Heating Boiler Expansion Tank Pressure Adjustment

Heating Boiler Expansion Tank Pressure Adjustment

How to set the air pre-charge pressure in an internal diaphragm type expansion tank (compression tank) on hot water heating systems

- POST a QUESTION or COMMENT about heating system expansion tanks: their function, size, location, maintenance, and need for draining (on some models)

Heating boiler bladder-type expansion tank / compression tank pressure adjustment:

For most installations the factory-set air pre-charge in an expansion tank is correct and should be left alone.

But there are some circumstances in which an adjustment to the pre-charge may be needed: when the pre-charge was not to factory specifications, when the air pre-charge pressure needs to be increased to accommodate building height, or when there has been air lost from the system through the bladder.

In this article series we provide a heating system expansion tank / compression tank Troubleshooting & Repair Guide that will address just about any problem traced to this heating system component.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Pressure Settings for Bladder-Type Heating Boiler Expansion Tanks

The photo at left shows a modern Extrol(R) bladder-type heating system expansion tank mounted above the heating water line.

The photo at left shows a modern Extrol(R) bladder-type heating system expansion tank mounted above the heating water line.

[Click to enlarge any image]

Typically the internal bladder in this type of expansion tank is made of butyl rubber and accepts water from the hot water heating system.

The area outside the bladder but inside the tank is where the tank's air pre-charge resides.

Factory pressure settings:

Typical factory air pre-charge settings is 12-psi, the same as the automatic water feed valve boiler set-pressure when the boiler is cold.

Watch out: excessive pressure in the heating boiler is unsafe and can risk a BLEVE explosion; if you see a dripping pressure-temperature relief valve the system may be unsafe and certainly needs prompt inspection and repair by a trained heating service technician.

The red cap atop the expansion tank shown at left covers the air valve through which the expansion tank's air pressure is pre-set at the factory.

Depending on the tank's installation position this plastic covered valve (not intended for homeowner use) may be on the tank's bottom rather than its upper surface.

I'm not sure about this position as shown, as Amtrol's installation instructions for the Amtrol Extrol models EX-15 through EX-90 state

Mount tank vertically in downward position only. Ensure the piping can support the entire weight of the tank when full of water.

Reader Question: how do I know the right PSI setting for my expansion tank?

Oct 5, 2014) Luis R. said: How I do know the correct PSI for my new expansion tank? Do I need a Fill Trol-valve in my new diaphragm expansion tank system?

I did eliminated the old horizontal expansion tank form my hot water boiler system and I decided to put a new diaphragm system , with the three part recommended , an air vent , air purge and the expansion tank.

The ET tank I did put in is not a Extrol Amtrol tank, is a Therm-o-Flex expansion tank.

I did not put a Fill troll valve, do I need one?, and do not know if I have to put more air into the new expansion tank that already came pre-charge with 12 PSI, and I do not know how much more will be need it .

My hot water heating boiler system is Gas; water 30PSI, min. relief valve cap. 144, water BTU/HR 125.200 input 180.000, output 144.000.

Reply:

The tank you installed comes with a proper air pre-charge in it. Usually the manufacturer sets that air pre-charge at 12-psi cold, a pressure suitable for most residential installations.

The installer may check the air charge using an accurate gauge type pressure gauge, and as we explain in this article series, for taller buildings requiring a higher cold starting pressure in the boiler, the expansion tank may need to be pre-charged to that same pressure level, a setting above 12 psi, in which case your heating service technician may add a bit of air to the pressure tank through its normally-sealed air valve.

Don't change the pressure tank air pre-charge pressure yourself.

First check to see if the expansion tank has lost its charge

There are two valid checks that can be made on the pressure of the air charge in an internal diaphragm or bladder type expansion tank on a heating boiler:

- Disconnect the expansion tank completely

from the heating system and then measure air pressure using an accurate air pressure gauge at the tank's air valve - Cool down and drain the hot water heating system until its pressure reading is at zero psi

and then measure air pressure using an accurate air pressure gauge at the tank's air valve

The only other time we might need to add air to an internal-bladder type compression / expansion tank on a hot water heating system is if over time the air pressure on a cold system's bladder tank has fallen below 12 psi.

This can happen by slow air migration through the tank bladder into the heating system water.

As we explain

at EXPANSION TANK DIAGNOSIS, experts estimate the air loss through the tank bladder at about 1 psi per year - a very low rate. So you should not have to be adding air to a bladder-type compression tank frequently.

