Drywall Installation: horizontal vs. vertical?

Drywall Installation: horizontal vs. vertical?

Pros & cons of vertical versus horizontal drywall hanging

- POST a QUESTION or COMMENT about the best methods used to install or hang drywall

Is it better to install drywall horizontally on walls or vertically?

Reader comments and expert replies along with supporting research argue that horizontally-installed drywall makes walls stronger with greater resistance to racking than vertical drywall jobs, but some readers disagree and others point out that for one installer working alone, vertical installation may be easier.

Both drywall orientations are permitted by drywall manufacturer's installation guides.

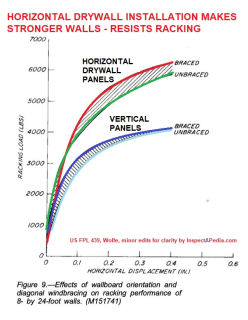

Page top figure excerpted and edited from US FPL 439, Wolfe's research on wall racking resistance strength for horizontal versus vertical drywall installation position. (Cited in detail below)

This article series describes the best practices when installing drywall in buildings. We describe the types of drywall and where each type should be used. We discuss different approaches to hanging drywall, including the necessary framing and adhesion or fastening specifications.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Drywall Installation Position

Our drywall installation photographs illustrate horizontal drywall application by professionals: notice the long horizontal tape joints beginning up 4 ft. from the floor (red arrow).

Our drywall installation photographs illustrate horizontal drywall application by professionals: notice the long horizontal tape joints beginning up 4 ft. from the floor (red arrow).

At DRYWALL INSTALLATION Best Practices we stated

For walls 8 feet high or less, run drywall sheets perpendicular to the studs [or horizontally, with the long side of the drywall sheets parallel to the floor. The installer in the job shown at left used 12-foot drywall lengths for even fewer joints. - Ed.]. This is stronger, bridges framing irregularities, and results in fewer joints.

But as you'll read in reader discussion comments below, some installers disagree.

On 2021-04-17 - by (mod) - we like horizontal drywall installation but ...

@larry,

A lot of professional drywaller's like to run the drywall horizontally claiming that it makes for fewer seams to be taped. I was also impressed by Wolfe's US FPL research giving both data and an explanation of why horizontally-run drywall improves building wall structural strength and resistance against racking.

However if you're working alone you might find it easier to lift the drywall in place if you place your panels vertical.

The horizontal design means you'll need to lift up an 8 foot lengths and set it on top of the upper edge of your lower length already in place and then hold it there while you shoot screws in so that it doesn't fall in your face.

On 2021-04-17 by larry

drywall horizontal or vertical I have a few walls about 177" long give or take, the ceiling is 85" not 96 or 8ft. Older home reno. is it better to run 8ft boards vertical or horizontal, I doing the job myself so 10ft or 12 ft boards would be trouble.

Thanks kman10kman@gmail.com

On 2019-11-09 - by (mod) -

Lakewood drywall said:

It's always nice to get a perspective on how other pros get the job done. We just started our drywall business in lakewood Colorado Thank you so much for sharing your knowledge on the topic!

On 2017-05-20 - by (mod) - blocking required for buttboard dywall taping method: horizontal vs. vertical drywall installation

Iggy, intersting points.

Glad you feel passionate, but these comments

will be heard more clearly by other readers with less shouting and insults. I'll later edit accordingly.

Frankly I found Wolfe's study carefully-written and providing compelling evidence.

It is important for us to keep in mind the differences among scholarly research, engineering analysis, field experience, and opinion.

For other readers:

Wolfe's US FPL study, cited above where a complete copy is provided as a PDF download found that

Horizontal panel orientation appeared to offer a significant

improvement over that obtained with vertical panel

orientation. Walls tested with panels oriented horizontally

were more than 40 percent stronger and stiffer than those

with panels oriented vertically

On 2017-05-19 by Iggy - buttboad drywall blocking: always fasten to blocking

Yep, Trim-Tex, Wilco or whomever's Buttboards (fake "blocking") are enablers for the SUPER dumb and lazy.

BUT, they should only EVER be first screwed to solid blocking! No users of that stuff do that and they VERY stupidly expect the seam to stand up to someone bumping into the wall or leaning on it. Well, they aren't durable because only drywall is "supporting" drywall.

