Asphalt Roof Shingles

Asphalt Roof Shingles

Home Page: Contractors, Claims, Diagnosis of Failures

Asphalt & Fiberglass-based Asphalt Shingle Failure Identification / Prevention, Warranty Claims Assistance

- POST a QUESTION or COMMENT about asphalt roofing: installation, inspection, leak or failure diagnosis, repair, replacement, warranties

Asphalt roof shingle inspection, diagnosis, installation & repair guides.

This article series on asphalt roofing explains how to recognize and diagnose the cause of the most-common asphalt roof shingle failures and how to obtain asphalt roofing shingle failure claims assistance.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Guide to Asphalt Roofing Shingles: installation, inspection, troubleshooting, repair

Common asphalt shingle failure factors include improper storage and handling of the asphalt shingles before installation, improper nailing, improper flashing (which pertains to any roofing material), and defective asphalt shingle product material leading to thermal splitting, cracking, blistering, staining, and in some cases curling or cupping shingles.

By listing common causes of asphalt roof shingle failures and how to recognize them, building owners and roofing contractors may also be able to reduce the occurrence of asphalt roof shingle storage, handling, and installation errors that affect roof life.

Shingle failures: Readers are also invited contribute roof failure information to the web author for research purposes. web author for research purposes.

[Click to enlarge any image]

What are Asphalt Roof Shingles ? What are Asphalt Shingles Made of?

Asphalt roof shingles are the most common covering used on residential properties in North America.

Early shingles were made by saturating rag-felts with asphalt and by coating each side of the saturated felt with an asphalt-mineral filler-coat, covering the top surface of the shingle with mineral granules (sunlight and weather resistance) and coating the bottom surface with a material to prevent shingles from sticking together in storage or shipment.

Beginning in the 1940's the felt mat was changed to a zero rag-content using wood fibers and cellulose (newspaper).

More recently many manufacturers began producing shingles using a fiberglass mat to replace the felt.

The fiberglass mat was thought to have good tear resistance, possibly slightly better fire resistance, and as the mat was generally thinner than the felt mat, we believe that there were also economic advantages for both the manufacturer (less asphalt used in the mat) and the roofing installer (lighter material, easier to install).

Examples of Roofing Shingle Failures by Failure Type

'Below we provide brief examples of a variety of roofing product failures. Please be sure to review the full-text articles in the list above.

FIBERGLASS SHINGLE CRACKS - Asphalt Shingle Failures Described & Explained

Fiberglass-based Asphalt Roof Shingle Cracking/Tearing/Splitting Failures

Fiberglass-based Asphalt Roof Shingle Cracking/Tearing/Splitting Failures

"Thermal splitting," or "cracking" which in fact is in most cases actually a tearing of the shingles is considered by experts to be the principal current problem with fiberglass-based shingles.

We prefer the term tearing as a most accurate description of what's probably happening.

Originally observed on the lightest-weight (15-year life) shingles this problem has now been found across all shingle styles, weights (life ratings), and we suspect, probably across most or all manufacturers of this type of product.

See CRACKS & THERMAL SPLITTING in FIBERGLASS SHINGLES for our full discussion of this type of asphalt shingle failure, its cause, how to recognize it, and what to do about it.

What do cracked, torn, defective asphalt roof shingles look like?

We have observed a variety of torn or split shingles, for which we include some example photos below:

[Click to enlarge any image]

Horizontal or vertical tears across multiple 3-tab shingles

Horizontal, vertical, and diagonal tears across multiple strip-type shingles

Horizontal, vertical, diagonal, and corner tears across multiple laminate-type shingles

Both horizontal and diagonal or vertical tearing may occur in the same roof

Probable Causes of Splits in Asphalt Shingles

- It's possible that shingles made by some manufacturers do not (or previously did not) meet the ASTM Standards for tear resistance.

- Even where shingles meet the Standards, it's possible (and was asserted by some roofing experts) that the roofing standards themselves were defective.

- In any case, Fiberglass mat used for asphalt roof shingles may lack adequate tear resistance

- Self-sealing tabs on shingle backs may glue shingles together with too much strength, causing the roof covering to form a single large membrane which cannot accommodate large temperature changes

- Reduced total amount of asphalt in thin fiberglass mats might become brittle after exposure to heat and sunlight

- Temperature swings probably contribute to the onset and extent of tearing, and we'd expect worse tearing where temperature swings are more extreme such as in Northern climates.

- Nailing or placement pattern of shingles: "laddering" vs.

