Expanded Metal Lath Systems

Expanded Metal Lath Systems

Interior Plaster & Exterior Stucco

- POST a QUESTION or COMMENT about identifying & installing types of plaster lath systems

Installing plaster on expanded metal lath:

This article provides a photo guide to identifying and installing types of plaster support systems: metal lath, wire lath, etc. that are installed in buildings. We use building ceilings and walls as a photo and investigation guide to plaster and mortar lath systems.

In this article series we describe and discuss the identification and history of older interior building surface materials such plaster, plaster board, split wood lath, sawn lath, and expanded metal lath, Beaverboard, and Drywall - materials that were used to form the (usually) non-structural surface of building interior ceilings and walls.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Expanded Mesh Metal Lath for Plaster Walls & Ceilings

Expanded metal lath has been widely used to support both interior plaster in buildings and exterior building wall stucco systems.

Expanded metal lath has been widely used to support both interior plaster in buildings and exterior building wall stucco systems.

This article explains plaster systems based on metal lath in building interiors.

Also see STUCCO WALL METHODS & INSTALLATION for a discussion of exterior uses of stucco and metal lath.

[Click to enlarge any image]

Plaster of the same general formula as discussed in the two wood lath based installations above was later applied over expanded metal lath.

Our photo shows expanded mesh metal lath used as plaster lath support for ceilings and walls; this material was also used on building exterior walls to support a stucco finish.

Metal lath was on occasion used also to support poured concrete ceilings (shown here) - unlikely to provide adequate strength for a thick pour unless additional reinforcement was used.

Depending on building age we may find a mixture of multiple types of plaster support, wood lath, gypsum board lath, and metal lath.

Wall or ceiling or stucco crack patterns may follow the borders of metal lath segments, especially if the lath was not securely nailed.

Van Den Branden and Hartsell explain that metal lath for plaster systems is divided into four groups with different properties for different applications:

Photo above: diamond pattern expanded metal lath stacked for sale at a building supply store.

- Expanded metal lath - diamond mesh plaster lath, formed from sheet metal cut into a diamond pattern, pulled to an expanded shape.

Modern diamond mesh lath is sold in a variety of metals including galvanized, stainless steel, finished to ASTM 653, and in a remarkable range of pre-formed shapes including

Photo above: expanded metal lath, diamond mesh, in a Canadian home, courtesy of an InspectApedia.com reader.

- Flat diamond mesh lath

- Self-Furred diamond mesh lath used in exterior stucco and stone work over exerior sheathing and as a plaster base over masonry walls

- Dimpled diamond mesh lath

- V-Grooved diamond mesh lath - As per current revisions of ASTM C1063, metal lath applied to solid substrates must have ¼” self-furring properties, built into the lath sheet. (AMICO 2019)

- Factory-applied paper-backed metal lath (galvanized)

Photo above: expanded rib lath with stiffening ribs.

- Expanded rib lath - similar to diamond mesh but with stiffening ribs added

Rib lath is used for installation of stone and tile on walls or plaster on interior ceilings. Heavier gauges of rib lath permit installation over spans of 19" o.c. instead of the stndard 16" o.c.

Rib lath is sold currently as 1/8" flat rib lath and 3/8 High-Rib Lath used for ceilings and soffits and conforming to ASTM C1063. - Wire lath (woven wire or welded wire - aka "chicken wire")

Photo above: perforated sheet lath

- Sheet lath (popular early in the history of use of metal lathing, with a resurgence of use when shot or gun-applied plaster or cement mortars became widespread, often in commercial projects)

- Spray Lath:

Spray Lath is used primarily on the West coast [of the U.S.], where stucco is spray applied to the surface of the lath to build stucco thickness.

The Kraft paper is factory applied to prevent over spray of stucco. The spaces between the strips of Kraft paper allow for the visual alignment of the sheet for mechanical attachment of the ribs to the substrate.

