Dampers & Dampeners in Buildings

Dampers & Dampeners in Buildings

Dampers as controls: types, uses, adjustments

- POST a QUESTION or COMMENT about dampers, fire/smoke dampers, duct dampers, vibration dampeners, or fire dampers or flue controls or HVAC duct controls

Types & definitions of HVAC duct & flue dampers, vibration dampeners, and fire dampers found in buildings.

This article defines and describes barometric dampers, draft regulators, automatic flue dampers, draft inducers, zone dampers, HVAC supply register controls, fire dampers, automatic fire and smoke dampers, fireplace dampers, and fresh air inlet dampers and controls.

We include photographs of each type of damper or dampener used in buildings or in building mechanical systems and we provide links to in-depth articles describing the choices, installation, inspection, troubleshooting and repair of all types of building and HVAC system air controls, dampers and dampeners such as automatic and barometric flue dampers used on heating equipment, coal stove, pellet stove, woodstove draft controls, draft inducer fans, HVAC duct air flow controls (manual register controls, duct dampers, zone dampers, automatic fire dampers, vibration dampeners), fireplace dampers, and fresh air supply dampers and controls.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Dampers and Dampeners, types, definitions

of flue damper, duct damper, fire damper, a draft regulator& other dampers or dampeners

of flue damper, duct damper, fire damper, a draft regulator& other dampers or dampeners

This article catalogs and describes all types of air and draft regulation devices used in buildings where control of heating appliances is needed.

Article Series Contents

- DAMPERS & DRAFT REGULATOR TYPES

- AUTOMATIC FLUE DAMPER or FLUE DAMPENER

- BARMOMETRIC FLUE DAMPER or FLUE DAMPENER

- COALSTOVE DRAFT CONTROL

- DRAFT INDUCERS

- DRAFT REGULATOR, DAMPER, BOOSTER - draft regulators on oil fired heating equipment

- DRAFT REGULATORS / HOODS GAS HEATERS - draft regulation on gas fired heating equipment.

- DUCT DAMPERS & ZONE DAMPERS, AUTOMATIC

- DUCT DAMPERS & ZONE DAMPERS, MANUAL

- DUCT DAMPERS, SUPPLY AIR REGISTER

- DUCT VIBRATION DAMPENERS

- FIRE DAMPERS

- FIREPLACE DAMPERS

- GAS FIREPLACES & GAS LOGS

- FRESH AIR DAMPER CONTROLS

- KEROSENE HEATER DRAFT CONTROL

- PELLET STOVE DRAFT CONTROL

- WOOD-OIL COMBINATION DRAFT CONTROL

- WOODSTOVE DRAFT CONTROL

Direct Vented Heating Appliances Don't Use a Barometric Damper

Direct-vented heating appliances that vent flue gases outside without using a chimney are typically operated by a power vent fan in or at the heating appliance. These vents don't use a barometric damper for draft regulation.

See DIRECT VENTS / SIDE WALL VENTS

Definition of automatic flue damper

An automatic flue damper is a device (shown below) that closes the heating flue when the furnace or boiler is "off" so that we won't continue to lose building heat up the chimney - it's a device to reduce heating costs and save on heating oil consumption.

When the heating system has turned off at the end of an "on" cycle of burning fuel, the automatic flue damper electric (see sketch above and photo at left) motor turns a baffle inside of the flue vent connector pipe to a position "across" the pipe so that the airflow inside the pipe is blocked or stopped.

Don't confuse an automatic flue vent damper with other "damper" devices: a heating system automatic duct damper or a duct fire damper or a heating zone damper.

Definition of Barometric Draft Control (also called Flue Damper) and they work

A barometric draft control, also called a "damper" or barometric damper, is a hinged, weighted door on an opening at a heating flue. The key difference between a barometric draft control or flue damper and an automatic flue damper is that the barometric damper operates by barometric pressure or natural draft while an automatic flue damper is operated by an electric motor.

The door opens or closes to let extra air into the flue to assure that the draft in the flue remains constant at the proper setting needed for proper heating system operation.

- Details about draft control on oil fired heating systems, including furnaces or boilers, are discussed

at DRAFT REGULATOR, DAMPER, BOOSTER barometric dampers on oil fired equipment. - Details about draft control for gas fired heating systems, including furnaces or boilers, are discussed

at DRAFT REGULATORS / HOODS GAS HEATERS On gas fired equipment.