"staggered." On laminate and strip type shingles we have inspected roofs

on which damage is found occurring at the corners of shingles rather than in

the middle of the shingle material. It appears that as temperatures dropped

and the glued-together-roof-membrane cools and contracts, the natural point at

which movement occurs is where shingles are end-butted together.

When the pattern of end-butts is laddered rather than staggered up the roof we have found corners tearing off of shingles following the laddering pattern exactly. - LADDERING SHINGLES is not a recommended installation pattern according to NRCA and

ARMA publications nor according to instructions from some manufacturers.)

Laddering alone cannot be blamed for this failure however, as we have seen

similar shingle tearing following a staggered end-butt pattern up other roofs.

However laddering may indeed create a more localized natural point of separation on a roof, causing most of the movement to occur in a smaller area when the roof material contracts with cooling.

Organic Felt Shingles: Photos of Organic-mat-based Asphalt Roof Shingle Wear & Failures

Please see ORGANIC FELT SHINGLE DEFECTS for our full discussion of this type of asphalt shingle failure, its cause, how to recognize it, and what to do about it. [Click any image to see an enlarged version]

Shingle granule loss may be normal and indicate roof shingles that wearing out with age - normal wearing. Granule loss may be caused by foot traffic, hail storms, or other mechanical damage too.

See GRANULE LOSS from SHINGLES

Buckling roof shingles - see cupping, curling, and fishmouth wear patterns

FISHMOUTHING ASPHALT SHINGLES asphalt roof shingles. Also, given the fishmouth pattern shown above, also

see LADDERING vs STAIR STEPPING SHINGLES.

Headlap coating wear out exposed at shingle cutouts

Holes and nail-pops in Asphalt Shingles

Algae, Fungus, Staining in Asphalt Shingles

Workmanship Failures in Asphalt Roofing can result in shingle blow-offs, fall-offs (improper nailing or sealing), and of course leaks, particularly at flashing errors.

WORKMANSHIP: Installation Pattern Problems:Laddering (Photo: Carl Gerosa, New Rochelle, NY)

WORKMANSHIP: Installation Pattern Problems:Laddering (Photo: Carl Gerosa, New Rochelle, NY)

Workmanship: Flashing and underlayment problems

Workmanship: Improper materials/roof-slope problems

Asphalt Shingle Blisters

BLISTERS on ASPHALT SHINGLES climates increase in wear rate from frost. Blisters are a manufacturing defect which are sometimes mistaken for hail damage.

Asphalt Shingles Buckled

There are several different asphalt shingle roof conditions that an inspector may refer to as "buckling" or buckled shingles.

Buckled Curled Organic Mat Asphalt Shingles: roof at end of life

Above: Older organic mat asphalt shingles may be cupped, curled, buckled: signs of wear and a roof near end of life.

Details of two sorts of "buckled" roof shingle deformation, cause, evaluation and recommended actions are at

and at

Buckled Roof Deck: Loose Plywood

As these photos from professional home inspector Dov Ber Kahn illustrate, we may see a combination of sagging, buckling, and poorly-nailed plywood on the same roof.

Above: the presence of raised asphalt shingles in a straight line at right angles to the roof ridge and eaves are most-likely due to poorly-nailed plywood whose edges are lifted from a rafter or truss below. I suspect on closer inspection of (an accessible attic) for a roof in this condition you'll usually see that the edges of abutting sections of plywood have lost their nailing connection to the rafters.

But this is a 1959 home with a cathedral ceiling; there's no under-roof access to inspect the plywood. When we see plywood that's sagging or buckling in line with rafters or trusses common causes causes include

- Inadequate original nailing: nails missed the rafter or truss or wree nailed too close to plywood edge or were wrong type or size of nail

- Attic or roof cavity moisture, contributing to plywood bucklilng or possibly plywood rot - more likely with poorly-vented roofs and roofs over homes with high interior moisture such as those suffering basement water entry or a history of leaks.

This home shows a ridge vent but we can't see the soffits; there may be no intake venting at all, or as it's a cathedral ceiling, there may be inadequate venting. - Use of thin plywood, perhaps 3/8" instead of 1/2"

- Damaged plywood from prior leaks

- Plywood too tight at installation: less common on older homes: plywood butted too tightly, moisture caused plywood swelling, causing buckling at plywood seams.

Below: more buckled shingles and sagging roof decking on the same home.

