Roof Underlayment Requirements

Roof Underlayment Requirements

Is roofing felt required?

Does omitting the felt (underlayment) void roof shingle warranty?

- POST a QUESTION or COMMENT about when & where roofing felt underlayment is required

Roofing underlayment - roofing felt requirements are explained here.

Is roofing felt required? Who says?

Roofing felt (underlayment) installation details are given for various roof slopes & conditions.

This article series discusses roofing felt, specifically addressing the roofing code or roofing manufacturer's requirements for use of an underlayment, such as roofing felt, tarpaper, or other underlayment products beneath asphalt shingles and other roofing materials.

We also discuss the moisture permeability of roofing underlayments in hot humid climates.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Roofing Felt / Underlayment Requirements & Recommendations

Here we review these roofing felt questions: Is roofing felt needed under asphalt shingle roofs?

Here we review these roofing felt questions: Is roofing felt needed under asphalt shingle roofs?

Roof shingle warranty requirements for roof shingle underlayment. NRCA recommendations for roofing felt underlayment.

Permeability of felt underlayments in hot humid climates.

What are the benefits from using roofing underlayment or felt? What problems can occur when using a roof shingle underlayment?

Our photo (page top) shows felt underlayment in good condition as a worn out roof was being stripped. It looks as if the installer of asphalt roof shingles (still visible at below right but now worn out) may have placed roofing felt on top of a still older wood-shingle roof.

Above is a peel-and-stick mineral surfaced roofing underlayment shown during installation of a metal standing seam roof installed by the author and builder Eric Galow.

Because we anticipated a delay in the delivery of the standing seam metal roof we covered the entire roof surface with a peel-and stick heavy-duty roof underlayment.

But on most roofs 15# or 30# felt is sufficient for the body of the roof surface.

Article Contents

- ROOFING FELT REQUIRED AT ALL ?

- ROOFING FELT CODES & SPECIFICATIONS

- ROOFING FELT, REASONS for USING

- ROOFING FELT on STANDARD SLOPED ROOFS

- ROOFING FELT on LOW SLOPED ROOFS

- ROOFING FELT & EAVES FLASHING

- ROOFING FELT & DRIP EDGE FLASHING

- ROOFING FELT INSTALLATION DETAILS

- ROOFING FELT USE IN HOT CLIMATES?

- ROOFING FELT / UNDERLAYMENT CODE & SPEC HISTORY

Is Roofing Felt Underlayment Needed Under Roof Shingles, Tiles, Slate, Wood Shingles or Shakes?

As stated in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

The roof deck should be sound and level before laying the underlayment. Fifteen-pound or heavier felt underlayment is required by code in some areas. Whether or not it is required, underlayment is cheap insurance against problems. There are several good reasons to install underlayment:

- It protects the roof deck from rain before the roofing is installed.

- It provides an extra weather barrier in case of blow offs or water penetration through the roofing or flashings.

- It protects the roofing from any resins that bleed out of the sheathing.

- It helps prevent unevenness in the roof sheathing from telegraphing through the shingles.

- It is usually required for the UL fire rating to apply (since shingles are usually tested with underlayment).

Our OPINION is that on new asphalt shingle, tile, fiber cement, slate, and many wood roofs, most roofing contractors apply an underlayment membrane of roofing felt ("tar paper"), or fiber-reinforced roofing felt. A special underlayment may be recommended by the manufacturers of specific roofing product and hybrid products.

Our photo (left) shows new felt underlayment in place during an asphalt shingle roof installation in New York.

While the requirement for felt underlayment beneath asphalt roof shingles seems to be a topic of almost timeless argument subject to much arm-waving and little reading of manufacturer's instructions and warranties, various sources recommend or require installation of a felt underlayment over the roof deck before asphalt roof shingles are installed.

Booth & Roberts reported at length on the uses of underlayments on asphalt shingle roofs, citing (quoting):

Asphalt shingle underlays are commonly used throughout North America. The National Roofing Contractors Association’s (NRCA’s) definition of underlay(ment) includes some important functions:

- To separate the roof covering from the roof deck

- To shed water

- To provide secondary weather protection

The authors point out that

"Resins from green lumber roof decks have been known to interact with roof shingles, and a separation layer of underlay can be useful. Underlays are quickly applied and they can provide temporary roofing before the roof shingles are installed. Underlays have remained intact after shingles have blown away, thereby providing temporary roofing [7].

Underlays provide secondary weather protection in ice-dam situations, when water backs up over the head-laps of shingles.

Other functions of underlays have been reported [8]. Two of the more important ones are air-flow resistance and moisture storage.

Air-flow resistance reduces windblown water penetration from the outside and moist air penetration from the inside of a roof. Moisture storage provides temporary storage for small amounts of leak water, which subsequently evaporates in dry weather. We know of no experiments that quantify these advantages.

There are disadvantages to underlays. Felt materials can wrinkle and buckle, and these imperfections can telegraph through the finished shingle layer [8,9].

Peterson reported

that underlays reduced the life of roof shingles in

California due to heat build-up [10]. Explaining how an

underlay will act as secondary weather protection when it

has shingle nails through it every 8 inches (203 mm) or so

can be a challenge.

The liquid water transmission test in

ASTM D 4869 for asphalt felt underlayments for shingles

[11] includes the following note:

“Take care to ensure that the staples do not protrude at the front surface of the plywood board so as not to puncture the test specimen,” this is hardly realistic. Slipperiness and poor ultraviolet (UV)"

NRCA, Building Code, & Manufacturers Recommend or Require Felt Underlayments on Shingle Roofs

Booth & Roberts and other sources also report that underlayment is required or recommended below shingles. [Reference numbers are to references in the cited document.]

NRCA: NRCA recommends underlays on all shingle roof systems without exception [1]. A 1990 survey indicated that 79 percent of U.S. roofing contractors always used underlays [12].

Roof Warranty: The absence of underlays can invalidate some manufacturers’ warranties and roof system fire classifications [13].

Manufacturer's Requirements: typical requirements found in roof shingle manufacturer's installation instructions specify the use of underlayment:

Non-perforated, [Type I, No. 15] [Type II, no. 30], asphalt saturated felt complying with ASTM D 226, ASTM

D 4869 or ASTM D 6757. - Oakridge Pro30 ™ shingle instructions.

Canadian building codes do not require general (full roof) underlays under roof shingles. Many Canadian roofing contractors use general underlays, while others do not. Typically, underlays are used more over wood plank roof decks and less over plywood. Underlays are more likely to be used on lower-sloped roof systems than on steeper sloped roofs.

There also are provincial preferences, for example, Ontario roofing contractors tend to use underlays less than their neighbors in Québec.

