Wall Anchor Choices, Types, & Capacities

Wall Anchor Choices, Types, & Capacities

Toggle Bolts, Molly Bolts, Drive Anchors, Flip Toggles, Self Drilling Anchors

- POST a QUESTION or COMMENT about wall anchor choices, types, and capacities

This article describes different types of wall hangers and wall anchors, giving their features such as ease of installation, drilling requirements, removal ability, re-usability, and weight bearing or load capacity.

What to use to hang something heavy on a wall when a nail just won't do.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Wall Anchors, Molly Bolts, Toggle Bolts & Driven Wall Anchors

How do we hang heavier objects on a wall that need more support than a nail?

How do we hang heavier objects on a wall that need more support than a nail?

Let's look past a simple picture hook and nail to the types of drywall and plaster board fasteners that can carry more weight.

Watch out: most (not all) of these larger, heavier duty and heavier load capacity drywall anchor products require some drilling or at the very least making a bit of dust. If you're concerned about possible dust hazards, use damp wiping and HEPA vacuuming to complete your cleanup.

The wall anchors described here are intended for use in building interiors, principally on walls, with focus on hollow walls such as those covered by drywall or plaster.

These fasteners are drilled or pushed or hammered through hollow wall coverings. They are not and can not be inserted into wall structural members like studs or headers.

For very heavy objects hung on walls such as televisions and appliances, you will usually want to use a strap hanger and to connect the fasteners to the building's structural frame.

We include a few anchors used in masonry walls but here we have not attempted to cover the large range of structural and similar fasteners used in solid masonry and concrete.

Best approach for hanging something heavy from a building wood or steel-framed wall

For wood frame or metal framed structures, where you can, and certainly for heavy loads, it's best to use a stud finder to locate the wood (or metal) studs or framing members and put your nail or screw right into a structural member.

Alternative approaches for hanging something heavy from a building wood or steel-framed wall

Choose a suitable wall anchor from those we describe below. All of these anchors are designed to insert into a wallboard or similar material. Some of these fasteners might also work in some masonry walls such as hollow concrete block, CMUs, or brick walls or in mortar joints.

Really? Do we need a toggle bolt or molly or some fancy strong wall hanger? Well, not if you're just hanging a rather light picture on a wall,

Article Contents

- HOW to CHOOSE a WALL ANCHOR DEVICE

- DRIVE ANCHORS & MOLLY BOLTS

- FLIP TOGGLE BOLT ANCHORS

- RIBBED WALL ANCHORS & LAG / EXPANSION SHIELDS, PLASTIC, NYLON, LEAD, ZINC

- SELF DRILLING NYLON & ZINC ANCHORS

- SELF DRILLING TOGGLE ANCHORS

- SPRING TOGGLE BOLTS / TOGGLE ANCHORS

- TAPCON CONCRETE ANCHORS / SCREWS

...

How to Choose a Wall Anchor Device

When we need to support a heavier load than a small picture frame and when the support can not be located directly into a wall stud, we use one of the products listed below, chosen based on at least the following criteria:

When we need to support a heavier load than a small picture frame and when the support can not be located directly into a wall stud, we use one of the products listed below, chosen based on at least the following criteria:

- What is the weight or load that the anchor has to carry?

Choose an anchor type that can carry the weight. Don't try hanging a wall TV from push-in ribbed plastic wall anchors. - What is the wall material?

Don't use a lead anchor in drywall nor a plastic self-tapping anchor in a mortar joint. - Does drilled wall hole size matter?

Using a toggle bolt like those shown above gives a very strong wall hanger but requires a much bigger hole than most other fasteners.

If you're installing a handrail bracket, you don't want the anchor bolt hole to extend out so far that it shows or so far that the bracket it's supporting has too little purchase space on the wall surface. - Are we going to need to remove the wall anchor later?

Reading below, you'll see that some of these anchors are easy to remove, some with minimal damage to the wall itself. - Precision requirements for mount hole location

Some of these fasteners, like toggle bolts, because they're inserted through a larger hole in the wall, can give you a little play in exact location of the supporting screw or bolt - pretty useful if you're not up to precise hole drilling.