Rib Lath is often attached directly to the vertical framing members without a solid board substrate included. (AMICO 2019 cited below)

Properties of Diamond Mesh Metal Lath

Illustrated by our photo: diamond mesh metal lath from the wall cavity side, in a bathroom plumbing access wall cutout, provided by an InspectApedia.com reader.

- Produced by stamping or perforating a metal sheet, then expanding the holes by pulling its edges apart

- Mesh size 5/16" x 9/16" diamond pattern - interior plastering, or larger mesh sizes for stucco work or as a support for loose fill rock wool or similar insulations

- Self-furring: dimples into the surface hold the lath 1/4" away from the attaching surface, used for fireproofing structural columns

- Paper-backed diamond mesh lath: waterproofed paper backing glued to the back to act as a moisture barrier and to reduce the amount of plaster consumed in applying the brown coat

- 2.5 or 3.4 pounds per square yard

- Sheet size: 27" x 96", packed in 10 sheet bundles to cover 20 square yards

A reader asked if the material shown in the plumbing access cutout photo here was asbestos. Our OPINON was that there is not likely to be a measurable asbestos hazard from this cement or plaster material, even if it contains asbestos, as long as it's left un-disturbed.

See details at ASBESTOS in PLASTER

Properties of Metal Rib Lath

- Similar to Diamond Mesh Metal Lath above, with the addition of metal ribs formed lengthwise in the lath to add stiffness

- Ribs are 1/8", 3/8" or 3/4" high.

- Rib lath sheet sizes: 27" x 96" for 1/8", 3/8" ribs, 29" wide & 5', 10', & 12' lengths for 3/4" rib sizes

- 2.75, 3.4, & 4.0 pounds per square yard

- A similar rib lath was produced by welding steel rods to the back surface of standard diamond mesh metal lath

Properties of Wire Mesh Lath

- 1" mesh: Constructed of galvanized woven wire (looks like "chicken wire") with 1" hexagonal openings, 20-gauge wire, sold in rolls, used over gypsum & fiber insulating lath board as reinforcement and for cornerite and stripite, used often as a stucco mesh over felt paper on open stud construction or over building sheathing

- 2" mesh: 16 gauge wire interwoven with fibrous absorbent paper backing secured by a 17 gauge wire corrugated every 4 3/8" to form a plaster key, in sheets 30 1/2 " x 49", in cartons of 44 sheets, 50 sq. yds., also used for stucco and open-stud construction.

- Gun Lath: Welded wire lath, also referred to as "gun lath" suitable for machine applied (sprayed) mortars.

Properties of Sheet Lath - Perforated Sheet Metal Lath

- Stiff metal sheet with perforations punched through the metal as slits, crosses, and ridges.

- Self-furring design, mortar pushed through the slits forms necessary plaster ears or keys

- 4.5 lb /sq.yd.

- 27" x 96" sheets or 24" x 96" sheets

The photographs of sheet metal lath shown above and below illustrate perforated sheet metal lath that was used as a base for exterior stucco on a Poughkeepsie New York home inspected by the author.

As you can see in these photographs, once water gets behind exterior stucco, especially in a northern climate subject to freezing temperatures, the action of water and frost break the mechanical bond that held the stucco cement to the metal lath.

As you can see in these photographs, once water gets behind exterior stucco, especially in a northern climate subject to freezing temperatures, the action of water and frost break the mechanical bond that held the stucco cement to the metal lath.

Stages in the deterioration of a leaky stucco wall proceed roughly in this order

- Loose stucco, still in place, but not firmly bonded to the wall. Often you can push the stucco in and it moves, or you can tap on it and it sounds more-hollow than surrounding secure stucco wall sections.

- Stains and water damage appear on the outer surface of the stucco, and spalling of the surface or paint loss begin if the stucco was painted.

- The stucco bulges out from the wall

- Sections of stucco fall away from the wall, increasing the rate of water penetration and accelerating the damage to the stucco surfaces.

Watch out: when you see any of these stucco damage signs there is a good chance of more-serious hidden damage in the wall or ceiling cavity such as rot, insect attack, or mold contamination.

Further investigation is in order.

Below, from a commercial building, we see collapsing ceiling plaster below an area of roof leaks.