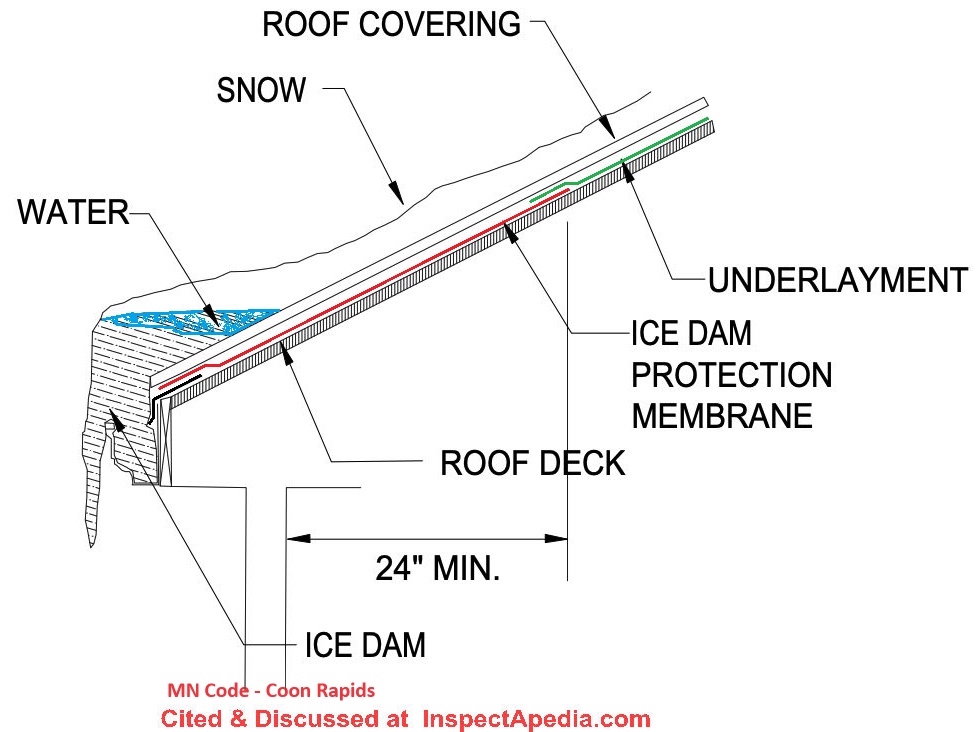

Local building code requirements: here is an example from Coon Rapids, Minnesota

All dwellings, structures attached to dwellings, and all conditioned (heated and/or cooled) structures, require eave flashing to be installed at the eaves and extending on the roof to a point even with 24” past the inside wall line

. This barrier shall consist of at least two layers of underlayment cemented together, or be a self-adhering polymer modified bitumen sheet (many times referred to as ice dam protection or ice and water shield).

It must be installed the full length of all valleys. On roof slopes of 2/12 to 4/12 the remainder of the roof shall be two layers of 15# felt (applied in shingle fashion), or 1 layer of ice dam protection. On 4/12 or greater slopes, the balance of the roof shall be one layer of 15# felt.

Five Best-Practices Reasons for Using Roofing Felt Underlayment

Best Practices Guide to Residential Construction lists five good reasons to install roofing underlayment:

- Roofing underlayment or felt protects the roof deck from rain before the roofing is installed.

- Roofing underlayment or felt provides an extra weather barrier in case of blowoffs or water penetration through the roofing or flashings.

- Roofing underlayment or felt protects the roofing from any resins that bleed out of the sheathing.

- Roofing underlayment or felt helps prevent unevenness in the roof sheathing from telegraphing through the shingles.

- Roofing underlayment or felt is usually required for the UL fire rating to apply (since shingles are usually tested with underlayment).

The roof deck should be sound and level before laying the

underlayment. Fifteen-pound or heavier felt underlayment

is required by code in some areas. Whether or not it is

required, underlayment is cheap insurance against problems.

Underlayment On Standard Slopes where Asphalt Roof Shingles are Installed

As stated in Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

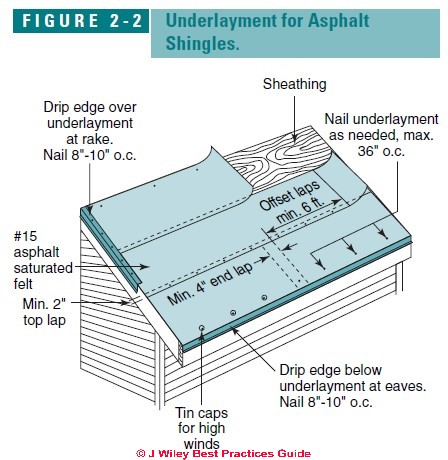

On roofs with a slope of 4:12 or greater, use a single layer of 15 lb. asphalt-saturated felt, starting at the eaves and lapping upper courses over lower by a minimum of 2 inches. Vertical joints should lap a minimum of 4 inches and be offset by at least 6 feet in successive rows (see Figure 2-2 above).

Secure each shingle course along seams and edges with enough corrosion-resistant nails to hold it in place until the roofing is installed.

In high-wind areas, apply fasteners a maximum of 36 inches on-center along overlaps.

Run Felt over Ridges & Hips

For best protection against leaks, run felt 6 inches over ridges and hips, from each direction, and 6 inches up any adjoining walls.

Valleys should be lined with a full width of roofing felt (or bituminous membrane) pushed tight into the valley so there is no slack.

Side courses of underlayment should run over the valley lining and extend 6 inches past its edge.

Line Roof Valleys with Felt, Ice & Water Shield, etc.

Also see ASPHALT SHINGLE VALLEY FLASHING or see page 59 in the printed text Steve Bliss - Best Practices Guide to Residential Construction - (J Wiley)

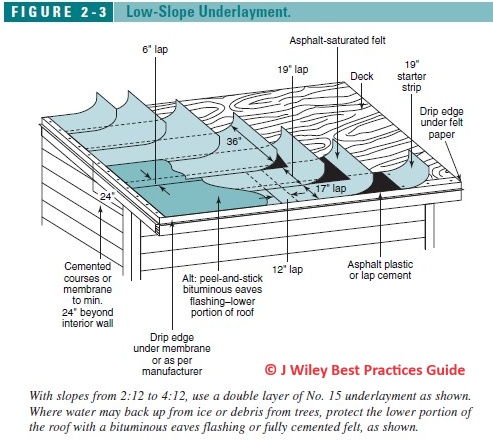

Underlayment Application of Asphalt Shingles on Low Slope Roofs

Continuing from from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) :

Asphalt shingles are permitted on lower-slope roofs with a slope of 2:12 to 4:12 provided that double-coverage underlayment (illustrated above) is installed.

See details

at ASPHALT SHINGLES on LOW SLOPE ROOFS

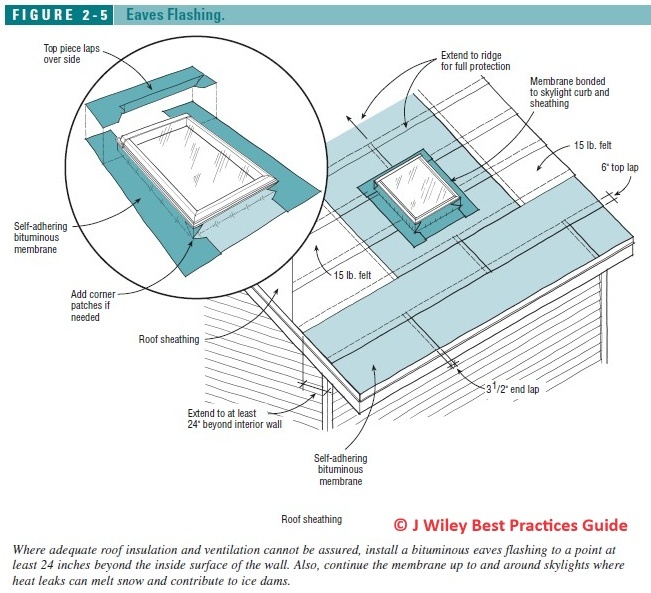

Eaves Flashing Recommendations for Asphalt Shingle Roofs: using ice & water shield

The best defense against ice dams in cold climates is a so-called “cold roof,” consisting of high levels of ceiling insulation separated from the roof surface by a free-flowing vent space (see “Preventing Ice Dams,” page 97 in the printed text Best Practices Guide to Residential Construction).

Where a cold roof cannot be achieved due to complex roof shapes, unvented roofs, or retrofit constraints, ice dams may form during severe winters, in some cases, causing pooled water to wet wall cavities and interior finishes.

Where adequate insulation and ventilation cannot be assured, self-adhering bituminous eaves flashing should be installed. The membrane should go from the lower edge of the roof to a point at least 24 inches inside the interior wall line ( Figure 2-5 at left).