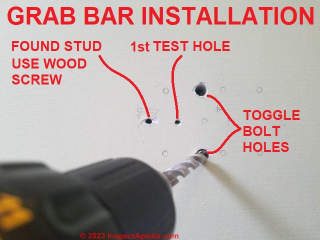

In our photo above, you can see that the large holes needed to install the toggle bolts for this grab bar give us some adjustment leeway in placing the grab bar exactly where we want it on the wall.

Below: the larger holes drilled for using toggle bolts allow accurate leveling up of this grab bar as its mounting bolts and screws are tightened.

The product drywall mounting devices or drywall anchors described in this article may look similar but they have some important differences that we'll outline.

Example choices are among traditional drywall anchors or properly named, Toggle bolts, Molly bolts, and a hybrid drywall anchor that requires little or no drilling, insert through a much smaller hole than a drywall anchor, but that sprouts wings similar to traditional drywall anchors.

For hanging something on a masonry wall

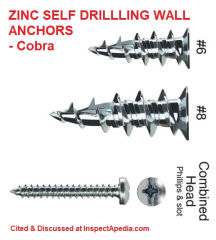

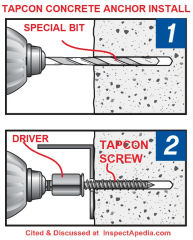

Best approach: quick and remarkably effective in concrete block or brick, use a Tapcon screw system. Self-tapping hard-steel "Tapcon" type screws for use in masonry are sold by several vendors including Tapcon, Cobra and other suppliers, shown below in our own hardware & tool supplies, just below.

For poured concrete use a lead or zinc lag shield for heavy items.

Second best: use a traditional lead or zinc or plastic anchor. In our OPINION, among these choices, lead or zinc may out perform plastic.

These fasteners are illustrated on this page.

...

Spring Toggle Bolts in Drywall or Plaster Walls - Toggle Anchors

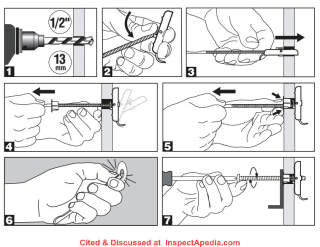

Above: Everbilt brand drywall anchors have wings that expand to give more strength and thus to carry more weight without damaging the wall or risking injury or damage when your cabinet or shelf or scimitar fall off of the wall. These steel toggles use spring-loaded toggles or "wings" that are folded as they're inserted through a drilled hole in a hollow wall.

As the machine-threaded screw is tightened, the toggle is pulled tight against the inside of the wall surface while the screw head, having passed through a washer, strap, or device mounting hardware component, is pulled snug against the wall exterior.

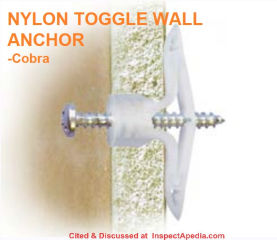

Lighter capacity wall toggles made of nylon and using a sheet metal thread-type screw are also described below.

This type of wall hanger will require the largest drilled opening in the wall to insert the spring-expanding anchor wings.

The 3-inch long drywall anchors shown above with "wing nut" or toggles that are spring loaded to expand once pushed through the hole drilled into the wallboard to give a very strong grip inside the wall.

Take a look at the spring-loaded wings to see the bolt size stamped into the wing surface. That's the diameter of the bolt itself, not the diameter of the hole you need to drill.

Above I'm holding a 3/16" toggle bolt and a 1/8" toggle bolt.

That 3/16" bolt size (uppermost in my photo above) requires a 1/2" diameter hole in the wall to push in the folded wings of the toggle assembly.

Sometimes you can get away with a slightly smaller hole and wiggle and push the toggle through - don't laugh, you'll be trying that when you see that the base of the bracket you're putting up won't cover the giant hole you'd need to drill into the wall.

That's especially true when mounting grab bars whose mount holes are close to the edge of their round escutcheon plate.

Watch out: the size stamped into the wings of those toggle bolts can trick you. It may be no accident. If you choose a bolt diameter that's heavier than your wall load weight requires, you may be in trouble when you see how large the hole must be that you'll have to drill into the wall.

The hole size you need to drill to use a toggle bolt depends not on the bolt shank diameter but rather on the diameter of its folded wings.

