Heating Oil Piping Vacuum & Pressure Tests

Heating Oil Piping Vacuum & Pressure Tests

- POST a QUESTION or COMMENT about how to install & use vacuum & pressure gauges on heating oil piping systems

Oil line vacuum gauge & pressure gauge installation & testing:

this article explains the installation & use of heating oil piping vacuum gauges & pressure gauges to diagnose, test, & repair clogged or leaky fuel oil piping lines or filters.

How to install & use test gauges on oil piping. Where should the vacuum gauge be installed, how is it used, and what vacuum readings mean on the oil line. Where is a pressure gauge installed on oil piping and what are typical pressure or vacuum gauge readings on oil piping?

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

VacuumTesting Oil Lines Detects Both Blockage & Leaks: Vacuum Standards for Oil Supply Piping

Reader Question: Is it normal practice to pressure test fuel lines when a new boiler has been fitted?

Reader Question: Is it normal practice to pressure test fuel lines when a new boiler has been fitted?

Is it normal practice to pressure test fuel lines when a new boiler has been fitted? We have an outdoor boiler that runs on a 2 pipe system as the storage tank is below the boiler.

The lines are buried as the distance between boiler & storage is 15-20 m.

We reported a vast increase in oil consumption after installation, would it be the normal course of action to then pressure test 'supply & return' lines? - Mark 5/29/12

Reply: How pressure & vacuum gauges are used on heating oil lines to check for leaks or fuel unit troubles

Mark, it is normal practice to inspect oil piping for leaks at all of its fittings & connections for leaks after a new installation, and there are indeed vacuum measurement tests (not pressure tests) that can be conducted that indicate an air leak into the oil supply line line (or oil leaks out when the fuel unit is not running).

But in my experience oil line vacuum tests are not performed as a matter of course but rather when a problem is under diagnosis, such as improper oil burner operation. And in my experience oil supply & return lines between the oil tank and the oil burner are not pressure tested. As I explain here, pressure testing those lines runs into some practical difficulties.

Similarly, a vacuum gauge installed on the heating oil supply line, often at or near the oil filter assembly, can help diagnose a leak in the supply piping itself.

Heating Oil Line Vacuum Reading Standards

Suntec gives this helpful guide to the use of a vacuum gauge and vacuum measurements on the heating oil suction line during oil burner operation - that is, while the system is running. This vacuum reading should be a routine check during heating system service, as it's diagnostic.

Table of Heating Oil Suction Line Vacuum Readings |

||

Heating Oil Piping System |

Maximum Running Vacuum Read |

Comments |

| Single stage fuel unit, one-pipe system | 6 inches of mercury (Hg) vacuum gauge | 4" is a safer design limit |

| Single stage fuel unit, two-pipe system | 12 inches (Hg) | 10" is a safer design limit |

| Two-stage fuel unit, two pipe system | 17 inches (Hg) | 15" is a safer design limit |

Notes to the table above

Sources:

Original: Heating Oil Pump Routine Maintenance, Suntec Pumps (2014)

Current: Suntec SUNTEC INSTALLATION & SERVICE MANUAL [PDF] Suntech Industries Inc., Website: www.suntecpumps.com Email: info@suntecpumps.com Tel: 800-0367-7116 retrieved 2020/02/24 original source: http://www.suntec.fr/wp-content/uploads/2018/11/Installation-and-Service-Manual.pdf

Unfortunately in a two-pipe system we don't install and cannot as easily use a similar gauge on that second line to check for leaks.

In a two-pipe oil line system, the return line is never under vacuum, only under pressure when excess oil from the fuel unit is cycling back to the oil tank. Because the exit end of that pipe is open into the oil tank, it is not and cannot be "pressure tested" without some diassembly and the fitting of a plug at the line's outlet end.

But the Suntec manual (cited above) provides vacuum test procedures for all fuel unit models and for both one-pipe and two-pipe systems by attaching the vacuum gauge to the proper port right on the fuel unit.

Oil Supply Line Vacuum versus Oil Supply Line Pressure: What's the Difference? Where are They Measured?

Oil supply piping vacuum measurements

Oil supply piping vacuum measurements are made on the oil line between the oil storage tank and the fuel unit or oil pump that supplies high pressure oil to the oil burner. Increases in the vacuum level on the oil line can indicate oil line clogging.

Typically the oil line vacuum is measured by a vacuum gauge attached downstream of the oil filter - which also gives an indication of oil filter clogging - it's time to install a new oil filter.

Our photo above shows a vacuum gauge installedon a tee between the oil filters and the oil burner. Some installations include a stop valve between the tee nipple and the guage.