Also check the boiler's cold pressure setting. SOME but no all model of expansion tank include an automatic fill-trol valve while others do not - check the model that you installed.

OK enough theory, how do I know the right expansion tank air pre-charge setting:

For most installations, the expansion tank pre-charge setting should be the same as the boiler's cold pressure setting.

For most installations, the expansion tank pre-charge setting should be the same as the boiler's cold pressure setting.

That's why the manufacturer ships the expansion tank pre-charged to 12 psi. That's the same default feed pressure found on hydronic boiler water feeders.

At WATER FEEDER VALVE, HYDRONIC BOILER we explain that because a hydronic heating system's circulator pump has little "lift" capacity (it just pushes the water around the loop of boiler and heating piping and radiators), the heating system depends on its internal water pressure to lift hot water to radiators (baseboards, or convectors) on upper floors in the building.

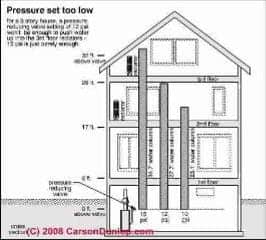

A higher building may therefore need higher heating system water pressure in order to be able to circulate heat adequately to upper floors. The sketch at left, courtesy of Carson Dunlop Associates, explains that a three-story building will need heating system pressure set up to at least 15 psi. when the heating boiler is cold.

[Click to enlarge any image]

Watch out: never pressurize any tank at levels above the tank's rated pressure range. Over-pressurizing any enclosed container risks a burst container, severe injury and building damage.

For pressure tanks on heating systems that need to operate at pressures over 30 psi - which would not be normal for a typical residential hot water heating system - an ASME-rated pressure tank must be selected and installed.

- Follow the manufacturer's installation instructions

about the air pre-charge setting that came with the boiler compression / expansion tank. Standard factory air pre-charge is 12 psi. measured with the tank disconnected from the system - see our next warning. - When measuring expansion tank air pressure the boiler pressure must be at zero -

which really means you will need to shut down the heating system, cool it, and drain all pressure off of the system before measuring expansion tank pressure,

or

you need to measure the expansion tank's air pre-charge pressure before the tank is installed.

Watch out: Measuring the pressure in an installed pre-charged internal bladder type expansion tank under any other circumstances doesn't give you an accurate factory air pre-charge pressure reading because pressure in the tank may be affected by pressure (or even vacuum in a few cases) exerted on the tank by the heating system to which it is attached. - To check other expansion tank air pre-charge levels

for bladder or diaphragm type expansion tanks,

see PRESSURE & TEMPERATURE SETTINGS, CONTROLS where you will see advice on setting boiler pressure and temperature. - To compare your expansion tank's pre-charge pressure with the effects of building height,

also

see WATER FEEDER VALVE, HYDRONIC BOILER for a neat boiler water pressure setting vs building height guide courtesy of Carson Dunlop Associates.

Hydronic Heating Boiler Expansion Tank Sources & Instructions

- AAtanks, the company's NLA Series ASME expansion tanks, - original source http://www.aatanks.com/expansion-tanks.php

- Amtrol, Extrol® HYDRONIC EXPANSION TANKS FOR NON-POTABLE WATER INSTALLATION & OPERATION INSTRUCTIONS [PDF] Amtrol Corporation 1400 Division Road, West Warwick, RI USA 02893 T: 800.426.8765 F: 800.293.1519 www.amtrol.com , retrieved 2016/06/06, original source http://www.amtrol.com/media/documents/extrol/9015183_06_15_EXTROL_IO.pdf

- Amtrol EXTROL EX-SERIES EXPANSION TANK INSTALLATION INSTRUCTIONS [PDF]

- Amtrol EXTROL® hydro pneumatic expansion tanks, (2004), Website: www.amtrol.com, - retrieved 20 March 2015

AMTROL Corporate Headquarters 1400 Division Road, West Warwick, RI USA 02893 Telephone: 401-884-6300

AMTROL Canada, Ltd. 275 Shoemaker Street, Kitchener, Ontario N2E 3B3 Telephone: 519-478-1138