A 1/4-inch heavy duty toggle bolt (remember this is bolt diameter not wing-hole size) will require a 5/8" hole in drywall or similar wallboard, and a 3/4" size if you're inserting the toggle bolt through the web of a hollow concrete block or "CMU" (Concrete Masonry Unit).

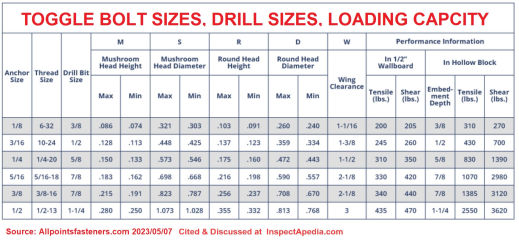

Table of Toggle Bolt Hole Sizes

Above: after using a stud finder and drilling a test hole to be sure we could get at least one structural screw into a wood stud (preferably two), we used the grab bar base as a template to mark the location of two more holes that would have to be large enough to accept our toggle bolt.

- 1/8" Toggle Bolt Drill Bit: 3/8"

- 3/16" Toggle Bolt Drill Bit: 1/2"

- 1/4" Toggle Bolt Drill Bit: 5/8"

- 5/16" Toggle Bolt Drill Bit: 7/8"

- 3/8" Toggle Bolt Drill Bit: 7/8"

- 1/2" Toggle Bolt Drill Bit: 1 1/4"

Often we want to avoid a large hole drilled into a wall, lest the hole show up behind or around the bracket or whatever else we're attaching to the wall.

So choose the smallest toggle bolt screw size that is strong enough to carry the weight that it must support.

Watch out: Don't do what you see in the picture above: if you push the bolt and toggle assembly into the wall before passing the bolt through the bracket it is going to support, you're sunk: removing the bolt to put it through the bracket later will let the expanded toggle assembly just fall down into the wall cavity - lost!

Remember that when installing a toggle bolt to support a bracket or to hang something else from a wall, the screw must be passed through the bracket or device hole and then the wings secured to the end of the screw before you push the expanding wing assembly through the hole in the wall.

Once installed in a wall, the expanded wings of a toggle bolt are almost impossible to remove without cutting open the wall, so if you unscrew the screw completely, the wing-nut assembly will just fall down into the wall cavity.

Toggle Bolt Drywall Anchor Re-use / Removal

A toggle bolt type wall anchor can be removed from the wall - at least the screw can be removed.

You'll be left with the hole to fill or re-use. To re-use the toggle bolt you'll need a new wing set - not sold alone, so in essence you'll have to use a whole new assembly.

Toggle Bolt Load Capacity

Toggle bolt load capacity, as with other fasteners discussed here, depends on both the bolt size and the wall material into which it is installed.

Example: using Cobra's spring toggle bolt capacity chart for drywall, a 1/8" toggle bolt in drywall, using just shear strength and ignoring "pull out" or withdrawal" resistance, can safely carry approximately

- 27 pounds in 3/8" drywall

- 31 pounds in 1/2" drywall

- 41 pounds in 5/8" drywall

- 55 pounds in 3/4" drywall

Really? You'll see in the references we provide below that some sources give much greater strengths, e.g. 205 lbs in 1/2" wallboard. We're uncertain of such data. The toggle bolt itself may have great shear strength, but hanging a heavy weight on a toggle bolt in drywall risks deforming or tearing the drywall such that the object might still fall.

The detailed Toggle Bolt data table from allpointsfasteners.com below gives drill bit sizes & load capacities for typical toggle bolts of various sizes.

Really? don't confuse shear strength and tensile strength with withdrawal strength nor load bearing capacity in the drywall.

- Allpoints Fasteners, Tel: 800-483-6354, Email: sales@allpointsfasteners.com - retrieved 2023/05/09, original source: allpointsfasteners.com - this is the source of the toggle bolt size table given above on this page.

- Cobra NYLON TOGGLE WALL ANCHOR SPECIFICATIONS & INSTRUCTIONS [PDF] Cobra Anchors Ltd., US Tel: 800-824-7717 Canada Tel: 514-354-2240 Web: www.cobraanchors.com

- Cobra SPRING TOGGLE BOLT TECHNICAL SPECIFICATIONS [PDF] Cobra Anchors Ltd.