Where two lengths of eaves flashing meet at a valley, run each across the valley, starting with the length from the roof with the lower slope or lesser height. The valley flashing should later lap over the eaves flashing.

Adapted/paraphrased with permission from Best Practices Guide to Residential Construction.

Install Drip Edge Flashing Below Underlayment or Ice-Dam Membranes at Roof Eaves & Gable Ends

[Click to enlarge any image]

Our photo above illustrates several details of roof drip edge, eaves flashing, and gable end flashing at an asphalt-shingle re-roof job we documented in Dutchess County, New York. From left to right:

- Green arrow:

points to the white aluminum drip edge installed at the lower roof edge. Drip edge is also sold in brown, black and some other colours.

Drip edge flashing directs roof runoff away from the roof fascia and edge and into gutters or at least not down the fascia board (if no gutters are installed) and it is recommended by roofing standards, manufacturers, and experts.

See DRIP EDGE FLASHING for ROOFS for complete details about installing drip edge.

- Orange arrow:

points to the installation of ice and water shield along the lower roof eaves - protecting against ice dam leaks that are common on un-vented roofs in cold-weather or snow-climates.

Install the ice and water shield membrane so that it laps securely over and bonds to the surface of the drip edge. The membrane does not have to extend fully to the outer edge of the drip edge flashing, but it should be on top of the upper surface of the drip edge in a best-practices roofing installation.

Otherwise as we repeat just below, some water is going to run under the drip edge rather than be directed off of the roof surface.

Watch out: if the roof is not using peel-and-stick eaves flashing membrane (ice and water shield), you will use roofing felt in this location. In that installation the lower edge of the felt must be on top of, not underneath the drip edge.

That is, the drip edge flashing is the first item installed onto the roof sheathing (or atop old shingles in a multi-layer shingle re-roof job). If you install the drip edge on top of the felt, any condensation or water running down the roof surface between shingles and felt will run underneath the drip edge, down the fascia, and perhaps into the building soffit or walls - not a nice thing.

See PEEL & STICK FLASHING MEMBRANES

and also

see ICE DAM PREVENTION on ROOFS - Blue arrow:

points to the first course of 15# roofing felt on this roof. The lower edge of the felt is overlapped 3-4" on top of and over the upper edge of the lower course of ice and water shield. - Brown arrow:

points to the first shingle course, doubtless installed as a reference point for this roof job.

Install the starter course (normally a 3-tab shingle installed upside down or a solid asphalt strip) so that its low edge is parallel to the drip edge and extends no more than 1/4" past the drip edge itself. Longer overlaps of asphalt shingles past the drip edge will hang over into the gutter, will send roof runoff off of the roof rather than into the gutter, and will eventually crack, break, and look gross.

See OVERSHOOTING GUTTERS

Just below we illustrate shingles installed with too much overhang into the gutter. - Pink arrow:

at the right of the roof along the gable end we see more drip edge being used to flash the roof gable end fascia / trim and roof edge.

I prefer to install the gable drip edge under the felt though that detail is less critical than at the lower roof edge or eaves. When understanding all metal flashings on buildings it makes sense to consider the direction in which water wants to flow: normally "down" (though small up-flows occur by capillary action).

See DRIP EDGE FLASHING for ROOFS for complete details about installing drip edge.

Roofing Felt Installation Details - omitted felt & felt specifications for various roof pitches or slopes

Reader questions on roofing felt installation specifics

Hi Dan, a couple of roofing questions:

1) We often see roof felt stopped short of the eaves.

Builders argue its not a problem. I once had a written opinion from NRCA stating felt needed all the way to the eaves but can't find it anymore. Any known reference clearly indicating need to felt to eaves?

2) Asphalt shingles on less than 2:12 pitch,

builder says ice&water shield under it, I know that's not OK but again any reference source you may know of?

Hope all is well in NY land, nice here in Raleighwood. - Steve Smallman - June 28, 2014 - Mr. Smallman is a professional home inspector in Raleigh NC - Ed.

Reply:

Thanks for the important questions Steve:

1. Felt underlayment omission from some roof areas:

this defect - taking a shortcut by leaving off some roofing felt, is an example of a wider problem: building codes & standards writers have given up on trying to anticipate every possible way that people can make a mistake, shifting instead often to "performance" codes that give the general intent of the code. So we'll have trouble finding an explicit citation for your question part 1.

But a reading of roof shingle manufacturer's specifications for using an underlayment (and the article above which is nicely researched) does not find any exceptions that allow leaving out some of the coverage area.

I'd excuse the omission of felt at the eaves and at rake edges of a roof IF instead the roofer is installing a stick-down impermeable barrier such as ice and water shield. Otherwise it's a mistake.

Also see ROOFING UNDERLAYMENT BEST PRACTICES

Quoting from NRCA you'll notice that nothing in NRCA's language refers to an "exception" for some roof areas where underlayment is required:

"Underlayment (or "felt paper" as it is frequently called) is installed over the roof deck before the application of asphalt shingles. An underlayment performs two primary functions: it provides temporary weather protection until the asphalt shingles are installed, and it provides a secondary weatherproofing barrier if moisture infiltrates the asphalt shingles."

2. Applying shingles on low slope roofs (< 4:12)

is discussed in detail

at ASPHALT SHINGLES on LOW SLOPE ROOFS

and also

at LOW SLOPE ROOFING - home

Please take a look. Ice and water shield over the entire roof should work ok and would be an update to the older method described by carson Dunlop Associates' sketch at inspectapedia.com/roof/0016s.jpg

- for asphalt shingles, NRCA recommends a single layer of no. 15 asphalt-saturated underlayment be used with roofs having slopes of 4:12 (18 degrees) or greater.

- for roof slopes between 3:12 (14 degrees) to 4:12 (18 degrees), NRCA recommends a minimum of two layers of no. 15 underlayment. if you are installing a heavier-weight shingle with a projected long service life, using no. 30 underlayment instead of no. 15 would be appropriate.

Inadequacy of Roofing Felt as a Vapor Barrier for Asphalt Shingles in Hot Humid Climates?

A Building Sciences Corporation report [at the citations section of this article] lso elaborates the usefulness of placing a vapor barrier on the roof deck below shingles in hot humid climates. BSC points out that: [some paraphrasing -DF]

A Building Sciences Corporation report [at the citations section of this article] lso elaborates the usefulness of placing a vapor barrier on the roof deck below shingles in hot humid climates. BSC points out that: [some paraphrasing -DF]

Unvented roofs with asphalt shingles in hot humid climates require a vapor barrier between the asphalt shingles and the roof deck. This is because asphalt roofing materials store water from dew or rain.

Thus asphalt shingles form a water reservoir not unlike wood shingle or shake roofs.

The report argues that this stored moisture is driven inwards [presumably as water vapor, not liquid water] when sun strikes the damp or wet roof surface, and it continues to argue that moisture is driven through vapor-permeable roofing paper, felt, and plywood or OSB roof decking, thus ultimately into the attic space

But unlike an asphalt shingle roof nailed [over felt] directly to a roof deck, a wood shingle or shake roof that has been installed using best practices includes a disposal path for water absorbed in the roof surface: an air space between the wood roofing and the roof deck, or the installation of wood roofing over spaced nailers or "skip sheathing".

In cool or temperate climates this does not present a problem because the combination of heavy wetting from due or rain i snot combined with solar heating at high outdoor temperatures, say the authors who go on to argue that that buckled roof shingles observed in the morning (caused by moisture migrating back up from the roof deck) relax during the day.

But on an un-vented roof moisture driven inwards [through the shingles, roofing felt, and OSB or plywood roof decking] in hot humid climates, needs to be addressed.