Leaving the stop valve closed when not reading the gauge reduces the risk of an oil leak at the guage itself - an improvement even more important if a guage is to be kept mounted on the oil supply pipe for pressure measurements as we discuss next.

Oil supply piping pressure measurements

Oil line pressure measurements are made at the oil burner by installing a pressure gauge in series on the high pressure oil supply line between the fuel unit outlet port or burner supply port and the oil burner nozzle - yellow arrow in our photo at left.

Oil line pressure measurements are made at the oil burner by installing a pressure gauge in series on the high pressure oil supply line between the fuel unit outlet port or burner supply port and the oil burner nozzle - yellow arrow in our photo at left.

These pressure readings allow adjustment of the oil pressure supplied to the oil burner. Typical pressures range between 100 psi and 140 psi.

Many high speed oil burners currently operate at the higher pressure.

Note that because oil burner nozzle flow rates in gallons per hour (GPH) assume a supply pressure of 100 psi, when increasing the oil line pressure above the standard 100 psi it may be appropriate to change to a smaller nozzle orifice.

Oil burner nozzle companies provide a nozzle chart that helps in this selection.

See OIL BURNER FUEL UNIT for setting the fuel unit pressure in PSI.

Question: Is it normal practice to pressure test fuel lines when a new boiler has been fitted?

Is it normal practice to pressure test fuel lines when a new boiler has been fitted? We have an outdoor boiler that runs on a 2 pipe system as the storage tank is below the boiler. The lines are buried as the distance between boiler & storage is 15-20 m.

We reported a vast increase in oil consumption after installation, would it be the normal course of action to then pressure test 'supply & return' lines? - Mark 5/29/12

Reply: How pressure & vacuum gauges are used on heating oil lines to check for leaks or fuel unit troubles

Mark, it is normal practice to inspect oil piping for leaks at all of its fittings & connections for leaks after a new installation, and there are indeed vacuum measurement tests (not pressure tests) that can be conducted that indicate an air leak into the oil supply line line (or oil leaks out when the fuel unit is not running).

But in my experience oil line vacuum tests are not performed as a matter of course but rather when a problem is under diagnosis, such as improper oil burner operation. And in my experience oil supply & return lines between the oil tank and the oil burner are not pressure tested. As I explain here, pressure testing those lines runs into some practical difficulties.

Similarly, a vacuum gauge installed on the heating oil supply line, often at or near the oil filter assembly, can help diagnose a leak in the supply piping itself.

Unfortunately in a two-pipe system we don't install and cannot use a similar gauge on that second line to check for leaks.

In a two-pipe oil line system, the return line is never under vacuum, only under pressure when excess oil from the fuel unit is cycling back to the oil tank. Because the exit end of that pipe is open into the oil tank, it is not and cannot be "pressure tested" without some diassembly and the fitting of a plug at the line's outlet end.

What causes pulsating oil pressure at the oil burner?

Reader question: Since I asked for one, my oil burner has a pressure gauge mounted on the unit showing the output pressure on the system. Usually the gauge is steady at 120 psi but now I see the needle is waving all over the place. What might be wrong. - anon

Reply:

I would be a little nervous about leaving a gauge on the outlet side of a fuel unit for heating oil equipment. There is a risk of blowout of the gauge and a horrible oil leak mess. That said, look for:

- a defective oil pressure gauge (check against a known-good gauge)

- an air leak in the intake oil supply piping line

- an air leak on the fuel unit itself. For example if someone pulled the fuel unit cover to replace the strainer and failed to install a new gasket, or failed to properly tighten the cover, you could get an air leak there. [8]

Other leaks and problems besides those air leaks above can also lead to oil burner shut-down or improper oil burner nozzle cutoff problems, including:

- Leaks at the heating oil filter cover, oil piping fittings, or air bleeder screw.

- Air trapped between the oil cut-off valve (oil safety valve) and the oil burner nozzle. Usually this problem will disappear with a few oil burner on and off cycles as long as new air is not leaking into the system.

- A partly clogged strainer on the inlet end of the oil burner nozzle. If the strainer is fully clogged the system won't start at all;

- A leak at the nozzle adapter. The nozzle adapter is a brass fitting that connects the oil burner nozzle to a small diameter oil supply tube that runs inside the oil burner gun assembly.

If you are heavy handed and over-tighten a steel oil burner nozzle in the end of the nozzle adapter, or if you mess up the other end of the adapter where it threads onto the end of the oil supply tube, you may get oil spray leaks out at the fitting, causing havoc with the oil burner flame.

