Two Line Jet Pump Install / Repair

Two Line Jet Pump Install / Repair

- POST a QUESTION or COMMENT on how two-line jet pumps work on water wells

This article describes the sequence of operating steps in a two-line jet pump water system.The process of diagnosis and the costs of the repair are explained.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How a Two-Line Jet Pump Well Water System Works - Sequence of Operating Steps

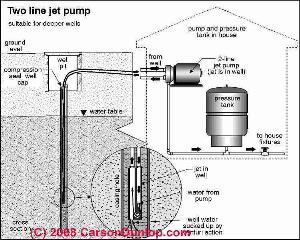

What happens when you turn on the water at a faucet in a building whose water is supplied by a two-line jet pump? (See the sketch at the top of This article for the basic components of a two-line jet pump system.)

The following steps describe normal operating of a building well pump and water supply system.

Other cases in which the well pump controls are not working properly, there is a problem with the controls, pressure tank, pump, or well itself are discussed

at WELL WATER PRESSURE DIAGNOSIS.

- Turn on building water

at a plumbing fixture: open a sink valve, tub valve, or flush a toilet. - Water runs out of the supply faucet,

into the fixture, down the drain - Water pressure and flow are being supplied to the building from a water pressure tank.

If we didn't use a pressure tank, because water is not very compressible, the second water was turned on, water pressure in the system would drop below the pump cut-on pressure, the pump would turn on, and probably bring water pressure up to the cut-off pressure quickly, causing short cycling and burning up pump controls or a pump motor.

See WATER TANKS HOW THEY WORK. - Pressure in the water pressure tank and in the building piping system drops

down to the well pump cut-in pressure. Typically this is 20 or 30 psi on a residential water system. - The well pump pressure control switch senses the pressure drop,

closes an internal electrical relay switch to turn on the well pump.

See WATER PUMP PRESSURE CONTROL SWITCH. - The well pump motor runs, drawing water back into the building

from the well by "sucking" or drawing water up from a shallow depth (a one-line jet pump can't draw water from much below 25 feet) - Water is forced into the building water pressure tank and simultaneously into the building piping

and on to the plumbing fixtures. - If the pump sends water into the building faster than water is flowing out

of the open faucet or plumbing fixture, the pump will "get ahead" of the water flow, successfully pressurizing the water tank, causing the pressure switch to turn off the pump (see step 10 below).

OR - If the pump cannot send water into the building faster than water is flowing out

of the open faucet or plumbing fixture,

the well pump will run continuously

and water will flow out of the open faucet or plumbing fixture at a rate limited basically by the pump's water delivery flow rate in gallons per minute.

You'll also find this condition if a building water supply pipe bursts. We say "basically" because the well piping and building piping and faucets themselves offer some back-pressure against the pump's flow rate.

In this case, the well pump will continue to run until the building faucets or plumbing fixtures are turned off. At that point ... - The well pump pressure control switch senses that water pressure has increased to the cut-out point,

opening its switch and turning off electrical power to the well pump. The well pump has re-pressurized the building water tank and piping up to the cut-out or cut-off water pressure. - The foot valve closes (at the bottom of the well piping)

and/or a check valve located in the building on or close to the well pump closes,

preventing water and pressure from flowing backwards down into the well, losing building water pressure and possibly losing pump prime.

See WELL PIPING FOOT VALVES

and

see WELL PIPING CHECK VALVES

and if necessary

see WELL PUMP PRIMING PROCEDURE.

How to Diagnose Poor 2-line Jet Pump Operation or 2-Line Jet Pump Water Pressure

For our complete water pressure and pump, well, and piping problems diagnostic article list,

see WATER PRESSURE REPAIR GUIDE & COSTS

and WATER PRESSURE LOSS DIAGNOSIS & REPAIR.

Separately we also provide

at WATER PRESSURE PROBLEM DIAGNOSIS TABLE.

The following articles pertain if you have a private well, pump, and tank system for your building or if your incoming community water supply pressure and flow are just too low to start with:

- Water Tank Problems?

