 1973.

- Setting the fireplace damper:

We add this "fireplace design rule" though it is not included in Rumford's original design advice.

Rumford and colonial fireplaces usually had no damper but nearly all modern fireplaces add this closure door so that the building heat isn't sent up the chimney when the fireplace is not in use.

The damper is set atop the smoke shelf at the bottom of the chimney flue and is controlled (usually) by an arm extending down into the fireplace. (You'll only forget to open the fireplace damper before lighting the fire once so I won't bother to warn you about that here.)

For wood framed homes into which a masonry fireplace and chimney are constructed, take care that no cribbing or wood is left exposed to flame or heat from the fire.

Watch out: At PYROLYSIS EXPLAINED we document a Phil Hansey fireplace design that set the author's house afire on New Years' Eve in 1973. Gaps in the fireplace exposed wood to heat from the fire, eventually setting the house wall on fire. Dan Martin passed me a fire extinguisher as he asked "Is your wall supposed to glow like that?"

Above: the 4-inch "hearth" in front of this fireplace wasn't enough to prevent scorching of the wood floor.

- Fireplace hearth:

We add this "fireplace design rule" though it is not included in Rumford's original design advice.

A hearth of sufficient depth and width in front of the fireplace and built of non-combustible materials is important to avoid burning a finish-floor with spilled coals or worse, burning down the house.

Details are at FIREPLACE HEARTH DIMENSIONS & SUPPORT

Also see FIREPLACE DAMAGE & UNSAFE HEARTHS

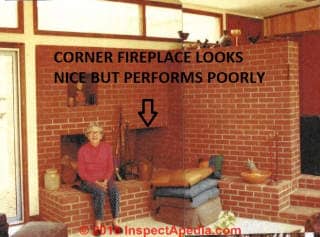

Above: an interesting but not so effective corner-fireplace as constructed in this 1960s home in Poughkeepsie, New York. This was the first home designed by the architect.

- Fireplace location:

Don't do what the beginner-architect did in designing this creative fireplace in a Poughkeepsie New York home [above].

Placing the fireplace in a corner abutting a brick wall was interesting but in fact it performs poorly, reflecting little heat into th room, lacking properly-angled sides, and - assuming we'd move those cushions before lighting a fire - the location is in my OPINION just awkward.

Watch out: there are of course other important chimney and fireplace construction and fireplace safety points that you will consider when building or repairing any sort of fireplace, masonry, insert, woodstove, etc. See our complete list in the ARTICLE INDEX.

References & Research on Rumford History, Biography & Rumford Fireplace Dimensions

- Amrhein James, E., & Walter L. Dickey, Eds., Masonry Design Manual, 2nd Ed. (1972), Masonry Industry Advancement Committee, Masonry Industry of California and Southern Nevada. pp. III-49 - 51 & flue liner sizes pp. III-54.

- Brown, G.I., Count Rumford: The Extraordinary Life of a Scientific Genius, Sutton Publishing (1999).

- Buckley, James, "Rumford Fireplaces", Buckley Rumford Company, Buckley Rumford Co. 1035 Monroe Street Port Townsend, WA 98368 360 385 9974, cell 360 531 1081 email: buckley@rumford.com Website: http://www.rumford.com Buckley / Rumford Fireplaces is a vendor of Rumford-design fireplaces and other heaters and appliances and accessories.

- Doucette, Peter A., BENJAMIN THOMPSON COUNT RUMFORD [PDF] - from Doucette, Peter A., el Camino College, also at InspectApedia.com at inspectapedia.com/chimneys/Benjamin-Thompson-Count-Rumford-elcamino.edu.pdf original source: www.elcamino.edu/faculty/pdoucette/Rumford.pdf

- Engineering Toolbox offers this fireplace flue sizing data at www.engineeringtoolbox.com/chimneys-fireplace-sizing-d_371.html

- Gillespie, G. Curtis, M.E. R.A., RUMFORD FIREPLACES and HOW THEY ARE MADE including PROPER FIREPLACE CONSTRUCTION, Benjamin Count Rumford's Essay [PDF] (1906) retrieved 2019/10/17 original source: https://babel.hathitrust.org/cgi/pt?id=gri.ark:/13960/t0cw0hp0b&view=1up&seq=13 courtesy of the HathiTrust www.hatitrust.org - this document is in the public domain

- Kreh, R.T., Sr., Masonry Skills, Delmar Publishers, Albany NY 1982, ISBN 0-8273-1958-4

