Force Drain a Heating Boiler Expansion Tank

Force Drain a Heating Boiler Expansion Tank

How to use a pony pump to drain an un-cooperative bladderless expansion tank

- POST a QUESTION or COMMENT about heating system expansion tanks: their function, size, location, maintenance, and need for draining (on some models)

How can we draw water out of an older-style traditional bladderless boiler expansion tank if water doesn't simply come out when we open the tank drain?

This article describes the steps in careful pump-assisted draining of a steel compression or expansion tank used on heating boilers. If this step is not taken when needed the waterlogged compression / expansion tank will cause boiler leaks and improper, even unsafe boiler operation.

In this article series we provide a heating system expansion tank / compression tank Troubleshooting & Repair Guide that will address just about any problem traced to this heating system component.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

How to Force-Drain a Non-Bladder Type Expansion Tank

Normally it's easy to drain a water-logged compression tank (expansion tank) on a hot water heating boiler by opening its drain valve.

Normally it's easy to drain a water-logged compression tank (expansion tank) on a hot water heating boiler by opening its drain valve.

If the proper plumbing fittings and controls are installed, draining the expansion tank and thus renewing its air-charge is straight-forward and should be done at annual boiler service.

That procedure is detailed at EXPANSION TANK DRAIN & AIR RE-CHARGE

But what can we do if someone has removed or modified the tank drain valve so that air can't enter the tank?

In that case the tank simply won't drain, and trying to cut open pipes or install an new, proper expansion tank drain can be both messy and expensive ,

Expansion Tank Won't Drain?

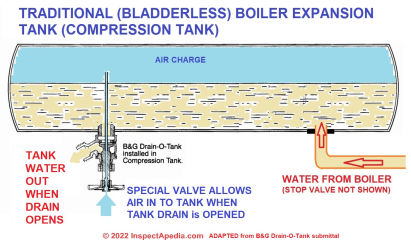

Properly, opening the drain valve on a traditional steel bladderless heating expansion tank will let the tank's water drain out of the drain valve - because the drain valve is a special one that includes an air inlet that allows air to enter the expansion tank as water drains out, as we illustrate above.

But what if someone has removed the special tank drain and installed a simple traditional stop valve on the tank - without that air inlet? That's what we see below.

Improperly-modified Expansion Tank (Compression tank) Drain Won't Let Water Out

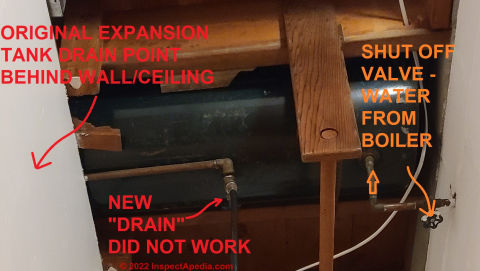

That's what happened to the expansion tank shown just below. This expansion tank serves a 1950s Weil-McLain gas boiler installed in a New York home.

During basement renovations a previous owner replaced the expansion tank with a simple copper elbow and horizontal drain line capped by a stop valve, thus permitting him to cover one end of the tank by a finished wall and ceiling.

We Noticed Water Dripping from the Relief Valve

The 1950's vintage Weil-McLain gas boiler worked OK for nearly seven years before its expansion tank became so water-logged that the new owners found that the tank needed to be drained.

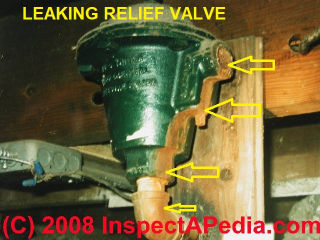

Noticing that the gas boiler's relief valve was dripping and that boiler pressure was a bit higher than normal (boiler pressure should always be lower than the relief valve's opening pressure - i.e. less than 30 psi on a typical residential heating boiler), the owner realized that the probable issue was a water-logged expansion tank.

Watch out: while in this case it was natural to check and try to drain the expansion tank first, there are other causes of temperature/pressure relief valve leaks and some of them can mean that there is a dangerous situation.

See details at RELIEF VALVE LEAKS

We opened the expansion tank drain but no water came out

The new owner opened the "expansion tank drain" but nothing happened. No air was able to enter the expansion tank - not enough to let the tank drain.

Worse, there was no easy to "fix" this improper installation without tearing down the finished wall and ceiling to regain access to the tank, and uglier still, simply removing the prior owner's plumbing would probably lead to a spill of nasty heating boiler water into the remodeled and "finished" part of the home.

Force-Drain the Expansion Tank using a Pump?