Coal stove draft control

Coal fueled heaters use manual dampers in the coal stove flue or for larger and automatically-fed coal fired boilers or furnaces the system may incorporate a thermostatically-operated automatic flue damper to control both draft and thus the system's heat output.

- Details about draft and heat output control for coal stoves are

at COAL STOVE OPERATION & SAFETY. Excerpts are below.

The coal stove shown at above left was installed by the author (DF) in the 1970's. A slider along the stove bottom permitted the user to adjust the air intake rate - a necessary combustion and heat control since the installation of this stove in front of a small fireplace gave no access room for a flue damper control.

The second fireplace-inserted heater at above right is a coal stove that was designed to also burn wood. This wood/coal heater, installed by Paul Galow in New York in the 1970's, also had a sliding air intake control and no accessible flue damper.

The vertical lines you see in the glass front of each of these coal burners allowed the installation of glass that would not fracture due to thermal expansion, allowing the occupants to enjoy watching the fire. Yes ultimately these get broken by a careless occupant or user, putting the stove out of use until the glass could be replaced.

Watch out: if the incoming combustion air cannot be shut down because of leaky coal stove gaskets or other damage like the broken glass in the coalstove door, the coal stove is unsafe as its burn-rate cannot be regulated.

See CHIMNEY FIRE ACTION / PREVENTION

Also see FIRE CLEARANCES WOOD & COAL STOVES

Reader Question: can I put to barometric dampers on the same flue along with a manual one on my Alaska Channing III Coal Stove?

I have a Alaska channing 111. My barometric damper is 6 in then [the flue vent connector goes to 8 in to connect ] to massonary chimney.

It seems I need two dampers. I installed a manual damper to help

My question is can I put 2 baro dampers in the same flue to control proper draft

Thanks, Bill

Reply:

Bill

Watch out: I infer that you are getting too much heat or having trouble controlling your coal stove. This condition can be unsafe and in fact in extreme cases can cause a house fire.

See COAL STOVE OPERATION & SAFETY for detailed suggestions on solving this problem with your coal stove. There we repeat your question and answer it in detail.

Definition of Draft Inducer Fan and how do they work?

A draft inducer is a booster fan that increases the flow of combustion gases up a chimney. In our photo at above left you can see the black motor and bronze-coloured fan cage of a draft inducer fan mounted underneath the flue vent connector between the oil fired boiler and the concrete block wall that affords entry into a chimney (not visible).

Draft inducers are used when there is a problem with the chimney or heating equipment installation that prevents natural draft from working adequately.

We discuss draft inducer or "draft boosting" fans for heating systems (and maybe for some fireplaces) in detail

at DRAFT INDUCER FANS.

Definition of automatic duct damper or HVAC zone damper

Zone dampers are manual or electrical (thermostatically controlled) baffles that open or close in heating or cooling air ducts to control heating or cooling zones in buildings.

Details about zone dampers are

at ZONE DAMPER CONTROLS

An automatic duct damper is a mechanical device (shown above), usually controlled by a room thermostat, which opens or closes a metal baffle inside of a warm air (or cool air) heating (or cooling) duct in order to provide multiple heating zone control in a building.

You can see photographs of and read about manual and automatic heating and air conditioning zone dampersat ZONE DAMPER CONTROLS.

Definition of Manual Duct Dampers used in HVAC system ductwork

A manual duct damper, also referred to as a manual HVAC zone damper, is a hand-operated baffle that can be turned to open or close a heating or air conditioning supply duct to thus control the flow of conditioned air into a building area.

Our photo below shows a manual duct damper control handle on an older (asbestos-paper-covered) heating duct. When the handle long axis is parallel to the ductwork (our blue line) the air flow is fully open (the red arrow).

Details about manual HVAC duct dampers are

at MANUAL HVAC ZONE DAMPERS.

Definition of Supply Air Register Damper

The most-common means of controlling heating or cooling air delivery out of an individual duct or zone is the opening or closing of individual supply air registers. A lever on the supply register grille permits opening or closing a baffle that controls air flow out of the duct system just at this individual register.

Details about individual supply air register controls are

at AIR REGISTER for ZONE CONTROL

Control of the entire duct zone is possible using a

manual (DUCT DAMPERS, MANUAL) or

automatic (DUCT DAMPERS, AUTOMATIC) duct zone control damper.

Definition of Automatic Fire Damper in Ductwork and how do they work?

A fire damper is required to prevent the spread of a building fire or smoke through air conditioning and heating ducts in some commercial installations and possibly by local residential building codes in some jurisdictions. Fire and smoke dampers are typically required in office buildings, health care facilities, and other commercial structures.