- Ramsey - Sleeper, Architectural Graphic Standards: Student Edition, Ramsey/Sleeper: Charles George Ramsey (Author), Harold Reeve Sleeper (Author), Bruce Bassler (Editor), Wiley; 11 edition (March 3, 2008), ISBN-10: 0470085460 or ISBN-13: 978-0470085462

- Mason-Lite tel 800 347 7078 mason-lite.com

- MIA, Masonry Fireplace and Chimney Handbook, ISBN 0-940116-29-4 (1995), Masonry Institute of America, 1315 Storm Parkway, Torrance, CA 90501-5041 Tel: (310) 257-9000 Mailing: P.O. Box 3905, Torrance, CA 90510-3905 , Tel: 213-388-0472 Website: https://www.masonryinstitute.org/

- Putnam, John Pickering. The open fireplace in all ages. No. 963. Ticknor, 1880.

- Rumford, Benjamin, Graf von, The COMPLETE WORKS of COUNT RUMFORD Vol I [PDF] (1873) American Academy of Arts and Sciences, Boston 1870-75, University of Michigan copy, courtesy of the HathiTrust www.hatitrust.org - this document is in the public domain

- Rumford, Benjamin, Graf von, The COMPLETE WORKS of COUNT RUMFORD Vol II [PDF] (1873) American Academy of Arts and Sciences, Boston 1870-75, University of California copy, courtesy of the HathiTrust www.hatitrust.org - this document is in the public domain

- Rumford, Benjamin, Graf von, The COMPLETE WORKS of COUNT RUMFORD Vol III [PDF] American Academy of Arts and Sciences, Boston 1870-75, University of California copy, courtesy of the HathiTrust www.hatitrust.org - this document is in the public domain, includes

Of the Management of Fire and the Economy of Fuel, On the Construction of Kitchen Fireplaces ..., Supplementary Observations relating to the Management of Fires in CLosed Fireplaces. - Rumford, Benjamin, Graf von, The COMPLETE WORKS of COUNT RUMFORD Vol IV [PDF] (1876) American Academy of Arts and Sciences, Boston 1870-75, courtesy of the HathiTrust www.hatitrust.org - this document is in the public domain

- von Rumford, Benjamin Graf, and G. Curtis Gillespie. Rumford Fireplaces and how They are Made. WT Comstock, 1906.

- T-CHIMNEYS & CHIMNEY TOPS - 1720's Colonial fireplaces & chimneys

- Thompson, Benjamin, The Collected Works of Count Rumford; Sanborn Brown, ed.; Harvard Press; 1969; vol. 2.

- Thompson, Benjamin. "Count Rumford." The Complete Works of Count Rumford 4 (1798).

- Thompson, Benjamin, Fireplace Essays This PDF version of Rumford's two essays on fireplaces [in multiple files) was scanned by Jim Buckley from photocopies of Rumford's original essays kindly provided by Stanley W. Brown, Curator of Rare Books, Dartmouth College Library. Retrieved in series original source http://www.rumford.com/chimneyfireplacesa.html and following.

- U.S. NPS, CADY-COPP HOUSE [PDF] (ca 1745), U.S. National Park Service, retrieved 2019/10/17, original source U.S. Dept. of Interior, National Park Service, citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.691.4821&rep=rep1&type=pdf

Question: what flue size does my fireplace need & can I narrow the firebox?

I have a round masonry flue size of 7.5 inc diameter. What should be its throat dimension and opening dimension?

Is there an effect if the fire box is narrowed from front to back?

Reply: typical chimney sizes for fireplaces

Alfred

There isn't one set of "right" numbers for the fireplace flue size - since you can build a range of sizes of fireplaces to Rumford's design specifications all of which will work.

Fireplace throat details

However fireplace throats are a minimum of 4" in depth and the width is that of the fireplace - the red arrow in our sketch, adapted from Masonry Design Manual, Armhein & Dickey 1972.

Metal Flue Sizing for Fireplaces

A 7.5" diameter flue gives us about 40 sq .in. of venting area; Flues of that size are probably too small for a wood-burning fireplace.

About the smallest fireplace flue I expect to see is 8" (50 sq .in. of venting area) and that's for a teensy fireplace.

A typical residential fireplace using a metal flue is going to vent through a 10-inch flue (78.6 sq .in.) or a 12-inch flue (113 sq .in.)

masonry flues serving a wood-burning fireplace will generally be a bit bigger, from 8.5 x 13" (70 sq.in) to 13x18" (156 sq.in).