Don't worry, those idiots have plenty of imbecile friends and most of those morons proclaim themselves to be "Professionals"...they MOST DEFINITELY ARE NOT. They're hack frauds slapping up a pretty piece of WORTHLESS work that's quite literally RUINING Brand New from the very start, while jeopardizing countless lives along the way.

If Real Blocking were used, like it should've been all along, then Buttboards would've never existed. To cut an extremely shallow "V" in a chunk of 2x4 or 2x6 takes just seconds with any cheap circular saw, jig saw, belt sander or grinder and the top and bottom blocking is bridged with a 2x4 or 2x6. Then, you'd be able to kick, punch or hammer any seam without any failure, like can be done with every single seam of the correct, easier, faster and way-way better Vertical Installation.

Again, if Fire is NOT a consideration for single-ply installations, then why use drywall at all? Sorry but, Steven's point that there shouldn't be any expectation of safety from drywall's use is rather ridiculous. Yeah, I've tried with the Gypsum Associations and Manufacturers and all they do is fallback to ASTM's errors and openly instruct that either orientation is fine by them. They're just promoting their product's further existence and repeated purchase.

Though, I'm glad to see that only 1-point of mine was confronted and so weakly.

On 2017-05-19 - by (mod) - drywall butt joints that do not meet over a framing member & TrimTex buttboard support

Regarding drywall butt joints that do not meet over a framing member, particularly in horizontally-run drywall, 've received enthusiastic comments from a reader about TrimTex buttboard that is specifically designed to provide a continuous backer across such joints. More research and expert comment on that drywall approach is needed.

The claimed fabulously-more-easy installation using TrimTex buttboard at butt joints of ends of horizontally-run drywall did not, for me, add-up, since in normal building framing with studs on 16" or even 24" centers, starting with full-size drywall panels in a multiple of feet, the joints should want to end in the center of framing members anyway - with the obvious exceptions for odd-sized spaces and perhaps one final drywall segment.

On 2017-05-19 by Steven Bliss

Comments from Steven Bliss, original author of Best Practices in Residential Construction

It may be that there is a theoretical fire-safety advantage to vertical installation of drywall, but most fire-rated wall assemblies allow for either vertical or horizontal installation. There are a number of other advantages to horizontal installation and it is by far the most common. However, like many things in construction, intelligent (or not) people may disagree about the best way to do things.

In the most recent version of the Gypsum Handbook in my possession (which is sadly from 2000), it states that:

“Two recent tests permit Sheetrock brand gypsum panel products…to be applied horizontally or vertically in partitions without compromising the fire rating. These tests are UL Design U419 for non-load bearing partitions and UL Design U423 for load-bearing partitions. When either of these tests are listed with a USG system, it means that the system can now be built with the panels oriented in either direction.”

Here’s what Georgia-Pacific has to say:

Should gypsum board be installed vertically or horizontally?

While gypsum boards are stronger in one direction, they may be installed either vertically or horizontally on wood or steel studs. If the boards are to be used in a fire rated assembly then use the board orientation that is stated in your specific rated assembly.

That said, there are certain commercial wall assemblies using some brands of Type X and Type C fire-rated drywall that were only tested with panels in the vertical dimension, so they must be installed that way to retain that fire rating. The only one I could find that required vertical installation of the drywall is for elevator shafts, but there may be others. Individual panels do not have a fire-rating – only the installed assemblies are rated.

Iggy seems to feel strongly about this and I don’t know enough to refute his claim. It is plausible that fire could escape more easily out of a horizontal drywall joint with no backing. I would check with the folks at US Gypsum, who have been setting standards in this area for decades.

As I’m sure you are aware, fire safety is a complex and controversial topic. Most people die of smoke inhalation or CO poisoning long before the house burns down. There was a time when healthy-house types expressed a lot of concern about urethane foam insulation in a fire until someone pointed out that they were probably sleeping on a urethane foam pillow. Of greater concern is polystyrene foam which, apparently, apparently melts and then burst into flame. However, the flame- spread test used to test the material for fire safety ignores this characteristic. Commercial interests sometimes trump safety concerns.

Let me know if you find out anything of interest.

