Guide to Tankless Coils on Heating Boilers

Guide to Tankless Coils on Heating Boilers

- POST a QUESTION or COMMENT about tankless coils used to produce domestic hot water: clogging, leaks, water quantity, water temperature, scale formation and cleaning

Tankless coils unwound: using a tankless coil for domestic hot water for washing and bathing.

Here we explain the function, use, capacity, inspection, and repair of Tankless Coils on heating boilers: a guide to tankless coils for domestic hot water supply: capacity, safety, clogging, adjustment, cleaning, & Repair Guide

This article series answers most questions about Heating System Boiler Controls on central heating systems to aid in troubleshooting, inspection, diagnosis, and repairs. Contact us to suggest text changes and additions and, if you wish, to receive online listing and credit for that contribution.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

A Guide to Tankless Coils for Domestic Hot Water Production

Tankless coils used on heating boilers:

This device, basically a coil of finned copper tubing which is inserted into the heating boiler, is used to provide domestic hot water to some buildings.

[Click to enlarge any image]

Watch out for leaks at piping fittings or more seriously the coil mounting plate which bolts the coil to the boiler (leaks at this location can destroy a steel boiler).

Watch out also for missing a mixing/tempering valve which mixes cold in with the outgoing hot water to avoid scalding temperatures at nearby taps. Some building jurisdictions require a separate temperature/pressure relief valve on hot water piping at the boiler.

The photo shows a pile of tankless coils found in a building basement next to the heating boiler.

We suspected that high mineral content in the building's water supply was causing frequent coil clogging.

Hot Water Temperature Control with Tankless Coil Heating Systems

The heating boiler, hot water or steam, will include a temperature limit control switch dedicated to maintaining temperature in the heater's interior for purpose of heating the coils of the tankless coil.

As the illustration at left shows, domestic hot water is heated by passing cold water through a finned copper coil which is in turn immersed in hot water inside of a heating boiler.

Drawing of a tankless coil for heating water shown here, courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

[Click to enlarge any image]

How much hot water can a tankless coil provide?

The temperature and effective quantity of domestic hot water received at a fixture in the building for washing and bathing is set, affected, or controlled by these things:

- The water temperature inside the boiler and in contact with the tankless coil

- The volume of hot water inside the boiler in contact with the tankless coil - larger boiler or larger volume of hot water in the boiler means that there is more heat to transfer into the coil

- The thermal mass of the boiler itself - steel boilers have less thermal mass than cast iron boilers of the same size, and modern, small-sized high-efficiency heating boilers are likely to have much less thermal mass than an antique and huge cast iron boiler.

Running the small efficient boiler at higher temperatures can grab back a little of this thermal storage. - The rate at which incoming water passes through the tankless coil - faster flowing water absorbs less heat from the boiler.

HOT WATER CIRCULATOR PUMP SPEEDS DELIVERY can speed up the water flow, at the cost of drawing heat out of the boiler faster, thus possibly reducing the time duration over which hot water is provided. - The settings of the aquastat or low-limit LO and differential DIFF controls. Keeping the boiler at a higher temperature and setting a higher DIFF will in general store more heat in the boiler and should thus allow a tankless coil to provide a greater volume of hot water before the system runs out of heat.

See AQUASTAT CONTROL FUNCTIONS. - The settings of the anti-scald valve or mixing valve - setting the anti-scald valve to a lower output temperature means that it mixes more cold in with outgoing hot, drawing heat out of the boiler and through the tankless coil more slowly than otherwise.

You get "longer hot water on time" because you draw heat out of the boiler more slowly.

See ANTI SCALD VALVES.

Considering these factors, you can understand that converting a large old cast iron home heating boiler with a tankless coil to a new small high-efficiency steel heating boiler that also includes a tankless coil may result in a new heating system which is more efficient and economical, but it may provide less total domestic hot water than the old system.

Tankless Coil BTU Rates

Question: btu input that a tankless coil can accept

2020/03/24 Al said:

What is the normal btu input that a tankless coil can accept?

Reply: rough calculation of the heat transfer rate from a residential heating boiler into the tankless coil for domestic hot water supply

Thank you for the interesting question, Al. Let's put some rough calculations behind my explanation (above) of why a tankless coil system on a conventional heating boiler will run out of hot water.