This phenomenon can typically be ignored in climates other than hot humid climates because the combination of extensive dew formation and solar heating at high outside ambient temperatures is not common.

In vented roofs, this is often manifested in the buckling of shingles early in the morning as the moisture migrates in to the roof deck sheathing and the joints close. This is followed by relaxation and opening up of the roof sheathing later in the day—the buckling disappears.

But in un-vented roofs in hot humid climates, the authors argue that water from the roof surface is drawn upwards in liquid form, by capillary action, between plies of overlapped shingle courses where it passes ultimately through the vapor barrier and through the roof decking to the roof cavity interior.

The driving force of moisture through the roof and into the building is by solar heating according to the authors.

OPINION-DF: from exterior roof inspections at all times of day and seasons, we have not observed this time-related morning roof shingle buckling in the Northeastern U.S. nor in Florida, nor the Southwest, though the authors report the phenomenon.

It is possible that the authors are not quite correct that daily buckling and relaxing of roof shingles can be ignored on a vented roof as harmless, since certainly the product is expected to remain flat, and flexing daily might reduce its anticipated wear life.

With unvented roof assemblies, this inwardly driven moisture must be addressed. The preferred method is to prevent the moisture from entering the roof deck material via the installation of a vapor barrier.

OPINION-DF: we argue at ROOF VENTILATION SPECIFICATIONS that un-vented roofs are not a best building method in any climate.]

Asphalt shingles are quite impermeable to the passage of liquid water directly through them. However the geometry of their installation allows wicking at overlaps. This inwardly driven capillary water is the source for the wetting of the roofing underlayment and roof sheathing.

The material properties of shingles change under elevated temperatures and moist conditions due to their hygroscopic nature. The large vapor pressures resulting from incident solar radiation and the changed material properties are sufficient to drive moisture inward through the shingles.

Roofing felts or underlayments vary greatly in their permeability to water vapor; the typical underlayment used under asphalt shingles in residential construction is quite permeable.

QUESTION-DF: we note that the test chamber constructed by BSC was itself in an enclosed, air-conditioned space, and that the underside of the test chamber roof was at least in part exposed to the air conditioning. It seems possible that the reduced humidity and lower temperatures on the "interior-side" of the test roof may have contributed to moisture behaviors that vary from what occurs in the field.

Attics and under-roof spaces such as in an un-vented "hot roof" cathedral ceiling are certainly not exposed to cool dry conditioned air. BSC may have addressed this concern but we did not find it in the referenced article.

The conclusion of the BSC report is an argument for installation of an impermeable moisture barrier underneath roof shingles, perhaps in place of the traditional and permeable roofing felt.

QUESTIONS-DF:

- What are the differences between the test roof and a roof's behavior in the field?

- How does the impermeable moisture barrier under roof remain impermeable when perforated by shingle nails or staples? What will be the market effects of suggesting entire roofs be underlaid first with a moisture barrier unaffected by roof shingle fasteners such as ice and water shield?

- Why not recommend that all roofs and roof cavities include ventilation in their design, not only solving the possible driven-moisture problem discussed by BSC but also providing for longer shingle life (cooler roof surface) and in cooling climates, possibly reduced building cooling costs?

See also HOT ROOFS in HOT HUMID CLIMATES

History of Roofing Felt & Underlayment Codes or Specifications

Reader Question: When was it made code to have tar paper/felt under shingles?

11 Sept 2015 Doug Nader said:

When was it made code to have tar paper/felt under shingles?

Reply: The history of tar paper or roofing felt goes back to at least the 1800's.

Doug:

"Code" is a bit vague of a question as to come up with a "first required" date for roofing felt in the building codes we'd need to say what code you are asking about: your local, state, country, or model code or what? Most modern codes require complying with the manufacturer's recommendations even if a specific detail or component is not addressed directly in the code.

The history of tar paper or roofing felt goes back to at least the 1800's.

I have not found an exact citation but I believe you'll find the discussion of felt underlayment in the earliest roofing codes. The first U.S. building codes date from 1859 (Baltimore, MD). - Wikipedia ret. 12 Sept 2015

Building codes in the U.K. obtained impetus with the first significant building regulations passes as the "Rebuilding of London Act" passed by Parliament after the Fire of London in 1666. For a U.S. history of the use of and requirements for roofing underlayment or felt see the following patent (I've edited and cleaned up some typographical errors in the Google patent version of this document to restore Josiah Jowitt to his position of honor).

- Jowitt, Josiah or Stanley, Felt, Roofing. "Roofing-felt and its manufacture." U.S. Patent 318,910, issued May 26, 1885.

Note that this patent refers to long-established earlier roofing felt processes. Excerpting:

Roofing-felt as usually made consists of two or more, usually three, layers of felt-paper which have been separately saturated with with coal-tar pitch and pressed together. The layers are thus coated by passing them in extended webs through a tank of hot ,pitch.

They are then passed between pressure-rolls to press them together and squeeze out the excess of pitch, and they are then cooled and dried, and finally wound up in a 'compact roll for the market.

As all the layers are coated with the pitch, the contacting convolutions in the roll are liable to adhere together, particularly in warm weather when the pitch is [softened] by the heat, and when this occurs the material becomes practically valueless, because of the impossibility of unrolling it.

To prevent this adherence of the superposed couvolutions, various expedients have been devised for preventing their contact, such as rolling up a web of Manila paper with the roofing-felt, or sprinkling upon the felt some absorbent powder which is rolled up with it. These precautions are somewhat effective, but entail considerable expense and annoyance both in the manufacture and use of the felt.

The principal object of my invention is to produce a roofing-felt or other similar material which shall be in all respects equal to that heretofore made, and which shall be cheaper, more durable, and heater to handle, and which, above all shall have a non-adhesive surface, so that the convolutions in the roll will not adhere together.

To this end I make the .felt with a dry outer surface, containing only enough tar or pitch to make it waterproof or weather-proof, and confine the heavier or cementing coating of tar or pitch to the interior of the felt-between the surfaces which entirely to the edge of the fabric, but by preference I leave the layers uncemented along each edge, so that the pitch cannot ooze out at the edges of the fabric and cause the confelt made according to my invention.Roofing felt history, development, patents & code citations

- Berg, Bo. "Method of laying roofing felt and means therefor." U.S. Patent 5,526,624, issued June 18, 1996.

- Ernst, Boley. "Roofing nail." U.S. Patent 1,435,134, issued November 7, 1922. - for fastening roofing felt to the roof deck

- Atlas Roofing, FELT ROOF UNDERLAYMENT #30 SATURATED ROOF FELT INSTALALTION INSTRUCTIONS [PDF] retrieved 2021/02/06 original source: https://www.atlasroofing.com/

Excerpt:

Roll out the felt toward the other end of the roof. Leave yourself enough room to pull the felt free of wrinkles and set it even with the eaves. Repeat the nailing pattern and remember not to walk on unnailed felt. Unravel a few more feet of felt and cut it with a utility knife. Trim any felt that overlaps the rake. Nail down the last few feet of the first course of felt.

Position the next course of felt so that there is a 2" overlap of the first course of felt. Use the lines printed on the felt as guidelines for lining up the courses. The bottom of the second course of felt should be on top of the first course so that any moisture will flow over the layers of felt.

Roll out a few feet of felt and align the edge of the felt along the rake and the first course. Remember to leave a 2" overlap. Drive about five nails in the top right-hand corner and roll out the felt about halfway (perhaps 25 feet) across the roof. Stand on the first course of felt and work with the second course of felt above you.

It is not necessary to completely nail the top edge of the course. A few nails to hold the top in place will be adequate because each top row will become a bottom row once you add another course of felt.

Nail down the bottom and middle of the second course of felt with a pattern of nails every 6 to 8 inches. Remember: never walk on felt that has not been nailed down. Continue laying felt over the remainder of the deck using the same techniques.