Steven Bliss

www.BuildingAdvisor.com

On 2017-05-19 by Iggy - importance of run direction of drywall butt joints

Well, which way the joints run SHOULDN'T matter, but IT SURE DOES. Why & How? Because of what BUILDING Inspectors FOOLISHLY "pass" on a daily basis...and have done so for decades. According to ASTM's C840 (2012 was the last I could obtain freely) ALL edges and ends MUST be attached to framing members or back-blocking to ensure air-tightness of any panel, regardless of panel size.

Yes, even partial or very small panel portions. BUT, NO-ONE building nor renovating homes does any sort of Back-Blocking to either fully support an ENTIRE edge or end nor do or can they achieve natural air-tightness. Therefore, why Fire-Rated Assemblies have (required) their layers laid perpendicular to each other.

However, the ASTM itself is the downfall and root of the problem and has been for my 15-years of trying. The ASTM language is - "Edges and ends of gypsum board shall occur on the framing members, EXCEPT those edges and ends that are perpendicular to the framing members."

The word EXCEPT needs to be SIMPLY corrected to ESPECIALLY. Since, the instruction and test results imply and establish that panel edges and ends (along with everything else) need to be air-tight and FULLY supported. In complete and total support of my discovery, it states for HORIZONTAL (perpendicular to framing members) installations upon ceilings must have - "BLOCKING of perimeter edges. All perimeter edges shall be blocked using a wood member not less than 2-inch by 6-inch nominal dimension."

The ASTM REFUSES the error and drywall work is passed everywhere without a stich of Back-Blocking in any ceiling and especially wall. I've tried to get drywall installers on-board, but as soon as they have to do Back-Blocking their falsely and fraudulently claimed "benefits" of the laughable Horizontal installation disappear entirely.

12 Reader Objections to Horizontal Drywall Installation

[given below is a Reader OPINION - Ed.]

Which, brings me to my 12-point list of why Horizontal installation IS JUST PLAIN WRONG and that Vertical installation is THE ONLY AND RIGHT WAY:

- DEFECTIVE SEAM - Horizontal rows needing more than one drywall panel CREATES (instead of AVOIDS) a butt-joint HUMP, which are NOT flat and are a TWICE (minimum) effort DEFECT. Outlet and switch cover-plates, window and door trim, baseboards, pictures, mirrors and cabinets don’t sit flat. Using ANY "butt-joint product" erases ALL "claimed benefits" of Horizontal!

- UNSUPPORTED SEAM – Horizontal’s tapered edge is MOSTLY unsupported, only 10% (instead of Vertical's 100%) contacts framing, the seam WILL AND DOES crack. Light switch and countertop electrical boxes within the seam equals MORE weakness and butt-joint doubled, MINIMUM, efforts.

- STRUCTURAL DEFECT - Horizontal only reinforces a wall height of 4’ or less and the wall's top-plate is never connected to the bottom-plate. As in and due to #2 above, Frictional Contact is MINIMIZED (instead of maximized by Vertical).

- SEAM DECEPTION...(4'x8' PANELS) – Example 1: 48” tall by 102” long wall, Horizontal = 48” (technically) and it’s a 24”-WIDE butt-joint (Vertical = the same, GENEROUSLY, 96” but they’re easy 6”-wide joints).

Example 2: 96” tall by 102” long wall, Horizontal = 222” with 50% being 24”-WIDE butts (Vertical = 192” of 6”-wide easy joints, yes LESS)...in a Kitchen Horizontal = 100% of 24”-WIDE butts (Vertical = 0%). Yes, Horizontal does the taper area TWICE in order to hide its butts, so VERY MINIMALLY just another 24” was added AND #5 below was not at all factored-in to Horizontal's continued failure. - SELF-DEFEATING ANGLES – Horizontal only uses ONE of a panel’s tapered edges and PUTS the other taper at the ceiling corner and baseboard, CREATING (instead of AVOIDING) a twisted angle that MUST be shimmed or ADDITIONALLY mudded.

This too, instantly ERASES ALL claimed benefits of Horizontal! The Panels are designed to be installed Vertically! - UNFRIENDLY SEAMS – Horizontal celebrates the chest height seam and PRETENDS there’s no 24”-WIDE floor to ceiling butt-joint that needs to be DONE AND DRY BEFORE doing the ceiling corner (Vertical has easy joints and the top's done later with the ceiling corner).

