Built-Up Roofing

Built-Up Roofing

Types, Product Sources, Installation, Defects, Repairs

- POST a QUESTION or COMMENT about built up roofs

Flat and built-up roofs:

This article describes flat and low-slope built-up roofing or BUR roofing materials, choices, installations, inspection, defects, built-up roofing repairs, and BUR product sources.

Our page top photo shows a worn-out multi-ply BUR roof. We were measuring the width between roofing seams to determine the number of plies that was probably installed.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Built-Up Flat & Low-Slope BUR Roofing Materials, Choices, Costs, Life Expectancy, Characteristics

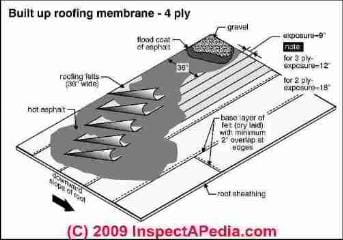

Built-Up roofs or BUR or "tar and gravel" roofs (if tar and gravel top coat were applied) are constructed traditionally using multiple layers of heavy-weight roofing felt (roof plies) cemented together by hot mopped asphalt. Cold applied asphalt methods are also used for some BUR roofs. Carson Dunlop's sketch illustrates a 4-ply built-up roof installation.

[Click to enlarge any image]

Built up roofing is usually used on flat or low-slope roofs (less than 3" rise in 12" of run). We have found an occasional BUR on steeper slopes, including a tar and gravel steep slope roof whose gravel kept washing down into the building's gutter.

The Asphalt Roofing Manufacturers' Association (ARMA) describes BUR as follows:

Built-up Roofing (or BUR) is the most popular choice of roofing used on commercial, industrial and institutional buildings. BUR is used on flat or low-sloped roofs and consists of multiple layers of bitumen and ply sheets. Components of a BUR system include the roof deck, a vapor retarder, insulation, membrane and surfacing material. The components are assembled at the job site to actually form the built-up roof. At the heart of this roofing system is the roofing membrane, which consists of roofing bitumen and multiple reinforcing plies of roofing felt.

Roofing bitumen is the primary adhesion/waterproofing agent used between roofing plies. Bitumen arrives at the job site in solid form, but is heated and applied as a liquid. Roofing bitumens may be either a product of petroleum refining (asphalts) or a product of the coal-cooking process (coal tar pitch).

Multiple reinforcing “plies” are asphalt-coated roofing sheets or felts installed in three or more layers to strengthen and stabilize the BUR membrane. These multiple reinforcing felts also make the membrane more pliable and resilient, protect the bitumen from water degradation, and serve as a fire-retarding element in the membrane system.

BUR roofing membranes can be protected from solar radiation by embedding gravel in the bitumen, applying a surface coating or applying a granular-surfaced “cap” sheet. Light-colored surfacing materials can be used to reflect heat from the building. In addition, surfacing agents can provide additional fire protection.

Shown below, a low-slope roof in Oxford in the U.K. This roof has a thick poured-on coating that has cracked badly.

The close-up photo of the same roof shown below shows some patching. BUR roofs rely on multiple plies of felt or equivalent material to give the roof membrane tensile strength.

Just pouring on more asphalt won't do the job - it is not true that the bigger the blob the better the job.

Given the regularity and spacing of the cracks in the roof above I suspect that someone has poured a stunningly-thick coating of a bituminous roof compound onto this surface, filling it up to cover the raised seams of a metal roof below. Just speculatin'.

As reported in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , chapter on BEST ROOFING PRACTICES:

Built-up roofing (BUR) systems dominated the commercial and residential low-slope roofing markets until the 1980s, when single-ply membranes became widely accepted. BUR roofs consist of layers of asphalt-impregnated felt bonded with hot asphalt, or in some parts of the country, hot coal tar.

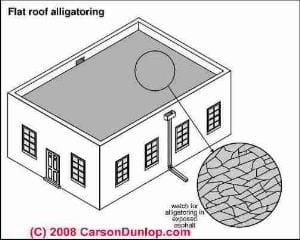

The average life span of a hot-mopped BUR roof is 15 to 20 years, although this can be extended by applying an aluminum coating every three to five years to reduce UV degradation and alligatoring.