When you reach the top course, lap about 6 inches of felt over the ridge top. The longer the deck will be exposed to the weather before shingles are applied, the more important it is to lay the felt so that the deck is watertight.

Using a utility knife, slice any wrinkles and nail the felt so that it is smooth. If the deck will be exposed to the weather overnight or longer, apply a very thin coat of asphalt-based roofing cement to waterproof the areas where cuts have been made.- GAF RoofPro™ UNDERLAYMENT APPLICATION INSTRUCTIONS [PDF] (2010) retrieved 2021/02/06 original source: https://www.gaf.ca/Residential_Roofing/Roof_Deck_Protection/RoofPro/RoofPro_Application_Instructions.pdf

Excerpt:

Slopes 4/12 and Greater:

• Install one layer of RoofPro™ Underlayment

• Starting at the eaves, apply a 39 3 /8” (1m) wide sheet of underlayment overlapping successive sheets 2” (51mm).

Lay lines are provided on the product.

• All end laps must be a minimum of 6” (152mm).

• Offset end laps 6’ (1.83m).

• Apply double coverage to all valleys, hips and ridges.- GAF Timberline (and other shingle) APPLICATION INSTRUCTIONS [PDF] (2015)

Excerpt:

UNDERLAYMENT (ROOF DECK PROTECTION):

Underlayment beneath shingles has many benefits, including helping to prevent wind-driven rain from reaching the interior of the building and to prevent sap in some wood decking from reacting with asphalt shingles. When an underlayment is installed, use a breather-type underlayment, such as GAF Shingle-Mate® or Deck-Armor™ underlayments. GAF Tiger Paw™ underlayment, with its moisture control design, can also be used.

Always have a design professional review ventilation requirements when using a moisture control design underlayment. Underlayment is also required by many code bodies and is required to maintain the shingles’ UL Class A fire rating.

When using FeltBuster™ High-Traction Synthetic Roofing Felt as underlayment, it MUST be installed over one layer of VersaShield® Fire-Resistant Roof Deck Protection in order to maintain a Class A fire rating for GAF asphalt shingles.- GAF INSTALLATION INSTRUCTIONS FOR FELTBUSTER® HIGH-TRACTION SYNTHETIC ROOFING FELT [PDF] (2019) retrieved 2021/02/06 original source: https://www.gaf.com/en-us/products/felt-buster/documents

Excerpts:

CHECK FOR PROPER UNDER-DECK VENTILATION.

FeltBuster® High-Traction Synthetic Roofing Felt retards moisture vapor movement. Humid air in the attic may therefore condense as water beneath the FeltBuster® HighTraction Synthetic Roofing Felt, resulting in deterioration of the deck and growth of molds.

A design professional must ALWAYS address the potential for moisture entrapment, excessive moisture build-up, and condensation. Moisturecontrol solutions may include, but are not limited to, use of:

• a continuous vapor barrier in the ceiling

• soffit and ridge vents

• gable vents

• power vents

Be sure to review local building codes in your area for ventilation requirements

STEP 3: Lay Out FeltBuster® High-Traction Synthetic

Roofing Felt.

a) Apply FeltBuster® High-Traction Synthetic Roofing Felt parallel to the eaves.

b) Install without wrinkles. Lay flat, cap nail flat. Do NOT STRETCH during installation.

- GAF, GAF Roof Underlayments & AsphaltApplied Underlayments Florida APPROVAL FL10626R19 [PDF] retrieved 2021/02/06 original source: https://www.gaf.com/en-us/products/felt-buster/documents

- GAF, Code FeltBuste HighTraction Synthetic_Roofing Felt FBC FL18686R4 [PDF] Op. Cit.

- GAF, Notice of Acceptacnce, GF 2-Part Roofing Adhesive Miami Dade Approval [PDF] Op. Cit.

Excerpt:

INSTALLATION:

GAF 2-Part Roofing Adhesive shall be installed in strict compliance with the roof assembly’s Notice of Acceptance, and manufacturer’s published literature.

- GMC Roofing ASPHALT SATURATED FELT UNDERLAYMENT INSTALLATION INSTRUCTIONS [PDF] GMC Roofing & Building Paper Products, Inc. 6400 Zerker Road Shafter, CA 93263, USA, Tel:(661) 399 4324 retrieved 2021/02/06 original source: https://www.gmcpaper.com/wp-content/uploads/2012/01/InstallInstruct_30ASTM226felt.pdf

Excerpt:

At hip and ridge intersections, fasten the top course if it terminates at the top edge of the roof. Otherwise, overlap the underlayment over the hip or ridge and fasten the roofing felt.- Hugh, Lucas Parsons. "Roofing." U.S. Patent 2,205,307, issued June 18, 1940.

Abstract excerpt:

An object of my invention is to provide a slate -roof structure wherein the slate units in each course are laid to expose relatively large areas to the weather so as to p rovide coverage for a relatively large roof area with a relatively small amount of slate, thereby reducing the cost of the roof as well as the load of the slate coverage.

Roofing felt or equivalent material underlies each course of slate for cushioning purposes in addition to providing an effective seal against the entrance of moisture.

I also provide novel means for rendering splices between adjoining strips of roong felt moisture-proof to the end that the roof structure may have moisture-proofed properties throughout in addition to permitting the use of strip material of shorter lengths than the width of the roof.- ICC, International Code Council, Section 1507, Requirements for Roof Coverings

- IBC Building Code, ICC, adopted, Oregon, Chapter 15, ROOF ASSEMBLIES & STRUCTURES, IBC, [PDF] (2004), Excerpt:

UNDERLAYMENT. One or more layers of felt, sheathing paper, nonbituminous saturated felt or other approved material over which a steep-slope roof covering is applied. ...

Underlayment shall be two layers applied in the following manner. Apply a minimum 19-inch strip or underlayment felt parallel to and starting at the eaves, fastened sufficiently to hold in place.

Starting at the eave, apply 35-inch-wide sheets of underlayment overlapping successive sheets 19 inches and fastened sufficiently to hold in place.

1508.3.3 Underlayment.

Unless otherwise noted, required underlayment shall conform to: ASTM D 226, Type II; ASTM D 2626 or ASTM D 249 Type I mineral-surfaced roll roofing.

1508.3.3.1 Low-slope roofs.

For roof slopes from 21/2 units vertical in 12 units horizontal (21-percent slope), up to four units vertical in 12 units horizontal (33-percent slope), underlayment shall be a minimum of two layers applied as follows:

1. Starting at the eave, a 19-inch (483 mm) strip of underlayment shall be applied parallel with the eave and fastened sufficiently in place.

2. Starting at the eave, 36-inch-wide (914 mm) strips of underlayment felt shall be applied overlapping successive sheets 19 inches (483 mm) and fastened sufficiently in place.

1508.3.3.2 High-slope roofs.

For roof slopes of four units vertical in 12 units horizontal (33-percent slope) or greater, underlayment shall be a minimum of one layer of underlayment felt applied shingle fashion, parallel to, and starting from the eaves and lapped 2 inches (51 mm), fastened only as necessary to hold in place.- Overbury, Frederick C. "Process of making roofing felt or like material." U.S. Patent 1,558,495, issued October 27, 1925. Abstract excerpts:

This invention has for its object to produce a fibrous material which will possess strength and flexibility and also marked fireproof qualities....

According to my invention and to meet the object thus specified, I provide a multiply sheet formed of layers of paper felt and asbestos, the fibers of the several layers being intermingled and adherent, so 25 that the sheet is an integral structure.

In the manufacture of this sheet, the paper felt layer a is formed of cotton and wool or other suitable fiber in the usual manner, into a wet pulpy web, upon which is deposited a wet pulpy web of asbestos fiber b.