- FIRE VIOLATION AND HAZARD - Horizontal only fills the coin-thin SEAM'S FACE and has NO back-blocking, inviting smoke and fire’s spread, including fuel-air for a fire's growth (Vertical is full depth and CONTINUOUSLY airtight).

- UNSAFE INSTALLATION - Horizontal needs 2-PEOPLE for a safe installation and the panel is airborne, literally CREATING the chance to CAUSE injury (Vertical easily tilts-up with just 1-person). Panel lifters aren't even as easy and safe as Vertical’s tilt-up.

- ADDITIONAL WASTE - When correctly covering a knee or half wall, tub front, column or soffit by first removing both tapered edges, Horizontal CAN'T use the tapers elsewhere (Vertical can and does).

- SELFISH IGNORANCE - Foundation and Framing crews go to great pains to make everything flat, level, plumb and square. Horizontal DESTROYS those efforts with their DEFECTIVE humps (Vertical keeps them all).

- GRASPING AT STRAWS WITH OUTRIGHT FRAUD - Horizontals FALSELY AND UNKNOWINGLY wave the absurdly INVALID (FPL439) 1983 testing “Contribution of Gypsum Wallboard to Racking Resistance of Light-Frame Walls” by the self-indicted fraud Ronald W. Wolfe.

FPL439 found that ALL tapered or paper wrapped edges must be FULLY INTACT for Horizontal to beat Vertical "structurally", PERIOD. In the real-world, bottom paper wrapped edges are REMOVED (at a minimum), BY LAW, for spacing from all floors and thereby COMPLETELY NEGATE Wolfe’s inexcusably deceitful and worthless "study" and summation. - JOINT OR SEAM TREATMENT - According to the ASTM's C840, Horizontal's joints and seams MUST be mudded to provide ANY fire, smoke and air travel resistance. Vertical is SO GOOD that it's NOT REQUIRED to have its joints or seams treated.

Only promote HORIZONTAL AS WRONG and confidently cite the above incontestable FACTS.

On 2017-05-19 - by (mod) - fire hazard at drywall joints not over framing

Thank you for commenting on the fire hazard that you associate with horizontal drywall.

As long as joints are taped to spec those meet residential codes (but in some jurisdictions not commercial fire codes). To a typical drywall hanger it's unclear why the joint location would affect fire spread until we consider un-backed drywall joints not over framing. ( Joerger 2011)

But you're quite right that at commercial drywall installations, local fire code can require that all drywall seams or joints fall entirely on framing members. To meet fire code one would either have to install drywall long enough to meet the full height of the wall, screwing it to studs and to the wall top and bottom plates (all thus along framing) or one could be required to install blocking behind any othewise-open drywall butt joints.

Drywall Installation Details vs Fire Risk

- Ferguson, Myron R. Drywall: Professional Techniques for Great Results. Taunton Press, 2012.

- Norgaard, J., and MA Othuman Mydin. "Drywall Thermal Properties Exposed to High Temperatures and Fire Condition." Jurnal Teknologi 62, no. 1 (2013): 63-68.

Abstract:

Drywall is a widespread fire barrier used in house and general building construction. Drywall partitions and ceiling membranes are possibly the most common fire resistant construction approach employed in an extensive range of building types. The utilization of drywall board as prime fire protection of light-flame wood or steel construction is ubiquitous.

Drywall board based systems are among those now broadly used, as walls or ceilings and it is principally employed as lining material in light-weight construction, which is a competent and cost effective technique of providing flexible partitioning assemblies in commercial and residential buildings.

The thickness of the drywall board lining and the configuration of the framing can be flexibly changed to meet specified fire performance requirements. The use of such systems is increasing every day and there demands to be more research on their properties and behaviour. This paper will presents the properties of drywall board which will includes the assemblies and standard fire tests and the thermal properties of drywall in general and includes suggested properties of drywall by different researchers. Drywall boards shrink and crack at high temperatures, and this leads to collapse of parts of the drywall boards in fire.

Fall-off of gypsum in fire affects the fire resistance of the assembly considerably, and cannot be overlooked when evaluating the fire resistance of drywall assemblies.

