Oil Piping Check Valves - Non Return Valves

Oil Piping Check Valves - Non Return Valves

Uses, locations, prohibitions & codes for the use of check valves in oil piping systems

- POST a QUESTION or COMMENT about the codes, regulation & use of check valves on heating oil piping systems

Oil piping check valve / non-return-valve use, installation & prohibitions: this article describes the use of check valves in heating oil piping systems. We explain where some manufacturers recommend that check valves should be installed, what the check valve is accomplishing.

We point out that other heating equipment and oil burner or fuel unit manufacturers prohibit using a check valve at all. We include citations from key industry sources & building codes on the use of oil piping check valves including Suntec & Webster.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Oil Piping Check Valves - Non Return Valves

Where & When do we Put an In Line Check ValveOn a Heating Oil Line? Ever?

Where & When do we Put an In Line Check ValveOn a Heating Oil Line? Ever?

Check valves are recommended for use with home heating oil (No 2 fuel oil) on the oil supply line (the suction line) just above the oil tank in some heating oil pumping & piping installations in order to keep oil in the pipeline and to make service of a foot valve in the oil tank a bit easier.

Check valves are also used on No. 6 fuel oil systems, but at the oil pump as drain-back problems are less troublesome with heavier grade fuel. - Pump School (2012)

Shown at left is an oil tank foot valve, a check valve used to help prevent the loss of prime in the oil suction line. This valve is installed at the end of the suction line in the heating oil tank.

[Click to enlarge any image]

The use of check valves on heating oil piping return lines has been found on some heating systems to prevent a messy oil spill from the return line and to make service of the fuel unit easier (Webster 2014). Check valves are described for this use to steer oil piping installers away from installing a fusible link type OSV on the return oil line - a possible cause of a fire disaster discussed separately

at OIL SUPPLY LINE SAFETY VALVES, OSVs.

Watch out: while some manufacturers' literature (Webster) describes where and why a check valve may be installed on a heating oil system pipeline, other equipment manufacturers (Suntec) and sources prohibit their use.

[Shown below is Beckett Corporation's oil line check valve. Click to enlarge any image.]

The worry is an oil-entrapment problem between the fuel unit and the return pipe that, combined with thermal expansion, is reported to cause return oil line leaks or leaks at the fuel unit itself. We have also read a claim that at fuel unit shut down the check valve could "blow the pump seal" - an explanation by Suntec.

If two oil lines are used to supply an oil burner, (a supply and a return) install an oil safety valve or OSV or fusible link oil line shutoff valve only on the oil supply line at the oil pump on the oil burner. Do NOT install an automatic oil line shutoff on the return oil line between the oil burner and the oil tank.

If a protection against oil back-flow at the return line is a concern, and if the manufacturer permits, use a check valve instead. Check valves like this one permit oil to flow just in one direction. They do not close down in event of a fire. Installed on the oil return line a check valve permits oil to flow from the oil pump in one direction only: back to the oil tank.

The check valve on the oil return line, like the OSV on the oil supply line, prevents oil from spilling back out of the oil piping should the service technician need to disconnect the oil piping from the fuel unit - for example during fuel unit servicing or repairs, or during service of a backup oil pump on larger and commercial systems.

Check valves suitable for placement on the oil return line are available from various oil heat equipment producers including Webster.

As Webster points out, check valves in the suction line between the oil tank and their SPM units assures that the oil line and pump are always full of oil, supporting fast oil burner starts.

[Click to enlarge any image]

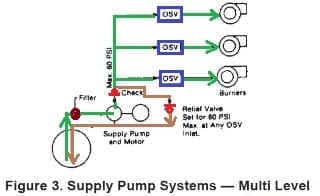

You will find this arrangement more likely on commercial and multiple-burner installations such as we illustrate in Webster's sketch, adapted and annotated at left. [7a] There the oil supply coming from the oil tank is marked in green, passing through an oil pump, a check valve (red) and on to three oil burners through three OSVs (blue).