I know, I made this mistake badly a time or two before I (DF) learned not to over-tighten these parts during oil burner assembly. - Oil burner pump (fuel unit) internal check valve failure: dirt or debris on the internal check valve can cause the fuel unit to leak fuel into the combustion chamber at oil burner shut-down, or it can cause an internal valve to fail to open, causing immediate loss of heat.

Incidentally, Suntec also offers these additional diagnostic suggestions regarding heating oil pressures: [8]

If oil pressure at the outlet side of the fuel unit is low, check the accuracy of the pressure gauge, then check that the nozzle capacity is not greater than the capability of the fuel unit. We add: check that someone has not misadjusted the fuel unit pressure screw.

Improper oil burner nozzle cut-off diagnosis - here is a diagnostic procedure from Suntec:[8]

With a pressure reading gauge in the nozzle port of the fuel unit (that is the fuel unit's output side), watch for a minute to see what happens to oil pressure as the oil burner stops running.

- If the pressure reading drops from normal operating level (say 100 to 140 psi depending on how the fuel unit was set) down to a lower number, then stabilizes, the system is working normally and the sloppy oil burner shut down is most likely due to air in the system.

- If the pressure unit drops all the way to 0 psi, the fuel unit is defective and needs to be replaced.

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: why is my oil line clogging-up?

What is slowly blocking my oil line? Over about 3 weeks, the oil pressure at the burner creeps down from its correct value of about 2-3 psi (depending on level; the 1000 gallon outdoor tank level when full is about 8 feet above the burner and gauge) to about 2 inches mercury vacuum.

[Click to enlarge any image]

The pressure reading stays negative even when the burner is on standby. Oil comes off about 1” below the top of the oil surface by a Scully Snorkel (floating inlet), so there's no sludge or water being sucked in.

There's no visible floating scum in the tank. It happened to me a couple times last year and now again this year. I switched to a new, bigger name oil supplier this year in case I'd gotten some questionable oil last year.

I'm on the east coast near Philadelphia, and it generally only gets below freeing for short periods of time, a couple days or so, before warming up for longer.

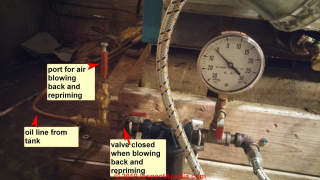

I'm pretty sure the filter isn't restricted, since I can reliably regain pressure by air blowing the line back into the tank through a tee and valve (see photo), and vacuum repriming the line, all with the filter completely blocked off from any of this action by a closed inlet valve right before the filter.

And earlier investigations showed no sludge in the filter.

The fact that the pressure stays negative even when there's no flow implies there's some kind of semisolid/gelled/sedimented/? obstruction forming upstream of the gauge and filter, which stops oil from flowing by gravity past the obstruction to the gauge.

Sort of acting like a check valve?

Something in the Scully Snorkel pickup tube?

No “no heat” situations have arisen yet, but it seems I need to keep a watch on this.

Reply:

Hill

The fact that you've been clearing a heating oil flow problem by blowing back fuel lines suggests that there is a debris or sludge clogging problem or a lift problem (or something else we've not thought-of).

Some diagnostic questions may be helpful:

- how old is the oil tank?

- has the sludge level in the oil tank been checked?

- does the clog problem appear more quickly after an oil delivery (that may stir oil storage tank sludge, debris, water)?

- Have you checked (again) BOTH the oil filter canister AND fuel unit screen for evidence of sludge and debris clogging?

- What's the diameter of the oil supply piping?

- What's the lift that the fuel unit has to achieve? Is it close to the limits of the fuel unit's ability?

- Have you considered going to a 2-line oil supply and return system?

Reader follow-up:

Hillpc12 said:, here are my answers and comments (in caps; no I'm not shouting):

The fact that you've been clearing a heating oil flow problem by blowing back fuel lines suggests that there is a debris or sludge clogging problem or a lift problem (or something else we've not thought-of).

It's not really a flow problem (yet), just a gradual loss of pressure reading on the gauge, which is just before the filter (not after; this is important). The attached photo shows the gauge reading the way it should, which it does after blowing back the line and repriming.

There's advice on this website saying that greater than 6 " mercury vacuum is an issue. Mine only drops to 2" vacuum, but it should never be at vacuum since the tank is above the unit(see below response on lift.)

How old is the oil tank?

18 years.

Has the sludge level in the oil tank been checked?