It's not an emergency repair, but the bent shingles over the raised plywood edges are likely to wear faster than their neighbors and can lead to early shingle failure or a roof leak.

If the rest of the shingles are in good shape with more than 5 years of remaining life I'd be inclined to repair this damage.

1. Best repair: after confirming from below that a properly aimed nail or screw can pull down the roof deck, from above shoot some constrruction screws through the decking into the rafter below - probably angling them to catch the rafter.

If the repairman can't lift shingle tabs so that screw heads will not be exposed to weather, then additional sealant (I like silicone as most-durable) is needed; take care to seal meticulously so as not to leak.

2. More troublesome repair: remove shingles over the damaged area, repair the roof decking, install new shingles (the color won't match).

- Dov Ber Kahn, a home inspector in Rockland County, NY has contributed photographs of various building features. Mr. Kahn is a licensed home inspector in New York and New Jersey, and can be reached at Website: Kahnbhomeinspectors, Tel: 845-445-8234, Email: kdovber@googlemail.com

Sagged Roof Deck

A sagging roof deck may be due to use of thin plywood, damaged or rotted roof sheathing, sagged rafters, too much space beween rafters, or other structural defects. Properly this is sagging, not buckling, but from the ground some inspectors may report "buckled roofing" or "buckled roof shingles" even though the problem isn't the shingles themselves.

Details are at SAGGING ROOF REPAIR

Asphalt Shingle Splice Damage / Defects

SPLICE DEFECTS on ASPHALT SHINGLES show up where manufacturing line splices are used to keep material moving during the manufacturing process should be discarded but they almost always end up installed on the roof.

Spliced asphalt shingles are a factory defect - and were not supposed to have been installed. The occurrence of spliced shingles on an asphalt shingle roof will be rare. We recommend simply replacing the damaged area with a new shingle.

Temporary repair can be made by sliding a piece of metal flashing under the damaged area.

Aesthetic or Cosmetic Roofing Issues

Some consumers have concerns with how their shingles look on the roof as much as with how long the roof will last. Roofing manufacturers offer a wide variety of products which give different "looks" and shadings. It's possible that in addition to site and installation conditions, variations in manufacturing process (granule adhesion, bleed-through) can affect how the roof looks from the ground.

We've also investigated client concerns with shadows appearing in early morning or late afternoon which show variations in the roof surface. (Some shadows which are only of cosmetic nature may be caused by slight buckling or unevenness in the roof decking and may not indicate a structural or durability concern.)

If you have particular concerns about roof appearance ask your roofer if s/he can direct you to a house where the product which interests you is already installed. Remember that site differences (orientation to sun, shade trees, height above ground, roof pitch, and probably other factors) may make shingles look a bit different on your house.

Please see BLACK STAINS on SHINGLES for our full discussion of the types and causes of stains on asphalt roof shingles.

Black Stains on Asphalt Roof Shingles

There are several common sources of roof shingle stains, each of which may have its own cause and treatment.

Bleed-Through or Extractive Bleeding Stains on Asphalt Shingles

Extractive bleeding or "bleed through" leaving black streaks running down an asphalt shingle roof is an indication of a defective roofing product.

The chemistry of the shingle is permitting black pigment from the asphalt to leach to the shingle surface and run down the roof. Typically bleed-through on asphalt shingles appears as black streaks running down shingles. You'll see black streaks of varying length.

Because of variations during the shingle manufacturing process, and possibly because of variations in site conditions (sun, shading, slope, moisture), different roof areas or slopes on the same building may display different amounts of black staining. (This term is commonly used with wood shingles.)

Remedies for bleed through staining on asphalt shingles: we wouldn't do much to a roof with this staining since we worry that power washing or chemical treatments may reduce the remaining roof life. At re-roof time I'd buy a better-grade replacement shingle.

Black Algae Staining on Asphalt Shingles

Misnamed as "mildew" or "fungus" by some writers, algae staining on asphalt shingles usually in shaded areas or on the more-shaded roof slopes- characterized by black staining fairly uniform over shingles, but appearing specifically in areas of the roof shaded by nearby trees.

Black algae stains on asphalt shingles tend to be fairly uniform over the stained area, not streaky as with bleed-through stained shingles.

Black algae staining on an asphalt shingle roof is actually dead organic debris from an alga, (possibly Gloeocapsa magma).

Remedies for black algae staining on shingles: Black stains on asphalt shingles caused by algae is avoided by some of the new roof shingle products which include chemicals to retard algal growth. Cutting back overhanging tree branches for more sun can also help reduce this problem. Zinc or copper strips tacked along the ridge will produce (in rain) metal salts which will kill algae as they wash down the roof.