The oil return line is marked in light brown; you will see a second check valve (red) on the return line.

Oil Line Check Valve Mistakes & Warnings

Watch out: do not install a check valve on the inlet of a 1-pipe oil system and do not install a check valve on the return line of a two pipe oil system (as we just described above) IF the oil burner or fuel unit manufacturer recommends against it. Example: R.W. Beckett, in describing the installation of their Cleancut Single Stage or 2-Stage Fuel Units (Part No. 21844 and 21941 respectively) warns:

Do not use a check valve in the inlet line of a 1-pipe system (with or w/o a boost pump), or in the return line of a 2-pipe system.

NFPA 31-25, 8.5 states that ‘A return line from a burner or pump to a supply line shall have no valves or obstructions and shall enter the top of the same tank.’ Check valve flow restriction in a return line

Check valve flow restriction in a return line can elevate pressures and damage the fuel unit seals.

Dangerous thermal expansion of oil trapped by an inlet line check valve can create extreme pressures that damage fuel unit seals, line fittings, inlet filters, gauges and other components.

A properly installed vacuum safety valve, such as Suntec PRV-38, having having accumulator effect and pressure relief to tank is acceptable in the inlet line. [See Oil Entrapment Safety Warning below - Ed.] - R.W. Beckett [2a]

When Do We Use or Not Use a Check Valve on Oil Line Piping?

One manufacturer, Webster, explains where & why to use check valves on an oil line, and oil piping texts (NYFD 2012) also refer to their use to keep an oil piping header full or to prevent siphonage, while other manufacturers, Beckett and Suntec, indicate that we don't use them (at least with a particular oil burner model, or according to citation of a poorly-worded NFPA 31-25 8.5 that is confusing itself). So do we install a check valve or not?

And weighing in, some heating equipment manufacturers say check valves are not necessary.

Each oil burner should have its own suction line. A common return line can be used as long as the diameter is large enough. Check valves are not required on properly installed systems. Service on fuel units should not be attempted without a suitable vacuum and pressure gage.

The information presented here is intended as a guide only. For piping system design data, consult the installation instructions from the pump manufacturer. - Newmac Boiler Installation Instructions [17]

Suntec Advice on Avoiding Use of Check Valves on Oil Piping

[Uses of Oil Piping] Check Valves, Other Valves & Thermal Expansion Check Valves

A properly-installed fuel oil heating system does not require check valves for proper operation. However, check valves are often used to compensate for deficiencies in oil line piping. For example:

a. Not having the return line submerged in the oil in the tank

b. Having vacuum leaks in the line due to using compression fittings, bad flare fittings, porous fittings, loose fittings or leaky lines.

See OIL TANK PIPING & PIPING DEFECTS for a table of normal running vacuum levels in heating oil piping installations.

Disadvantages [of installing check valves on oil piping]

Check valves increase the amount of vacuum the fuel unit must overcome to supply oil to the system and reduce the distance supply lines can be run.

When installed near the fuel unit, check valves cause turbulence and stripping of air from the oil, resulting in dirty and/or noisy combustion.

Do not use check valves in gravity feed (tank above pump) single-pipe systems, or in a system supplied by a boost or transfer pump. Thermal expansion can cause serious problems.

Thermal Expansion [Problems & Check Valves - aka "Oil Entrapment" Problem]

Thermal expansion is a phenomenon in which a fluid increases in volume when heated.

When fuel oil is heated from 40°F to 70°F, it will increase in volume by 1 - 1/2%. Since oil will only compress at a rate of 1/10%, thermal expansion will greatly increase the oil pressure in a closed system.