See WATER PRESSURE TANK REPAIRS. Examples of water tank problems include poor water pressure or the well pump rapidly turning on and off (short cycling). - Water pump problems? Examples of water pump problems include poor water pressure or no water pressure at all. See

- WATER PRESSURE CONTROL SWITCH ADJUSTMENTS - poor building water pressure or flow

- PUMP PRESSURE CONTROL REPAIR - pump is not delivering water at all or water pressure is poor

- WATER PUMP RELAY SWITCH - submersible pump has stopped working

- WATER PUMP PRIMING PROCEDURE - well pump keeps losing prime - pump runs but gives no water

- WATER PUMPS & TANKS & WELLS - complete list of articles

- WATER PUMP CONTROLS & SWITCHES - complete list of well pump controls and switches, identification, diagnosis, repair

- WATER PRESSURE GAUGE ACCURACY - maybe water pressure is fine and it's the gauge that's bad?

- Water piping or well piping problems? If your water pump keeps losing prime, a shallow well jet pump well line could have a bad foot valve (in the well

WELL PIPING FOOT VALVES) or there may be

a bad check valve on well piping at or near the water tank or near the above-ground water pump

(CHECK VALVES, WATER SUPPLY, DRAINS, PUMPS) and so be losing prime.

A leak in the well line piping itself can also lead to loss of prime. - Well Problems? Do you run out of water or after running water for some interval water pressure and flow are poor? Well problem diagnosis starts

at WELLS CISTERNS & SPRINGS.

Before assuming that there is no water in the well, check to see if the water pump is working properly, including

loss of pump prime

WATER PUMP PRIMING PROCEDURE

and a bad or leaky well piping foot valve

WELL PIPING FOOT VALVES - Bad water pump or water tank pressure regulator control?

See WATER PRESSURE REDUCER / REGULATOR (not usually installed on private well and pump systems, often present on municipal water supply systems that use an in-building local water pump and pressure tank to boost pressure). Water pump pressure regulator switch diagnosis and repair steps include these:- How to Adjust Water Pump Pressure: The detailed, step by step procedure for inspecting and adjusting the water pressure control switch is

discussed in detail

at WATER PRESSURE CONTROL SWITCH ADJUSTMENTS. - Diagnosing Water Pump Short Cycling on and off: If your water pump is clicking on and off too often or quite rapidly

see SHORT CYCLING. - Diagnosing Water Pressure Drops without explanation when the pump stops,

see WATER PRESSURE FALLS SLOWLY, ERRATIC PUMP: bad pressure control switch, building water running or leak, bad pressure gauge, bad check valve, bad foot valve. - Diagnosing & Repairing Lost Air in the Water Tank: The problem of lost air in the water pressure tank along with how to correct that condition are discussed

beginning

at SIGNS OF AIR LOSS. - Diagnosing & Repairing a Water Pressure Control or Water Pump Control Switch: We discuss diagnosing and repairing a water pressure control switch that sticks "on" or "off" or simply won't operate,

at water pump Pressure Switch Repairs.

- How to Adjust Water Pump Pressure: The detailed, step by step procedure for inspecting and adjusting the water pressure control switch is

discussed in detail

- Bad Hot Water Pressure?

See HOT WATER IMPROVEMENT especially if the building cold water pressure is acceptable but hot water pressure and flow are poor.

Accumulated debris in a water heater, and debris from a corroded or disintegrating hot water tank dip tube or hot water tank sacrificial anode can also block the hot water outlet opening, resulting in low hot water pressure in a building. - Bad cold or hot water pressure and flow just at certain plumbing fixtures? See our discussion

of POOR WATER PRESSURE at JUST SOME PLUMBING FIXTURES just above. - Problems with water treatment equipment can cause loss of water pressure or no water flow: a clogged water filter, or a malfunction in water disinfection or other water treatment equipment can cause a reduction in water pressure or even a complete stop in water flow in a building.

