EPDM Rubber Roof Seam Repair Methods

EPDM Rubber Roof Seam Repair Methods

How to use EPDM Seam Tape & Other Methods at Seams

- POST a QUESTION or COMMENT about EPDM roof installation and repair procedures

Leaky EPDM rubber roof seam repair procedures.

How to use seam tape or strips of EPDM to repair leaky seams in a rubber roof.

This article series describes an EPDM roof installation study & roof repair history spanning fourteen years, from original rubber roof installation (and the mistakes & shortcuts that led to leaks and trouble) to an extensive tear-off and re-roof repair that was made along the entire problem roof's lower edge.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Fix a Rubber Roof Leak using EPDM Rubber Roof Seam Tape

This rubber roof on a New York home was installed in 2011. Most of the work has proven durable but five years after initial work a couple of roof seams had failed, particularly where the new EPDM roof had been seamed against older EPDM sections by gluing down the EPDM to the paper surface of older insulating roof panels below.

This rubber roof on a New York home was installed in 2011. Most of the work has proven durable but five years after initial work a couple of roof seams had failed, particularly where the new EPDM roof had been seamed against older EPDM sections by gluing down the EPDM to the paper surface of older insulating roof panels below.

Photo: we've peeled open the seam in an EPDM rubber roof after finding signs of leaks in the ceiling below.

You can see, stuck to the under-side of the peeled-up EPDM, the wet paper coating that formed the skin of the insulating panels under the EPDM.

That paper contamination on the new EPDM under-side means that simply gluing down this seam again wont' be a reliable repair.

Instead it's necessary to clean and seal the seam using a surface-applied strip of repair material.

[Click to enlarge any image]

Three Approaches to Seam Repair on an EPDM Roof

At an area of open or leaky seam or a cut split or damaged area on a rubber roof, when the damage is sufficiently limited in scope that a surface repair is all that's needed, you can either

- clean and prime the rubber surface and glue down a new strip of EPDM rubber roof material itself (method 1 shown below)

OR

- you can clean and prime the surface and apply a pre-gummed peel-and-stick EPDM Repair Tape (method 2 below)

- At the end of this discussion we describe EPDM seam "repair" method #3 - just peel back and glue down old EPDM over the new EPDM, and we explain why that approach does not work well if insulating board kraft facing has stuck to the under-side of the old EPDM..

Watch out: While these and other small roof repair jobs are within the ability of many home owners, there are the dangers of injury or fall from the roof surface, and for a larger EPDM installation or repair job we do not recommend that a homeowner attempt the work.

If you are not expert and experienced in EPDM installation you won't know what you don't know: you'll make mistakes and have a leaky roof with a short life. The ultimate costs of a DIY rubber roof job may be much greater than if you'd hired an EPDM roofing company in the first place.

Method 1: Repair a Leaky EPDM Roof Seam with a new Strip of Rubber Roofing

- Sweep off all roof debris

Watch out: Before applying any EPDM or rubber roof repair to a leaky roof seam, check that you'll have several days of dry weather, then take care to prop open the EPDM seam so that the area can dry thoroughly before you seal it up.

Else you'll have moisture bubbles in your roof and you may develop a mold problem in the ceiling below. [Photo above]

- Cut the repair strip of EPDM needed, starting with a fresh, new clean section of rubber roofing.

- Clean & Prime: As is usually necessary use a roof cleaning product to completely clean the rubber surfaces.

Clean and prime both the roof surface where the patch will be applied and also the under-side of the EPDM strip that you've cut to make the repair.

Watch out: if you leave dirt, debris, algae on the rubber surface your repair will fail quickly. Some roof cleaner primer products are simply sprayed-on, allowed to sit, then hosed off with clean water, followed of course by allowing the roof surface to dry.

Other EPDM cleaners use solvents and must be handled with care, but may be faster and more-reliable. - Apply Adhesive: Mask off the seam area to the width of your rubber patch strip so that your adhesive spray won't gum up the rest of the roof surface.

For small jobs a can of spray EPDM adhesive is fine but over-spray is a mess.

- Allow the adhesive to dry to a tacky surface. In our photo above I've sprayed adhesive on the roof surface and on the pre-cut strip of EPDM rubber.

That white tape in the center of the repair area is a seam repair or flashing tape previously applied to cover the open EPDM seam that was leaking. - Apply the EPDM patch: Starting at one end and with a helper to keep your repair strip straight, apply the repair strip, adhesive down, to the repair area, rolling it down to avoid air bubbles

- Roll the EPDM: Finish rolling down the repair strip flat in place

- Seal the repair strip edges with EPDM lap sealant.