In a typical single-pipe system, an air pocket within the pump serves as a cushion against changes in pressure. In a gravity feed- or boost pump-supplied system, the air cushion is eventually absorbed, creating a hydraulically "hard" or closed system which is unable to absorb pressure increases. - "Check Valves, Other Valves, and Thermal Expansion", Suntec, Fuel Oil Pump Service Manual [8][8a][9]

Suntec continues to point out that the effects of thermal expansion are leaks at joints, fittings, pressure gauges, filters, and fuel unit seals. The thermal expansion problem is most-likely in single pipe oil systems, in dual-fuel heating systems during alternate fuel use, and where the ambient temperatures are higher than the fuel temperatures - something particularly likely when pumping heating oil from an underground oil storage tank or after a fresh fuel delivery in winter.

Really? OK so this is confusing, right? Field technicians are obligated to respect the advice of the experts at the equipment manufacturer - in this case Suntec. But the applicability and use of check valves on oil piping installations may also depend on the installation particulars; some of the literature appears to contradict itself most likely because the manufacturers are describing oil piping on different types of systems: residential, commercial, and multiple heater applications.

Really? Suntec recommends use of an oil line pressure relief valve rather than a check valve if there is a problem on a particular oil piping installation - advice that does not address service convenience when working on a fuel unit connected to lengthy oil return piping that may perhaps even run overhead in some buildings.

Here's the bottom line:

Of critical importance is the avoidance of any potential blockage on the oil return piping (such as by installing an OSV on the return pipe or by installing a check valve where one is not recommended by the heater or equipment manufacturer) - because we don't want to blow an oil line, creating a leaky mess (due to oil entrapment), blow the seals in a fuel unit, nor feed a fire by an oil line blow-out during a fire.

More Check Valve Oil Piping Warnings

Watch out: where multiple heating appliances are fed from a common supply and return oil piping loop, a check valve is installed on the return line at each oil burner. [7a]

Watch out: some fuel unit manufacturers whose oil pumps include an internal check valve (Webster SPM series for example) may advise against installing extra external check valves on the systems where their equipment is used.

Watch out: Oil Entrapment Safety Warning:

Webster's Service Technicians Manual describes a potentially dangerous oil entrapment problem as follows:

In [ heating oil ] supply systems having a check valve on the supply pump discharge, an entrapment condition may exist between the supply pump and OSV®. In the burner OFF condition, cold oil in the line expands when heating to room temperature, causing a line pressure increase that may prevent the OSV® from operating, or may cause leakage at the threaded joints.

The condition may be observed by use of a pressure gauge at the inlet side of the OSV®, or on the discharge side of the supply pump check valve. Correction requires use of a pressure relief valve as shown in Figure 3 [Illustrated and annotated at above left] , set to insure a maximum 60 PSI at any OSV® inlet under all conditions. - Webster [7a]

Watch out: don't confuse an OSV with a check valve: the valve shown at left should not be used as a check valve in the application we just discussed. This is a Webster OSV & requires a vacuum to open.

If installed in the return line the valve would be pressurized, not open, cause the shaft seal to rupture or blow out & result in a major oil leak.

Thanks to reader Rick Johnston for adding clarification.

In contrast, Webster's Vacuum Breaker (P/N 48598) can be used in the oil suction line as a check valve. - Webster [7a p. 129]

Oil Line Check Valve Brands, Sources, Manufacturers

- R.W. Beckett (produces fusible link oil line safety valves, check valves, and thermal switches. - Website: www.beckttcorp.com

- Duda Diesel Enterprises produces a stainless steel check valve used with water, oil, biodiesel, air, and other fluids. P/N DudaDiesel SS304. Check valve sizes are available from 1/2" to 2". Contact Duda Energy LLC, 1112 Brooks St. SE, Decatur, AL, Website: http://www.dudadiesel.com Tel: 256-340-4866

- Envirosafe Above Ground Fuel Systems, 901 12th St., Clermont FL 34711, Tel: 800-555-4754, Website: http://abovegroundfuelstoragetanks.com, quoting:

Fuel Tank Check Valves:

Envirosafe™ Above-Ground Fuel Systems carries fuel tank check valves for above ground fuel tanks and other bulk fuel systems. We carry a variety of valves for bulk fuel tanks including vent valves, solenoid valves, by-pass valves, anti-siphon valves, and overfill prevention valves. These valves are suitable for the dispensing of a variety of fuels including gas, oil, methanol, diesel, and alternative fuels. - Global Industries produces a huge range of check valves for most applications, website: GlobalIndustrial.com

