Types of Splines & Gaskets on Solid & Milled Log Homes

Types of Splines & Gaskets on Solid & Milled Log Homes

- POST a QUESTION or COMMENT about log home sealants, caulks, splines, gaskets, and special chinking materials

Here we the types of sealants, chinking, splines or gaskets used during the construction of both traditional rough cut logs and modern milled log or solid log houses.

This series of articles provides information on the inspection and diagnosis of damage to new and older log homes and includes description of log house and log siding insulation values and alternatives, and also a description of the characteristics of slab-sided log homes as well as all other types of log home construction.

We include illustrations of log structures from several very different areas and climates in both the United States and Norway. Our page top photo shows a modern kit log home constructed in New York State.

For modern kit and factory-sourced log structures we include details of common construction and building defects that cause water and air leaks and ultimately rot damage and we point to key problem areas that need to be inspected carefully when buying or maintaining a log home.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Types of Log Wall Spline & Gasket Sealing Methods

On both traditional rough-cut log buildings and on modern kit logs and milled log structures there are many designs for sealing the interfacing logs as well as sealing at windows, doors, and building eaves. Here we provide photos and text of basic log sealing methods, both traditional chinking and weather stripping and modern splines, gaskets, and caulks.

Our page top photo shows a modern milled log that uses a double raised rib or "spline" that mates itno a groove milled into the bottom surface of each log above. Gaskets (or in some cases caulk) are used on top of each spline (or on occasion along side them) in this design.

Traditional Log Walls Used Chinking not Splines nor Gaskets

As our photo (above left) shows, a traditional log house, built from individually-cut logs, may have included cutting or sawing the mating surfaces of horizontally (usually) or vertically (less common) placed logs against one another to obtain a flat surface. Other homes were constructed with fully-round logs and no planing of the mating surfaces.

But in all cases, to avoid terrible drafts and water leaks, a variety of log wall chinking methods were used between the logs of a log house:

- Mud and straw or oakum or animal hair (FIBER & HAIR IDENTIFICATION)

- Wood strips nailed between logs on the building interior often over newspaper or oakum. Often milled quarter-round strips were added on the interior of an older cabin such as this one that was built in the 1920's on the shore of Lake Superior. (Photo at above right is of a combination vertical and horizontal log cabin wall in Two Harbors, Minnesota)

- Concrete log wall chinking (photo at above left is of a native-log rough-cut un-milled vertical-wall log cabin in Pennsylvania)

- Modern log wall chinking materials such as Perma-Chink™ that may be used as a retrofit repair product on all of these older log buildings

Single-Splined Log Mating Surfaces

Our photo (left) shows a simple single-spline log constructed building built probably after 1970.

The top and bottom of each log was milled flat and a single rabbet groove cut into the log.

The groove was intended to carry a single wooden spline between logs to stop draft. You'll notice that no chinking is used between logs in walls that use a spline design.

Omission of log splines or log gaskets specified by the log manufacturer will lead to infiltration losses, drafts, possibly water leaks from wind-blown rain, and higher heating bills.

Double Splines Between Log Mating Surfaces

Logs in more recent modern kit homes are mated along their horizontal surfaces either by one or more splines that are set into grooves cut into the mating surfaces of logs as they are stacked, or the upper surface of the lower log may one or more raised ridges that set into grooves cut into the bottom surface of the log being placed on top of the lower unit.

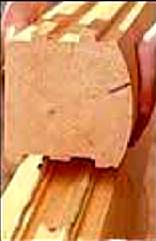

Our photo shows a typical "D" profile log in cross-section at a building corner. The checking you see in this log end is normal and is not a structural concern.

But notice how the left-hand large check just below the middle of the log slopes down to the log interior ? This opening will collect water and can lead to long term log rot or frost damage.

Log kit specifications usually call for either caulk applied atop the raised spline, or as in the case of the log we show here, along the two raised splines.