These'may be then subjected to a felting action in a machine or apparatus of the ordinary construction, or be dried in the usual dryin machine, thus producing a sheet, one face of which is paper felt (so-called) and the other face of which is asbestos, the two layers being interlocked I together by the intermingling of their fibers without the use of any foreign binder or cement.

It is quite apparent that the sheet may consist of more than two layers of the asbestos and of the Wool fiber, as for instance the layer of asbestos can be laid between the layers of Wool felt, or vice versa.

After the sheet has been dried into a porous absorbent condition, it then may be saturated with asphalt or any other of the usual waterproofing compositions which are employed in the manufacture of prepared roofings, and then faced, preferably on the wool-felt side, with a layer of high-meltingpoint asphalt or pitch a, as shown in Figure Renewed November 14, 1919. Serial No. 338,118. produce commercially a roofing material which is substantially fireproof.

It has been proposed to cement together, as by the use of pitch, sodium silicate, or the like, a layer of asbestos upon a layer of roofing felt, but this increases the cost of production of the roofing material.

Sheet asbestos, when sufiiciently thin to be used alone, does not possess the necessary tensile strength, whereas wool felt alone, while relatively slow-burning when impregnated as described, does not really possess the desirable fireproof qualities.

According to my invention, I provide a single integral sheet, in which the strength is afforded by the felt layer, and the fireproof qualities of the asbestos layer. It is unnecessary herein to describe the operations by which the raw material, cotton ,or wool rags, or the asbestos, are disintegrated and reduced to awet fibrous pulp, or the machines by which they are formed into webs 01'' layers, as the same are well known.

If desired, the sheet may have only the felt layer saturated or coated, or both, with a waterproofing or non-heat-conducting compound, or the asbestos layer may be saturated or coated, or both, in either instance leaving the other layer untreated, this being of course subject to particular requirements.

While the composite sheet as herein described is particularly applicable for use in the manufacture of flexible waterproof roofing, yet its use is not confined thereto, as it may be employed for a variety of other uses.

For instance, but without limitation, the sheet may be'employed for the purpose of insulation, or as a flooring, or for other purposes. For some purposes, the sheet may be so treated as to saturate with a waterproofing or non-heat-conducting compound only the fibrous layer, leaving the asbestos layer unsaturated, or vice versa.

What I claim is The herein described method of producing-a flexible composite sheet of fibrous material, consisting in bringing into face contact two layers of wet pulpy felted fiber and asbestos fiber, causing the said fibers of said layers to interlock, and then drying the sheet thus formed.- Wilson, James. "Apparatus for laying roofing-felt." U.S. Patent 1,278,272, issued September 10, 1918.

- THE USES AND PERFORMANCE REQUIREMENTS OF STEEP-SLOPE ROOF UNDERLAYS IN NORTH AMERICA AND THE UNITED KINGDOM [PDF] Robert J. Booth, Keith Roberts, Proceedings of the North American Conference on Roofing Technology, p. 112-118 - Web Search 07/12/2010.

This scholarly article cites 33 research articles on the role of roofing underlayments.- Also see theReferences or Citations section of this article

- Also see STANDARDS for ROOFING and WARRANTIES for ROOF SHINGLES (live links below)

...

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

GAF specifies lapping felt over roof ridge - is this in the roofing codes?

I researched this in manufacturers instruction manuals and found that GAF, Owens Corning and Certainteed require the 6" lap over the ridges and hips.

This is Direct quote from GAF:

For ridges, the underlayment should … be lapped over the ridge at least 4” (102 mm) to 6” (152 mm) as would be done on a new or complete tear-off installation.

I read that as a good practice is to run felt 6 inches over ridges and hips, from each direction, and 6 inches up any adjoining walls. Is this mentioned in IRC or any other publications? - On 2021-02-06 by George M -

Reply by (mod) - lap roofing felt over hips & ridges but ... cut through at ridge for ridge vent installation

George

Thanks for the roofing felt overlap at ridge and hip question. IBuilding codes require that we comply with roofing product manufacturer's instructions.

Felt lapping requirements appear as a manufacturer recommendation in the article above - and you've reminded us of it once again.

The "code" requirement for overlapping felt at the ridge (during construction) derives from general building code statements requiring that the manufacturer's roof installation recommendations be followed.

Where I've installed asphalt shingle roofs, because usually we are going to cut out a vent opening along the ridge, there was no point in lapping felt over the ridge top except when the roof and building below are going to be left exposed to the weather before the shingle and ridge vent installation have been completed.

We don't, of course, install ridge vents on hips but there are special venting products for roof hips where that's needed.

I would be grateful if you could point me to the source where you read that lapping felt over ridges and hips is desirable - that way I could look for more-authoritative citations on the topic.We should not forget however that the felt at a ridge is going to be cut away for the ridge vent opening. So it won't be continuous over the ridge as the roof is completed.

In the original article above on this page we agreed with your point, as Steve Bliss put it at "Run Felt over Ridges & Hips"

For best protection against leaks, run felt 6 inches over ridges and hips, from each direction, and 6 inches up any adjoining walls.

Valleys should be lined with a full width of roofing felt (or bituminous membrane) pushed tight into the valley so there is no slack.

Side courses of underlayment should run over the valley lining and extend 6 inches past its edge.

The blocking of the ridge vent opening above by roofing felt is improper. So we can see that even if the installer complies with the GAF instructions, following additional instructions to install proper roof exit ventilation at the ridge, that felt has to be cut away.

Really? well yeah but ...

The Atlas Roofing felt underlayment instructions specifically state:

When you reach the top course, lap about 6 inches of felt over the ridge top. The longer the deck will be exposed to the weather before shingles are applied, the more important it is to lay the felt so that the deck is watertight.

The GF RoofPro felt application instructions (cited above on this page) require "Apply double coverage to all valleys, hips and ridges."

The GAF instructions for the company's Timberline shingles and for GAF FeltBuster high-traction synthetic roofing felt provided in PDF format above make no mention of this "lap over the ridge" detail.

Bottom line: So where does this "run the felt over the hip and ridge" requirement come from?

- Protect the building during construction:

Often a roof is considered "watertight" and left exposed to the weather with just felt underlayment installed - something that is acceptable provided the felt is properly-installed and the weather exposure is not excessive in duration or conditions. Lapping over the ridge helps assure that the roof remains weather-tight during this eipsode in building construction.

Once the roof shingles, including ridge cap shingles and/or ridge vent have been installed, that overlap detail becomes moot, as I've explained. The felt at the ridge will be cut away at the ridge for ridge venting installation.

- Heard of omission of the uppermost courses of felt:

Having seen some roofs where the installers were in a bit of a rush, didn't care about roof longevity, and used the manufacturer's installation instructions to sit upon during lunch, I've seen the last course of felt near the ridge omitted entirely. It's possible that manufacturers are trying to head off those taking such a shortcut.I'd be grateful to see the specific reference that you found, George as that would be helpful to other readers too.

When did double layer underlay (roofing felt) become standard code?

Does anyone know around what year did double layer underlay become standard code?

Does anyone know around what year did double layer underlay become standard code?

Not looking for exact dates just around about time frame - On 2020-09-06 by Charles -

Reply by (mod) - since at least 1970s, we use double coverage underlayment on low slope roofs and possibly at eaves.

Charles

From our review of many 1970s building codes and possibly earlier, I have not found a building code that requires "double underlayment" for the entire roof surface, on all roofs but

double coverage underlayment or "felt" is indeed recommended on low-slope roofs (roof pitches between 2 in 12 and 4 in 12 inches), as we illustrate above as well as earlier on this page.