A typical residential heating boiler will have itself an input BTUh between say 70,000 and 200,000 BTUs/hour. That's the rate that the oil burner is pumping heat INTO the boiler.

The rate that heat is transferred out of that hot boiler water and into the building's potable water as that potable water passes through the tankless coil is a different (unknown) number that depends on factors we cited above on this page, or below in summary:

- the thermal conductivity of the copper tankless coil and its fins

- the tankless coil shape, total area of exposure to hot water

- the difference in temperature between the boiler water and the tankless coil itself and the water inside the coil: defining the heat transfer rate

- the temperature of the water entering the tankless coil (typically between 50 °F and 70 °F in most areas)

- the temperature of the boiler water around the coil (typically 120 to 200 °F)

- the flow rate of water through the coil in gpm (typically 1-5 gpm but possibly faster)

That analysis is possible but is so complex and so theoretical as to be unlikely to describe an arbitrarily-selected home heating boiler using a tankless coil.

For that reason tankless coil and boiler manufacturers typically rate the tankless coil's ability to provide hot water as some temperature rise (increase in temperature between incoming and outgoing water - say 40 °F) for a **limited period of time** (say 5 minutes!).

The reason for that time limit is that the oil burner is sized to put heat into a boiler designed for heating the home.

In that application the temperature rise across the boiler (cold zone water entering the boiler and hot zone water leaving it) may be rather small (less than 20F) while in contrast there is an enormous temperature difference between the cold water entering the coil (40F in winter) and the desired output temperature (120F) - that's an 80 deg rise.

The burner can keep up with the boiler's need for heating the home but it cannot keep up with the rate at which a tankless coil can suck heat out of the boiler. That's why the tankless coil on a conventional hydronic boiler can never ever deliver "endless" hot water.

Calculation of Heat Transfer Rate into a Tankless Coil Hot Water System - BTUs needed to Heat Tankless Coil Water

- One BTU will raise one pound of water by 1ºF (at 1 ATM - that is, at sea level).

- One gallon of water weighs 8.33 pounds.

- At 5 gpm flow rate through the coil we'd need (8.33 gallons x 5 BTUs per minute) about 42 BTUs per minute per degree of temperature rise.

- At 5 gpm we need (42 BTUs/min x 60 mins/hr) = 2520 BTUs per hour per degree of temperature rise.

At 5 gpm, to heat water up from an incoming 40 °F to 120 °F we need to raise the water temperature by 80 degrees, so we will need

- At 5 gpm, to produce 120 °F hot water in a tankless coil we will need (80 °F x 2520 BTUs/hr/deg) = 201,600 BTUs / Hour

Factor in the boiler's efficiency in burning heating oil. The boiler is not running at 100% efficiency.

The INPUT BTUh is always more than the boiler's OUTPUT BTUh - the rate at which heat is actually delivered. A typical output BTUh is maybe 80% of the input rate.

- A 100,000 INPUT BTUh boiler is maybe capable of putting 80,000 BTUh into the water.

The above is a rough back-of-the-envelope calculation - an approximation, but we can see that

- The boiler's total heating capacity at (80,000 BTUh) is less than half the tankless coil's ability to draw heat out of the boiler (at 201,600 BTUs/Hr)

Bottom line answer to your question: the tankless coil can accept as much heat as the boiler water temperature can provide, but the coil will always cool off a conventional residential heating boiler faster than the burner can keep up.

Sanity-check on the above calculation.

Advantage Engineering offers their own cute formula that is simpler than my calculations above:

- BTUs = Flow Rate In GPM (of water) x (Temperature Leaving Process - Temperature Entering Process) x 500.4

Their calculator has mashed together all of the details that I preferred to give and explain above.

Using their calculator and plugging in 5 gpm, 40 °F starting temperature and 120 °F ending temperature gives 200,000 BTU/hr - which is so close to my calculation that I think we're both in the right ballpark.

Advantage Engineering, Inc. 525 East Stop 18 Road Greenwood, IN 46143 USA, Tel: 317-887-0729 - retrieved 2020/03/24, original source: https://www.advantageengineering.com/fyi/288/advantageFYI288.php

Use of a Single Function Boiler Temperature Limit switch and Anti Scald Valves with Tankless Coils

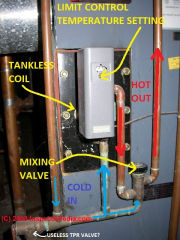

Here is a photo of a more traditional single-function heating boiler limit controls. In this example the limit switch is being used on a tankless coil, and in the enlarged version of the photo you'll see that the temperature limit on the control is set to about 140 °F.