AMTROL Asia Pacific Ltd. 89 Owen Road, Singapore 218902 Telephone: 65-6294 4611 - Amtrol ASME Commercial Expansion Tanks, Amtrol, 1400 Division Road, West Warwick RI, 02893, USA, TEl: 800-426-8765, ASME-rated expansion tanks, - retrieved 19 March 2015, original source: http://www.amtrol.com/media/documents/extrol_asme/

MC2682_01_14_EXTROL_ASME_Brochure.pdf - Bell & Gossett AIRTROL® SYSTEM INSTALLATION, OPERATING AND SERVICE INSTRUCTIONS [PDF] Bell & Gossett, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379. Retrieved 8/9/2012, original source B&G, [copy on file as Airtrol_Installation_Manual.pdf linked in this reference]

- Bell & Gossett, BELL & GOSSETT PRESSURIZED EXPANSION TANKS (ASME) INSTALLATION, OPERATION, & SERVIVE INSTRUCTIONS [PDF] Instruction Manual A01500, [PDF] retrieved 2016/06/06, original source: http://www.azurecorp.com.tw/download/ITT/Expansion%20Tank-IOM.pdf

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- Bell & Gossett (Xylem Brand) ASME Expansion Tanks, Series HFT Pre-Charged Tanks,Xylem Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700 , - retrieved 19 March 2015, original source: http://bellgossett.com/tanks/asme-expansion-tanks-series-wta-pre-charged-tanks/

HFT tanks are for use on heating water in closed hydronic heating systems (hot water heat) not for potable water. Excerpting from the company's installation instructions:

After initial venting and purging of air from the system, more air will be released from the water as it is heated. Therefore, it is recommended that a B&G air separator be installed on the main.

If the system has multiple loops or zones, the supply water for all loops and zones must pass through the air separator for complete and continuous air removal.

In case the piping arrangement does not permit the installation of a single air separator on the main, air separators should be installed on each loop or zone. In this event, only one expansion tank is required for the system.

Even with a B&G air separator installed on the main or mains, it is recommended that B&G air vents be installed on high points in the system.

It is also recommended that manual (key or coin type) air vents be installed at higher points on the radiation. - ExpanFlex, by Calefactio, 1120 Blvd Michele-Bohec

Blainville, Quebec

Canada

J7C 5N5

Our opening hours are from Monday to Friday, 8:30 am to 4:30 pm EST.

Phone 450-951-0818,

ASME tanks and accessories including thermal expansion tanks (for domestic hot water) and ExpanFlex ASME expansion tanks (for heating systems), Website: http://calefactio.com/ - REFERENCES contains research citations and more how-to references for this topic.

Some attic expansion tanks never needed a pressure adjustment nor air charge

In older hot water heating system installations an expansion tank was sometimes placed on the highest building enclosed space such as in the attic or under-roof space. These systems were often open to the atmosphere.

An expansion tank overflow drain emptied out onto the roof or into a roof gutter or drainage system.

When heating system pressures dropped and water level in the expansion tank dropped as well, air could be drawn back into the attic expansion tank through its drain opening.

In a few cases I (DF) have also found cistern-like designs for attic expansion tanks in which the tank in the attic had not top at all, simply an overflow drain.

I'm not sure but I think the interesting open water receptacle shown below, and something I observed while inspecting the Justin Morrill Smith Homestead in South Stratford, Vermont in the U.S., was a heating boiler overflow system.

It was quite small, certainly not large enough to be used as a water supply cistern. Its piping was incomplete.

See ATTIC & ANTIQUE EXPANSION TANKS, HEATING for details about these systems.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-12-02 by Inspectapedia Com Moderator - "Air in boiler" light was on

@Mohamed,

Great news, glad you've got heat again. And thanks for taking time to report back - that will help other readers.

Daniel

On 2021-12-02 by Mohamed

@Inspectapedia Com Moderator,

Thank you very much. Problem solved when I realized how to top up the pressure using two valves around the expansion tank.

When the pressure started to increase, the boiler automatically kicked in and the "Air in boiler" light went off.

Many thanks again and best regards.

On 2021-12-02 by Inspectapedia Com Moderator

@Mohamed,

There may indeed still be air in the boiler.

If your automatic water feed valve did not send more water into the boiler, then when you released enough air pressure from the boiler top the pressure in the system falls to zero.

Get that water feeder working or feed a bit of water into the boiler manually to raise its pressure to 12 psi (cold), then try bleeding more air.

In most residential hot water heating boiler installations those air vents should be working automatically.