Steve Bliss' Building Advisor, explains that there are (best practices) shown in his illustration just above:

Double layer on low slope roofs: 2-ply underlayment roof systems

(half overlap 19" or 50% overlap of each successive course of underlayment over the one below) - illustrated above in figure 2-3

and also

Single layer on steep slope roofs: 1-ply roof underlayment systems

that overlap the felt just 4" horizontally and 2" at vertical lap joints (used on steep slope roofs above 4 in 12 inches in pitch) - illustrated below in figure 2-2

Steve's own article on How to install two-ply roof underlayment is at https://buildingadvisor.com/how-to-install-two-layer-roof-underlayment/ - use your browser's "BACK" button to return to InspectApedia.com

Double felt for ice dam protection?

Also some building or roofing codes require two layers of felt, cemented together, at the lower roof edges where there is risk of ice dams - as an alternative to a self-adhesive ice and water membrane.

For an example see our ice dam prevention illustration below that is adapted from this 2010

ASPHALT SHINGLE ROOFING [INSPECTION & INSTALLATION GUIDE] [PDF] Coon Rapids Minnesota, Coon Rapids City Hall 11155 Robinson Drive Coon Rapids, MN 55433 763-755-2880, -

Web search 07/12/2010

City Website - http://www.ci.coon-rapids.mn.us/ Contact the City of Coon Rapids at 763-755-2880

Web search 07/12/2010

City Website - http://www.ci.coon-rapids.mn.us/ Contact the City of Coon Rapids at 763-755-2880

- illustrated here with color additions added for clarity by InspectApedia.

To find the dates for applicable roofing codes that apply to you we'd need to know the country and city where you reside or the locations of the buildings of concern.

In my OPINION self-adhesive waterproof ice and water shield membranes, because they seal around the shingle nails, are a better approach to ice dam protection than double underlayment.

Still better is to design a roof that won't suffer from ice dams at all, either by good under-roof ventilation

or by a super-insulated "hot roof" design (as a second-best alternative).

See ROOF ICE DAM CURE: COMPARING TWO HOUSES

for a dramatic example of eliminating ice dam leaks by good roof ventilation.

What year did underlayment requirements take effect in Ohio?

What year did ice barrier underlayment requirement code go into effect in Hamilton County, Ohio? - On 2021-05-18 by Sandra

-

Reply by danjoefriedman (mod) - 1973 or possibly earlier

@Sandra, interesting question, Sandra; My reading of the OH roofing code is that an ice barrier can be formed by more than one means - even today.

905.2.7.1 Ice Barrier

In areas where there has been a history of ice forming along the eaves causing a backup of water as designated in Table 301.2(1), an ice barrier that consists of a least two layers of underlayment cemented together or of a self-adhering polymer modified bitumen sheet, shall be used in lieu of normal underlayment and extend from the lowest edges of all roof surfaces to a point at least 24 inches (610 mm) inside the exterior wall line of the building.

Exception: Detached accessory structures that contain no conditioned floor area. - https://up.codes/viewer/ohio/oh-residential-code-2013/chapter/9/roof-assemblies#9

I could guess 1973, but as our records are not complete, to get the full history of when Ohio adopted the various model building codes you may want to check with your local building department.

Also see HISTORY OF BBS for OHIO [PDF] Ohio State Department of Commerce - Original source: https://www.com.ohio.gov/documents/bbst_BBSAbout.pdf

On 2023-08-31 by mark - Is New Roof Underlayment Required when re-roofing?

does new underlayment have to be installed when we roof any house long is the underlayment is already good

Reply by InspectApedia Publisher (mod)

@mark,

I'm not sure who determines what is meant by the words "already good" in this case.It is nearly impossible to tear off a roof and leave the underlayment intact so I'm very skeptical about that claim. And even if you could do so, that existing underlayment will have thousands of extra nail holes from the previous shingle installation. It may still be able to do its job as a cushion for new shingles but it's benefit as a moisture or water barrier is pretty much nil.

More significant in my OPINION: new roofing felt is an extremely small cost percentage of the cost of a roofing job in a certainly worth that added expense for the added reliability of the roof installation.

I don't think you'll find there's a code or law or rule on this point.

On 2022-06-17 by Toni M Doty - "Condensation" on ceiling in hot humid weather after a new roof

I had a new roof put on.

I had a new roof put on.

Now the hallway ceiling only sweats badly on hot/humid days.

We have lived in house for 20 years and have had no problems before.

Nothing has changed except a new roof.

I even noticed the exhaust fan in bathroom doesn't do the job that it used to.

Reply by InspectApedia-911 (mod)

@Toni M Doty,

Have you checked that the ridge vent is completely open along the entire ridge?

It's possible that the new roof job covered over or blocked the roof ventilation system

- either at the ridge or even at the eaves or soffits.

Check also for new or unusual moisture sources inside your home.

When I inspect properties for an indoor condensation or moisture problem such as that you are describing, I include the entire building in an inspection, starting outside looking for sources of water entry; inside I'd look at the basement or crawl space for water or moisture signs.

I'd also check that the air conditioning system - if present and in use - is working properly as an A/C failure also means a dehumidification failure.

On 2022-06-06 by Brooke - What's the proper underlayment overlap at roof hips?

Underlayment overlap on hips? How much should underlayment overlap on hips for proper installation?

On 2022-06-06 Reply by InspectApedia-911 (mod) - Proper Roof Underlayment Overlap at Hips & Ridges is 4-inches

@Brooke,

Roofing manufacturers such as GAF recommend that at roof hips the felt should be overlapped at least 4-inches. Here are the company's details:

ROOF UNDERLAYMENT SPECIFICATIONS for HIPS & RIDGES [PDF] GAF Corp., 1 Campus Drive, Parsippany NJ 07054 USA, Tel: 877-423-7663 Technical advisory bulletin TAB-R-164, original source: https://www.gaf.com/Excerpts:

For hips, the underlayment should … be lapped over the hips at least 4” (102 mm) to 6” (152 mm) as would be done on a new or complete tear-off installation.

For ridges, the underlayment should … be lapped over the ridge at least 4” (102 mm) to 6” (152 mm) as would be done on a new or complete tear-off installation.

Roofing Underlayment Overlap Over the General Roof Area (the field of the roof): two-ply vs one-ply

In normal roofing underlayment, for example on low slope roofs using 15# felt, over the FIELD of the roof, we overlap 19" or half the underlayment width - in a best-workmanship installation - that gives two layers of underlayment over the entire roof surface.

Really? some sources inluding some roofers note that more-common (at least on steep slope roofs) is to see a 6-inch overlap or even just 2-inch overlap as felt courses step up the roof. What's the difference?

Our sister site, Steve Bliss' Building Advisor, explains that there are (best practices)2-ply underlayment roof systems (half overlap as I just described),

and 1-ply roof underlayment systems that overlap the felt as little as 2" horizontally and just 6" at vertical lap joints.

Steve's article on how to install two-ply roof underlayment is at https://buildingadvisor.com/how-to-install-two-layer-roof-underlayment/

Overlap felt 6" at hips and ridges and up walls?

I read that as a good practice is to run felt 6 inches over ridges and hips, from each direction, and 6 inches up any adjoining walls. Is this mentioned in IRC or any other publications? - On 2021-02-05 by GEORGE M -

Reply by danjoefriedman (mod)

George,

Bottom line: lapping over hips and ridges when installing roofing felt is particularly important if the roof and building and roof are to be left exposed to the weather for a time before shingling and ridge vents or ridge cap shingle installations are complete.Typical codes set a minimum lap of 4" at hips and ridges and in some codes it's 6".

On 2022-01-05 by maureen - What's the best underlayment when building a hot roof in Minnesota?

I'm in minnesota-we have a hot roof (polyurethane foam against the rafters in the attic.

I'm in minnesota-we have a hot roof (polyurethane foam against the rafters in the attic.