See WATER FILTERS, HOME USE for details about clogged filters,

and

see WATER TREATMENT EQUIPMENT CHOICES for our complete list of types of water treatment equipment.

Methods Cleaning the Water Pump Intake Screen or Well Bore Sediment

Reader Question: how to clean the well bore sediment or screen clog without pulling well piping

(Aug 18, 2014) Bill K said:

Would it be conceivable to use a jet pump to clean out sediment at the bottom of a water well bore? We have six windmills on our ranch that are all around 140 feet deep that are 50 to 60 years old and sediment can get to be a problem over time.

I was hoping to achieve a new "lease on life" for these wells if I could clean them out in some way and a jet pump is the only thing I could think of that would be able to lift mud and such off the bottom if it could fit down the bore hole.

Reply:

Bill

It's no surprise that articles on removing sand or silt from water wells mostly focus on filtering the water using various methods ranging from a cartridge filter to a centrifugal sand separator. But for removing sand or silt from the bottom of a well bore, well drillers have had to deal with this matter for generations and have several approaches.

The most common approach, provided we're not also going to exhaust the well's flow rate, is to pump silty sandy water from the well bottom for an extended period of time - possibly days. (Normally the water pick up in a well is set several feet above well bottom to avoid picking up settled debris).

You could use a 2-line jet pump whose pickup is at the end of the pair of pipes near well bottom COMBINED with some other jet to stir up muck to try to pump it out of a well bore, but you may destroy the pump in the process. Well drillers have a variety of approaches to removing debris from wells.

Typically a pump particluarly designed to handle sludge is used. Some examples are the Waterra pump line (waterra dot com)

Or search for sludge-pumps made by a variety of manufacturers.

Assuming your well bores are lined, it's possible that your lining has leaked or corroded or cracked. So you want to inspect the well bore (well bore camera) and if necessary, insert appropriate repair sleeves to cut the dirt or sediment or sand entry rate into the bore.

In 2010 the state of New Hampshire in the U.S. published a helpful article "Sand and Sediment in Water Wells", WD-DWGB-3-14 online as a PDF. des.nh.gov

Farmshow dot com has an interesting article about a home-made well-cleaner (Richard Guthrie's design) that uses a combination of a steel cylinder lowered into the well and compressed air - which may not be practical for deep wells such as you describe.

(Aug 19, 2014) Anonymous said:

Thanks Dan.

That gives me a lot more directions to go than I had before. I've been searching for an affordable well camera or even a rental place for one for several days now but they seem to be few and far between in West Texas. With six wells, not all working but we have plans for renewal on two, I'm tempted to buy one but at $3 to $4 grand or more each I'd hate to have one just sit for years after using it several times. I'd assume their resell value, if intact, would hold, though.

One personal theory of mine is that old well bores like this may also decline in production due to lime deposits at the layers of water production and may need to either be scraped in some way or acidized to promote continued flow.

This would produce a lot of debris that would need to be removed from the bottom of the bore but the cost of drilling another well (hit-or-miss proposition at $$$/ft regardless) and either moving the windmill or putting in a solar pump like we've done on one last year makes you go "hmmmm....

The well that's given us the most problems over the years is a high sulfur content water well. As of earlier this year the sulfur aquifer or layer has either played out or caked over and what little water is coming out is now sweet but production has gone down to almost nothing. Hence my longing for a well camera to reduce the guess work. Have any suggestions for any brands or opinions yea or nay on personal ownership?

Reply:

A bit costly to buy a well bore inspection camera. Here are a couple of ideas;

See if there are any chimney sweeps (probably not) in your area. Those guys may have a camera that can inspect the dry portion of the bore (which would be a partial exam)

OR

See if you can partner with a local well driller - one of the younger, more interested, technical fellows but who does not have an inspection camera. Offer to share the camera cost with him or her in exchange for examining your wells. S/he will then have a tool and expertise that expands her business.

(Aug 19, 2014) Bill K said:

Thanks again Dan,

I finally had time to more carefully read over your suggestions and the well cleaner of Mr. Guthrie's in Early, TX is intriguing. My uncle may actually be acquainted with him as he's from that area. I may contact him or his family to get a better understanding of that cleaner's design.