No, though I believe this should be immaterial, since the oil is pulled from 1 inch below the top surface of the oil (whefre there should be no sludge or water) by the scully snorkel. I stick the tank, even with the scully snorkel float, and never see anything unusual at the bottom of the wooden 1 x 2 stick. Samples of the oil from neart the surface are crystal clear red, as expected.

Does the clog problem appear more quickly after an oil delivery (that may stir oil storage tank sludge, debris, water)?

No. I only get one delivery a year to this 1000 gallon tank

Have you checked (again) both the oil filter canister and fuel unit screen for evidence of sludge and debris clogging?

Not recently, since the pressure comes back up immediately after blowing the line back to the tank, with the filter completely undisturbed and blocked by its inlet valve being shut. Observing the location of the pressure/vacuum gauge in the photo, relative to the filter (it's upstream of the filter, at the bottom of an 8 foot head of oil), it can't be the filter clogging, rather it has to be upstream of the gauge (the piping).

What's the diameter of the oil supply piping?

3/8" (I'm considering going to 1/2".)

What's the lift that the fuel unit has to achieve? Is it close to the limits of the fuel unit's ability?

There's zero lift, since the tank is 8 feet above the gauge and fuel unit. The only time lift would be required is to prime an empty line, which I do with a hand vacuum pump.

As soon as oil gets out the top of the tank and starts flowing downhill into the basement, that siphon should keep the line full, with positive pressure of about 1 to 3 psi at all times, depending on level in the oil tank.

Have you considered going to a 2-line oil supply and return system?

I had one but disconnected half of it when I got rid of the underground tank and installed the aboveground one 18 years ago. Aren't 2-pipe systems used where the fuel unit has to pull a lift?

Note: oil line pressure gauge is on the outlet side of the oil filter

It's obvious I've screwed up with the location of the gauge!

OK, I screwed up parts of 2 of the answers that were based on the location of the gauge. If I find out a way, I can correct them.

The gauge is AFTER the filter, so it going negative (vacuum) CAN be explained by the filter itself (or anything upstream of the filter) clogging.

I have another gauge that I can add just before the filter to nail it down better - a direct measurement of pressure loss across the filter.

The strange thing is that when I blow back the line and reprime, without touching the filter, the gauge immediately comes back to a positive pressure, and will only very slowly drop back to a vacuum (weeks).

Moderator follow-up: what can affect an oil burner fuel unit lift capacity and vacuum level readings?

First-off I am a bit confused: I am not sure why you are seeing positive pressure on your oil line pressure gauge.

Suntec and other fuel unit manufacturers provide a vacuum test port right on the fuel unit. That may be a better place to perform these checks.

Normally when the fuel unit is running I expect to see a vacuum at the inlet side of the fuel unit. I'm guessing you're saying that your oil piping system, once "primed" by that initial lift by the fuel unit to get oil out at the top of the tank is then siphoning oil "downhill" to the oil burner so that when the burner and its fuel unit are OFF you see positive pressure at the pressure/vacuum guage.

About the lift that your fuel unit has to achieve: even though you note that oil tank is higher than the oil burner, there is still some lift, as much as four feet, depending on the depth of the oil pick-up point in the oil storage tank.

A single line oil pipe system to a typical residential fuel unit can lift four feet of oil.

A typical two-line oil piping system using a typical residential single-stage fuel unit can draw up to 6" of vacuum while a two-stage fuel unit can pump up to 12" of vacuum - under perfect conditions.

Experts typically figure that a safer design limit assumes that

- a single-stage fuel unit should not be asked to lift more than 4" vacuum

- a two-stage fuel unit should not be asked to lift more than 10" vacuum

Why?

Watch out: the lift capacity of both one-line and two-line oil piping systems and their oil pumps will be affected by more factors than you might think.

Suntec lists the maximum oil piping suction line length as determined by three factors:

- total lift between the fuel unit and the oil tank

- The oil burner nozzle "capacity" or gph

- the fuel line diameter (assuming an altitutde of 200m above sea level and 0.45 bars (6.52 psi) or (13.27 inches of mercury) vacuum

Take a look at the Sunstrand techincal manual link below to see additional adjustments and details such as assumptions about the number of oil line elbows, valves, restrictions and altitude.Section Vacuum Test-Fuel Units - IV-7 in that document describes how to test a Sunstrand fuel unit and gives pass/fail criteria for the fuel unit.

For example, with the vacuum gauge connected to the vacuum port on the Sunstrand fuel unit, if the fuel unit can't pull 15" hg. or hold that vacuum level for 5 minutes then the fuel unit needs to be replaced.