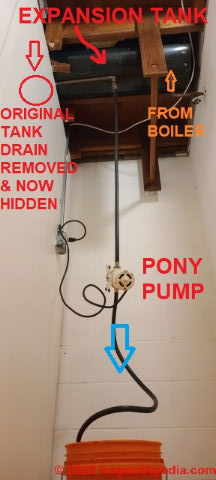

We had success with this simple "fix" for drawing the water out of a water-logged expansion tank: we connected a small pony pump (Little Giant) between two washer hoses.

(An alternative that involves harder-to-rig-up parts might have been to combine an air inlet valve or schrader valve with a cap over the tank drain, more shut-offs, and a tee to allow using a source of compressed air to put some air into the expansion tank. In our OPINION that's a messy and dangerous solution that we don't recommend.)

Prepare the Boiler for Expansion Tank Draining

To prepare for draining the expansion tank safely the owner:

- turned off the heating boiler and allowed it to cool down

- closed the boiler's feed line into the expansion tank - orange arrow in our photo

- turned off water feed into the boiler (perhaps un-necessary)

- found a 5-gallon plastic bucket to be used to collect water from the expansion tank

- borrowed a pair of washing machine hoses (female connectors on both ends) and a small electric pony-pump

Plugging the pony pump in allowed it to begin to "suck" water out of the expansion tank.

Watch out: don't run the pony pump expansion-tank drain system continuously. You could damage the tank.

Watch out: don't run the pony pump expansion-tank drain system continuously. You could damage the tank.

Particularly if the expansion tank is an old one that is badly rusted, perhaps rusted where you can't see the damage, there is risk that the tank might collapse, spilling that nasty heating water all over the place.

On one of our longer pump-suck-out cycles we heard a loud CLUNK! sound from the expansion tank. It may have simply been the now-lighter tank moving in its strapping up to the ceiling, or it could have been movement of the steel of the tank itself. Scary!

Taking care not to create too much vacuum in the expansion tank, we ran the pony pump just long enough to drain a couple of gallons out of the expansion tank and into that bucket shown on the floor below.

Then we stopped the pump by un-plugging it and, taking care to hold the down-end of the bottom washer hose out of water in the bucket, the vacuum created inside the expansion tank took a deep breath and we could hear the gurgling sound of air being sucked backup into the expansion tank.

We repeated this expansion tank pump-out cycle until, the "dink factor" approaching one, we allowed the tank to take one final deep breath of air.

Now it was time to return the boiler to operation

Steps to return the heating boiler to operation

- closed the tank drain valve,

- opened the boiler feed into the expansion tank

- checked that the water feed into the boiler was also open and working

- turned the boiler back-on

- set the room thermostat to call or heat

- heard the circulator pump start and felt the heating loop return pipe to the boiler to confirm that hot water was returning to the boiler (the heating system was thus known not to be air-bound)

- allowed the boiler to run until it reached its operating temperature and the primary control shut off the burner

- checked the boiler pressure and temperature to see that they were within a normal range

- confirmed that there was no longer dripping at the boilers temperature-pressure relief valve

To understand the "dink factor" - the ratio of improvement to risk of a disaster -

see DINK FACTOR - Remembering Carol Schneirer

Watch out: using a pony pump to speed drain of a heating boiler itself can damage a bladder-type expansion tank too.

Those details are

at BOILER DRAIN DAMAGES EXPANSION TANK

Where to Buy a Boiler Expansion Tank Drain Valve with Air Inlet

The best repair for the boiler expansion tank shown above would be the re-installation of the proper type of tank drain, even if that means cutting an access opening in a finished ceiling.

The best repair for the boiler expansion tank shown above would be the re-installation of the proper type of tank drain, even if that means cutting an access opening in a finished ceiling.

But if the homeowner wanted to restore the proper original type of drain valve on this bladderless boiler expansion tank, she might have a devil of a time finding the proper valve to buy.

That's because most new hydronic heating systems use an expansion tank that uses an internal bladder and that never needs to be drained.

But the proper valve for these old steel expansion tanks still is available from heating and plumbing suppliers and from online vendors such as supplyhouse.com .

Shown here is the B&G Bell & GOssett DT-2 Drain-O-Tank Air Charger described by the manufacturer as:

DT-2 Drain-O-Tank Air Charger offers a sure, quick way to recharge a water-logged compression tank. The Working Pressure is 125 PSIG, and the Maximum Operating Temperature is 240F.

See this

- DT-2 DRAIN-O-TANK EXPANSION TANK DRAIN VALVE INSTALLATION INSTRUCTINONS [PDF] (1992) ITT Bell & Gossett, 8200 N. Austin Avenue, Morton Grove, IL 60053, USA, Tel: (847) 966-3700 – Facsimile (847) 966-9052.