We have an old well cleaner in the barn that might be convertible to this method. And, yes, we have our own "magic pile" of junk that we've been re-purposing for three generations now! You NEVER throw anything away on a ranch or farm. Junk is a ag man's gold.

Our wells were drilled at a time that casing was only partially inserted down the bore to a depth, I'm assuming, that the rock layers began. I guess they thought the rock wall would hold for at least a generation or two but that would put us just about at the end of that time line.

Reply:

(Aug 20, 2014) (mod) said:

Indeed the casing is usually stopped some short distance into the rock if rock is encountered - since we expect water to enter the well bore through fissures in that very stone.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-05-18 - by (mod) -

Do you have the parts explosion and manual for your pump? I'd check the parts schematic there.

On 2020-05-17 by Pat

I have a two pipe gould pump from 1985 model j05n i had to change the diagram gasket im not sure if the two holes go on the top

On 2018-06-17 - by (mod) -

Farm

It doesn't sound like you did anything wrong.

It does sounds like while the power was off and therefore the pump could not run, water draining back into the well through leaky or failed foot valve cause the pump to lose Prime. In this article series you'll find two ways to reprime the pump to get water going again.

However if you lose power again you're likely to lose Prime again and have no water. Therefore the correct fix is going to be to pull the well pipe and replace the foot valve. Some systems use a check valve right at the pump or between the pump and the well so that's another place to check for a failed or leaky check valve.

On 2018-06-17 by Farmer Blu

I turned off circuit breaker going to my below ground, two line , jet pump and then opened my water faucet to relieve water pressure so could replace a faucet valve located along same supply line. I left my water faucet open and turned on circuit breaker but no water came from open faucet.

My pump was running but never got water. Why not? What did I do wrong ? I need step by step troubleshooting procedure and please explain why my repair cause an issue?. Thank You Farmer Blu

On 2016-08-16 - by (mod) -

David,

Well that's a painful diagnostic.

Water might run continuously out of an artesian well, but still if your pump's output rate exceeds the well's flow rate you might temporarily run out of water and run the pump dry, damaging it.

But more likely explanations are

- a pressure control switch with a cut-off pressure set above the pump's capacity

- water running somewhere or a burst, leaky well pipe or water pipe

Gurgling out of the well usually means a leaky check valve or foot valve, but with an artesian well set-up I don't know.

IF your artesian well uses a well spool to seal water near the well top that could be leaking.

Also search InspectApedia.com for PUMP WON'T STOP RUNNING to read a longer list of causes and cures.

On 2016-08-15 by David Banks

I have a 2 pipe jet pump...it's brand new...it's still doing same thing old pump did...runs continually. ..pressure tank is good...28 psi in tank...

I have an artesian well and water continuously runs out of well....when I turn power off to pump I will get gurgling sound out of well....any ideas

On 2016-04-22 - by (mod) - can't get the well pump to prime

Frank,

I'd look for a leak in well piping in either of the lines, the downline or the upline

I'd look at the pump impeller assembly for scale or internal damage

I'd check the voltage level vs the pump requirements

If you search InspectApedia.com for HOW TO PRIME THE PUMP you will see a couple of methods; the "garden hose" method might work for you.

Keep us posted

On 2016-04-21 by Frank

I just bought a vacation property were it sat dorment for 5 years I have a deep well two-line jet pump that set without power this entire 5 years upon inspection of the well it appeared to still have Prime

water tank was still full of water pump motor needed some work to do to setting try as I might I cannot get it to Prime

now it passes a pressure test no leaks but no amount of priming seems to get it to the point where it will carry itself approximately 90 foot deep

it appears to have excellent suction not sure if next move is to pull Center pipe and check foot valve comments suggestions please thank you

On 2016-03-30 - by (mod) -

Mahfooz:

ऊर्ध्वाधर दूरी उठाने के लिए एक पानी पंप करने की क्षमता आम तौर पर निर्माता द्वारा पंप विनिर्देशों की एक तालिका में दी गई है । असल में उच्च पंप उठाने के लिए है, कम प्रति मिनट लीटर में उसके प्रवाह दर होगी। और अगर लिफ्ट पंप दर से अधिक है तो आप कुछ भी नहीं मिलता प्रबंधन कर सकते हैं । पाइप व्यास , पाइप झुकता है या फिटिंग, और साथ ही साथ ही अन्य कारकों में बह रही पानी की दर से मतलब हो सकता है कि पंप तरह से आप चाहते काम नहीं कर रहा है। लेकिन यह लौटने से पहले , चलो यकीन है कि पानी का खूब साथ ही ज , कि पंप क्षतिग्रस्त नहीं है , भरा न हो , और गरमा लीक नहीं है कि । यह भी जांच की जा रही है कि वोल्टेज से वितरित करने के लिए पंप मैचों क्या पंप डेटा टैग का कहना है कि उम्मीद है।

oordhvaadhar dooree uthaane ke lie ek paanee pamp karane kee kshamata aam taur par nirmaata dvaara pamp vinirdeshon kee ek taalika mein dee gaee hai . asal mein uchch pamp uthaane ke lie hai, kam prati minat leetar mein usake pravaah dar hogee. aur agar lipht pamp dar se adhik hai to aap kuchh bhee nahin milata prabandhan kar sakate hain . paip vyaas , paip jhukata hai ya phiting, aur saath hee saath hee any kaarakon mein bah rahee paanee kee dar se matalab ho sakata hai ki pamp tarah se aap chaahate kaam nahin kar raha hai. lekin yah lautane se pahale , chalo yakeen hai ki paanee ka khoob saath hee ja , ki pamp kshatigrast nahin hai , bhara na ho , aur garama leek nahin hai ki . yah bhee jaanch kee ja rahee hai ki voltej se vitarit karane ke lie pamp maichon kya pamp deta taig ka kahana hai ki ummeed hai.

On 2016-03-30 - by (mod) -

Mahfooz

The ability of a water pump to lift vertical distances is usually given in a table of pump specifications by the manufacturer. Basically the higher the pump has to lift, the less will be its flow rate in liters per minute. And if the lift rate is higher than the pump can manage you get nothing.

Pipe diameter, pipe bends or fittings, and the rate of water flowing into the well as well as other factors can mean that the pump is not working the way you want. But before returning it, let's be sure that the well h as plenty of water, that the pump is not damaged, not clogged, and that the piping is not leaking.

Also check that the voltage being delivered to the pump matches what the pump data tag says it expects.

On 2016-03-29 - by (mod) -

English translation of Mahfooz' question:

Translation

I bought a j1 1hp. The dealer stated the water level would be upto 60 feet. But the water’s something capacity something. Thereafter after getting/ buying the fitting, the water is not coming. The water level is about 35 feet and it is not working.

On 2016-03-29 by mahfooz alam

Mai ne j1 1hp kharida dealer ne bataya ki pani ka level 60 feet tak ho fir vi pani khichne ki capicity hai lekin fitting larne ke baad pani nahi aaraha hai jis ka water level lagbhag 35 feet hai kaam nahi kar raha hai

Question:

(Dec 11, 2011) Ken said:

Problem: Pump will lose it's pressure very quickly.

It is a Two Line Jet Pump.

Question: If I put a check valve at the pump side do you think this will fix the problem?

The small line pushes the water down the well. The large line is pulling the water up the pipe. If the pressure leak is cased by something at the small pipe how could I put a check valve on the pump side to prevent the problem?

(June 30, 2012) Mike said:

Hi,

I just bought the house with old Myers 2 line jet pump which is used for the sprinkler system only.

On the instruction for home owner ( paper on the basement wall ) said to keep one valve ( intake) open , the other one ( from the pump) closed. I thought they both should be open. Any idea why ?