More generally these factors affect the lift-capacity of an oil burner fuel unit or "oil pump":

- fuel line diameter

- fuel line length

- one line vs 2 line fuel piping system

- air leaks anywhere in the oil piping system or even right at the fuel unit itself

- oil temperature (and thus oil viscosity)

- obstructions in the oil piping system: elbows, bends, or even sludge in the oil piping system or in the fuel filter and its canister.

You probably don 't need a 2-line oil pipe system for your set-up but there's more checking to do - for air leaks, obstructions, clogs, and proper oil line vacuum gauge installation and use.

Having just gone through the detailed steps of replacing an above-ground oil storage tank that required converting from one-line to a two-line oil piping system we reviewed the advantages of a 2-line oil piping system with the onsite experts.

We all agreed that even though the total lift was just a few feet (even in your case there's some lift to get oil to the top outlet of your oil tank), the oil delivery system was more-reliable with the 2-line set-up.

Details of that set-up are

at OIL TANK REPLACEMENT PROCEDURE

Just to rule out any leaks in the oil piping system between tank and fuel unit, Beckett Corp. describes this among severalt tests of the oil line for leaks:

The Vacuum Method (Suction Line Test)

This test will be most effective when you have a shut-off valve near the oil tank.

- Install a vacuum gauge in the optional inlet port of the pump. (Single or two-pipe). Leave suction line connected.

- Close shut-off valve nearest to the oil tank.

- Start burner and allow your vacuum to stabilize.

NOTE: On either system you may need to jumper the F-F terminals after burner start-up to allow sufficient time to stabilize vacuum reading.

- Turn power to the burner off after vacuum reading has stabilized. The vacuum reading should hold steady for 5 minutes.

- If the vacuum reading does not hold and your fuel unit is leak tight, we must then assume that the leak is between our fuel unit and shut-off valve.

- Proceed with the leak detection method of your choice to locate the fitting or connection point which is at fault.

- On a system which does not have a shut-off valve near the tank, you will need to test with an alternate method. Please note Pressure, Visual and Sight Glass Methods.

- R.W. Beckett Corp., SUCCESSFULLY LOCATING SUCTION LINE LEAKS [in heating oil piping systems], [PDF] (1937 - 2020) R.W. Beckett Corporation, 38251 Center Ridge Rd., North Ridgeville, OH 44039 USA Tel:440.327.1060 retrieved 2020/02/24 original source: https://www.beckettcorp.com/support/tech-bulletins/successfully-locating-suction-line-leaks/

- Suntec SUNTEC INSTALLATION & SERVICE MANUAL [PDF] Suntech Industries Inc., Website: www.suntecpumps.com Email: info@suntecpumps.com Tel: 800-0367-7116 retrieved 2020/02/24 original source: http://www.suntec.fr/wp-content/uploads/2018/11/Installation-and-Service-Manual.pdf

- Suntec, SUNTEC TECHNICAL MANUAL [PDF] (2018) European edition: retrieved 2020/02/24 original source: http://www.suntec.fr/wp-content/uploads/2018/03/Technical-manual_GB_ed2018_web-1.pdf

...

Continue reading at OIL LINE CLOGGING FIX or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- FUEL UNIT INSTALLATION & ADJUSTMENT PROCEDURES

- HEATING OIL SLUDGE

- OIL BURNER FUEL UNIT

- OIL BURNER MANUALS Manuals for oil burner fuel units

- OIL STORAGE TANKS - home

- OIL TANK INSPECTION & TROUBLESHOOTING

- OIL TANK PIPING & PIPING DEFECTS - home

- OIL LINE AIR REMOVAL PROCEDURE

- OIL LINE BUZZ & VIBRATION CURE

- OIL SUPPLY & RETURN LINE CONTROLS & VALVES

- OIL SUPPLY LINE CHECK VALVES

- OIL LINE CLOGGING FIX

- OIL SUPPLY & RETURN LINE DE-AERATORS Tigerloop™

- OIL SUPPLY LINE PIPING LEAKS

- OIL LINE PIPING LEAK CAUSES

- OIL LINE QUICK STOP VALVES

- OIL SUPPLY LINE SAFETY VALVES, OSVs

- OIL SUPPLY LINE SAFETY VALVE TURN DIRECTION to OPEN or SHUT

- OIL LINE VACUUM & PRESSURE TESTS

- OIL SUPPLY LINE VACUUM-ACTIVATED OSVs & PRVs

Suggested citation for this web page

OIL LINE VACUUM & PRESSURE TESTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING OIL, OIL BURNERS, OIL FIRED HEATERS, OIL TANKS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.