Shown here is Mason-Lite's more-sophisticated chart giving fireplace flue sizing for masonry fireplaces relates fireplace opening dimensions (width and height) to the recommended chimney size where three parameters are given: chimney inside diameter, flue area in sq .in. and chimney height in feet. - Original source: www.mason-lite.com/wp-content/uploads/2013/05/ChimneySizeChart-new.pdf

- Mason-Lite tel 800 347 7078 mason-lite.com sells pre-fabricated fireplaces, pizza ovens, accessories [and has no connection whatsoever to InspectApedia.com]

About changing the shape of a fireplace or changing the fireplace opening height to width ratio, it was Rumford who figured out the optimal fireplace dimensions to assure that a fireplace would draw (have adequate draft to avoid smoking out the building's occupants), provide heat most efficiently, and thus would burn wood far more efficiently than the wide shallow fireplaces that preceded his design.

You can change the shape of your fireplace or violate the Rumford fireplace proportions but doing so risks a fireplace that simply doesn't work well. But, then, your chimney's too small to start with so you might want to consider other options.

Support Below a Fireplace Hearth

Please see FIREPLACE HEARTH DIMENSIONS & SUPPORT

Fireplace Damage and Unsafe Hearths due to Chimney or Fireplace Settlement

Our discussion of unsafe fireplaces & hearths including hearth settlement, cracks in the fireplace box and other unsafe conditions is now found

at FIREPLACE DAMAGE & UNSAFE HEARTHS

More unsafe hearths and inadequate clearance from fireplaces or wood or coal stoves are show

n at FIRE CLEARANCES, WOOD COAL & PELLET STOVES.

Watch out: while this particular article series discusses fireplace dangers & fire risks related to cracks or settlement in the fireplace chimney, the most common fire hazard associated with fireplaces is a chimney fire caused by the ignition of accumulated creosote in the fireplace chimney flue.

See CHIMNEY FIRE ACTION / PREVENTION

and

See CHIMNEY CLEANING PROCEDURE - home

Fireplace Damper Trouble Inspection, Diagnosis, Repair

Please see details at this article:

FIREPLACE DAMPER DEFECTS, REPAIRS

A fireplace damper is a metal door installed in the fireplace chimney throat. To avoid wasting building heat by sending it up the chimney when a fireplace is not in use, the fireplace damper door is closed when the fireplace is not in use.

...

Continue reading at FIREPLACE DAMPER DEFECTS, REPAIRS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FIREPLACES & HEARTHS - home

- BRACKET CHIMNEYS & GALLOWS BRACKETS

- CHIMNEY CLEANOUT DOORS

- CHIMNEY FIRE ACTION / PREVENTION

- CHIMNEY FLUE INSPECTION CAMERA

- CHIMNEY DRAFT & PERFORMANCE

- COMBUSTION AIR DEFECTS

- CREOSOTE DEPOSITS, FIRE HAZARD

- FIREPLACE CHIMNEY ROOF CLEARANCE

- FIREPLACE & WOODSTOVE CONTAMINANTS

- FIREPLACE DAMPER DEFECTS, REPAIRS

- FIREPLACE FLUE SIZE SPECIFICATIONS

- FIREPLACE HEARTH DIMENSIONS & SUPPORT

- FIREPLACE INSERTS INSTALL, INSPECT, REPAIR

- FIREPLACE INSPECTIONS

- FIREPLACE INSPECTION PRE-FAB

- FIREPLACE DAMAGE & UNSAFE HEARTHS

- GAS FIREPLACES & GAS LOGS - home

- GAS FIREPLACE VENT CLEARANCE REQUIREMENTS

- GAS FIREPLACE CERAMIC STAINS

- INACCESSIBLE CONNECTIONS FIREPLACE, WOODSTOVE

- RUMFORD FIREPLACE DESIGN RULES

- PYROLYSIS EXPLAINED

- WOOD BURNING FIREPLACE ROOF CLEARANCE

- MASONRY CHIMNEY GUIDE - home

Suggested citation for this web page

FIREPLACES & HEARTHS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

...

INDEX to RELATED ARTICLES: ARTICLE INDEX to CHIMNEYS & FLUES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- American Gas Association - New Vent Sizing Tables

- Brick Institute of America - Flashing Chimneys

Brick Institute of America - Proper Chimney Crowns

Brick Institute of America - Moisture Resistance of Brick - [8] BOCA Fire Inspector Guidebook, A Correlation of Fire Safety Requirements Contained in the 1987 BOCA National Codes, (newer edition available), Building Officials and Code Administrators International, Inc. (BOCA), Country Club HIlls, IL 60478 312-799-2300 4th ed. Note: this document is reissued every four years. Be sure to obtain the latest edition.