- Morso Oil Accumulator Check Valves Morso# 710-23875 1/2" intended for use with oil accumulators and oil coolers

- Northern Tool & Equipment produces the Northman fluid Power In-line hydraulic check valve Model# CIT0405 designed to allow one-way flow of oil in a hydraulic system as well as large number of other types of check valves in valve port sizes fro 1/2" to 3/4". We did not find a check valve for heating oil piping systems.

- OPW, OPW Fueling Components Corporate Headquarters 9393 Princeton-Glendale Road Hamilton, Ohio, USA 45011 Tel: (800)-422-2525 , Website: http://www.opwglobal.com. The company has offices worldwide.

Oil Line Check Valve Troubleshooting & Diagnosis

When diagnosing high or abnormal vacuums (over 15 inches) in the oil supply line ahead of the fuel unit, don't forget to consider a debris-clogged or stuck check valve. Conversely, abnormally low vacuum may indicate an air leak in the oil piping system.

If the oil supply appears blocked and there is oil in the tank, in addition to checking for a blocked oil line or a debris-clogged valve or a sticking check valve, double check each check valve to be sure that it has been installed in the right direction. OSVs and check valves should have an arrow embossed on the valve body indicating the intended direction of oil flow through the valve, or some products may be embossed with an "IN" and "OUT" indication.

...

Continue reading at OIL SUPPLY LINE SAFETY VALVES, OSVs or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- OIL TANK PIPING & PIPING DEFECTS - home

- OIL LINE AIR REMOVAL PROCEDURE

- OIL LINE BUZZ & VIBRATION CURE

- OIL SUPPLY & RETURN LINE CONTROLS & VALVES

- OIL SUPPLY LINE CHECK VALVES

- OIL LINE CLOGGING FIX

- OIL SUPPLY & RETURN LINE DE-AERATORS Tigerloop™

- OIL SUPPLY LINE PIPING LEAKS

- OIL LINE PIPING LEAK FAQs

- OIL LINE PIPING LEAK CAUSES

- OIL LINE QUICK STOP VALVES

- OIL SUPPLY LINE SAFETY VALVES, OSVs

- OIL SUPPLY LINE SAFETY VALVE TURN DIRECTION to OPEN or SHUT

- OIL LINE VACUUM & PRESSURE TESTS

- OIL SUPPLY LINE VACUUM-ACTIVATED OSVs & PRVs

- OIL TANK PIPING & PIPING DEFECTS - home

Suggested citation for this web page

OIL SUPPLY LINE CHECK VALVES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING OIL, OIL BURNERS, OIL FIRED HEATERS, OIL TANKS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Pump School, "Pumping Fuel & Fuel Oil", [online article] (2012), retrieved 2/24/2014, original source: http://www.pumpschool.com/applications/fueloil.asp [copy on file]

- "Supervise Fuel-Oil Piping and Storage in Buildings, P-98, Study Material Certificate of Fitness For", Fire Department, City of New York, (2008), retrieved 2/24/2014 [copy on file as Oil_Pipe_Store_Supervisor_NYFD_csm_p_98.pdf]

- [1]AUDELS OIL BURNER GUIDE, INSTALLING, SERVICING, REPAIRING, [PDF online copy of this book] Frank D. Graham, Theo. Audel & Co., New York 1946, 1947, 1955 (out of print, copies occasionally available from antique book dealers and on EBay). Use THIS LINK to read a free online copy of this helpful classic textbook.

