Amtrol Extrol®, Fill-Trol® Expansion Tank FAQs

Amtrol Extrol®, Fill-Trol® Expansion Tank FAQs

Q&A on installation, diagnosis, repair of Amtrol's boiler expansion / compression tanks

- POST a QUESTION or COMMENT about heating system expansion tanks: their function, size, location, maintenance, and need for draining (on some models)

Amtrol / Extrol® internal-bladder heating equipment expansion tank questions & answers:

Questions and answers, FAQs, about how to install, diagnose, or repair an Amtrol Extrol® or Fill-trol® expansion tank - diaphragm or internal-bladder type expansion tanks, how do they work, and how are they installed, adjusted, maintained & repaired.

This article series describes how to identify, inspect, install, repair, or service heating boiler expansion tanks: here we explain the function of expansion tanks on hot water (hydronic) heating systems. We provide a heating system expansion tank Troubleshooting & Repair Guide.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Amtrol's Extrol® or Fill-Trol® Diaphragm-Type Expansion Tank Questions & Answers

Question: is it safe to remove and replace an old steel expansion tank with the newer type? Which is better?

is it safe to remove the horizontal type tank and replace it ? Is the old type better? is it ok to let the valve relieve the pressure and not have a tank at all? - Anon 9/11/11

Reply:

Anon, you can usually replace an old bladderless expansion tank with a much smaller internal diaphragm tank, as we describe above. The new tank will be smaller yet can handle the same job.

Newer internal-bladder heating system expansion tanks such as the Fill-Trol® Diaphragm-Type Expansion Tank have the advantage that you don't need to periodically drain the tank to re-charge its air.

In choosing the size of a heating system expansion tank, the service technician will consider the size of the building being heated, or more accurately, the volume of water in the boiler and heat distribution piping & radiators.

Question: New steam heater installed for first floor; old boiler had two expansion tanks - was it ok to remove one?

I am a home owner, i had a plumber switched and installed a steam heater in the first floor. when he saw my oil boiler that had two Expansion Tanks, he said it would work more efficient if he removed one on the two.

He removed a green horizontal one at no charge, but took the Expansion Tank with him. Now that same steam heater he installed does not warm up at all. Is this because he removed one Expansion Tank.

please help - Laura 10/30/11

Reply:

Laura: steam boilers won't use an expansion tank, not normally, as the boiler is making steam and open to the atmosphere up through the radiators and steam vents.

Usually on a modern hot water (not steam) heating system you wouldn't need two expansion tanks, certainly not if one of them is a new internal bladder type. So, recognizing that I can only guess from afar, it sounds like two different problems.

There are some steam heat systems that use steam to distribute heat to upper building areas and use hot water from the same boiler to circulate through hot water radiators or baseboards in a lower building area. Maybe that's what you've got ?

Question: I have to empty our boiler's expansion tank every month - the relief valve spills; how far away can I put the new replacement tank I'm planning?

I have oil burner and I have to empty the expansion tank about once a month. I know it's full when the relief starts passing water. It's an old tank that lay's on top of the heater. My question is if I install the new type what is the max distance can it be from the heater? Is 8' to far? - Tony 6/5/2012

Reply:

Tony,

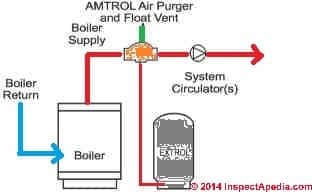

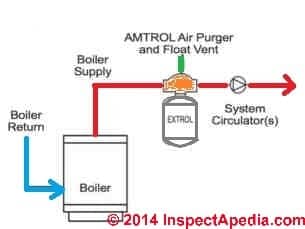

Amtrol makes both thermal expansion tanks and hydronic expansion tanks used on heating and plumbing systems. Amtrol's expansion tank installation instructions specify "Install the EXTROL on the supply side of the boiler, on the suction-side of the heating circulator(s) (see Figure 1)." That is, the location is more critical than the distance.

Question: what do I need to do after my contractor removed an attic expansion tank?

Would you be able to help me determine what to do when my contractor removed my tank. I'd like to send you a before and after photos if possible? - Contractor removed attic tank 7/8/12

Reply:

We will try. Use the CONTACT US link at page top or bottom to send photos for comment, best accompanied by a specific question or concern. Keep in mind that if your building is quite old there may have been an old, unused, atmospheric pressure expansion tank in the attic.