- Chimney Safety Institute of America - Chimney Fires: Causes, Effects, Evaluation

- Cohen, Donald V., "Chimney Inspection Procedures & Codes," This article was to be published in the first volume of the 1994 ASHI Technical Journal by D. Friedman, then editor/publisher of that publication. The production of the ASHI Technical Journal and future editions was cancelled by ASHI President Patrick Porzio. Some of the content of Mr. Cohen's original submission has been included in this more complete chimney inspection article: CHIMNEY INSPECTION DIAGNOSIS REPAIR . Copies of earlier editions of the ASHI Technical Journal are available from ASHI, the American Society of Home Inspectors.

- Costello, Martine, & Josh Kovner, "Rooftop View Turns to Darkness," New Haven Register, 12 May 1992 p. 11: Catherine Murphy was sunning on a building roof when a chimney collapsed; she fell into and was trapped inside the chimney until rescued by emergency workers.

- GAMA - Gas Appliance Manufacturers' Association has prepared venting tables for Category I draft hood equipped central furnaces as well as fan-assisted combustion system central furnaces.

- [9] International Association of Fireplace and Chimney Inspectors, Inc., IAFCI, 5325 N Commerce Ave Ste 5 Moorpark, CA 93021, Website: http://www.membersiafci.org/

- Murphy, Bill & Hansen, Bob, "Top Ten Chimney (and related) Problems Encountered by One Chimney Sweep," Hudson Valley ASHI education seminar, 3 January 2000, contributed by Bob Hansen, ASHI

- [7] National Chimney Sweeps Guild, NCSG, 2155 Commercial Drive, Plainfield, IN 46168, Tel: 317) 837-1500, Website: http://www.ncsg.org/ , Email: mmcsweeney@ncsg.org

- [8] National Fireplace Institute - NFI, Website: http://nficertified.org/ Quoting from the associations website:

The National Fireplace Institute® is the professional certification division of the Hearth, Patio & Barbecue Education Foundation (HPBEF), a 501(c)3 non-profit educational organization for the hearth industry. - National Fuel Gas Code, an American National Standard, 4th ed. 1988 (newer edition is available) Secretariats, American Gas Association (AGA), 1515 Wilson Blvd., Arlington VA22209, and National Fire Protection Association (NFPA), Batterymarch Park, Quincy MA 02269. ANSI Z223.1-1988 - NFPA 54-1988. WARNING: be sure to check clearances and other safety guidelines in the latest edition of these standards

- NFPA 211 - Standards for Chimneys & Fireplaces, NFPA 211: [book at Amazon] Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances, 2006 Edition (older editions and standards are found at the same bookstore)

- Natural Gas Weekly Update: http://tonto.eia.doe.gov/oog/info/ngw/ngupdate.asp Official Energy Statistics from the U.S. Government

- New York 1984 Uniform Fire Prevention and Building Code, Article 10, Heating, Ventilating, and Air Conditioning Requirements

- New York 1979 Uniform Fire Prevention & Building Code, The "requirement" for 8" of solid masonry OR for use of a flue liner was listed in the One and Two Family Dwelling Code for New York, in 1979, in Chapter 9, Chimneys and Fireplaces, New York 1979 Building and Fire Prevention Code:

- NFPA #211-3.1 - Specific to chimneys, fireplaces, vents and solid fuel burning appliances.

- NFPA # 54-7.1 - Specific to venting of equipment with fan-assisted combustion systems.

- NFPA 211 - 3-1.10 - Relining guide for chimneys

- NFPA 211 - 3-2 - Construction of Masonry Chimneys

- NFPA 211 - 3-3 - Termination Height for chimneys

- NFPA 211 - 3-4 - Clearance from Combustible Material

- NFPA 54 - 7-1 - Venting of Equipment into chimneys

- Reinmiller, Mark J., P.E., "Chimneys and Vents," Mark J. Reinmiller, P.E., ASHI Technical Journal, Vol. 1 No. 2 July 1991 p. 34-38.

- [9] Armhein, James E., E.E., Masonry Fireplace and Chimney Handbook, 2nd Ed., [sold at Amazon] M.I.A. Masonry Institute of America, 22815 Frampton Ave. Torrance, CA 90501-5034 Toll free: 1-800-221-4000; the original text noted that mIA was prepared to include requirements of the 1994 UBC and other codes. Website ht.masonryinstitute.org

- DeMayo, Robert D., Fireplaces, Friend or Foe, [book at Amazon]

- Gitlin, Jane, Fireplaces, a Practical Design Guide, [book at Amazon]

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.