- [2] Beckett Model SR Oil Burner Instruction Manual, R.W. Beckett Corporation, PO Box 1289, Elyria OH 44036 and R.W. Beckett Canada, Ltd., 430 Laird St., Guelph, Ontario, Canada N1G 3x7

- [2a] "Beckett Cleancut Installation Information, Single Stage Fuel Unit PN 21844 & 2-Stage Fuel Unit PN 21941", R.W. Beckett Corporation, (2007) op .cit.,

- [3] Thanks to Bottini Fuel service technician Bob for discussing the buzzing aquastat relay problem, 4/18/2012. Bottini Fuel is a residential and commercial heating oil distributor and oil heat service company in Wappingers Falls, NY and with offices in other New York locations. Bottini Fuel, 2785 W Main St, Wappingers Falls NY, 12590-1576 (845) 297-5580 more contact information for Bottini Fuel

- [4] Beckett Model SF Oil Burner Instruction Manual, op .cit.

- [4a] R.W. Beckett Corporation, website: http://www.beckettcorp.com, 38251 Center Ridge Rd.

North Ridgeville, OH 44039,

Phone:

440-327-1060,

Fax:

440-327-1064,

Email:

sales@beckettcorp.com

Quoting:

Fusible Fire Safety Valves are designed to reduce fire damage by shutting off the flow of oil from the oil tank in the event of a fire. These valves conform to UL/ULC 842 and are listed in the US and Canada. They are required by code in residential oil heating installations in conformance with NFPA 31.

All valves are embossed with the direction of oil flow and include unique part number identification ring or each valve. The seal stem uses a double seal washer/ o-ring system with high grade Viton® equivalent materials suitable for No. 2 fuel oil, Kerosene and up to 20% Biodiesel blend. - [5] Sunstrand Corporation - Sunstrand Fuel Units, 4949 Harrison Avenue P.O. Box 7003 Rockford, Illinois 61125-7003 U.S.A. Telephone: (815) 226-6000 Fax: (815) 226-5399 http://www.sundstrand.com,

- [6] Sunstrand Transmission Service Manual, May 1974, web search 08/19/2011, original source: http://www.cushmantrackster.com/pay-pdfs/sundstrand.pdf - Sunstrand Series 15 hydrostatic transmissions

- [7] Webster Fuel Pumps & Valves, Capitol City Tool, Inc., http://www.websterfuelpumps.com/

- [7a] "Service Technician's Handbook, Webster Fuel Pumps & Valves" [handbook]. Webster Fuel Pumps & Valves Co., Division of Capital City Tool, Inc., Op. Cit.

- [7b] "Dimensions & Specifications, OSV Series Oil Safety Valves, OSVA 38, OSVA 50", Webster Fuel Pumps & Valves, (1980), Op. Cit. retrieved 2/24/2014, original source: http://www.websterfuelpumps.com/pdffiles/osv1.pdf

- [8] Suntec Industries, 5000 Glasgow KY, 42142-5000, Tel: 270-651-7116, Website: www.suntecpumps.com, Email: info@suntec.com. See "Check Valves, Other Valves, and Thermal Expansion", retrieved 2/24/2014, original source: http://www.suntecpumps.com/CheckValves.htm

- [8a] Suntec Model A-7400 Fuel Unit Solenoid Dumping Pump,

Suntec Industries Inc., 60 Aberdeen Drive - PO Box 5000 Glasgow, KY 42142-5000 - USA Tel : 270 651 7116 - Fax : 270 651 9276 e-Mail : info@suntecpumps.com and

Suntec Industries France, 1 Rue Lavoisier - B.P. 102 F-21603 LONGVIC Cedex - FRANCE Tel : +33 (0)3 80 70 60 70 - Fax : +33 (0)3 80 70 61 11 e-Mail : information@suntec.fr, [copy on file as /heating/Oil pumps fuel units/Sunted_Solenoid_DumpingPPump.pdf] ,

Also /Suntech_Solonoid_Safety_Valves.pdf (brochure)

web search 4/19/12, original source: http://www.suntecpumps.com/Suntecus/PDFs/Form%202740%20

-%20Solenoid%20Dumping%20Pump.pdf - [9] Suntec Model PRV-38 Oil Safety Valve Installation Information, Suntec Industries Inc., 60 Aberdeen Drive - PO Box 5000