Watch out: OPINION and direct experience: some roofing suppliers like the very un-friendly people at Jim Waters Home Corporation in Poughkeepsie, New York simply will refuse to sell small quantities of EPDM repair materials to you if they think you are a homeowner or a small contractor.

That supplier probably feels they need to protect the "territory" of their major customers. It's an unpleasant experience. I would buy roof repair materials elsewhere. Fortunately all of these roof repair materials for small repair jobs are widely available as we document below. - Weights? I put a brick weight over any problem areas that are not perfectly flat or are slightly bubbled, allowing the patch to cure and bond flat.

Method 2: Repair a Leaky EPDM Roof with EPDM Rubber Roof Seam & Repair Tape

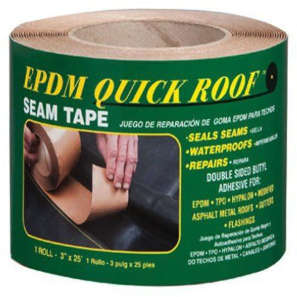

EPDM or rubber roof seam tape, available in white and black, and in several widths (typically 3", 4" or 6"), is used at roof edges, over edge flashing, and to provide an extra seal or a repair seal over roofing membrane seams, splits, or damaged spots.

EPDM or rubber roof seam tape, available in white and black, and in several widths (typically 3", 4" or 6"), is used at roof edges, over edge flashing, and to provide an extra seal or a repair seal over roofing membrane seams, splits, or damaged spots.

To install EPDM seam tape follow the specific instructions provided by the manufacturer of your product.

Watch out: when buying seam tape to check price, suitability for your roof surface type, and the tape width. I prefer wider 4" or greater tape widths for repairs as a more reliable seal over seams and splits or tears in the roof surface.

Don't think you can just buy seam tape and slap it on - that repair won't be reliable. You need to clean the roof surface, and in some cases apply a primer before applying the seam tape.

Here are example seam tape installation instructions from LionGUARD cited in detail below.

Product is a peel and stick cured cover tape. Used for covering metal termination bars, drip edge, and /or all purpose bar in seam applications etc. Cover Tape is not for use in flashing applications.

- Always clean and prime membrane using roofing industry standard products for tape applications.

- Allow primer to dry before installing tapes.

- Apply in primed area by peeling release paper off of 6-12 inches of tape.

- Stick the tape onto the membrane, while continuing to pull release paper off.

- Make sure you start on a straight line.

- Continue pulling release paper off as you move down the pre-primed area.

- Use sharp scissors for cutting the cover tape.

- Use metal seam roller with some force perpendicular to tape for proper adhesion. - LionGuard 2019

Sources of EPDM Seam Tape for Rubber Roof Repair

- CoFair Products Inc., "Quick Roof" EPDM Roof Seam Tape, black, EPDM, 3-in x 25 ft rolls (under $25. U.S.) sold online and at TrueValue hardware stores

- EPDM Seam Tape, Automotive Authority info@AutomotiveAuthorityLLC.com www.automotiveauthorityllc.com - we have used this supplier's EPDM seam tape for an EPDM / rubber roof repair

- Eternabond Roof Repair tape - from roofing material suppliers, building suppliers, and online at Grainger Industries.

Designed specifically for granulated roof surfaces and surfaces requiring a deeper seal, this tape can be used on "all types of roofs" including roofs, surfaces, gutters, skylights, flashings, copings, tubing - includes extra sealant. Check prices: on sale online at a "web price" of about $140. USD for a 6" x 25 ft. 65 mil roll in black or white. - GacoFlex Roof Tape, Self-Adhesive seam tape, 2" x 50', sold at building and roofing supply stores such as Lowes, under $20. U.S. This is a "fleece-backed" self-adhesive tape consisting of butyls and EPDM

Website excerpt:

RoofTape is a fleece-backed self-adhesive tape consisting of butyls and EPDM rubber; intended for sealing seams, fasteners, edge transitions, small cracks, vents and drains before application of GacoRoof 100% Silicone Roof Coating. - LionGuard Black EPDM Coverstrip seam cover tape, 5" - 12" in width, in rolls of 50' or 100', black or white-faced EPDM 0.30" (thickness) using black butyl adhesive also 0.30", rolled with a silicone-coated release paper, available from various vendors including Best Materials, website: www.bestmaterials.com, Email: sales@bestmaterials.com, Tel: 1-800-474-7570 or 602-272-8128 $3.25 per foot

LionGUARD COVER TAPE INSTALLATION INSTRUCTIONS [PDF] - RoofKit Rubber Roofing Seam Tape is a butyl tape used to splice two layers of RoofKit rubber roofing membrane into a watertight seam. - sold at Menards Building supply stores. $40. for 3" x 50' roll, or under $90. for a 5" x 50' roll.