...

Flip Toggle Wall Toggle Bolt Anchors

- Cobra FLIP TOGGLE WALL ANCHOR INSTRUCTIONS [PDF] Cobra Anchors Ltd., op. cit., - retrieved 2023/05/11

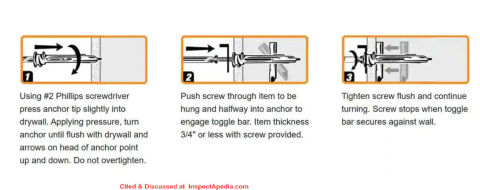

As illustrated just below, a "Flip Toggle" works similarly to spring toggles but is flipped by hand instead to "flip" to an open position in the wall rather than being forced open by springs.

Like the self-drilling toggles listed below, the flip toggle uses a smaller hole in the wall than traditional spring toggles.

...

Self-Drilling Toggle Wall Anchors

Similar to the spring toggles and flip toggle wall anchors described above are toggle bolts that are "self-drilling" - that is, you don't need to use a separate drill bit to insert the toggle into the wall.

A significant difference between a spring toggle (above) and flip and self-drilling toggles (below) is that these toggle bolts require a significantly smaller hole in the wall.

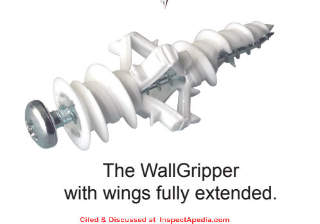

The E-Z Ancor [sic] Drywall Toggle Anchor shown above (and similar products from other brands we will list below) combines the expanding wings feature of a traditional toggle bolt (the first fastener discussed above) with the remove-and-re-use feature of a Molly Bolt.

In softer drywall installations, you do not need to use a power drill nor make a pilot hole at all.

The anchor itself is turned into the wall with a screwdriver. It's self-tapping tip and very coarse threads at the toggle anchor head pull the anchor body through the drywall and then snug it down into the drywall surface.

Once the anchor has been installed, the anchor screw can be used to pull the toggle snug against the interior surface of the drywall. We haven't used these anchors in plaster walls.

Self-Drilling Wall Toggle Anchor Removal / Re-Use?

Good question, [help needed]. It may be possible to withdraw the screw and fold the hinged anchor wing for removal. Sometimes.

Self-Drilling Wall Toggle Anchor Load Capacity

Using as an example, the E-Z Ancor (that's their spelling not ours - Ed.) using a #8 screw can support 75 to 100 pounds.

Other brands of similar products include the Cobra Toggle (45 lbs), Pot-Toggle (60 lbs), Toggler (80 lbs). Some of these supports have been tested and claimed to support heavier loads than promised by the manufacturer but we warn that the actual load capacity almost certainly varies due to variations in drywall thickness, density and composition, exposure to moisture, and care of installation.

Watch out: the warning that you read in this web page excerpt from the EZAnchor web page given below is likely to apply to similar fasteners made by other manufacturers.

EZ Anchor Drywall Toggle Anchors are rated at 100 lbs. for holding products that hang flush to the wall. This rating is per job, not per anchor.

Using additional anchors does not incrementally change the weight that can be supported.

For example, using 2 EZ Ancor Drywall Toggle Anchors rated at 100 lbs. will not hold 200 lbs.

Do not use for mounting televisions.

Sources of Self-Drilling Wall Toggle Anchors

- Cobra DRILLER TOGGLE SPECIFICATIONS [PDF] Cobra Anchors Ltd., US Tel: 800-824-7717 Canada Tel: 514-354-2240 Web: www.cobraanchors.com

- EZ-Anchor TOGGLE LOCK Wall Toggle Installation Instructions [shown just below]. EZAnchors, Web: easyanchors.com/ - retrieved 2023/05/11, original source: https://www.easyanchors.com/Products/Toggle-Locks/

...

Drive Anchors = Molly Bolt Wall Anchors

The anchors shown here may be inserted into a hollow wall through drywall or wallboard. For drywall, molly bolts or wall anchors that have a pointed tip like the one shown just above can usually be hammered through the wall - a drill is not necessary.

To use this fastener in a plaster wall, you'll still need to use a drill.