Some folks recommend power washing to get reduce the staining - we would be concerned that the power washing process might damage the shingles and significantly reduce the remaining shingle life.

Debris Staining on Asphalt Shingle Roofs

Debris staining on roofs produces fairly uniform black or brown staining in areas where due to low-slope or presence of overhanging trees, organic debris collects on the roof slope. Decaying debris may encourage fungal or algal growth (cited above).

Lichens or even thick moss may also grow on such roof areas. Debris, lichens, or moss on a roof will shorten its life by holding water on the roof surface, preventing drying, and (in cold climates) adding wear and tear on the roof surface by freeze-thaw cycling.

Remedies for black or brown or gray debris staining on asphalt shingles: As cited above, cleaning off debris (gentle sweeping or washing, watch out for damaging the roof during cleaning), or cutting unnecessary overhanging tree branches may help.

Black Stains on Roof Shingles Around Chimneys

Soot from fireplace flues washing down onto the roof - characterized by staining appearing below and in line with the chimney

Similarly, soot from oil-fired heating flues washing down onto the roof, characterized by the same pattern of staining around and below the chimney; also probably an indicator of an operating problem with the heating system.

Gas Flue Safety Warning: If this same sooting appears on and around a gas-fired appliance flue, there is a very unsafe condition present and risk of fatal carbon monoxide production inside the building. Immediate action is be needed.

Roofing Warranties - Valuable or Worthless?

In certain instances specific roofing products have shown common early failure, failing in a characteristic pattern which is easily identified (such as the thermal splitting defect. Some manufacturers offer limited warranty coverage of their product.

Many roofers also guarantee their work to be free from leaks, but usually for a time period substantially shorter than the manufacturer's rated life of the roof material.

Please see ROOFING WARRANTIES for our full discussion of roofing shingle warranties, class actions and settlements, how to report shingle failures, and a shingle failure report form.

In cases which we've handled recently involving thermal splitting or tearing of fiberglass-based asphalt shingles, some manufacturers (such as GAF) offer a limited product warranty.

Following a fairly involved claims procedure requiring documentation, photographs, and a sample of damaged material the manufacturer may elect to warrant the roofing material on a pro-rated basis depending on the age of the roof and its warranted life. Sometimes the manufacturer's warranty covers only material cost, not installation cost (labor, demolition, removal of old materials) unless the roofing contractor chooses to extend such coverage.

The cost of roofing material is not the main ingredient in roofing cost. Labor and possibly disposal of old roofing material are significant costs. Out of concern for future roof life, some roofers are reluctant to install new roofing atop failed material even where additional layers of roofing are permitted by local codes.

Some homeowners are reluctant to install as new roofing the same product which failed early in the first place. Manufacturers might have changed the formulation of the product to improve durability, but they are understandably reluctant to say so, out of concern for increasing product liability.

Without assurance from the manufacturer that a product which failed early has been modified to correct the problem, we advise our clients to consider using alternative products with design and performance expectations having a better track record.

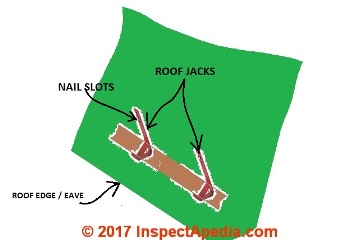

Using Roof Jacks

Question: how do you use roofing jacks?

how to use roofing jacks

Reply:

Good question, Terry,

Unfortunately I gave away my roof jacks so long ago I'm not sure I've got good photos.

Basically we used roof jacks in several courses up a roof that's too steep to walk upon safely. Typically the jack is installed after a few courses of shingles have been run at the roof lower edge.

The nails (3 10d or 12d common) are located so that they will catch a rafter edge not just the roof decking, and are spaced so that subsequent courses of shingles can be laid over the nailed-down jack nailing strap. Nails are driven with the nail head just lightly flush with the roof jack strap, not so tight that you can't later tap the jack up to remove it.

Planks are laid across the jacks as the next working level up the roof, and when we near the end of our reach we nail on another course of jacks and set more planks.

After the ridge and all shingles are in place, as we work our way back off the roof we take down the highest course of planks.

Then, as you can confirm by looking at the nail openings on the nailing heads of your roof jacks, you can simply tap the jack on its down-roof end to slide it up and off of the nails.