Other log companies call for a special gasket to be placed either atop the splines or along side them to assure that these joints will be weather tight.

Caulk or Gaskets Used at Multi-Splined Log Mating Surfaces in a Log House Wall

Most milled-log manufacturers now use a more complex spline design, often with two raised splines on the upper surface of each log that are intended to mate with two rabbets cut into the bottom of the log above (see our photos just above). (Photos courtesy of Merrimac Log Homes)

Gaskets are placed on or between or in front and behind each of these mating spline/groove seals, or on top of a single wide spline (photo above-right) or the manufacture may specify use of a bead of special caulk on top of each spline (photo at far left).

In Merrimanc's photo (above-left) you can see the required bead of caulk set atop each spline as the log is being placed. Don't let too much time elapse between caulk placement and log placement or the caulk may be dry and may not seal well.

We advise against simply using generic caulks in these locations.

Luckily, and probably because this is a common error, there are special products that can be used to remedy leaks in log walls. If inspection or if cold, windy weather reveals air infiltration leaks, call your inspector or log manufacturer for suggestions for special log chinking, caulks, or other log home crack or leak sealants.

...

Continue reading at SPLINE GAPS & GASKET OMISSIONS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Log Home Articles

- LOG HOME GUIDE

- AIR LEAK DETECTION TOOLS

- ANTIQUE & OLD LOG CABINS

- CRACKS CHECKS SPLITS in BEAMS, LOGS & POSTS

- DIAMOND WEDGE CUT LOG CABIN

- ENERGY EFFICIENCY of LOG HOMES

- INSULATION R-VALUE, SOLID LOG WALL

- KIT HOMES, Aladdin, Sears, Wards, Others

- LEAK DIAGNOSIS & CURE in LOG HOMES

- LOG HOME CONSTRUCTION

- R-VALUES & THERMAL MASS in LOG HOMES

- ROT, TIMBER ASSESSMENT

- SEALANTS CAULKS COATINGS for LOG HOMES

- SHRINKAGE & HEIGHT CHANGES, LOG WALL

- SLAB SIDING LOG HOMES

- SPLINE & GASKET DESIGNS for LOG HOMES

- SPLINE GAPS & GASKET OMISSIONS

- THERMAL MASS in BUILDINGS

- VERTICAL LOG WALL CABINS

Suggested citation for this web page

SPLINE & GASKET DESIGNS for LOG HOMES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING STRUCTURES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about log home sealants, caulks, splines, gaskets, and special chinking materials

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Thanks to Arlene Puentes for the photograph of a checked log in a log home exterior. Arlene Puentes, a licensed home inspector, educator, and building failures researcher in Kingston, NY. Photographs © Arlene Puentes 2006 All Rights Reserved. Text © Daniel Friedman Arlene Puentes 2008 All Rights Reserved.

- "The Logless Log Home," Jim Robbins, New York Times, 05/05/2010 Home section, p. D1 & D6.

- "Shop Talk," Martin Mintz, AIA, Builder Magazine, April 1986, detailed solutions for log shrinkage movement by using a "T" jamb at windows and doors. A January 1986 Builder Magazine article shows window installation details in 8" thick log walls.

- "Caulking, Chinking, Insulators, Sealants - which System works Best," Log Home and Alternative Housing Builder, Nov-Dec 1983.

- Insulating Characteristics of log homes were neatly summarized by Roger Rawlings in "Log Homes in a New Light," Rodale's New Shelter, April 1983, p. 28

- Lincoln Log Homes Marketing, Inc., 6000 Lumber Lane, Kannapolis NC 28081 704-932-6151

- Merrimac Log Homes, Henniker, NH, sells log home products, milled log home kits, log siding, and log home plans and log home construction accessories. 866-637-7462 or logs@mlhnh.com - merrimacloghomes.com

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for certain articles found at this website. All rights and contents to those materials are ©Journal of Light Construction and may not be reproduced in any form.