The automatic fire/smoke damper operates (usually) by automatically closing a door or doors within the damper on the detection of a temperature increase or by operation of a separate smoke detector.

Our photo at below left shows a pair of open fire damper doors in the ceiling of a commercial building in New York City. In event of a fire these doors are intended to be automatically closed. Similar dampers may be installed right in HVAC ducts where the ducts pass between different building areas.

More about the photo of ceiling return air plenum fire dampers shown at above left is

at RETURN AIR REGISTERS & DUCTS

A fire damper might work similarly to an automatic duct damper, but its purpose is quite different: in the event that a fire is detected in a building or in its mechanical systems, (by heat or smoke or other means of fire sensing), the fire damper closes off the air duct to avoid spreading smoke or fire rapidly through the building. The fire damper is otherwise normally "open".

See photographs of and read details about automatic fire dampers and automatic fire/smoke dampers

Definition of Duct Vibration Dampeners

Duct vibration dampers or properly called vibration dampeners are fabric joints placed in HVAC ductwork to prevent the transmission of vibration and noise from the air handler of a heating or air conditioning system into the ductwork and through the ductwork into the occupied spaces of a building.

Details about duct vibration dampeners are found

Definition of Fireplace Damper

A fireplace damper is a metal door installed in the fireplace chimney throat. To avoid wasting building heat by sending it up the chimney when a fireplace is not in use, the fireplace damper door is closed when the fireplace is not in use.

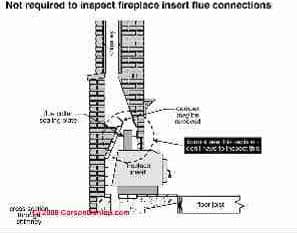

Our sketch below, provided by Carson Dunlop Associates and used with permission, shows the location of a fireplace damper in the chimney flue where a woodstove or fireplace insert has also been installed.

Details about fireplace dampers, their installation, inspection, repair, replacement, and defects are

at FIREPLACE DAMPER DEFECTS, REPAIRS

Definition of Fresh Air or Outdoor Air Supply Dampers & Controls

Definition of fresh air or outdoor air supply control damper

Outdoor air or fresh air is supplied (or can be or often should be) supplied to combustion equipment such as gas or oil or other fuel fired heaters as well as to fireplaces or woodstoves. Outdoor or fresh air is also supplied to the HVAC duct or air delivery system to improve indoor air quality. Below we list articles describing these various outdoor air or fresh air supply controls.

You can see photographs of and read about fire dampers in ductwork or read about strategies for managing building fresh air intake at

- FRESH AIR DAMPER CONTROL - for combustion air at large HVAC systems

- INDOOR AIR QUALITY & HOUSE TIGHTNESS - fresh air for indoor air quality

- VENTILATION, BALANCED - savings by balancing fresh air supply or using a heat recovery ventilator HRV

- VENTILATION, SUPPLY-ONLY - fresh air for indoor air quality

- ZONE DAMPER CONTROLS - zone control or balancing air flow in heating or air conditioning ductwork systems

Kerosene Heater Draft Control

Our photo below shows a kerosene heater installed in an older New York Home. There is no visible draft control on this heater's flue. Instead the user regulates heat by controlling the fuel flow level.

[Text and illustrations are in process, text, comments, photo, contributions are invited. CONTACT US]

Pellet Stove Draft Adjustment & Measurement

Pellet stoves usually make use of a draft fan for proper burning, though in event of a power failure some models permit limited operation using natural draft.

Pellet stoves usually make use of a draft fan for proper burning, though in event of a power failure some models permit limited operation using natural draft.

Illlustration: The AGP Pellet Stove from Lopi, Travis Industries, excerpted from the company's instruction manual cited below.

Travis Industries recommends a minimum vertical vent of 5’ to ensure adequate draft

during a power outage.

Other pellet stove installation manuals, for example the Harman Pellet Stove cited below, specifically describe using a manometer to check the appliance draft and may provide a mechanical adjustment of the combustion motor speed.

Harman specifies a normal pellet stove "high" draft (for their model) of -0.50 to -0.60 inches of W.C. (Water Column) and normal pellet stove "low draft) of -0.35 to -0.45 in. W.C.