Method 3: Just Apply EPDM Lap Seal or Surface-Applied Patch Coating to a Leaky EPDM Seam

In 2012 we removed an improper gravel-stop drip edge along the lower edge of a rubber roof, and we installed a new length of EPDM with proper (flat) drip edge at this home in Poughkeepsie, New York.

With Eric Galow we under-took this repair in the first place because the original roofer (not Eric) had used the wrong form of drip edge. The result of the originally-installed raised lip gravel stop drip edge was constant ponding inviting leaks in the roof membrane.

But because the gravel stop drip edge was well-bonded to the first course of EPDM roofing our repair crew decided to pull off the entire first course of EPDM, then install new proper (flat-roof) drip edge without a gravel lip and a new lower-course run of rubber roofing.

[Click to enlarge any image]

The bottom edge of the upper run of EPDM was peeled back, the old lower run of EPDM roof was removed, new EPDM was glued down, and the roughly 5" lap of the old EPDM atop the new EPDM was glued down and also treated with lap sealant.

Within a year portions of that seam had failed and water was backing up under the old EPDM. We decided to repair this leak before water got into the ceiling below.

Watch out: there are two durable ways to repair this old-to-new EPDM rubber roof: using a glued-down strip of rubber roofing or using a self-adhesive EPDM roof repair tape.

Those are discussed above. We do not recommend the method described here - I include it as a a diagnostic example of why the original seam failed.

A closer look at the photo below shows why this roof seam failed.

The upper run of EPDM, parallel to the roof eaves, had been peeled back to allow installation of a new run of EPDM below, along the roof edge.

But peeling back the old roofing left insulating-board paper facing stuck to the under-side of the older roof rubber that was to be then glued-down atop the new rubber.

Wherever paper remained the adhesive did not make a durable seam. This roof seam, glued down in 2012, had failed by 2013.

Just applying a blob of sealant over top of an open and leaky rubber roof seam, exposed to weather and varying temperatures, may make a temporary fix but ...

Watch out: this method is widely advertised but in my experience rarely provides a durable rubber roof leak repair.

I don't recommend this method of roof repair.

...

Continue reading at EPDM ROOF LEAK REPAIRS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Low Slope & Flat Roof Repair Articles

- BUILT UP ROOFS

- CONCRETE ROOFING

- DEFECTS LIST - ROOF LOW SLOPE

- EPDM, RUBBER, PVC ROOFING

- EPDM ROOF COATING REPAIRS

- EPDM ROOF LEAK REPAIRS

- EPDM ROOF SEAM REPAIR TAPE

- FLAT ROOF DRAINAGE SYSTEMS

- FLAT ROOF LEAK REPAIR

- FLAT ROOF MOISTURE & CONDENSATION

- LOW SLOPE ROOFING

- LOW SLOPE ROOF CONVERSION

- MEMBRANE & SINGLE PLY ROOFS

- MODIFIED BITUMEN ROOFING

- MODIFIED BITUMEN ROOF DEFECTS & ROOF LIFE

- ROLL ROOFING, ASPHALT & SBS

- ROOF LEAK SOURCE DIAGNOSIS

Suggested citation for this web page

EPDM ROOF SEAM REPAIR TAPE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- "Choosing Roofing," Jefferson Kolle, January 1995, No. 92, Fine Homebuilding, Taunton Press, 63 S. Main St., PO Box 5506, Newton CT 06470 - 800-888-8286 - see http://www.taunton.com/FineHomebuilding/ for the magazine's website and for subscription information.

- Low Slope Roofing, Manual of, 4th Ed., C.W. Griffin, Richard Fricklas,

McGraw-Hill Professional; 4 edition, 2006, ISBN-10: 007145828X, ISBN-13: 978-0071458283

- Roof failure causes in depth (and specific methods for avoiding them)

- Roof design fundamentals and flourishes, based on voluminous industry research and experience

- New technologies and materials -- using them safely and correctly

- Comprehensive coverage of all major roofing systems pecifications, inspection, and maintenance tools for roofing wor

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for this article. All rights and contents are ©Journal of Light Construction and may not be reproduced in any form.

- Asphalt Roofing Residential Manual from ARMA the Asphalt Roofing Manufacturers Association Website https://www.asphaltroofing.org/product/residential-asphalt-roofing-manual/ ,

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Problems in Roofing Design, B. Harrison McCampbell, Butterworth Heineman, 1991 ISBN 0-7506-9162-X (available used)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.