- Drywall Thermal Properties Exposed to High Temperatures and Fire Condition. Available from: https://www.researchgate.net/publication/289299565_Drywall_Thermal_Properties_Exposed_to_High_Temperatures_and_Fire_Condition [accessed May 18, 2017].

Abstract:

Drywall is a widespread fire barrier used in house and general building construction. Drywall partitions and ceiling membranes are possibly the most common fire resistant construction approach employed in an extensive range of building types. The utilization of drywall board as prime fire protection of light-flame wood or steel construction is ubiquitous. Drywall board based systems are among those now broadly used, as walls or ceilings and it is principally employed as lining material in light-weight construction, which is a competent and cost effective technique of providing flexible partitioning assemblies in commercial and residential buildings. The thickness of the drywall board lining and the configuration of the framing can be flexibly changed to meet specified fire performance requirements.

The use of such systems is increasing every day and there demands to be more research on their properties and behaviour. This paper will presents the properties of drywall board which will includes the assemblies and standard fire tests and the thermal properties of drywall in general and includes suggested properties of drywall by different researchers. Drywall boards shrink and crack at high temperatures, and this leads to collapse of parts of the drywall boards in fire. Fall-off of gypsum in fire affects the fire resistance of the assembly considerably, and cannot be overlooked when evaluating the fire resistance of drywall assemblies.

- Harmathy, T.Z., The SFPE Handbook of Fire Protection Engineering. Society of Fire Protection Engineers/National Fire Protection Association: Boston, 1988.

- Joerger, Scott. A SIDE-BY-SIDE COMPARISON OF NEW AND OLD CONSTRUCTION [PDF] Fire Engineering 164, no. 9 (2011): 73-86. original source:

Full article as PDF is at http://www.fireengineering.com/content/dam/fe/online-articles/documents/FEU/FEU_Joerger_Sept_11.pdf

This author cites fire spread through "bad drywall joints": Excerpt:

A stove fire could enter the ceiling from a poorly constructed vent, a light fixture in the ceiling, or a bad drywall joint. - Rahmanian, I., Thermal and Mechanical Properties of Gypsum Boards and Their Influences on Fire Resistance of Gypsum Board Based Systems. Phd Thesis, University of Manchester, 2011

- Roy-Poirier, A. and Sultan, M.A., Approaches for Determining Gypsum Board Fall-Off Temperature in Floor Assemblies Exposed to Standard Fires. National Research Council of Canada, Research Report No. 226, 2007

Drywall Installation Methods, Guides, Research

- CERTAINTEED DRYWALL INSTALLATION INSTRUCTIONS [PDF] (2007) CertainTeed Corporation P.O. Box 860 Valley Forge, PA 19482 Professional: 800-233-8990 Consumer: 800-782-8777 www.certainteed.com http://blog.certainteed.com

- CERTAINTEED DRYWALL FINISHING GUIDE [PDF] Op. Cit.

- USG SHEETROCK™ INSTALLATION MANUAL [PDF] U.S. Gypsum Corp. (2015) Website: https://www.usg.com/

- Everett, John G., and Dennis L. Kelly. "Drywall joint finishing: productivity and ergonomics." Journal of construction engineering and management 124, no. 5 (1998): 347-353.

Abstract

Gypsum drywall panels are used extensively for wall cladding and structural fireproofing. Most interior building walls are of sufficient length and width to require at least two panels of drywall for complete coverage. Generally speaking, in residential construction, boards are placed horizontally (perpendicular to studs), and in commercial construction, boards are placed vertically (parallel to studs).

This paper analyzes the effect of drywall panel and joint orientation on joint finishing operations. Productivity comparisons are made by investigating the total quantity of joint produced, productivity rates for various types of horizontal and vertical joints, and total time required to finish the joints. For typical residential applications, horizontal joints require less time to finish. For many commercial applications, vertical joints require less time to finish. However, there are many exceptions. Contractors and designers can save time and money by selecting the proper orientation.

The locations of the joints on the wall also affects the motions and positions the craft worker must endure to complete the work.