Give the age, country and city location of the boiler and its brand and model and we might be able to say more.

On 2021-12-02 by Mohamed

I needed to release the air in the boiler as the "Air in boiler" light was on. After releasing the air from the two valves at the top of the boiler, the pressure gauge of the expansion tank fell to zero. And the "Air in boiler" light is still on ! Any suggestions please? Thanks.

On 2021-11-04 by Inspectapedia Com Moderator

@Cubitus700,

to be clear,

A presssure tank or an expansion tank that uses an internal bladder should never need pressure adjustment after its initial installation set-up.

If such a tank stops working properly it's likely that its internal bladder is leaking.

Non-bladder type (older, traditional) pressure tanks and expansion tanks need periodic draining to prevent water-logging.

On 2021-11-04 by Cubitus700

@inspectapedia.com.moderator, Thank you. Effectively, the metric thing could make sense but I thought all this equipment was uniform for all of North America.

Anyway, I tried on my EX-30 a couple of times, but if that one doesn't work it may be because the plug is clogged by iron and manganese residues from the inside (it was 21 years in service and never cleaned or readjusted...). I just can't get the air in.

I was using it to practice, because I did not want to accidentally bring out to much air while I was taking the pressure, or trying to inflate it.

But now that I know it's necessary to do this while its not connected to the system, I will attempt it this weekend. Without it installed, it may probably work better.

It's just that the stem's diameter appears smaller than the usual tire ones from either my lawn tractor, car or trailer. I tell you how it went. Mine was never services, and service people told me you never touch that (an expansion tank).

Now I read it's preferable to readjust the pressure every year...But the whole system is so silent, it's incredible, no more buzz.

Thank you "moderator"...

On 2021-11-02 by inspectapedia.com.moderator (mod)

@cubitus700@gmail.com,

For decades I've used an ordinary tire pressure gauge on countless pressure tank air valves -

If your tank uses an air valve that doesn't fit a standard US Tire gauge the tank (or your gauges) might be encountering an incompatibility between Metric and US valve sizes.

OR some prior user might have swapped the valve on your EX-60.

Here's a copy of

the EXTROL EX-SERIES EXPANSION TANK INSTALLATION INSTRUCTIONS [PDF]

On 2021-11-02 by cubitus700@gmail.com

Question on checking and adjusting air pressure in Expansion Tank, Model EX-60

I just replaced my expansion tank, my old ex-30 had a ruptured diaphragm. I noticed in the Amtrol paper work that a chart recommend for a system of my BTU with Steel cast radiators (my system is mixed, fins and steel cast), to use an EX-60. By chance I found a free one with some years on it but in excellent shape. I installed it before checking the pressure. My system is calibrated at 18 psi.

Interestingly, my aquastat stop sticking and the system is working completely silently, as it had not done so for years. Most pros told me it was normal for Aquasat to stick, and that you may need to replace it.

But I was wondering is an inadequately functioning Expansion Tank allows for pressure shocks, which creates irregular voltage feedback from the circulating pump towards the Aquastat getting the relay to stick and be noisy...it's the only explanation I can make of this. (but this is a side question). My system had always been noisy (electric buzz).

Back to the main topic.

Now, on attempting to test the pressure, my nozzles didn't fit the stem properly. My tools are tire nozzles including a clamp. I have used them on various tires stems (car, lawn tractor, and trailer tires, always works fine).

Amtrol/Extrol doesn't specify if a special caliber nozzle is necessary. But all of mine let the air pass away and don't capture a pressure reading nor are able to inflate the tank.

I now understand that I will have to take the tank out to test it and adjust it if need be. I am putting a picture of my tools so you can understand my dilemma and a picture of the old tanks stem against my pressure gauge.

On 2021-02-28 by danjoefriedman (mod) - expansion tank on solar hot water system

@Keith Briggs,

Thank you, that's an interesting question. Since I don't know the answer I've been doing some reading and research and will report further here including providing some references to the experts.

What I see so far is that there are concerns with the choice of type of expansion tank because you need one that can tolerate high temperatures, and the actual calculations for size and pressure pre-set are both important and a bit complex.

You could of course, the manufacturer of your particular system but I suspect they're going to want to know some details about your installation including the total volume of hot water or glycol mix circulating through the solar heating system.