When a heating boiler uses a tankless coil to produce domestic hot water, a third single-function control may be installed for that purpose.

In this photo a Honeywell limit control switch is being used to monitor hot water temperature at the tankless coil which is in turn mounted on a steam boiler of an older home in Portland, Maine.

You can see the black-handled mixing valve in the lower right of this photo.

Cold water from the building is entering the tankless coil via the bottom pipe (green corrosion) and hot water, heated by the coil is leaving at the upper part of the tankless coil, where it turns downwards to enter the left side of the mixing valve.

Cold water from the building is entering the tankless coil via the bottom pipe (green corrosion) and hot water, heated by the coil is leaving at the upper part of the tankless coil, where it turns downwards to enter the left side of the mixing valve.

Additional cold water is permitted to enter the bottom of the mixing valve, and tempered (non-scalding) hot water then leaves at the right side of the mixing

More details about this single function limit switch are

Anti-scald valve used with water heater limit switch: In this photograph a single function limit switch is in use on a water heater, not on a heating boiler.

Here too you will notice that there is also a mixing valve installed to prevent scalding - the gray-handled device to the right of the control (and leaking we might add).

The use of a mixing valve or anti-scald valve permits us to set the Honeywell 6006 limit control switch to a higher number, keeping the water in the heater at a higher temperature.

The mixing valve in this photo adds cold to the outgoing hot water to avoid scalding, and at the same time we have more total domestic hot water for washing and bathing than if we omitted this pair of controls.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-10-29 by (mod) - do we need a relief valve on a tankless coil for hot water on a boiler?

Thanks so much for continuing the discussion, kudos for being a careful observer, and thanks also for pointing out where clarification of our information is needed; I have now updated the original photo that was found at page top and that you included again in a screen shot.

Thanks so much for continuing the discussion, kudos for being a careful observer, and thanks also for pointing out where clarification of our information is needed; I have now updated the original photo that was found at page top and that you included again in a screen shot.

You're quite right that there's a TPR valve at lower left in the photo, and even crazier, if you follow the pipes you'll see that this particular relief valve is on the COLD side of the piping system where as far as I can tell it's doing nothing useful whatsoever. This particular anti scald valve is at the tankless coil mounted into a steam boiler, using the steam boiler's internal very hot water to produce domestic hot water.

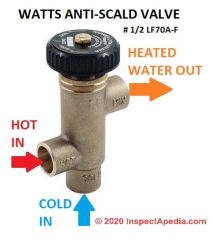

I'll include below a close-up of that Watts anti-scald valve showing the identification of its ports as HOT (out from the coil), COLD in from building supply, and MIX (the tempered water being sent as "hot" to the building plumbing fixtures.

I made use of one of my photos of an actual installation without pointing out or commenting on that particular relief valve so it's good to have a chance to clarify that now.

The presence of that relief valve does not hurt anything (as long as it's not itself leaking) but it's not doing anything useful that I can see in this installation.

On 2020-10-29 by Josh

Thank you for the response. The main reason I.was asking is because I saw in a couple pictures you have posted on this site that the tankless coil piping has a pressure relief, and every where I looked I could not figure out why. I don't have one and wondered if I needed one. I attached an image from this page and I see what looks like a pressure relief on the cold side. Thank again

On 2020-10-07 - by (mod) -

Josh

You may have seen a Tempering device or anti scald or mixing valve at a tankless coil used for producing hot water. But you will not commonly find a pressure relief valve on the tankless coil piping. That's because there is no significant volume of hot water in the tankless coil such as would be needed to produce a BLE VE explosion

On 2020-10-07 by Josh

What relief valve should I use on my indirect coil? I see in the diagram on this website it is on the hot side but I do not see mention of the pressure rating,etc. Also I have seen pictures of some installations on this website with a pressure relief on the cold side. Help would be appreciated

On 2020-06-28 by (mod) - fixing broken tankless coil mounting bolt

Mac

To have room for a detailed answer please find your question and my reply now near the end of

TANKLESS COIL / HOT WATER COIL LEAKS how to recognize, evaluate, and repair boiler leaks on or around the tankless coil.