- EXPANSION TANK DRAIN VALVE & OTHER ITT B&G ACCESSORIES SUBMITTAL SHEET [PDF] ITT

8200 N. Austin Avenue

Morton Grove, IL 60053

Phone (847)966-3700

Facsimile (847)966-9052

www.bellgossett.com

Includes the DT-2 expansion tank drain, part # 113041, Drain-O-Tank shown above.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2016-07-28 by (mod) - no water comes out of drain?

Darn I hate when that happens; I suspect that the tank is waterlogged but the drain is also clogged, perhaps with rust and sediment. OR the valve is a simple drain valve not a special valve designed for expansion tanks. The special valve allows air INTO the tank while water drains OUT so that the water can actually leave the tank.

You might need to replace the valve with the proper type (from your heating supplier).

But first try the procedure we show above on this page.

On 2016-07-28 by Danny jenks

What if tank is heavy and full of water but no water comes out of drain?

...

Continue reading at BOILER DRAIN DAMAGES EXPANSION TANK or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- EXPANSION TANKS, BOILERS - home

- AMTROL's EXTROL®, the FILL-TROL®

- ATTIC & ANTIQUE EXPANSION TANKS, HEATING

- BOILER DRAIN DAMAGES EXPANSION TANK - a bladder-type expansion tank can also be damaged by pulling a vacuum with a pony pump.

- EXPANSION TANK AIR VALVE LEAKS

- EXPANSION TANK DIAGNOSIS

- EXPANSION TANK DRAIN & AIR RE-CHARGE

- EXPANSION TANK IO MANUALS & SIZING GUIDES

- EXPANSION TANK LEAK REPAIRS

- EXPANSION TANK PRESSURE ADJUSTMENT

- EXPANSION TANK SIZING GUIDE

- EXPANSION TANK WATERLOGGING CAUSES

- EXPANSION TANK WON'T DRAIN

- FIND the EXPANSION TANK

- HEADER TANKS

- RELIEF VALVE LEAK DUE TO EXPANSION TANK

- TANKLESS COIL INTERNAL LEAKS INTO the BOILER

- THERMAL EXPANSION of HOT WATER

- THERMAL EXPANSION TPR VALVE LEAKS

- WATER PRESSURE TOO HIGH: DANGERS

Suggested citation for this web page

EXPANSION TANK WON'T DRAIN at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Holohan, Dan, "Why compression tanks waterlog", HeatingHelp.com (June 2014) - retrieved 19 March 2015, original source: https://heatinghelp.com/systems-help-center/why-compression-tanks-waterlog/

- Etherton, Mark (contractor), "Expansion Tanks 101: the facts and myths", Contractor Magazine, contractormag.com, (March 2000), retrieved 19 March 2015, original source: http://contractormag.com/hydronics/cm_column_75

- Extrol Corporation, "Installation & Operation Instructions, Extrol (R) Hydronic Diaphragm Expansion Tanks In-Line & SX-Series", Extrol Corporation, 1400 Division Road, West Warwick RI 02983, Tel: 401-884-6300, Website: www.amtrol.com, retrieved 3/3/2014, original source http://www.amtrol.com/media/documents/extrol/9015183_3_11_EXTROL_IO.pdf

Research on permeability of rubber used in internal bladder-type heating system compression tanks or expansion tanks

- Bodell, Bruce R. "Distillation of saline water using silicone rubber membrane." U.S. Patent 3,361,645, issued January 2, 1968.

- Ciesielski, Andrew. An introduction to rubber technology. iSmithers Rapra Publishing, 1999.

- Fuller, James, and David M. Stedham. "Expansion tank with a predictive sensor." U.S. Patent 8,633,825, issued January 21, 2014.

- Martinello, Ermanno, and Mark Weih. "Membrane coating for a water pressurization Bladder." U.S. Patent Application 12/498,128, filed July 6, 2009.

- Stern, S. A., F. J. Onorato, and Charles Libove. "The permeation of gases through hollow silicone rubber fibers: Effect of fiber elasticity on gas permeability." AIChE Journal 23, no. 4 (1977): 567-578.

- Terashita, Fumihiro, Shingo Takagi, Shinzo Kohjiya, and Yasutoshi Naito. "Airtight butyl rubber under high pressures in the storage tank of CAES‐G/T system power plant." Journal of applied polymer science 95, no. 1 (2005): 173-177.

- [5] Bell & Gossett Airtrol® System Installation, Operating and Service Instructions, Bell & Gossett, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379. Retrieved 8/9/2012, original source B&G, [copy on file as Airtrol_Installation_Manual.pdf linked in this reference]

- Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.