Question: why would my heating system's expansion tank lose its air after just 3 or 4 days - the sight glass fitting shows no air

what makes expansion tank lose air in 3-4 days. I checked for air leaks with soap bubbles around tank and sight glass fittings, found none. Serviceman says domestic hot water coil may be leaking. How does that make tank lose air? Replacing coil will be expensive because of position of furnace. - J Warden 10/1/2012

Reply:

J Warden, I have to agree that I'm confused by this question. I've not found a hot water heating system whose expansion tank included a sight glass (a feature I find on steam boilers) - can you give me some details: boiler brand, type, model, and some photos to allow further comment?

In any case, if your expansion tank (if that's what we've got here) is losing its proper air charge every few days, there is either a leak out of the tank piping and fittings.

Question: confusion about how to drain an expansion tank and what boiler pressures should be found

I drained exp.tank and shut valve and bleeder valve. I noticed the entire system was low. I brought system up to proper pressure and bled all radiators. Then I opened the valve to the expansion tank. When water entered tank the pressure for the heating system dropped. Do I now add more water to system or will pressure come back when water is heated .? Thank you - Lee Davidson - Filling entire system 10/8/12

Sirs, drained the exp. tank with tank supply valve closed. Closed drain valve and bleeder valve. Entire system pressure was low so brought it up and bled whole house system. Bleeding drops pressure so brought up then i opened tank supply valve this makes pressure drop but i think it will come back when water is heated. Right or wrong? - Lee Davidson 10/8/12

Reply:

Lee, I agree with your procedure except the last step. On opening the expansion tank connection between the tank and the boiler, I would expect the boiler pressure drop briefly as water feeds into the expansion tank to bring it (and its air) up to the standard heating system cold pressure, eg. 12 psi presuming that the boiler is cold.

But unless your system lacks an automatic water feed valve, the automatic water feeder would be expected to add the necessary makeup water. Or doesn't your system gave one?

Or finally, if at a low pressure heat makes it to the highest radiator or baseboard you are provably OK.

Lee, about your second question:

Wrong.

It is a mistake to set the water pressure in a hot water heating system to an abnormally high level, and further, you shouldn't need to. Presuming that your equipment has a water feed/pressure reducing valve in place, that valve will automatically feed water to the system up to the usual COLD water starting pressure. Typically that's around 12 psi, though it may be higher for some taller buildings.

Expecting the problem to be fixed when the water is hot is also an error. It's the cold starting pressure that we attend.

Watch out: some readers have been confused about the bladderless expansion tank drain procedure: one has to close the water feed valve into the tank (from the boiler) before opening the tank drain.

Otherwise we are not draining the water out of the tank to let air in, we're just running water through the heating system: from the building water supply, through the water feed valve, through the boiler, and up and out through the expansion tank drain - accomplishing nothing.

Question: once or twice a year the expansion tank needs to be emptied - else heating system pressure goes above 30 psi. How do I stop this problem?

Hi. I seem to be having an issue once or twice a year that the expansion tank needs emptied, i.e. pressure goes above 30. Is there something I can do to stop this? Thanks. Sandy. sweisber@pitt.edu - Sandy 11/12/12

Reply:

Sandy,

Sure. You can eliminate the need for periodic draining the heating boiler expansion tank by replacing it with an internal bladder type tank like the Extrol shown at the top of thus article.

Question: Comment - thanks for discussing old bladderless expansion tank systems

Thank you for this informative information. Many articles just mention the expansion tank with bladders but I have an old bladderless system and I was not sure if I should let the water out The over pressure valve was periodically going off. Thanks again, I believe you solved my problem. - John OHare 11/16/2011

Reply:

Thanks for the nice comment, John. We work hard to make InspectAPedia information accurate, complete, and unbiased and are thrilled when a reader reports that our data has been helpful. Indeed, there are still lots of buildings around whose heating systems use an older type of steel bladderless expansion tank - a component that needs periodic attention to keep the heating system working safely.

An bladderless expansion tank that loses its air charge not only causes the relief valve to spill, it is a more subtle safety hazard - as a spilling relief valve may eventually clog up from mineral deposits and crud, then stop opening, risking a BLEVE or boiler explosion. Sp if you see water on the floor under a relief valve it is something that should never be ignored.

Just how often we need to drain the water out of a bladderless heating boiler expansion tank varies from one installation to another; some need attention twice a year while I've worked on other systems that ran OK for three years or more before the expansion tank became waterlogged.