The drive-anchor molly bolt like the Primeline brand Molly bolt wall anchor shown above is designed for medium to heavy loads and can carry between 10 and 50 pounds of weight if properly located, installed and spaced in otherwise undamaged drywall or plaster walls.

In our photo below, the traditional molly bolt shown just above my ruler is not pointed and can not be driven into the well. You'll need to use a drill.

For drilling plaster or drywall, the drill bit is sized to the same diameter as the molly bolt's body. Once the bolt has been pushed through the bracket or hanger it's fastening to a wall and then through its pilot hole in the wall itself, tightening the screw pulls the end of the bolt's outer shell towards the wall, expanding the molly to latch itself tightly onto the wall.

At right in the photo are an all-plastic (less load capacity) molly type wall anchor next to two smaller, lighter-load-capacity push-in plastic ribbed screw anchors.

For an example of a nylon expanding molly type fastener, see Cobra's WallGripper documented below.

In normal installation, you install the steel Molly bolt into the wall by itself first, expanding its wall interior latch assembly, then you remove the screw, insert the screw through the bracket or device it's intended to support, then screw the Molly Bolt screw back into its anchor.

Watch out: don't so over-tighten the Molly bolt anchor during initial installation that you pull its outer face down into the drywall or you may find that in softer drywall products you've made it useless. Best to stop tightening the Molly as soon as its face is snug and just-recessed into the drywall paper surface.

On a harder plaster wall, this will be less of a concern.

Molly Bolt Drywall Anchor Re-Use / Removal

You can remove the screw itself from a Molly bolt, then re-insert it and re-use the assembly.

Unlike the toggle bolt wall anchor discussed earlier, when you remove the screw from the molly bolt, the molly-bolt anchor will remain in place in the wall.

Watch out: a molly bolt type anchor can not be removed from the wall by pulling it out without creating a much bigger hole.

Where we have to remove these anchors, we either tap them all the way through their hole and let the anchors drop down into the wall cavity OR we use a hole saw to cut a round hole around the anchor big enough to remove it entirely.

Molly Bolt Wall Anchor Load Capacity

Typical molly bolt wall anchor load capacity for the smaller sizes shown here is 10-50 pounds per fastener.

But some of these products, even in plastic or nylon form, can carry more weight, and even some nylon versions can support up to perhaps 85 pounds like the Self Drilling Nylon Molly Type wall anchor shown below.

- Cobra HOLLOW WALL DRIVE ANCHOR SPECIFICATIONS & INSTRUCTIONS [PDF] Cobra Anchors Ltd., US Tel: 800-824-7717 Canada Tel: 514-354-2240 Web: www.cobraanchors.com

- Cobra WallGripper NYLON SELF-DRILLING MOLLY ANCHOR [PDF] Cobra Anchors Ltd., US Tel: 800-824-7717 Canada Tel: 514-354-2240 Web: www.cobraanchors.com

Illustrated just below

...

Self-Drilling Plastic / Nylon & Zinc Wall Anchors

Shown above is a #8 self drilling anchor that is 1 1/2" long intended for use in drywall between 1/2" and 1" in thickness. These nylon or plastic wall anchors require no drilling but do make a bit of dust, cut by the device self-tapping tip, as it is turned into a drywall surface. Self-drilling wall anchors are sold in plastic, nylon, and zinc composition.

A very small pilot hole may be required to insert this anchor and some claim no pre-drilling is needed.

You can see in my photo below that while you can use a flat-bladed screw driver these wall anchors are designed to be turned into the wall using a Phillips-head screw driver.

Really? Well yeah but: I find that in hard wallboard and using cheap made-you-know-where plastic or nylon wall anchors, it's easy to strip the Phillips driver opening in the anchor.

The good news is that if you need to make additional turns to install or remove one of these nylon wall anchors and the Phillips head driver is slipping, just switch to a flat-bladed screwdriver of small enough width that it fits into the anchor's head.

Self-Drilling Nylon Drywall Anchor Re-Use / Removal

You can unscrew this wall anchor to remove it completely from a wall. And unlike a molly that crushes itself against the wall and can't be removed without making a mess of the wall (just tap it in instead), these nylon self-drilling wall anchors come out leaving less damage to the wall surface than most other anchor types.

Can we re-use one of these self-drilling plastic or nylon wall anchors?