Glasgow, KY 42142-5000 - USA

Tel : 270 651 7116 - Fax : 270 651 9276

e-Mail : info@suntecpumps.com and

Suntec Industries France, 1 Rue Lavoisier - B.P. 102 F-21603 LONGVIC Cedex - FRANCE Tel : +33 (0)3 80 70 60 70 - Fax : +33 (0)3 80 70 61 11 e-Mail : information@suntec.fr, [copy on file as /heating/Oil pumps fuel units/Form 2155 - PRV-38 Installation.pdf]. You can download this file from Suntec's website. , - [10] Firomatic Globe Type Oil Line Valves & Lever Type Fusible Link Control Valves: ISP Automation, Inc., 1035 Old Georges Road, North Brunswick, NJ 08902, Phone: 866-383-3481, FAX 866-383-3482, Email: support@ispautomation.com

- [11] Fusible link oil line control valves for commercial equipment: ASCO products by Emerson Industrial Automation, P.O.Box 160, 17 Airport Road Brantford, Ontario Canada N3T 5M8 Tel: (519) 758-2700 Fax: (519) 758-5540

- [12] Fuel oil safety valves, Webster Fuel Pumps & Valves, 219 Hahn Road Frankfort, Ky. 40601, Tel: (800) 766-1233 Email: czahalka@cctoolinc.com (Curtis Zahalka Sales Mgr/Mkt /Cust Service/Tech Support/Webmaster ) web search 10/12/2011 original source http://www.websterfuelpumps.com/pdffiles/osv1.pdf

- [13] Webster Service Technicians' Handbook, Webster Fuel Pumps & Valves, 219 Hahn Road Frankfort, Ky. 40601, Tel: (800) 766-1233

- [14] "The Oil Safety Valve (Service)", Charles Bursey, Sr., Fuel Oil News, February 2006 (Still trying to get the full article - October 2008 - DF) Charles W. Bursey Sr. can be reached at F.W. Webb Co. www.fwwebb.com/

- [15] "Installation Information for Suntec A-2000, A-7000 Single Stage and B-8000 two stage fuel units"Suntec Industries, 60 Aberdeen Drive, Glasgow KY 42141, 270-651-7116 (1725 rpm black label, 3450 rpm white label)

- [16] Tigerloop: oil line de-aerator devices, Westwood Products Inc., 330 William St., PO Box 610, South River, NJ 08882-0610 - (732) 651-7700

- [17] Newmac Furnaces & Boilers, "Installation, Operating, and Service Manual, Oil Fired Boiler Model NBR-2001 NBR 2002", (2007) Newmac Manufacturing, Inc., Debert Air Industrial Park, Lancaster Crescent, PO Box 9, Debert, Nova Scotia, BOM 1GO Canada, Tel: 902-662-3840, retrieved 2/23/2014

- Dave Ferris - M&S Environmental Systems, Dutchess County, New York. Mr. Ferris was an HVAC expert. Personal communication to DJF 1987. Remove the firematic or fusible oil supply line valve on return oil-line side - in case of fire if this one closes first the pump continues to run, blows its seal, and sprays oil all over the fire. Proper installation is to have a fusible link valve only on the supply side, and to install a check valve on the return line to prevent back-siphonage from the tank.

- Thanks to Rick Johnston for pointing out that the more likely cause of a fire safety valve in the return oil line is a burst seal on the fuel unit 4/6/2009

- Thanks to reader Bernie Daraz for suggesting the need for clear photographs illustrating the OSV or oil line safety valve in the open and closed positions. Personal correspondence 2/15/2013.

- Thanks to reader T.R. for suggesting clarity on where oil safety valves should or should not be installed and for discussing the proper hook-up location for the Tigerloop and similar oil line prime protection & air removal devices. April 2011.

- Thanks to reader Anonymous by request 2/23/2014, for requesting clarification of the safety hazards involved in placing an OSV on the return line of a two-pipe oil system.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.