If your bladderless tank doesn't need attention too often, say not more than once a year, there is no reason it can't continue in service.

Question: banging pipes vs new Amtrol Extrol® expansion tank

(Jan 11, 2013) Rick said:

I have a fairly new Amtrol expansion tank (~2 years old). Lately we are getting banging in the pipes when the heat is circulated. I know I probably have to bleed the system, but the valves that are on the unit are the handle-less type that have to be turned with a wrench to open, and they take a while to seal again once closed.

Will loosening the valve at the top of the expansion tank a little more allow the trapped air to escape eventually - or will I have to bleed the lines manually with a hose and bucket? I have loosened it a bit and I can hear air escaping occasionally and I am hoping this will eventually bleed the heating system.

Also, I cannot find any other leaks in the system to allow air in. All help is appreciated.

Reply: Rick, it should not be necessary ever to bleed a captive-air type expansion tank such as the Extrol® unit and I'm not sure how a waterlogged expansion tank would cause banging pipes in a hot water heating system. Instead please take a look at our banging pipes diagnostic article:

BANGING HEATING PIPES RADIATORS (more often a concern on steam heating systems) or if your heating system is only a hydronic unit (hot water heat only)

seeHEATING SYSTEM NOISE DIAGNOSIS where we comment:

Bubbling or rumbling heating system noises in hot water heating piping can be caused by air in the heating lines.

If the amount of air becomes excessive the heating system may be unable to circulate hot water and extra steps to bleed unwanted air will be required.

See AIRBOUND HEAT SYSTEM REPAIR by WATER FEED VALVE

Also see OIL BURNER RUMBLING NOISE

Reader Question: Water-logged Amtrol Extrol Expansion Tank No. 30 - vs tank mounting position?

(Jan 29, 2013) claude st-pierre said:

Hi I find your site very helpful.

I have an Amtrol Extrol Expansion Tank No. 30 (with disphram inside). The pressure inside the system was under 12 psi before I pumped it back up to over 15 PSI (18 PSI). The tank has a tendency to loose its air over time, especially after many days of cold weather (minus 15 Fareiheit).

The tank was installed in 2007 and is mounted with the water inflow into the tank at the bottom and the air valve on the top. The maintenance guy mentioned that this type of tank could be mounted upside down and that does not matter but on the Amtrol web site, they always show the Extrol tank with the water intake at the top and the air valve at the bottom.

Could mounting an Extrol tank upside down reduce the life of the tank or reduce the capability of the tank to keep the pressure under 30 psi when the heating system works at its maximum temperature?

Reply: Claude, Amtrol does not specify tank mounting position in the installation instructions (found at the References section of this article) for the Amtrol Extrol Expansion Tank No. 30 but the company does provide these notes:

1. Although the EXTROL does not have to be installed at the base of an air purger, this installation is recommended to reduce air in the system and provide a compact installation. Some method of air elimination is required to ensure an oxygen-free system.

2. The EXTROL must not be placed overhead in the floor joist space. When replacing a plain-steel tank, the EXTROL should be relocated per Figure 1. [see our schematic drawings in the article above]

3. Do not place the EXTROL on a dead-end pipe. Air can collect in the EXTROL, causing internal corrosion and possible leakage.

4. Radiant systems with non-barrier tubing or high oxygen content should use a Radiant EXTROL ® expansion tank with a plastic liner. See the EXTROL brochure, or call (401) 535-1216 for sizing assistance.

*

Models #15 through #90 come with a 5 year warranty. All other

EXTROL models come with a 1 year warranty. See reverse side for

warranty information.

* Do not hang models SX-30V through SX-160V. They are floor standing models only

You state "The tank was installed in 2007 and is mounted with the water inflow into the tank at the bottom and the air valve on the top." which leaves me a little uncertain. There is only one water connection on the Extrol expansion tank and one air valve fitting. The air valve is used to adjust the initial tank pressure to match the boiler cold or fill pressure at the time of installation.

As water entering the tank enters an internal bladder, I'm doubtful that the tank orientation affects its position. I think that the reason you see the tank mounted with it water entry port at the top is that it is being connected to the bottom of a typical air purging device whose tapping for that purpose is on the under-side of the air purger.

See AIR SCOOPS PURGERS SEPARATORS

If your expansion tank is water logged and it's an Extrol unit it needs to be replaced as most likely the bladder has burst.

Reader Question: water-logged expansion tank prevents boiler operation?