BUR roofs can have either a smooth coated surface or a stone surface created by spreading crushed stone or gravel into a thick flood coat of hot asphalt or tar.

Aggregate-faced roofs are typically more durable due to the heavier flood coat and the protection offered by the stone from UV radiation, hail, and other environmental wear and tear. However, the stone coating makes leaks harder to find and repair.

Proper detailing of metal flashings at openings, parapet walls, and roof edges for BUR roofs is critical, and these areas need regular inspection and maintenance. The most likely place for leaks is flashings, particularly metal edge flashings due to their thermal movement. Asphaltic or rubber flashings may also become brittle and crack.

Pros and Cons of Built-Up Roofs

BUR roofs are reliable if properly installed, and their multiple layers provide some protection against small installation errors.

However, the long set-up time makes BUR expensive for small residential jobs. Also the heavy equipment, odors, and potential spills associated with a hot-mop job are not welcome on many residential job sites.

-- Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Examples of Flat & Low Slope Roof Defects

Our photo shows our client inspecting built-up roofing installed on a low-sloped roof with surrounding parapet walls. The roof was worn, badly cracked, having been "repaired" with multiple coatings of tar - it needed to be replaced.

Thanks to Carson Dunlop for providing the sketches (below) of these common low slope or flat roof defects.

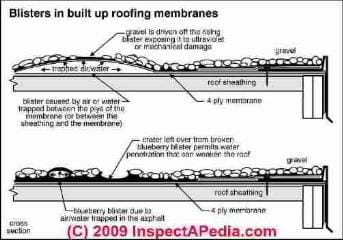

We illustrate blisters in built-up roofing membranes (these can occur in modified bitumen roofs and EPDM roofs too), alligatoring or cracking (sketch and photo just below) on flat roofs, particularly where tarred surfaces or un-coated modified bitumen roof surfaces are exposed without gravel or mineral granule protection.

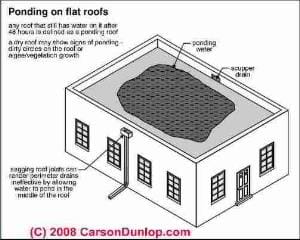

Ponding, a problem on flat roofs likely to lead to leaks, is illustrated just below.

Any roof needs to drain properly to survive.

The flooded BUR (photo, above right) in New York is likely to leak soon as it does not drain, leaving ponding over much of the roof surface for days after rainfall. Especially in a freeze-thaw climate, even the smallest imperfection in a flat or low-slope roofing seam will become a leak on roofs that flood.

Carson Dunlop's sketch of blisters in built up roofing membranes, left, illustrates a problem than can occur in other membrane roof types as well, including MODIFIED BITUMEN ROOFING and EPDM or rubber membrane roofs MEMBRANE & SINGLE PLY ROOFS.

Life Expectancy of Built-Up Roofs

A "rule of thumb" used by some roofers is to estimate that the typical life expectancy of a built-up roof will be 5 x the number of plies installed. It is not uncommon for a well-installed built-up roof covered with tar and gravel (for protection from sunlight) and properly drained to last for 40 years.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2018-04-23 - by (mod) -

Anon

IMO at least annually since in addition to wanting to spot opening seams, mechanical damage, etc. you want to inspect the roof drainage system for blockage.

On 2018-04-23 by Anonymous

How often should I inspect a BUR

On 2017-05-03 - by (mod) -

Todd,

Please see this article on roof drain clogs and repairs

https://inspectapedia.com/roof/Flat_Roof_Drainage_Repairs.php

On 2017-05-03 by Todd

Fix drain on build up roofs

On 2016-08-03 by Jillian Page

The easiest way to mix tar& rocks for your roof

On 2014-11-10 - by (mod) -

Anon:

Snow or hail or ice formed on a roof might indeed block roof drainage, causing ponding and water accumulation that can cause related building problems, leaks, even a roof collapse.