Professional finishers prefer horizontal joints because they greatly reduce the ergonomic stresses associated with bending down and reaching overhead. - Memari, Ali M., and Matt Sambol. "Experimental Evaluation of the Effect of Two Different Types of Drywall Joint Compound on Shear Capacity of Wood-Frame Walls." In AEI 2008: Building Integration Solutions, pp. 1-10. 2008.

Abstract:

This paper summarizes the findings of a pilot study to determine whether the type of drywall joint compound will influence the shear strength of wood-frame stud walls sheathed with drywall. In this study, five 8 ft x 8 ft specimens were tested under in-plane cyclic racking loading following CUREE loading protocol for light-frame wall systems. Three specimens were finished using non-cement based joint compound and the other two using cement based joint compound.

Based on the limited number of specimens tested, the results show that the use of cement based joint compound on drywall joints as in the specimens tested will result in higher wall shear capacity compared to similar specimens finished with conventional non-cement based joint compound. The failure modes for the specimens finished with the two different types of compound were different.

The result of the study is particularly important for high seismic regions where interior stud walls in residential construction effectively take part in seismic resistance even though wood shear walls are normally used on exterior walls. - Raffaele, Landolfo, Tatiana Pali, Bianca Bucciero, Maria Teresa Terracciano, Sarmad Shakeel, Vincenzo Macillo, Ornella Iuorio, and Luigi Fiorino. "Seismic response assessment of architectural non-structural LWS drywall components through experimental tests." Journal of Constructional Steel Research 162 (2019): 105575.

- Wolfe, Ronal W. CONTRIBUTION OF

GYPSUM WALLBOARD

TO RACKING

RESISTANCE OF

LIGHT-FRAME WALLS [PDF] U.S. FPL 439, USDA, Forest Service, Forest Products Laboratory

Abstract:

Gypsum wallboard is the most commonly used interior wall sheathing material. Evidence suggests that it contributes to the shear performance of light-frame walls; however, it has received little recognition as a structural material. A better understanding of the structural behavior of gypsum wallboard could contribute to more efficient light-frame construction.

Thirty light-frame walls were evaluated to characterize the gypsum wallboard contribution to shear wall racking performance. Variables studied included windbracing, wall length, and wallboard orientation. Wallboard and windbracing were found to interact as parallel elements. The relationship between racking resistance and wall length was nonlinear for continuous wallboard diaphragms and varied with deformation level.

Wallboard orientation had a significant effect on strength and stiffness. Results of this study provide a basis for engineers and code authorities to judge the contribution of gypsum wallboard to the shear resistance of walls under windloads and seismic loads. Results will also be useful in planning future research for light-frame construction.

Excerpts:

The objective of this study was to determine the significance of gypsum wallboard contribution to wall racking resistance.

Wallboard Orientation

In addition to windbracing and wall-length effects, 24-footlong walls were also used to evaluate the effects of wallboard panel orientation on racking performance. Two of the 24-foot-long walls were tested with 12-foot-long panels applied parallel to the wall length (walls 29 and 30) which are referred to as horizontal application. Two others were tested using 8-foot long panels applied parallel to the wall height (walls 25 and 28) which are referred to as vertical application.

Wallboard Installation Details

Variations in wallboard installation have a significant effect on wallboard contribution to racking resistance. Three contributing factors include panel orientation, taping of the wallboard joints, and the panel-frame connection.

Panel Orientation Wallboard panel orientation had a significant effect on wall racking performance. Figure 9 shows that strength and stiffness were greater for panels oriented horizontally.

These plots show an average increase in ultimate strength of 50 percent, and 43 percent average increase in stiffness. Although the small sample size would not support the use of these factors in design, their magnitude suggests that the horizontal orientation of 12-foot-long sheets is structurally superior to the vertical orientation of &foot-long sheets.

Two explanations for the improved performance observed for horizontal panel orientation are,

(1) the directional properties of the paper facing, and

(2) edge differences. Tensile strength tests of paper facing samples taken from the tested walls (table 8) showed the strength of the paper was about four times greater in the machine direction (parallel to panel length) than in the cross direction for both front and back paper facings.

Edge differences include core confinement and a thinner section along the long edge. A continuous paper edge confines the gypsum core and provides improved support for the nailhead. The thinner section, due to edge taper, results in smaller nail bending moments. These two factors combine to provide increased nail holding ability along the long edge of the gypsum board.