2/27/2014 Trish said:

Can a waterlogged expansion tank cause an oil boiler to not kick on?

Reply:

In short, no, normally a waterlogged expansion tank doesn't keep a boiler from turning on, but there could be these exceptions:

The principal effect of a waterlogged expansion tank would be spilling at the temperature-pressure relief valve.

Residential hydronic heating boilers (hot water heat) usually are rated for a maximum of 30 psi - the TP valve will open at that pressure and spill water.

I suppose if a boiler lost water and didn't include an automatic water feeder, a low-water cutoff safety switch on such a boiler in that circumstance would shut down the boiler.

Some heating systems might include a pressure control sensor switch that would shut down the boiler if its pressure became abnormally high - a condition that follows a waterlogged expansion tank, but that's not a control I've seen on a residential heating boiler.

Question: separate tank for electric water heater?

(May 31, 2014) Matt said:

I have a HWB heating system with an expansion tank. I am now installing an electric water heater. Does this need a separate expansion tank? Thank you.

Reply:

You might, Matt, depending on local regulations and the operating properties of your system, including water pressure.

Take a look at our article on the topic over at

and let me know if questions remain.

Question: have to add air to expansion tank

(Oct 16, 2014) Tom B. said:

My Amtrol-Fitrol Model 110 needs to be topped-up w/air to every now and then to bring it up to 12 PSI. I figure it needs replacing. There is a shut-off valve in line immediately before the tank. Can I just shut off that (I guess water inlet valve) and swap out the old tank for a new one of the same model and manufacturer? Thanks.

Reply:

Look for a leaky air valve or a burst internal bladder in the tank - replace it.

Question: troubleshooting expansion tank

(Oct 18, 2014) Swen said:

Hi there and thanks for running this site. Great resource since hydronic heating is not commonplace in the US yet (at least not in CA).

I am trouble shooting a broken brass fitting on my hydronic system and here is what I found:

- The valve to the Extrol expansion tank was shut-off

- The expansion tank (and the air trap) are on the return side and not the supply side

Here are my questions:

- Is the return side installation of the Extrol tank a serious issue?

- What is the right pressure to preload the entire system (My heating system is in a basement in a two story above ground house)?

- Is there ever a need to check pre-load charge of the Extrol tank in accordance of the set system pressure (see above)?

BTW, the brass fitting burst during the summer month without any system load (it is a weak fitting - or rather connector type element - most likely not suited to the application).

Thanks for your answers in advance,

Swen

Reply:

Swen:

The Extrol tank comes pre-charged at the factory recommended pressure and will work on either side of the boiler water circulating loop but I would indeed prefer to follow the manufacturer's instructions - as described in the article above.

Probably 12 psi cold is the start pressure you need, but first read the details of how to decide on and set heating boiler pressure found in our article at

inspectapedia.com/heat/Heating-Temp-Pressure-Settings.php

Question: leaks at expansion tank pressure gauge

10/26/2014 Jason Little said:

Came home to a flooded basement. The Amtrol Extrol Model 30 is leaking from the pressure gauge. Is this a easy repair?

Reply:

Jason,

I'm not sure what's going on with the pressure gauge: water intrusion vs. a damaged gauge vs. some other trouble. If the gauge was immersed by flooding or is damaged/leaking, I'd start by replacing the pressure gauge.

Reader question: ok to mount an Extrol 30 sideways?

I have a system 2000 gas fired furnace that has a Extrol 30 that is mounted sideways instead of hanging down. It has waterlogged for a fourth time in the last 20 years and about four years ago was the last time until now.

Does the tank being mounted horizontally instead of vertically have an effect on the life of the bladder? I don't remember ever having to replace one in any house I lived in until I moved in here. Rick Bouchard globe56@myfairpoint.net 3/25/2014

Reply: no it's not. Do not mout the Amtrol Extrol expansion tank upside down nor sideways nor on a dead end pipe.

Amtrol specifies the expansion tank mounting position in the installation instructions for the Amtrol Extrol Expansion Tank No. 30 (found at the References section of these articles) in text, from which I quote:

Mount tank vertically in downward position only. Ensure the piping can support the entire weight of the tank when full of water.

The instructions also include this line "Do not place the EXTROL on a dead-end pipe.

ir can collect in the EXTROL, causing internal corrosion and possible leakage."

Which I take to warn you that *any* installation that might allow air to collect in the device could cause corrosion and leakage.