Reply:

Mike I'd like to help but am flying blind here - I just don't understand what valves are where - certainly if you close a valve found immediately on the outlet side of a water pump (that is between the pump outlet and the pressure tank or any other piping) you're likely to blow the pump seals or damage the unit.

I am making a WILD GUESS that perhaps your home converted from private well to municipal water, and that the old pump and well were kept for yard watering, and you are being instructed not to feed pump output into the house (try following the pipes to see what's going on).

If this is the case, the installation is improper and unsanitary. If it's the case I describe the pump should have no connection to house piping whatsoever.

Question: need for a double foot valve?

(May 11, 2014) Harold said:

I need to know if a double foot valve is requuired when the pump is drawing water from a lake.

Reply:

Harold:

You might need a larger size or larger capacity foot valve when picking up water from a lake if fast or frequent clogging of the foot valve screen is a problem.

You might need multiple check valves over the height of a long vertical water pick-up line if, for example, the total rise in height was more than 250 feet. In that case experts often say you need an additional check valve for every 250 feet of vertical rise.

Question: switch from 2 line to 1-line well piping system?

(July 8, 2014) Anonymous said:

can i switch from a two drop pipe system to a one drop pipe system

Reply:

Anon it depends on the well depth - the total lift that the pump has to achieve. If your well water pick-up point is more than 27 ft. below ground level you'll need a 2-line jet pump or if you need to go to just one pipe, then you'll need to use an in-well submersible pump.

Question: jet pump won't turn off

(Sept 14, 2014) frank s said:

pump wont go up to forty lbs only goes to 36 and wont stop running

Reply:

Frank

IN the More Reading links in the article above see

WATER PUMP WONT STOP RUNNING

...

Continue reading at WATER PUMP, TWO LINE JET - home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SHORT CYCLING WATER PUMP

- WATER PRESSURE PROBLEM DIAGNOSIS TABLE

- WATER PUMP DIAGNOSTIC TABLE

- WATER TANK & PUMP DRAIN & WINTERIZE

Suggested citation for this web page

PUMP, TWO LINE JET OPERATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER SUPPLY, PUMPS TANKS WELLS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Thanks to our reader, Carole Cimitile, 2/17/2009, for reminding us that small problems like faucet o-rings, clogged faucet strainers and similar local plumbing fixture defects can have a big impact on hot water flow, cold water flow, or both hot and cold water flow and pressure problems.

- Penn State, Water Fact Sheet #3, USING LOW-YIELD WELLS [PDF], Penn State College of Agricultural Sciences, Cooperative Extension, School of Forest Resources, web search 07/24/2010, original source: http://pubs.cas.psu.edu/FreePubs/pdfs/XH0002.pdf

- Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Water Ace Jet Pump Installation Manual, instructions from Water Ace Pump Co., web search 08/28/2010, original source: http://www.waterace.com/pdf/R510%20R520%20and%20R100%20Jet%20Pumps%20Manual.pdf

Consumer hotline: 800-942-3343 - instructions for the installation and maintenance of

Water Ace shallow well pump Model R510 1/2 HP

Water Ace deep well pump Model R100 convertible 1HP and

Water Ace deep well jet pump Model R250 convertible 1/2 hp.

Water Supply & Drain Piping, Wells, Pumps, Water Supply Equipment

- Access Water Energy, PO Box 2061, Moorabbin, VIC 3189, Australia, Tel: 1300 797 758, email: sales@accesswater.com.au Website: http://www.accesswater.com.au/

Moorabbin Office: Kingston Trade Centre, 100 Cochranes Rd, Moorabbin, VIC 3189

Australian supplier of: Greywater systems, Solar power to grid packages, Edwards solar systems, Vulcan compact solar systems, water & solar system pumps & controls, and a wide rage of above ground & under ground water storage tanks: concrete, steel, plastic, modular, and bladder storage tanks. - Grove Electric, Typical Shallow Well One Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Grove Electric, Typical Deep Well Two Line Jet Pump Installation [PDF], Grove Electric, G&G Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -7/15/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.