On 2020-06-28 by mac

twisted off middle bolt front of New Yorker furnace domestic water coil to replace a gasket. What to do?

On 2020-03-24 - by (mod) -

Al,

Thank you for asking a great question. Please find your question and my very detailed reply in the article above on this page.

Bottom line:

A typical residential hydronic heating boiler's total heating capacity at (80,000 BTUh) is less than half the tankless coil's ability to draw heat out of the boiler (at 201,600 BTUs/Hr).

Do let me know if that explanation leaves you with further questions.

On 2020-03-24 by Al

What is the normal btu input that a tankless coil can accept?

On 2019-12-09 - by (mod) -

No, Anon.

On 2019-12-09 by Anonymous

Is it a requirement to install a vacuum breaker on a tankless coil piping

On 2019-11-26 - by (mod) -

Tankless coils are always Limited in the quantity of hot water that can be delivered. In addition to maybe an anti scald device located near the coil that limits the temperature of the water leaving the system. In that case it's both a safety feature and also one that gives you longer run of hot water before you run out.

However sometimes if the plumbing fixture that's farthest away has the least water it may be that too much heat is being lost along the route of the hot water pipe. In that case you could try insulating the hot water piping.

On 2019-11-26 by Paul J. Cullinane

Why do I have to turn up my heat to get hot water in the shower? Oil fueled steam. Tankless

...

Continue reading at CLOGGED PIPES / TANKLESS COIL DE-SCALE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see TANKLESS COIL FAQs - questions & answers posted originally on this page and offering more help diagnosing tankless coil troubles.

Or see these

Recommended Articles

- ANTI SCALD VALVES

- CLOGGED PIPING / TANKLESS COIL & HOT WATER FLOW

- HOT WATER IMPROVEMENT - improve hot water quantity and flow when a tankless coil is installed + other methods of hot water heating

- TANKLESS COILS - home

- AQUASTAT CONTROL FUNCTIONS

- BODY OVERHEATING HAZARDS

- CLOGGED PIPES / TANKLESS COIL DE-SCALE

- HOT WATER ANTI-SCALD REGULATIONS

- MIXING / ANTI-SCALD VALVES an anti-scald or tempering valve can increase the volume of hot water available

- TANKLESS COIL ABANDONMENT or CONVERSION

- TANKLESS COIL HOT WATER HEATER TEMPERATURE CONTROL

- TANKLESS COIL HOT WATER INCREASE - how to get more hot water

- TANKLESS COIL INSTALLATION PROCEDURE

- TANKLESS COIL INTERNAL LEAKS INTO the BOILER

- TANKLESS COIL / HOT WATER COIL LEAKS how to recognize, evaluate, and repair boiler leaks on or around the tankless coil.

- TANKLESS WATER HEATERS - home

- WATER PIPE CLOG REPAIR for a discussion of loss of water pressure due to clogged piping or clogged tankless coils.

Suggested citation for this web page

TANKLESS COILS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER HEATERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about tankless coils used to produce domestic hot water: clogging, leaks, water quantity, water temperature, scale formation and cleaning

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] Bosch Tankless Water Heaters - http://www.boschhotwater.com/

- [1a] Bosch, "Instrucciones de instalacion y manejo, Calentador de agua instantaneo, Confort / Confort S 6BP / 6BP n 10BP / 10BP N 13BP / 13BP N" Robert Bosch, S. de R.L. de C.V., Calle Robert Bosch 405, Zona Industrial, Toluca, Edo de Mexico CP 50070, website: www.bosch.com.mx, Tel: 800-11-26724 (2010)

- [2] Chromolite Tankless Water Heaters

- [10] U.S. Department of Energy on Tankless Water Heaters - http://apps1.eere.energy.gov/consumer/your_home/water_heating/index.cfm/mytopic=12820

- [11] "Tankless or Demand Type Water Heaters,"U.S. Department of Energy, retrieved 10/14/2012, original source: http://energy.gov/energysaver/articles/tankless-or-demand-type-water-heaters [Copy on file as Tankless_Water Heaters_DOE.pdf] retrived anew 2/25/2014

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.