On 2021-02-28 by Keith Briggs

My Solar Hot Water system is closed so adding an expansion tank. Water pressure in the loop varies from 38 to 50 psi. What is the preferred pressure to charge my bladder to before installing?

I mounted upside down (threads down) with an inline shutoff valve exactly as my boiler plumber mounted the new one in Colorado on my hydronic system.

On 2020-11-29 by danjoefriedman (mod) - differences between potable and non potable connections

Alan

Yes, the pressure tank on a potable water system - a pump and well system for example - is usually much larger than the pressure tank used on a hydronic heating system or to handle expansion in a domestic water heater.

Piping connections may also vary - obviously larger on larger tanks.

On 2020-11-29 by Alan

Is the pressure preset on the tanks different from potable to non potable and are non potable connections at 1/2 inch rather than 3/4 inch?

On 2020-02-13 by (mod) - internal bladder heating system expansion tanks don't need adjustment (usually)

Frank,

For most installations the factory-set air pre-charge in an expansion tank is correct and should be left alone.

However, if you will review the article above on this page, you'll see that we handle other situations where you might need to adjust the pressure from other than factory setting.

On 2020-02-12 by Frank

how much air pressure do you put in a bladder on a weil mclain residential CGa4 gas boiler

On 2018-12-24 by (mod) -

Paul,

If the circulator pump works and you are dead sure that all valves are open but hot water isn't circulating, I'd look for a problem with air in the system somewhere in the higher piping. Can you follow the hot water pipes out of the boiler?

Does the pipe get hot up to but not past the circulator? Past the circulator but not at the return?

In any case it's not an expansion tank pressure setting problem - that's where you posted this query.

You might try AIR-BOUND HEATING SYSTEMS

On 2018-12-23 by Paul

My in floor heat system isn’t working. I took the pump apart and all seems fine with that. I repressurized the tank but in line pressure gauge still reads zero. What could be the problem?

Image lost please re-post

On 2018-10-29 by (mod) - bookmarking web pages with long names

Guest

On your Windows Internet Explorer window, at the top right click the icon that looks like a star - that's the "bookmark this page" feature in your Explorer browser.

You'll see that a window pops open showing the page name and allowing you to edit the name to be as short or long as you like.

On 2018-10-29 by guest

Cannot bookmark this page in Windows Explorer. Page title is too long to create a shortcut by drag & drop into a sub folder.

On 2016-07-13 by (mod) -

Todd:

Your buddy should SHUT OFF the system IMMEDIATELY as letting it continue to run is potentially dangerous, even risking a BLEVE explosion. (Search InspectAPedia for BLEVE EXPLOSION to read details).

An on-site service tech will figure out if the problem is a bad control setting allowing overheating, bad starting water pressure, or a leaky relief valve.

On 2016-07-13 by Todd

Hi my buddy has a hot water boiler and water is coming out of the relief valve.Expansion tank has 12p.s.i.boiler is building up to much pressure this is the second relief valve.any ideas.

On 2016-01-24 by (mod) -

Danie

Residential boilers use an expansion tank that normally is filled with partly water and partly air. You should not release air nor change the tank's operating pressure. If the tank uses an internal bladder (such as AMTROL products) it should not need maintenance.

Climbing pressure in your boiler sounds like a different problem, a bad water feeder, pressure regulator, or a leak of water into the boiler from a tankless coil.

On 2016-01-18 by Danie;

my gas boiler has always been at about 15lbs pressure @ 160-180 degrees i noticed it recently at 30lbs .

I have a Vent Rite expansion tank the water enters the top the air value is on the bottom tapping on the tank from the top sounds like there is air on top when i get about an inch or 2 down it sound solid until i get to the rib , from the rib down sound like just air .

I depressed the air value slightly to see if there was any water in the tank below the bladder letting out a small amount of air there is no water there , unit has a armstrong 12psi automatic fill value ..I

drain the water down to 15psi but within a day or to it climes back up to 25-30 psi the pressure relief value is 30psi I'm surprised it has not opened

On 2016-01-09 by (mod) - 3 types of expansion tanks

1. expansion tanks on heating systems

absorb the pressure increase caused by heating water in a home heating boiler - for heating the occupied space - to avoid possible spillage at the relief valve

2. expansion tanks on hot water making systems

such as a gas, oil or electric water heater (geyser, cylinder) used to produce hot water for bathing or washing is used on some systems to avoid occasional high pressure surges that can cause relief valve spillage

3. water pressure tanks installed on a building water supply systems

are designed to deliver water to the building by using compressed air in the tank to push water into the building - when the tank and system pressure fall below the pressure pump cut-in setting the pump turns on to both re-pressurize the tank and to continue delivering water to the building.