The nails are left in the roof but driven flush with the surface below so that we don't leave a nail head to wear through the shingle.

You can buy the least-costly fixed-angle 60 degree roof jacks or you can find ones like mine that have a stop and an adjustable angle, making them more versatile across various roof pitches.

Roofing Manufacturer Contact Information

Image above: H.M. Reynolds Shingle Co., showing green colored asphalt shingle roof in a 1910 catalog, retrieved 2021/08/05, original source: https://archive.org/details/HMReynoldsShingleCo

H.M. Reynolds was established in Grand Rapids, Michigan, U.S., in 1868. The image below shows that the company's shingles were approved by the Board of Fire Underwriters (for fire resistance), and were available in red, green, and blue-black.

Remarkably the little advertising flyer shown above includes a note that this H.M. Reyolds paper and asphalt-shingle-sample brouchure could be folded together and blown-throug to play a tune or to make a noise like a parrot or rooster! The flyer's patent gives it an earliest-possible date of April 1909.

More about H.M. Reynolds and the early history of asphalt shingles is

at ROOFING MATERIALS, AGE, TYPES

Please see ROOFING WARRANTIES for our full discussion of roofing shingle warranties, class actions and settlements, how to report shingle failures, and a shingle failure report form.

- Atlas Roofing, 802 Highway 19 N, Ste. 190, Meridian MS 39307 601-484-8900

- Bird Inc., (obs. address: 1077 Pleasant St., Norwood MA 02062

617-5551-0656) is - an affiliate of CertainTeed Corporation - so try contacting

CertainTeed: P.O. Box 860, 750 East Swedesford Road, Valley Forge, PA 19482 USA Phone: (610) 341-7000 Fax: (610) 341-7113 E-mail: corporate@certainteed.com - Brookline School District v. Bird, Inc. - web: http://www.state.nh.us/courts/supreme/opinions/9710/brooklin.htm

- BPCO, 9510 St. Patrick, LaSalle, P! H*R 1R9 Canada 514-364-0161

- Celotex Corp., 4010 Boy Scout Blvd., Tampa FL 33607-5750 813-873-1700

- Certainteed, 750 E. Swedesford Rd., BOx 860, Valley Forge PA 19482 610-341-7000

- Elk Corp., 14643 Dallas Pkwy, Ste 1000, Dallas TX 75240-8871 214-851-0400

- GAF, 1361 Alps Rd., Wayne NJ 07470 201-628-3000 - Technical Services & Guarantee Status Office 1-800-ROOF-411 Web: http://www.GAF.com

GAF class action settlement - call 800-414-4370 for more information or see the GAF Class Action Lawsuit Settlement Website: http://www.gaf.com/settlement/ - Globe Building Mtls, 2230 Indianapolis Blvd, Whiting IN 46394 219-473-4500

- IKO Chicago, Inc., 6600 South Central Ave., Bedford Pk, IL 60638 708-496-2800

- Malarkey Roofing, 3131 N. Columbia Blvd., Portland OR 97217 503-283-1191

- Owens-Corning Fiberglas, Fiberglass Tower, Toledo OH 43659 419-248-8000

- PABCO Roofing, 1715 Thorne Rd., Tacoma WA 98241 206-272-0374

- TAMKO Roofing, 220 W. Fourth St., Joplin MO 64802 417-624-6644

- Intec/Permaglas, POB 2845, Port Arthur TX 77643 404-724-7024

NOTE: Some manufacturers may consolidate with others or may have ceased operation.

Storm Damage to Asphalt Roofs

See Storm damage from wind -

For distinguishing hail damage from other roof wear or defective asphalt shingle product or asphalt shingle installation errors

see HAIL DAMAGED SHINGLES & OTHER ROOF COVERINGS

Where to Report a Failing Asphalt Shingle Roof

Please see ROOFING WARRANTIES for our full discussion of roofing shingle warranties, class actions and settlements, how to report shingle failures, and a shingle failure report form.

If you have a roof failure that appears to be due to a defective product, first try:

- Contact the installing roofer for assistance - s/he may be able to assist with a claim and certainly should want to know if you're having a problem with the roof.

- Contact the building supply company who provided your shingles - they may be able to assist with a claim.

- Contact the roofing manufacturer directly

- For large claims you may need assistance from an independent roofing consultant who can prepare failed-shingle samples, provide photographic and written documentation, and assist you with your claim.

- Roofing material test laboratories can also provide assistance in evaluating damaged roof material but usually this service is too costly

for a small residential claim.