Exterior Stucco Applications using Metal Lath

An example of the cause of leaks behind and extensive damage to the stucco on metal lath covered home shown above is the extreme degree of water leakage and rotted trim shown in our photograph of a Poughkeepsie NY home.

Lack of maintenance of the building trim led to extensive wall leaks and costly damage to the building stucco, trim, and windows.

Van Den Branden and Hartsell continue to point out that metal lathing for exterior stucco is similar to interior installations, with these changes:

- Use of a covering of all exterior surfaces with a waterproof building paper or plastic,

- Use of heavier gauge metal lath with larger mesh openings

- Lath is not applied in direct contact with the background or base, by using furring nails that hold the lath out 1/4" to 3/8" from the base or framing

[this permits plaster to penetrate the lath and form securing keys] - Use of protective flashings and details to keep water from passing behind the lath (and stucco surface)

- Use of control joints

Watch out: do not use interior-grade metal lath for exterior wall stucco applications.

Metal lath is supplied in most markets in hot dipped galvanized (G 60) for exterior applications, and in painted or some equivalent rust-inhibitive coating, such as electrogalvanizing, for interior applications.

I have included this element because some contractors have installed painted or electrogalvanized lath for exterior applications.

According to ASTM C 1063, only G-60 hot dipped galvanized lath is allowed to be used for exterior applications. (Maylon 1996)

More photographs of plaster walls & ceilings built on metal lath:

Our ceiling cavity photograph of a plaster on metal lath system (below left) shows how plaster applied to metal lath has considerably more adhesion security than plaster applied over wood lath.

Below (a New York garage ceiling) the plaster coating was left quite thin; you can see rusting metal lath around the light fixture and at the upper right in our photograph.

See LOOSE PLASTER is UNSAFE for an example of a collapse of an expanded wire lath ceiling that had been improperly installed.

Loose Plaster is Unsafe, Especially Loose, Falling Plaster Ceilings

Watch out: for loose plaster that can fall and injure building occupants.

If ceiling plaster is bulged and moves when you apply gentle pressure to it, chances are that the plaster keys, the protruding plaster that oozed between the plaster lath strips to mechanically secure the plaster surface in place, have broken off.

Expanded Metal Lath Plaster Ceiling Catastrophic Collapse Case

As we discuss in detail at at PLASTER, LOOSE FALL HAZARDS, plaster ceilings in newer buildings are not immune from collapse either, as you'll see by the catastrophic ceiling collapse shown just below.

This plaster ceiling was applied on expanded metal lath.

The lath was wired to steel pipes or bars that in turn were hung from a smaller number of steel supports.

The final steel supports were hung from wire ties connected to fasteners that had been "pin-shot fasteners" shot into the sides of concrete ceiling joists.

The combination of several factors led to this ceiling collapse:

See DRYWALL, FIBERBOARD, PLASTER INTERIORS where we include photographs of non-plaster interior wall and ceiling coverings including drywall, beaverboard, and paneling

For plaster type surfaces used on building exteriors,

see STUCCO WALL METHODS & INSTALLATION.

Metal Lath Standards, Installation, History & Dates for Use as a Plaster Base

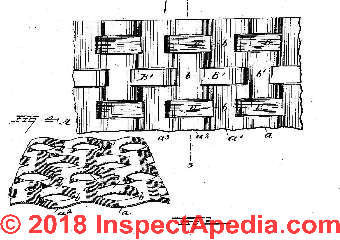

In North America metal lath was in popular use before 1890, and the term "expanded metal lath", appearing in McCall's 1900 patent, was in popular use by 1914.

In North America metal lath was in popular use before 1890, and the term "expanded metal lath", appearing in McCall's 1900 patent, was in popular use by 1914.

You'll see from the Hayes 1890 patent that early forms of metal lath were punched but were not using the "expanded metal lath" technique.

- Amico, METAL LATH and ACCESSORIES, [PDF] Alabama Metal Industries Corporation

3245 Fayette Avenue, Birmingham, AL 35208 USA Tel:(205) 787-2611 (800) 366-2642 Website: www.amico-lath.com Email: sales@amico-online.com Amico is a Gibraltar Industries company.