- Appliances and Home Electronics, - energy savings, U.S. Department of Energy

- Avongard FOUNDATION CRACK PROGRESS CHART [PDF] - structural crack monitoring

- BASEMENT MOISTURE CONTROL [PDF] U.S. Department of Energy

- Building Failures, Diagnosis & Avoidance, 2d Ed., W.H. Ransom, E.& F. Spon, New York, 1987 ISBN 0-419-14270-3

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- The Circular Staircase, Mary Roberts Rinehart

- Construction Drawings and Details, Rosemary Kilmer

- CRAWL SPACE MOISTURE CONTROL [PDF] U.S. Department of Energy

- Design of Wood Structures - ASD, Donald E. Breyer, Kenneth Fridley, Kelly Cobeen, David Pollock, McGraw Hill, 2003, ISBN-10: 0071379320, ISBN-13: 978-0071379328

This book is an update of a long-established text dating from at least 1988 (DJF); Quoting:

This book is gives a good grasp of seismic design for wood structures. Many of the examples especially near the end are good practice for the California PE Special Seismic Exam design questions. It gives a good grasp of how seismic forces move through a building and how to calculate those forces at various locations. THE CLASSIC TEXT ON WOOD DESIGN UPDATED TO INCLUDE THE LATEST CODES AND DATA. Reflects the most recent provisions of the 2003 International Building Code and 2001 National Design Specification for Wood Construction. Continuing the sterling standard set by earlier editions, this indispensable reference clearly explains the best wood design techniques for the safe handling of gravity and lateral loads. Carefully revised and updated to include the new 2003 International Building Code, ASCE 7-02 Minimum Design Loads for Buildings and Other Structures, the 2001 National Design Specification for Wood Construction, and the most recent Allowable Stress Design. - Diagnosing & Repairing House Structure Problems, Edgar O. Seaquist, McGraw Hill, 1980 ISBN 0-07-056013-7 (obsolete, incomplete, missing most diagnosis steps, but very good reading; out of print but used copies are available at Amazon.com, and reprints are available from some inspection tool suppliers). Ed Seaquist was among the first speakers invited to a series of educational conferences organized by D Friedman for ASHI, the American Society of Home Inspectors, where the topic of inspecting the in-service condition of building structures was first addressed.

- Domestic Building Surveys, Andrew R. Williams, Kindle book, Amazon.com

- Defects and Deterioration in Buildings: A Practical Guide to the Science and Technology of Material Failure, Barry Richardson, Spon Press; 2d Ed (2001), ISBN-10: 041925210X, ISBN-13: 978-0419252108. Quoting:

A professional reference designed to assist surveyors, engineers, architects and contractors in diagnosing existing problems and avoiding them in new buildings. Fully revised and updated, this edition, in new clearer format, covers developments in building defects, and problems such as sick building syndrome. Well liked for its mixture of theory and practice the new edition will complement Hinks and Cook's student textbook on defects at the practitioner level. - Guide to Domestic Building Surveys, Jack Bower, Butterworth Architecture, London, 1988, ISBN 0-408-50000 X

- "Avoiding Foundation Failures," Robert Marshall, Journal of Light Construction, July, 1996 (Highly recommend this article-DF)

- "A Foundation for Unstable Soils," Harris Hyman, P.E., Journal of Light Construction, May 1995

- "Backfilling Basics," Buck Bartley, Journal of Light Construction, October 1994

- "Inspecting Block Foundations," Donald V. Cohen, P.E., ASHI Reporter, December 1998. This article in turn cites the Fine Homebuilding article noted below.