On 2016-01-09 1 by KEN

Hi

What is the difference between a potable expansion tank (pressure aside) and a hydroponic heating system. Expansion tank.

Thanks

...

Continue reading at AMTROL's EXTROL®, the FILL-TROL® or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- EXPANSION TANKS, BOILERS - home

- AMTROL's EXTROL®, the FILL-TROL®

- ATTIC & ANTIQUE EXPANSION TANKS, HEATING

- BOILER DRAIN DAMAGES EXPANSION TANK

- EXPANSION TANK AIR VALVE LEAKS

- EXPANSION TANK DIAGNOSIS

- EXPANSION TANK DRAIN & AIR RE-CHARGE

- EXPANSION TANK IO MANUALS & SIZING GUIDES

- EXPANSION TANK LEAK REPAIRS

- EXPANSION TANK PRESSURE ADJUSTMENT

- EXPANSION TANK SIZING GUIDE

- EXPANSION TANK WATERLOGGING CAUSES

- EXPANSION TANK WON'T DRAIN

- FIND the EXPANSION TANK

- HEADER TANKS

- RELIEF VALVE LEAK DUE TO EXPANSION TANK

- TANKLESS COIL INTERNAL LEAKS INTO the BOILER

- THERMAL EXPANSION of HOT WATER

- THERMAL EXPANSION TPR VALVE LEAKS

- WATER PRESSURE TOO HIGH: DANGERS

Suggested citation for this web page

EXPANSION TANK PRESSURE ADJUSTMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Holohan, Dan, "Why compression tanks waterlog", HeatingHelp.com (June 2014) - retrieved 19 March 2015, original source: https://heatinghelp.com/systems-help-center/why-compression-tanks-waterlog/

- Etherton, Mark (contractor), "Expansion Tanks 101: the facts and myths", Contractor Magazine, contractormag.com, (March 2000), retrieved 19 March 2015, original source: http://contractormag.com/hydronics/cm_column_75

- Extrol Corporation, "Installation & Operation Instructions, Extrol (R) Hydronic Diaphragm Expansion Tanks In-Line & SX-Series", Extrol Corporation, 1400 Division Road, West Warwick RI 02983, Tel: 401-884-6300, Website: www.amtrol.com, retrieved 3/3/2014, original source http://www.amtrol.com/media/documents/extrol/9015183_3_11_EXTROL_IO.pdf

Research on permeability of rubber used in internal bladder-type heating system compression tanks or expansion tanks

- Bodell, Bruce R. "Distillation of saline water using silicone rubber membrane." U.S. Patent 3,361,645, issued January 2, 1968.

- Ciesielski, Andrew. An introduction to rubber technology. iSmithers Rapra Publishing, 1999.

- Fuller, James, and David M. Stedham. "Expansion tank with a predictive sensor." U.S. Patent 8,633,825, issued January 21, 2014.

- Martinello, Ermanno, and Mark Weih. "Membrane coating for a water pressurization Bladder." U.S. Patent Application 12/498,128, filed July 6, 2009.

- Stern, S. A., F. J. Onorato, and Charles Libove. "The permeation of gases through hollow silicone rubber fibers: Effect of fiber elasticity on gas permeability." AIChE Journal 23, no. 4 (1977): 567-578.

- Terashita, Fumihiro, Shingo Takagi, Shinzo Kohjiya, and Yasutoshi Naito. "Airtight butyl rubber under high pressures in the storage tank of CAES‐G/T system power plant." Journal of applied polymer science 95, no. 1 (2005): 173-177.

- [4] B&G / ITT Reducing Valves, Instruction Manual V55999: Reducing Valves Installation, Operation, & Service Instructions, Bell & Gossett Air Separators and other heating system components, Bell & Gossett, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379. Original source www.bellgossett.com/literature/files/610.pdf

- [5] Bell & Gossett Airtrol® System Installation, Operating and Service Instructions, Bell & Gossett, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379. Retrieved 8/9/2012, original source B&G, [copy on file as Airtrol_Installation_Manual.pdf linked in this reference]

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- Installation Guide for Residential Hydronic Heating Systems

- Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.