Amico has offices throughouth the U.S. and Canada as well as in the United Kingdom and Germany. - Clark Dietrich, BEST PRACTICES for SELECTION & INSTALLATION of EXPANDED METAL LATH PRODUCTS [PDF], (2014) ClarkDietrich™ Building Systems, 9050 Centre Pointe Drive, Suite 400 West Chester, OH 45069 USA, Tel:(513) 870-1100 Website: https://www.clarkdietrich.com, E-mail: support@clarkdietrich.com retrieved 2019/01/12, original source: https://www.clarkdietrich.com/sites/default/files/imce/pdf/WhitePapers/2014_Jan_Lath/CD_WP_Expanded_Metal_Lath-Jan2014.pdf

- ASTM C 842 - 05 (2015) Standard Specification for Application of Interior Gypsum Plaster, available from ASTM at https://www.astm.org/Standards/C842.htm

Abstract:

This specification covers the minimum requirements for full-thickness interior gypsum plastering on gypsum, metal, masonry, or monolithic concrete bases designed or prepared to receive gypsum plaster.

Gypsum plaster applied to the interior side of exterior walls of masonry or concrete shall be isolated from the exterior wall. Gypsum plasters shall not be used in exterior locations or interior wet areas.

Plasters and other cementitious materials shall be kept dry until used; they shall be stored off the ground, under cover, and away from walls with condensation and other damp surfaces.

Metal products shall be protected, while stored, against rusting.

The surface preparations of plasters are presented in details. All plaster mixing shall be done by mechanical means unless hand mixing is specified. Plaster shall be applied by hand or machine as specified. - ASTM C 841 - 03 (2013) Standard Specification for Installation of Interior Lathing and Furring, available from ASTM at https://www.astm.org/Standards/C841.htm

Abstract:

This specification covers the minimum requirements for, and the methods of application of, interior lathing and furring to receive gypsum plaster applied. Other materials are not prohibited from being used provided that their physical characteristics and durability under conditions of usage are at least equal in performance to those described.

All materials shall be kept dry, preferably by being stored inside.

Where necessary to be stored outside, materials shall be stacked off the ground, supported on a level platform, and protected from the weather and surface contamination. Materials shall be neatly stacked flat with care taken to avoid damage to edges, ends, or surfaces.

The materials to be used are the following: tie wire and hanger wire, gypsum lath, expanded metal lath, welded wire lath, woven wire lath, nails, screws, staples, paper, and accessories such as control joints, cornerite, channels, rod and flat hangers, clips, and striplath.

In general, during installation, the following shall be required: application of gypsum lath to supports, application of gypsum lath to wood supports, application of gypsum lath to metal supports, studless solid partitions (gypsum lath and plaster), application of metal plaster bases to framing members, studless solid partitions (metal lath and plaster), suspended and furred ceilings (metal lath and gypsum lath construction), main runners, cross furring, and metal furring for walls. - EMLA, GUIDE SPECIFICATIONS for EXPANDED METAL LATHING and FURRING [PDF] 5th Ed., (2009) NAAM EMLA 920-09 Expanded Metal Lath Association, NAAMM Headquarters 800 Roosevelt Rd. Bldg. C, Suite 312 Glen Ellyn, IL 60137 USA (630) 942-6591 phone info@naamm.org Website: NAAMM EMLA https://www.naamm.org/division/3

Retrieved 2019/01/12 original source https://www.naamm.org/content/uploads/products/emla_920-09.pdf

Wegsite Excerpt:

The Expand Metal Lath Association (EMLA) of the National Association of Architectural Metals Manufacturers (NAAMM) has run a comprehensive testing program to determine the minimum acceptable load for expanded metal lath for transverse loading with a traditional 3-coat stucco wall system.