That is, in my opinion, precisely the risk that you might face if your unit is mounted horizontally.

A review of both product brochures and installation literature all show the expansion tank in the positions shown in Amtrol's Extrol sketches adapted above.

You can contact the company directly as well both for warranty claims or to double check the tank mount position. Note that the warranty will not cover damage or failure attributed to improper installation of the device.

- Amtrol Inc., 1400 Division Road, West Warwick, RI 02893, Tel: 401.884.6300 Website: www.amtrol.com

Question: signs of burst bladder in the expansion tank

(Feb 8, 2016) Dock said:

After draining the expansion tank the system runs pretty quiet. Any more the tank fills again and it gets to be quiet often. What is causing it to fill so often? Lived here 26 years and never had this problem before.

Reply:

If the expansion tank in an older bladderless expansion tan k system loses its air charge rapidly the heat may be cycling on and off more often or working harder, or there may be a leak in the expansion tank or its piping. It's unusual.

If your expansion tank uses an internal bladder I suspect it's burst.

Question: install the expansion tank on the boiler's suppy side. Ok to move it to return?

2016/05/09 Bruce Benner said:

I need to install an Amtrol EX-30 expansion tank on a boiler that has the circulating pump on the return side of the boiler.

I am confused as to where it should be installed?

I would think it should go on the supply side with the hotter water and thus more thermal expansion.

Any advice would be appreciated.

Thanks!

Reply:

Bruce,

In a water piping system filled with water, excluding surges when valves open or close, water pressure is pretty much the same throughout the system. But a look at Amtrol's Extrol hydronic expansion tank shows this instruction from the manufacturer:

"Install the EXTROL on the supply side of the boiler, on the suction-side of the heating circulator(s) (Figure 2)."

In the live links at the end of this article or in the ARTICLE INDEX see the article titled AMTROL's EXTROL®, the FILL-TROL®

where you can find the manufacturer's installation instructions as PDF files in the article's REFERENCES section. There and in our article itself you'll see that typically the expansion tank is on the supply side.

So before moving the expansion tank to the return side I'd contact the company for advice:

Amtrol Corporation

1400 Division Road, West Warwick, RI USA 02893

T: 800.426.8765 F: 800.293.1519

www.amtrol.com

Keep in mind that the company offers a variety of expansion tank designs including a floor-standing model might let you locate the expansion tank where you have room, but piped to the supply side of the hot water piping loop.

...

Continue reading at AMTROL's EXTROL®, the FILL-TROL® - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- EXPANSION TANKS, BOILERS - home

- AMTROL's EXTROL®, the FILL-TROL®

- ATTIC & ANTIQUE EXPANSION TANKS, HEATING

- BOILER DRAIN DAMAGES EXPANSION TANK

- EXPANSION TANK AIR VALVE LEAKS

- EXPANSION TANK DIAGNOSIS

- EXPANSION TANK DRAIN & AIR RE-CHARGE

- EXPANSION TANK IO MANUALS & SIZING GUIDES

- EXPANSION TANK LEAK REPAIRS

- EXPANSION TANK PRESSURE ADJUSTMENT

- EXPANSION TANK SIZING GUIDE

- EXPANSION TANK WATERLOGGING CAUSES

- EXPANSION TANK WON'T DRAIN

- FIND the EXPANSION TANK

- HEADER TANKS

- RELIEF VALVE LEAK DUE TO EXPANSION TANK

- TANKLESS COIL INTERNAL LEAKS INTO the BOILER

- THERMAL EXPANSION of HOT WATER

- THERMAL EXPANSION TPR VALVE LEAKS

- WATER PRESSURE TOO HIGH: DANGERS

Suggested citation for this web page

AMTROL EXTROL® FILL-TROL® FAQs at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Amtrol Corporation, "Installation & Operation Instructions, Extrol (R) Hydronic Diaphragm Expansion Tanks In-Line & SX-Series", [PDF] (06/15), Amtrol Corporation, 1400 Division Road, West Warwick RI 02983, Tel: 401-884-6300, Website: www.amtrol.com, retrieved 2016/05/10, original source http://www.amtrol.com/media/documents/extrol/9015183_06_15_EXTROL_IO.pdf

- Amtrol Corporation, "Extrol® Hydronic Expansion Tanks for Non-Potable Water Installation & Operation Instructions, Models EX-15 through EX90 Models SX-30V through SX-160V", Amtrol corporation,

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.