In theory it might be re-usable though in our informal testing we found that often the gnawing up of the device by turning it into and then back out of a wall combined with its low price means using a new one for a new installation is probably smarter.

Self-Drilling Nylon Drywall Anchor Load Capacity

Typical load capacity for a nylon self-drilling wall anchor sized like the one shown above from EZ Wall Anchors is 15 pounds.

Really? Well yes, that's what Home Depot said. But we note that a very similar self-drilling anchor with screw ( and more expensive) like the blue and white Walldriller #8 Anchor, also made of nylon and also self-drilling, is rated for 115 lbs!

The nylon Cobra WallDriller self-drilling #8 screw sized wall anchor has a tension (pull-out) resistance of 23-38 pounds depending on drywall thickness, and a shear strength of 50 to 80 pounds, again depending on drywall thickness.

We found some self-drilling wall anchors for drywall capable of holding 65 pounds in tension (pull-out resistance) and about 200 pounds in shear strength in 3/4" drywall and up to about 130 pounds on 1/2" drywall.

See these self-drilling wall anchor capacity documents

- Cobra WALL DRILLER PLUS TECHNICAL SPECIFICATIONS [PDF] Cobra Anchors Ltd., US Tel: 800-824-7717 Canada Tel: 514-354-2240 Web: www.cobraanchors.com

- Cobra WallDriller NYLON INSTRUCTIONS [PDF] for use in drywall 3/8" (10mm) to 5/8" (16mm) in thickness.

...

Ribbed Wall Anchors & Lag Shields, Expansion Shields, Plastic, Lead, Zinc

Ribbed wall anchors like the Midwest Fastener plastic anchor shown here are sold in various sizes and are available in plastic as well as much older lead form and from some vendors, in zinc or nylon.

Ribbed lead anchors have been used in solid masonry walls; both plastic and lead ribbed anchors can provide a very strong support in masonry walls. These anchors are used in drywall, plywood panels, ceramic tile walls, brick and concrete block walls.

The plastic ribbed anchor shown above is intended to accept #10 or #12 screws and is 1-inch long. In this size, a 1/4" drill bit is used to pre-drill the wall for anchor insertion.

Below, at LEAD WALL ANCHORS where we describe both lag shields and ribbed anchors, you'll see an example of ribbed lead wall anchors. Those smaller lead ribbed anchors, driven into a masonry wall, are stronger and can carry greater loads than ribbed plastic anchors in drywall.

Plastic Ribbed Wall Anchor Load Capacity

Plastic ribbed wall anchors generally will support less weight than their fancier cousins listed above on this page.

Depending on the anchor size and manufacturer, typical load capacity for ribbed plastic anchors like the one shown above will be in the 20-40 pound range.

Ribbed Plastic Wall Anchor Removal / Re-Use

These anchors are easy to remove. Just back out the screw far enough to get a grip on with fingers or pliers and pull it straight out of the wall. You'll make a bit of dusty mess.

While in an emergency the anchor might be re-used, we recommend using a new one whose ribs and wall-gripping shape are undamaged.

- Cobra PLASTIC WALL ANCHOR SPECIFICATIONS & INSTRUCTIONS [PDF] Cobra Anchors Ltd., US Tel: 800-824-7717 Canada Tel: 514-354-2240 Web: www.cobraanchors.com

- Cobra TRIPLEGRIP PLASTIC WALL ANCHOR SPECIFICATIONS & INSTRUCTIONS [PDF] ribbed plastic wall anchors, Cobra Anchors Ltd.

Lead & Zinc Wall Anchors & Lag Bolt Shields

Shown above as the two smaller devices at left in our photo, ribbed lead anchors are driven into a hole drilled in masonry or tile surfaces and then expanded by a sheet-metal threaded screw.

The ribbed anchors shown above are by Rawl, as are the larger lead lag bolt shields. Both types of devices are tapped into a hole drilled into a masonry wall, brick, concrete block, or for a stone wall, usually into a mortar joint.

Lag shields and expansion shields are also used in concrete floors, for example to secure a sill plate or possibly a stair component.