Horizontal panel orientation appeared to offer a significant improvement over that obtained with vertical panel orientation. Walls tested with panels oriented horizontally were more than 40 percent stronger and stiffer than those with panels oriented vertically. - Yuan, Lu, and Bryan Buchholz. "The effects of position and size of drywall on the physical demands for installers." In Proceedings of the Human Factors and Ergonomics Society Annual Meeting, vol. 58, no. 1, pp. 1612-1616. Sage CA: Los Angeles, CA: SAGE Publications, 2014.

...

Continue reading at DRYWALL FINISH LEVELS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- DRYWALL, FIBERBOARD, PLASTER INTERIORS - home

- ASBESTOS in DRYWALL

- CHINESE DRYWALL HAZARDS

- COATING TYPE CEILING & WALL SURFACES: CATALOG OF

- DOMTAR GYPROC ASBESTOS?

- DRYWALL & GYPSUM BOARD COMPOSITION & HISTORY

- DRYWALL CONTROL JOINTS

- DRYWALL CRACK CAUSES & CURES

- DRYWALL FINISH LEVELS

- DRYWALL TYPE IDENTIFICATION STAMPS

- DRYWALL INSTALLATION Best Practices

- DRYWALL INSTALLATION HORIZONTAL vs VERTICAL

- DRYWALL GREEN LOW TOXICITY MAGNESIUM OXIDE MgO

- DRYWALL MOLD RESISTANT

- DRYWALL MOLD TESTING

- DRYWALL NAIL POPS & DENTS

- GYPSUM BOARD GYP ROCK SHEATHING

- WALL FINISHES INTERIOR

Suggested citation for this web page

DRYWALL INSTALLATION HORIZONTAL vs VERTICAL at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING INTERIORS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about the best methods used to install or hang drywall

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Steve Bliss's Building Advisor at buildingadvisor.com helps homeowners & contractors plan & complete successful building & remodeling projects: buying land, site work, building design, cost estimating, materials & components, & project management through complete construction. Email: info@buildingadvisor.com

Steven Bliss served as editorial director and co-publisher of The Journal of Light Construction for 16 years and previously as building technology editor for Progressive Builder and Solar Age magazines. He worked in the building trades as a carpenter and design/build contractor for more than ten years and holds a masters degree from the Harvard Graduate School of Education. Excerpts from his recent book, Best Practices Guide to Residential Construction, Wiley (November 18, 2005) ISBN-10: 0471648361, ISBN-13: 978-0471648369, appear throughout this website, with permission and courtesy of Wiley & Sons. Best Practices Guide is available from the publisher, J. Wiley & Sons, and also at Amazon.com - Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- [1] Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- [2] "Finishing Drywall Systems", U.S. Gypsum (USG) Corporation [copy on file as USG_Finishing_Drywall_Systems_Ch5.pdf] 2009

- [3] "Sheetrock® All Purpose Joint Compound - Select for professional drywall finishing", Submittal Sheet 09250

- [4] "Quality Drywall Finishing in All Kinds of Weather", USG Folder J-75 (out of print), U.S. Gypsum corporation

- [5] Gypsum Construction Guide, National Gypsum Corporation

- [6] Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- [7] Lath & Plaster Systems [copy on file as /interiors/LathPlaster_Nat_Gypsum.pdf ] - , 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- [8] Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster [copy on file as/interiors/Amico_lath-inside.pdf ] - from Amico, a lath and plaster accessory producer.

- [9] Plastering, PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

[copy on file as/interiors/Plastering_USG.pdf ] -

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started. - [10] Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- [11] Drywall Finishing Council www.dwfc.org, Members: CertainTeed Gypsum • Freeman Products • Georgia Pacific Gypsum LLC • LaFarge North America • Magnum Products • National Gypsum Company • Panel Rey SA • Rapid Set Cement • Saint-Gobain, Inc • Sherwin-Williams Company • Solid Products, Inc. • Southern Wall Products • Trim-Tex, Inc. • United States Gypsum Company • Westpac Materials

- "Joint Compound Drying Time, the Impact of Environmental Conditions", Drywall Finishing Council, Retrieved 8/16/12, original source: http://www.dwfc.org/wp-content/files/2010_03_16_Joint_Compound_Drying.pdf [copy on file as Joint_Compound_Dry_Tmie_DWC.pdf]