Beware: there are some excellent independent roofing material test laboratories but if you find a company whose primary customer is the roofing manufacturer they may have a conflict of interest when testing for a supplier, installer, or private building owner.

Roof failure basic field report information for Research Purposes

For research purposes we would also like to receive your reports & photographs of roofing product failures as we are actively researching roof failures, repair alternatives, and warranty claims procedures.

Please see ROOFING WARRANTIES for our full discussion of roofing shingle warranties, class actions and settlements, how to report shingle failures, and a shingle failure report form.

- Roof type: e.g. asphalt shingle, fiberglass-based or asphalt shingle, organic-mat based

- Age of roof: date installed, or approximate age if known, or indicate unknown

- Roof Ventilation: none, ridge, soffit, gable-end, roof vents, power vents, blocked/unblocked at eaves or ridge, unknown.

- Shingle color, weight, rated or claimed life expectancy if known.

- City and State where building is located

- Contact information: Name, telephone, Email. Note: contact information is optional. Our privacy policy: 100% private. Your personal information is released to no one. Period.

- Describe conditions under which the roof failed, when the failure was first observed, and what related building damage occurred. Photos are helpful.

- Describe the results you obtained when contacting your roofer for assistance.

- Describe the results you obtained when contacting the roofing product manufacturer or local supplier for assistance.

...

Continue reading at ASPHALT SHINGLE FAILURE TYPES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ASPHALT ROOF SHINGLE FAQs - questions about asphalt shingles posted originally on this page.

Or see these

Recommended Articles

- ASPHALT-ASBESTOS FELT

- ASPHALT ROOF SHINGLES - home

- ASPHALT ROOF MATERIAL ASBESTOS

- ASPHALT ROOF SHINGLES on WALLS

- ASPHALT SHINGLE CELLOPHANE STRIP REMOVAL

- ASPHALT SHINGLE CELLOPANE STRIP POSITION

- ASPHALT SHINGLE CELLOPHANE STRIP ENGINEERS' VIEW

- ASPHALT SHINGLE STARTER STRIPS

- ASPHALT SHINGLE DEFINITIONS

- ASPHALT SHINGLE FAILURE TYPES

- ASPHALT SHINGLE INSTALLATION

- ASPHALT SHINGLE LIFE / WEAR FACTORS

- ASPHALT SHINGLES on LOW SLOPE ROOFS

- ASPHALT SHINGLE NAIL TYPES

- ASPHALT SHINGLE PROPERTIES

- ASPHALT SHINGLE RE-ROOF GUIDE

- ASPHALT SHINGLE REMOVAL TOOLS

- ASPHALT SHINGLE STAPLE vs NAIL

- ASPHALT SHINGLE TEMPERATURES

- ASPHALT SHINGLE UNDERLAYMENT SPECS

- ASPHALT SHINGLE VALLEY FLASHING

- ASPHALT SHINGLES on VERY STEEP ROOFS

- EARLY ROOF FAILURE DIAGNOSTIC QUESTIONS

- LADDERING vs STAIR STEPPING SHINGLES

- LIFE / WEAR FACTORS in SHINGLE

- RIDGE & HIP CAP SHINGLES

- SHINGLE EXPOSURE AMOUNT

- TEST LABS - ROOF SHINGLE

- BEST ROOFING PRACTICES

- ROLL ROOFING, ASPHALT & SBS

- ROOFING MATERIALS, AGE, TYPES - includes history about aspalt roof shingles

- STAIN DIAGNOSIS on ROOFS

- WARRANTIES for ROOF SHINGLES

Suggested citation for this web page

ASPHALT ROOF SHINGLES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Architectural elements: the technological revolution: Galvanized iron roof plates and corrugated sheets; cast iron facades, columns, door and window caps, ... (American historical catalog collection), Diana S Waite, available used out of Amazon.

- Asphalt Roofing Residential Manual from ARMA the Asphalt Roofing Manufacturers Association Website https://www.asphaltroofing.org/product/residential-asphalt-roofing-manual/ ,

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- Patio Roofs, how to build, Sunset Books

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Roofing The Right Way, Steven Bolt, McGraw-Hill Professional; 3rd Ed (1996), ISBN-10: 0070066507, ISBN-13: 978-0070066502

- Smart Guide: Roofing: Step-by-Step Projects, Creative Homeowner (Ed), 2004, ISBN-10: 1580111491, ISBN-13: 978-1580111492

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.