The third party test results proved these types of wall systems perform exceptionally well in high-wind zone environments. The stucco tests were performed in August, 2011 at Smith-Emery Laboratories in Los Angeles, CA, following the ICC’s – Acceptance Criteria (AC) 191 – Acceptance Criteria for Metal Plaster Bases (Lath) – using Code-Compliant Lath & fasteners, studs, weather-barrier and sheathings.

The test frames were constructed in accordance with AC191 and the lath plaster were installed according to ASTM C-1063 – Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster and ASTM C-926 Standard Specification for Application of Portland Cement-Based Plaster. - LATH & PLASTER SYSTEMS, 092300/NGC, [PDF] National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- Gypsum Construction Guide, National Gypsum Corporation

- Home Depot Stores, HOW to INSTALL METAL LATH [PDF], retrieved 2019/01/12, original source: Home Depot Stores, https://images.homedepot-static.com/catalog/pdfImages/0a/0afff321-4174-47da-96bc-768e2f52d66d.pdf

- Maylon, Gary J., EXPANDED METAL LATH INSTALLATION for the APPLICATION of PORTLAND CEMENT STUCCO [PDF] "The Seven Deadly Sins" Constructin Dimensions, December 1996, retrieved 2019/01/12, original source: https://www.awci.org/cd/pdfs/9612_c.pdf

- METAL LATH SPECIFICATIONS, SPECIFICATION FOR METAL LATH AND ACCESSORIES, LATH AND PLASTER [PDF] Amico, a lath and plaster accessory producer.

- Minnesota Lath & Plaster Bureau, LATH INSPECTION RESOURCE MANUAL [PDF], 2nd. Ed., Minnesota Lath & Plaster Bureau, Minnesota Lath and Plaster Bureau

10600 University Avenue NW Suite 3 Coon Rapids, MN 55448 USA Tel: 763-757-MLPB (6572) Email: info@mnlath-plaster.com

retrieved 2019/01/12, original source: http://www.mnlath-plaster.com/library/documents/LathInspectionResourceManualUpdate2009.pdf

Website excerpt: The Minnesota Lath and Plaster Bureau has promoted the industry since 1953. It is widely recognized as an education and technical spokesman for the industry. It provides services to architects, the construction community and the public on a variety of matters relating to the plastering trades.

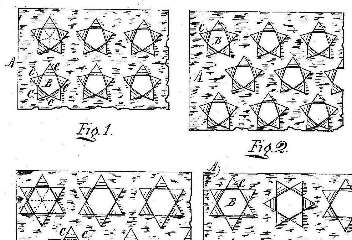

Effective 1-1-19 the office operations of the Minnesota Lath and Plaster Bureau were suspended. - Hayes G., "Metallic Lathing", U.S. Patent 420656, issued February 4, 1890

Excerpt: ... have invented a new and useful Metallic Lathing, of which the following is a specification.

My invention consists of a lathing of sheet metal having at intervals throughout tongued apertures of polygonal shape, the perimeter of each opening having more than four sides and with all its angles obtuse, the aperture made by cutting incisions and turning out ward the edge metal of the cuts outward until the proper size and shape of the opening are obtained.

The edge metal so turned outward is left projecting beyond the plane of one side of the sheet as tongues, hooks, or barbs to grasp plaster when applied thereto, all as hereinafter more fully specified, reference being had to the accompanying drawings, in which-

Figure 1 is a face view of a piece of the sheet-metal lathing, showing the tongued apertures of pentagonal shape arranged in direct lines. Fig. 2 is a face view of a piece of the lathing with pentagonal aperture arranged in diagonal line across the sheet.

Fig. 3 is a face view of a piece of the lathing having tongued apertures of hexagonal shape arranged in diagonal lines across the sheet.

Fig. i is a face view of a piece of the lathing having hexagonal apertures arranged in direct lines. Fig. 5 is a face View of a piece of the lathing with apertures of elongated hexagonal shape arranged in diagonal lines across the sheet.