Lead Anchor Wall Load Capacity

The load capacity of these lead anchors set into a masonry wall, provided you didn't over-drill the mounting hole, is likely to be the shear strength of the screw or bolt installed into the wall. Deeper holes, longer anchors, larger screws or bolts, in more solid types of masonry are, of course stronger.

The lead or (in more modern versions zinc) lag shields shown at right in our photo above may be called an expansion shield or double expansion shield by some manufacturers.

These anchors are installed by tapping them into a pre-drilled hole, setting the anchor end flush with the wall face. When a lag bolt is screwed into the lag shield or expansion shield the tapered diameter of the bolt both bites into the soft metal of the shield and also exerts an expanding force to anchor the lead or zinc shield in the hole into which it was inserted.

Really? Well that's not the whole story. The strength of a wall anchor in a masonry wall depends on what sort of masonry: brick, concrete, and terra cotta have very different ultimate load capacities as will mortar in masonry joints, depending on the materials involved.

Example: a 1/2" Zinc Double Expansion Shield from Cobra, in 3000 psi concrete and embedded at least 2 1/16" into the concrete wall, has a "safe" pull (withdrawal) resistance of 534 kg (1177 pounds) and "safe" shear resistance of 606 kg (1336 pounds).

For examples of more careful performance data for lead wall anchors used in concrete, brick, or block, see the example lead anchor capacities and specifications documents given just below.

Lead Anchor & Lag Bolt Shield Instructions & Specifications

- Cobra LAG SCREW SHIELD CAPCITY & INSTRUCTIONS [PDF] Cobra Anchors Ltd., op. cit.

- Cobra LEAD ANCHORS TECHNICAL SPECIFICATIONS [PDF] Cobra Anchors Ltd., op. cit.

- Cobra Zinc DOUBLE EXPANSION SHIELD ANCHOR SPECS & INSTRUCTIONS [PDF] Cobra Anchors, op. cit.

- DeWalt SCRU-LEAD WALL ANCHOR INFORMATION [PDF] (2021) Technical Guide from DeWalt, Web: www.deWalt.com

Important excerpts:

1. Ultimate load capacities are provided for reference and must be reduced by a safety factor of 4.0 or greater to determine allowable working loads.

2. These fasteners are not recommended for use overhead or applications where holding values are critical.

Example: a #10-#14 structural or wood screw inserted 1-inch into 2,000 lb concrete has a tension strength of 580 lbs. and a shear strength of 575 lbs.

...

Tapcon type Fastener Resources

Above: tapcon screws, special masonry bit, and driver attachment.

- Buildex TAPCON CONCRETE ANCHORS INSTALLATION INSTRUCTIONS [PDF] 3/16" & 1/4" Diameter, Tapcon, Web: www.tapcon.com - retrieved 2023/05/12, original source: tapcon.com/getattachment/82d4f874-9bd5-4110-84c6-e7d472656971/tapcon_installation_instructions_3-16and1-4

Note that drill bit sizes, drivers, and installation instructions will vary among fastener head type, diameter, & other features. Below: the author's "tapcon kit."

Watch out: when using one of these self-tapping masonry screws, be sure to use the masonry drill bit provided by the manufacturer/supplier. Conventional masonry bits will not be exactly the right size and your screw connection may be weak and unsafe.

- Cobra, CobraTap SELF TAPPING CONCRETE SCREWS [PDF] Cobra Anchors Ltd., US Tel: 800-824-7717 Canada Tel: 514-354-2240 Web: www.cobraanchors.com

...

Continue reading GRABRAIL GRAB BAR SPECIFICATIONS, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS in DRYWALL

- ASBESTOS in DRYWALL MUD - TEST LOCATIONS

- ASBESTOS in DRYWALL TAPE?

- ASBESTOS in PLASTER - what about the use of asbestos in plaster walls & ceilings?

- DRYWALL, FIBERBOARD, PLASTER INTERIORS

- DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

- DRYWALL INSTALLATION Best Practices

- GRABRAIL GRAB BAR SPECIFICATIONS - fastening grab bars to a wall requires strong connections

- PICTURE HANGING NAILS

- PLASTER ASBESTOS CONTENT

- PLASTER REPAIR METHODS

- PLASTER TYPES & METHODS in BUILDINGS

- WALL ANCHOR CHOICES

Suggested citation for this web page

WALL ANCHOR CHOICES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.