- "When Block Foundations go Bad," Fine Homebuilding, June/July 1998

- Historic Preservation Technology: A Primer, Robert A. Young, Wiley (March 21, 2008) ISBN-10: 0471788368 ISBN-13: 978-0471788362

- LOG HOMES: MINIMIZING AIR LEAKAGE [PDF] U.S. Department of Energy

- Manual for the Inspection of Residential Wood Decks and Balconies, by Cheryl Anderson, Frank Woeste (Forest Products Society), & Joseph Loferski, October 2003, ISBN-13: 978-1892529343,

- Masonry Design for Engineers and Architects, M. Hatzinikolas, Y. Korany, Canadian Masonry (2005), ISBN-10: 0978006100, ISBN-13: 978-0978006105

- Masonry Structures: Behavior and Design, Robert G. Drysdale, Ahmid A. Hamid, Lawrie R. Baker, The Masonry Society; 2nd edition (1999), ISBN-10: 1929081014, ISBN-13: 978-1929081011

- Masonry, Engineered: Using the Canadian Code, J. I. Gainville, Cantext publications (1983), ASIN: B0007C37PG

- Masonry, Non-reinforced masonry design tables, Hans J. Schultz, National Concrete Producers Association and the Canadian Masonry Contractors Association (1976), ASIN: B0007C2LQM

- MOISTURE CONTROL in BUILDINGS [PDF] U.S. Department of Energy

- MOISTURE CONTROL in WALLS [PDF] U.S. Department of Energy

- Quality Standards for the Professional Remodeling Industry, National Association of Home Builders Remodelers Council, NAHB Research Foundation, 1987.

- Quality Standards for the Professional Remodeler, N.U. Ahmed, # Home Builder Pr (February 1991), ISBN-10: 0867183594, ISBN-13: 978-0867183597

- Slab on Grade Foundation Moisture and Air Leakage, U.S. Department of Energy

- Straw Bale Home Design, U.S. Department of Energy provides information on strawbale home construction - original source at http://www.energysavers.gov/your_home/designing_remodeling/index.cfm/mytopic=10350

- More Straw Bale Building: A Complete Guide to Designing and Building with Straw (Mother Earth News Wiser Living Series), Chris Magwood, Peter Mack, New Society Publishers (February 1, 2005), ISBN-10: 0865715181 ISBN-13: 978-0865715189 - Quoting:

Straw bale houses are easy to build, affordable, super energy efficient, environmentally friendly, attractive, and can be designed to match the builder’s personal space needs, esthetics and budget. Despite mushrooming interest in the technique, however, most straw bale books focus on “selling” the dream of straw bale building, but don’t adequately address the most critical issues faced by bale house builders. Moreover, since many developments in this field are recent, few books are completely up to date with the latest techniques.

More Straw Bale Building is designed to fill this gap. A completely rewritten edition of the 20,000-copy best--selling original, it leads the potential builder through the entire process of building a bale structure, tackling all the practical issues: finding and choosing bales; developing sound building plans; roofing; electrical, plumbing, and heating systems; building code compliance; and special concerns for builders in northern climates. - VAPOR BARRIERS or VAPOR DIFFUSION RETARDERS [PDF] U.S. DOE - how vapor barriers work, types of vapor diffusion barriers, installing vapor barrier

- VENTILATION for ENERGY-EFFICIENT BUILDINGS [PDF] Purpose of ventilation, ventilateion strategies, etc.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

Log Home Design, Inspection, Maintenance, Repair References & Product Sources

- LOG HOMES: MINIMIZING AIR LEAKAGE [PDF] U.S. Department of Energy

- Log Homes: Controlling Moisture in Log Homes, U.S. Department of Energy

- Log Homes: Log Home Design, U.S. Department of Energy

- Lincoln Log Homes Marketing, Inc., 6000 Lumber Lane, Kannapolis NC 28081 704-932-6151

- Merrimac Log Homes, Henniker, NH, sells log home products, milled log home kits, log siding, and log home plans and log home construction accessories. 866-637-7462 or logs@mlhnh.com - merrimacloghomes.com

- PermaChink Systems, Knoxville TN 800-548-1231 provides a range of log chinking products, coatings, and sealants for log and other wood buildings.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.