... A sheet-metal lath having at intervals throughout apertures of polygonal shape whose perimeter consists of more than four sides and of which all angles are obtuse,

each aperture formed by cutting incisions radiating from centers and turning outward with a backward bend or roll, the pointed edge metal from between the cuts to stand at the verge of the aperturaprojecting beyond the plane of the sheet as tongues, hooks, or barbs to grasp plaster when applied thereto, as herein set forth. - Curtis, O.H., "Metal Lathing", U.S. Patent 460,850, issued 10 October 6, 1891

Excerpt:... have invented a new and useful Improvement in Metal Lathing, of which the following is a full, clear, and exact description.

This invention relates to that description of metal lathing which is constructed of sheet metal having cuts made in it forming openings for entry and clinching of the plaster and in which the cut portions remain attached and are bent to protrude beyond the surface of the sheet, which is made corrugated in addition, to give strength.

The object of my invention is to produce a simple, easily manufactured, and improved fire and vermin proof metal lath of this description, substantially as hereinafter described,and more particularly pointed out in the claims. - Ohl, G.A., "Machine for Making Metal Lathing", U.S. Patent 475,700 Issued 24 May 1892

Excerpt: ... have invented certain new and useful Improvements in Lath- Machines, fully described and representedin the following specification and the accompanying drawings, forming a part of the same.

The apparatus herein described is adapted to form slots in a sheet of thin metal, with strips attached at both ends to the sheet behind the slot to form a metallic lath to retain plaster upon walls; and the improvement c011- sists in the particular construction of the rolls and strippers hereinafter described.

- Eckstein, William, "Metallic Lathing", U.S. Patent 514313, issued 6 Februray 1894 previously patented in Great Britain in 1892.

Excerpt: Be it known that I, WIILLIAM ECKSTEIN, of 187 Union Street, London, S. E., in the county of Surrey, England, have invented a new and useful Improvement in Metallic Lathing, (for which I have obtained Letters Patent in Great Britain, No. 11,036, dated June 11, 1892,) of which the following is a full, clear, and exact description.

The invention relates to metallic lathing having means such as keys, loops, or spurs, for causing the plaster when applied thereto, to be interlocked with such lathing.

Various forms of plaster-engaging devices have been provided, and the present invention has for its object to improve and make more efficient such plaster engaging devices, and at the same time greatly increase the rigidity of the plate. - Mccall, William. "Metal-lath attachment and support." U.S. Patent 657,827, issued September 11, 1900.

Excerpt: The objects of my invention are to provide a means for rapidly attaching the sections of wire or expanded metal laths to the partitions, ceiling, or other portions where the lath and plastered surfaces are to be applied - Chester, Frank Stanley. "Metal lath." U.S. Patent 764,989, issued July 12, 1904.

Excerpt: ... a new and improved metal lathwhich can be economically manufactured and which will hold plaster securely in position on the surface of the lath and one which will economize in the quantity of plaster to be used. - Alschuler, Alfred S. "Metal-lath construction." U.S. Patent 802,727, issued October 24, 1905.

- Scammell, Charles H. "Expanded metal lath." U.S. Patent 1,087,511, issued February 17, 1914.

Excerpt: ... new and useful Improvements in Expanded Metal Lath, fully described and represented in'the following specification and the accompanying drawings, forming a part of the same.

This invention relates ,to expanded "metal lath of that class formed by slitting the metal. and drawing out the strands to open the slits and turn the strands at an angle to the plane of the metal and which is used generally as lathing to hold plaster in building construction, althi'iugh applicable, also to other uses. - Scammell, Charles H. "Metal lath." U.S. Patent 1,210,849, issued January 2, 1917.

- Dickinson, Clarence W. "Expanded-metal lath." U.S. Patent 1,372,741, issued March 29, 1921.

- Sagendorph, Robert H. "Metal lath." U.S. Patent 1,701,125, issued February 5, 1929. Assigned to Eastern Expanded Metal Co.

Patent excerpt: This invention relates to metal lath, an object of the invention being to provide an improved lath formed by first slitting and then expanding a met-al sheet, and thereafter applying a coating material to the face of the slitted

and expanded sheeting such manner as to cover predetermined portions of the sheet so as to provide keyways or spaces of, considerable less total area than the area of the sheet for retaining the plaster when applied, thereby enablin a very considerable saving in the amount of plaster used.