On 2014-11-10 by Anonymous

Can hail cause ponding to occur if there is enough of it to stand on roof system

On 2014-10-20 - by (mod) -

Interesting and not unusual problem, Ken. You could prepare an example report: take a small area or a representative roof, inspect it, photo-document the conditions, record the roof repair history, record the history of water damage or other secondary leak effects on the building over the roof's life, calculate the cost of maintenance

+ damage repairs over a representative period, project those costs forward (probably increasing) and compare that with the projected cost of a new roof

+ anticipated maintenance of that roof over the same projected forward period.

Multiply the cost savings of a new roof, amortized over its life, by the total sqft of roofing to get a plausible project cost and savings.

Use the "most-conservative" estimates of benefits at every opportunity to obtain a most-confident conclusion.

Keep me posted.

On 2014-10-19 by Ken

The roofs in question are in Southwest Michigan.

On 2014-10-19 by Anonymous

I have a client with over 1.5 million sf of BUR, almost all tar and gravel. The roofs average 40+ years and have constant leaks from deteriorated flashings and occasional blisters. These roofs have hundreds of penetrations from duct, pipe, conduit and a variety of flashing treatment from coved to pitch pockets, some of the newer penetrations are poorly installed and a continual problem.

I am attempting to get them to do a roof survey to prove to them that most of the roofs are beyond their useful life.

They are balking at the cost of a roof survey and would rather pay for constant repairs...good for me but short sighted? Any suggestions?

On 2014-10-06 by Hunter A

How old is the roof? Hail won't usually damage a built up roof, especially one with gravel. If it is a newer roof, it is likely shedding gravel from the initial pour or the roofer might have over poured it. The only possible damage hail could have done to a roof like that is to impact it so hard that it drives gravel into the roof damaging it and that is highly unlikely even with tennis ball size hail.

The main thing you have to worry about with flat roofs are leaks. Check it after it rains and look for anyplace water is pooling. If you see pooling, get it checked out and fixed before it seems in and rots anything.

On 2014-04-09 by (mod) - hail damage to gravel roof

I could imagine that heavy hail might loosen gravel on a roof, but most of the gravel on a tar and gravel roof is loose to start-with; only the bottom -most granules might adhere to the hot tar.

If you had an inspection report of roof condition from an independent expert, or even photos of roof condition before the hail storm that'd be helpful in discussing the matter with your insurance company.

On 2014-04-09 by DEBBIE

I have a gravel and tar roof and in april, 2012 we had a hail storm with about tennis ball size hail. At the time the insurance adjusters didn't find any damgage to my roof. But since the storm, my gravel has been washing away, especially when we have torrential downpours. I use to have a little gravel in my gutters, but now, I have three inches!

Could the hail have broken loose the gravel. My adjuster now is not familiar with the gravel and tar and I need help! My roof is about 25 years old and was in great conditon before the hail storm. I appreciate your assistance!

...

Continue reading at LOW SLOPE ROOFING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Key Articles About Low Slope & Flat Roofs

- BUILT UP ROOFS

- CONCRETE ROOFING

- DEFECTS LIST - ROOF LOW SLOPE

- EPDM, RUBBER, PVC ROOFING

- EPDM ROOF COATING REPAIRS

- EPDM ROOF LEAK REPAIRS

- EPDM ROOF SEAM REPAIR TAPE

- FLAT ROOF DRAINAGE SYSTEMS

- FLAT ROOF LEAK REPAIR

- FLAT ROOF MOISTURE & CONDENSATION

- LOW SLOPE ROOFING

- LOW SLOPE ROOF CONVERSION

- MEMBRANE & SINGLE PLY ROOFS

- MODIFIED BITUMEN ROOFING

- MODIFIED BITUMEN ROOF DEFECTS & ROOF LIFE

- ROLL ROOFING, ASPHALT & SBS

- ROOF LEAK SOURCE DIAGNOSIS

- ROOF SEALANTS & MASTICS

- WALKABLE ROOF SURFACES

Suggested citation for this web page

BUILT UP ROOFS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.