Details are

Wood-Oil Combination Boiler or Furnace Draft Control

The combination wood-oil fueled heater shown above regulates draft by a combination of Input air and oil burner adjustments at the oil burner and a barometric damper regulated draft when the heater is being fired using heating oil (indicated in yellow)

A themostatically operated combustion air inlet regulates the wood fire when the heater is being fired using wood. In this mode a barometric damper may be replaced with a manual draft control or an automatic draft control in the exhaust flue between the heater and its chimney (green arrow 1, 2, 3, 4)

Details of wood-oil combination heaters and the difficulty of attempting to control draft on these devices are now found

at WOOD-OIL COMBINATION DRAFT CONTROL

Wood Stove Draft Control

I'm not so sure the wood burning stove shown above is a fire-safe installation, but you can plainly see the manual flue damper handle (pointed-to by our blue arrow) in the rusty flue section about 30 inches above the top of the woodstove.

When the damper handle's long axis is parallel to the flue the damper is in its fully open position.

Details of how this control is used are at

Also see

...

Continue reading at DRAFT REGULATOR, DAMPER, BOOSTER or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AUTOMATIC FIRE DAMPERS

- COAL STOVE OPERATION & SAFETY

- DAMPERS & DRAFT REGULATOR TYPES

- DRAFT REGULATORS / HOODS GAS HEATERS

- DRAFT INDUCER FANS

- DRAFT MEASUREMENT, CHIMNEYS & FLUES

- DRAFT REGULATOR, DAMPER, BOOSTER - home

- FIREPLACE DAMPER DEFECTS, REPAIRS

- GAS FIREPLACES & GAS LOGS

- MANUALS for HEATING & A/C SYSTEM CONTROLS

- MANUALS & PARTS GUIDES - HVAC

- PELLET STOVE DRAFT CONTROL

- PYROLYSIS EXPLAINED

- SHARED CHIMNEY & FLUE HAZARDS - home

- WOOD / OIL HEATER AIR DAMPER CONTROL

- WOOD-OIL COMBINATION DRAFT CONTROL

- WOOD STOVE, CATALYTIC PUFF-BACKS

- WOODSTOVE DRAFT CONTROL

- WOOD STOVE DRAFT TEST

Suggested citation for this web page

DAMPERS & DRAFT REGULATOR TYPES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING FIRE SAFETY

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Airflow Breeze air movement register booster fans are produced by AirFlow Technology, Airflow Technology 1427 West 86th Street, Suite 328 Indianapolis, IN 46260 1-800-458-5540 website: http://www.aftproducts.com/Airflow_Breeze_3ff0ef340c6e0e13b.dept

- Fuel Oil & Oil Heating Magazine, 3621 Hill Rd., Parsippany, NJ 07054, 973-331-9545 rk 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- [1] "Instructions for Installing FIELD Type AF Barometric Draft Controls," Form No. 31 DC 30666, Field Corporation, Mendota, IL 61342, web search 04/02/2011, original source: http://www.fieldcontrols.com/pdfs/04592700.pdf, Field Controls, Kingston, North Carolina 28501, Tel: 919-522-3031

- [2] Tjernlund Draft Controls, A Series (single action for oil, solid fuel, and fan-assisted gas burners) and B Series (double action for gas heating appliances), web search 04/02/1011, original source: http://www.tjernlund.com/Tjernlund_8500490.pdf , Tjernlund Products, Inc., 1601 Ninth Street, White Bear Lake MN 55110-6794, Tel: 651-426-2993 or 800-255-4208 website: www.tjernlund.com Email: fanmail@tjfans.com

- Carbon Monoxide Gas Toxicity, exposure limits, poisoning symptoms, and inspecting buildings for CO hazards

- DUST, HVAC CONTAMINATION STUDY An Investigation of Indoor Dust Debris Blamed on a Heating/Cooling System Reveals Carpet Dust

- Fuel Oil & Oil Heating Magazine, 3621 Hill Rd., Parsippany, NJ 07054, 973-331-9545

- Goodman Furnace High Temperature Plastic Vent HTPV safety recall US CPSC notice

- Home Heating System Should Be Checked[for proper venting and for CO Carbon Monoxide Hazards - DJF]

- Inspection Procedures for Oil-Fired Heating Systems Detailed step by step approaches for inspecting complex systems]

- Lennox Pulse Furnace Safety Inspection/Warranty Program: Carbon Monoxide Warning

- Plastic Heating Vent Pipe & Other Heating Safety Recall Notices

- Weil McLain Model GV Gas Boiler/gas valve CPSC recall/repair

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.