...

Continue reading at PLASTER, LOOSE FALL HAZARDS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see PLASTER LATH, METAL FAQs - questions and answers about metal lath posted originally on this page.

Or see these

Recommended Articles

- PLASTER TYPES & METHODS in BUILDINGS

- PLASTER ASBESTOS CONTENT

- PLASTER BULGES & PILLOWS

- PLASTER DUST EXPOSURE HEALTH HAZARDS

- PLASTER INGREDIENTS, MIX, PROPERTIES

- PLASTER LATH, METAL

- PLASTER, LOOSE FALL HAZARDS

- PLASTER REPAIR METHODS

- PLASTER TYPE IDENTIFICATION

- PLASTER VENEER Best Practices

- PLASTERBOARD / DRYWALL EXPANSION COEFFICIENTS

- STUCCO WALL METHODS & INSTALLATION

Suggested citation for this web page

PLASTER LATH, METAL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- America's Favorite Homes, mail-order catalogues as a guide to popular early 20th-century houses, Robert Schweitzer, Michael W.R. Davis, 1990, Wayne State University Press ISBN 0814320066 (may be available from Wayne State University Press)

- American Plywood Association, APA, "Portland Manufacturing Company, No. 1, a series of monographs on the history of plywood manufacturing",Plywood Pioneers Association, 31 March, 1967, www.apawood.org

- ASHI, American Society of Home Inspectors,® Inc., 932 Lee Street, Suite 101, Des Plaines, Illinois, 60016. The American Society of Home Inspectors is the first and leading national association of home inspectors in the U.S. Website: www.ashi.org

- ASTM C 842

- ASTM C 841 Metal Lath or gypsum lath installation

- Building Research Council, BRC, nee Small Homes Council, SHC, School of Architecture, University of Illinois at Urbana-Champaign, brc.arch.uiuc.edu. "The Small Homes Council (our original name) was organized in 1944 during the war at the request of the President of the University of Illinois to consider the role of the university in meeting the demand for housing in the United States. Soldiers would be coming home after the war and would be needing good low-cost housing. ... In 1993, the Council became part of the School of Architecture, and since then has been known as the School of Architecture-Building Research Council. ... The Council's researchers answered many critical questions that would affect the quality of the nation's housing stock.

- How could homes be designed and built more efficiently?

- What kinds of construction and production techniques worked well and which did not?

- How did people use different kinds of spaces in their homes?

- What roles did community planning, zoning, and interior design play in how neighborhoods worked?

- Isham: "An Example of Colonial Paneling", Norman Morrison Isham, The Metropolitan Museum of Art Bulletin, Vol. 6, No. 5 (May, 1911), pp. 112-116, available by JSTOR.

- Plastering, PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started. - Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- Gypsum Construction Guide, National Gypsum Corporation

- Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster from Amico, a lath and plaster accessory producer.

- Lath & Plaster Systems, 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- Gypsum Construction Guide, National Gypsum Corporation, 2001 Rexford Road, Charlotte, North Carolina 28211, Tel: 704-365-7300, Email: ng@nationalgypsum.com, Website: http://www.nationalgypsum.com

- MSDS: Gold Bond® brand gypsum board products, plaster base, National Gypsum Corporation. Other drywall MSDS sheets are found at Drywall MSDS.

- Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster from Amico, 3245 Fayette Ave. P.O. Box 3928, Birmingham, AL 35208, (205) 787-2611, (800) 366-2642 and in Canada: 1080 Corporate Drive, Burlington, Ontario L7L 5R6, Canada, (905) 335-4474, (800) 663-4474. Amico is the largest metal lath producer in North America. Website: http://amico-lath.com/

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- What Style Is It?: A Guide to American Architecture, Rev., John C. Poppeliers, S. Allen Chambers, Wiley; Rev Sub edition (October 6, 2003), ISBN-10: 0471250368, ISBN-13: 978-0471250364

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.