- "Jobsite Conditions for Applying Interior Finishing Materials", Drywall Finishing Council, Retrieved 8/16/12, original source: http://www.dwfc.org/wp-content/files/2011_09_16_Interior_Job_Condition_Specifications.pdf [copy on file as Drywall_Finish_Conditions_DWC.pdf ]

- DWFC. Interior Job Condition Specifications For The Application of Drywall Joint Compounds,

Drywall Textures, and Paint/Coatings". Drywall Finishing Council, Incorporated. www.dwfc.org - DWFC. Recommended Specification for Preparations of Gypsum Board Surfaces Prior To Texture

Application, Drywall Finishing Council, Incorporated. www.dwfc.org - GA. GA-214, Recommended Levels of Gypsum Board Finish. Gypsum Association, 6525 Belcrest

Road - Suite 480. Hyattsville, MD 20782 www.gypsum.org - National Gypsum Company. ProForm Brand Drywall Finishing Products Construction Guide,

National Gypsum Company, 2001 Rexford Road, Charlotte, NC, 28211, www.nationalgypsum.com - [12] The Gypsum Association www.gypsum.org

- Gypsum Construction Handbook H-17 [purchase at Amazon.com] . USG Corporation, 550 West Adams Street,

Chicago, IL, 60661, www.usg.com - [13] Painting and Decorating Contractors of America www.pdca.org Smartwood/Rainforest Alliance www.smartwood.org

- [14] "Joint Compounds", United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124, retrieved 8/16/12, original source: http://www.usg.com/interiors/joint-compounds.html [copy on file as Mud_Types_USG.pdf]

- Gypsum Construction Guide, National Gypsum Corporation

- Gypsum Construction Handbook [purchase at Amazon.com] H17, Technical Folder SA920 and PM2, PM3 and PM4, United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

- Lath & Plaster Systems, 092300/NGC, National Gypsum Lath and Plaster Systems, National Gypsum Corporation, 800-628-4662 describing National Gypsum's Kal-Kore brand plaster base

- Metal Lath Specifications, Specification for metal lath and accessories, Lath and Plaster from Amico, a lath and plaster accessory producer.

- Plastering Skills, F. Van Den Branden, Thomas L. Hartsell, Amer Technical Pub (July 1, 1985), ISBN-10: 0826906575, ISBN-13: 978-0826906571 [purchase at Amazon.com]

- Plastering, PM 5, Product & Systems Technology, US Gypsum, May 1998, web search 10.5.2010, original source: http://www.usg.com/rc/technical-articles/plaster/

plastering-technical-guide-veneer-plaster-joint-reinforcement-systems-en-PM5.pdf

United States Gypsum Company, 125 South Franklin ST., PO Box 806278, Chicago, IL 60680-4124,

Paraphrasing from this document: USG uses the term shadowing in this document in describing the visual effect over gypsum board joints caused by the lower moisture absorption rate (take-up) and lower capacity than gypsum base face paper. Shadowing at joints occurs where veneer plaster is applied over tape joints, requiring a second coat to completely hide the tape, providing a visually uniform surface. USG Advises: "This [second] cover coat must be allowed to harden and dry before plaster application is started. - DRYWALL INSTALLATION Best Practices

- DRYWALL INSTALLATION HORIZONTAL vs VERTICAL tems, infrared radiant heating, and water heating); Air-Handling Equipment (chapters on duct construction, air distribution, fans, coils, evaporative air-coolers, humidifiers, mechanical and desiccant dehumidification, air cleaners, industrial gas cleaning and air pollution control); Heating Equipment (chapters on automatic fuel-burning equipment, boilers, furnaces, in-space heaters, chimneys and flue vent systems, unit heaters, makeup air units, radiators, and solar equipment); General Components (chapters on compressors, condensers, cooling towers, liquid coolers, liquid-chilling systems, centrifugal pumps, motors and drives, pipes and fittings, valves, heat exchangers, and energy recovery equipment); and Unitary Equipment (chapters on air conditioners and heat pumps, room air conditioners and packaged terminal equipment, and a new chapter on mechanical dehumidifiers and heat pipes)."

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.