Wondering the best underlayment? Tiger Paw & ice/water shield 6' up from the eaves? But Tiger Paw or just regular felt? And we're using Class 4 shingles. Sound good or?

What is the correct underlayemtnfor a 'hot roof' (an attic that has poly-foam on the roof decking & covering all the t=rafters?

Reply by Inspectapedia Com Moderator (mod) - continuous ice and water shield type membrane covering the entire roof, not regular 15# felt

@maureen,

Bottom line: In my opinion, because of the significant risk of very expensive hidden water and rot damage should leaks occur in a hot roof design I prefer to make those roofs as bullet-proof as possible. That means accepting the modest additional cost of covering the entire roof in a self-adhesive continuous waterproof membrane.

All of the brands of self adhesive waterproof membranes (products that seal around roofing nails) should work fine.

Examples include

- Blueskin WP200 Self-Adhered Waterproofing Membrane

- GAF Liberty Cap Sheet

- GAF Stormguard Peel

- MS-300 Ice and Water Armor Underlayment

- WR Grace Ice and Water Shield

Details:

Let's be clear about your roof design: Where is the foam? On top, really ? Or on the underside of plywood decking?Normally a foam insulated roof will fill or partly-fill the under-roof space between rafters by being sprayed up under the roof sheathing surface as you can see in my foam insulation photo just below - this was an open-celled foam insulation job under a metal roof supported by wood I-trusses in a New York building.

If the roof will be exposed to the weather for days before the metal goes on, or as good general practice anyway, we cover the whole assembly with ice and water shield.

However according to most roofing manufacturers, provided your roof covering manufacturer's instructions agree, ordinary roofing elt is also acceptable except at areas where ice dam leaks are at risk.Be sure you see our hot roof design details

On 2020-10-25 by Lee - what is that half-inch thick layer over the plywood on mg 1954 rolled asphalt roof?

I know about 15# and 30# felt but what is half inch thick sheet OVER the plywood on my near flat 1954 rolled roof?

On 2020-10-26 - by (mod) - Fiberboard sheathing?

That's most likely a layer of insulation, probably a wood fibre or fiber board product. Search this website for

FIBERBOARD SHEATHING IDENTIFICATION

to see examples

On 2020-09-19 by Trent - OK to put modified bitumen over skip sheathing ?

Can you install modified bitumen over spaced decking in Oregon.

On 2020-09-20 - by (mod) - NO

We need continuous solid decking

On 2020-09-14 by Robert Parker - Need cure for water backing up under the underlayment and starter shingle course

New asphalt shingles installed over 3:12 roof using synthetic felt as per mfg instructions: eg, double layer a eves with 22" overlap on

succeeding layers.

Drip edge under underlayment on eves and over on gable ends. Massive capillary action from heavy fog condensate

leaking under both layer of underlayment and starter shingles. What's the cure?

On 2020-09-14 - by (mod) - peel and stick ice and water shield along lower roof edge

Sounds as if you want to remove the lower courses of shingles and install ice and water shield, then re-shingle.

On 2018-01-21 by donna - Can I use roofing felt to cover basement ceiling insulation?

can this felt underlyng material be used to cover insulation in a basement ceiling?

will it be safe we live in rhode island

On 2018-01-21 by (mod) - NO, don't use felt as a basement ceiling cover

No.

There are concerns for both fire safety and for trapped moisture .

Check with your local building department: if the basement is occupied space you're probalby required to install a fire-resistant covering such as drywall.

On 2017-12-01 by dj - Is this underlayment recommended for flat roofs?

Is this underlayment recommended for flat roofs?

On 2017-12-01 - by (mod) - NO

DK

Use of felt on a flat roof would be less common. On a flat roof the surface is waterproof membrane

You would indeed find heavier 30# felt used in multiple plies in a traditional built up tar and gravel roof

That's a different system.

On 2017-11-06 by carole brinkert : New roof without drip edge, underlayment: it leaks; where do I get an inspector?

New roof installed, an have had nothing but leaks, no drip edge either...water is wicking up into the roof!! Were can l get an inspector or do l need a lawyer too?

On 2017-11-07 by (mod) - bad roof job, leaking, where do I get an inspector

I would start by focusing on identifying what needs to be fixed on the roof and having those problems corrected as quickly as possible in order to avoid expensive damage to the building. In the experts directory at the top of any of our Pages you may find a home inspector who is able to help you.

On 2017-11-06 by Tom - how many layers of felt were actually installed under the shingles?

I have a doublewide mobile (low slope) that the contractor says he put double felt on. I was not on site that day. Roof is now coverded in 30 year composite shingle. The city inspector says it's single layer of felt.

With flashing all around the edge of the roof I'm wondering where he's looking? Contractor is standing by his statement. How do I tell?

On 2017-11-06 by (mod) - OK to use single layer underlayment on steep slopes (lapped at least 6"), and double coverage felt on low slope roofs (lapped 50% each course)

Tom,

A detailed answer to your question about determining whether or not the roofer used single or double felt underlayment is given at

Thanks to readers for kind compliments about InspectApedia

On 2021-04-08 by Orange county roofing - Thanks, for this great article

Orange county roofing said

Thanks, for this great article many bloggers and marketers would really get a great amount of priceless information from this post. Bless you.

...

Continue reading at ROOFING UNDERLAYMENT BEST PRACTICES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see ROOFING FELT UNDERLAYMENT REQUIREMENT FAQs questions & answers posted originally at this page.

Or see these

Recommended Articles

- ASPHALT ROOF MATERIAL ASBESTOS

- BUILDING CODE DOWNLOADS - free downloadable PDF files of building codes & standards

- DRIP EDGE FLASHING for ROOFS

- ROOFING FELT UNDERLAYMENT REQUIREMENTS - home

- ROOF LEAK SOURCE DIAGNOSIS

- ROOF VENTILATION SPECIFICATIONS - home

Suggested citation for this web page

ROOFING FELT UNDERLAYMENT REQUIREMENTS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "Unvented Roofs, Hot-Humid Climates, and Asphalt Roofing Shingles Research Report - 0306 Feb-2003 Building Science Corporation", Building Science Corporation, 30 Forest Street, Somerville, MA 02143

Quoting from the article abstract:

"When constructing unvented roofs with asphalt shingles in hot-humid climates, a vapor barrier must be installed between the asphalt shingles and the roof deck." - Web Search 5/21/2010 - NRCA Roofing & Waterproofing Manual, 5th Edition, National Roofing Contractors Association, 10255 W. Higgins Road Suite 600 Rosemont, IL 60018-5607 Telephone: (847) 299-9070 Toll Free: (866) ASK-NRCA (275-6722), e-mail: info@nrca.net. - http://www.nrca.net/rp/pubstore/details.aspx?id=243&c=9

- Asphalt Shingle Roofing [Inspection & Installation Guide] [PDF] Coon Rapids Minnesota, Coon Rapids City Hall 11155 Robinson Drive Coon Rapids, MN 55433 763-755-2880, - Web search 07/12/2010 City Website - http://www.ci.coon-rapids.mn.us/ Contact the City of Coon Rapids at 763-755-2880

- Oakridge Pro30™ shingle installation instructions [PDF] for Owens Corning Oakridge® PRO 30™ fiber glass-based asphalt shingles - Web Search 07/12/2010

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- Steve Smallman, Raleigh, NC, Email: steve@stevesmallman.com, Website: http://stevesmallman.com/ - Quoting: Steve Smallman Property Inspections (SSPI) inspectors have performed or supervised over 25,000 inspections since we introduced home inspections to the Triangle area in 1980. Mr. Smallman is a contributor to InspectApedia.com and has commented on or provided information on plumbing traps, commercial FPE electrical panels and DIY Tests of FPE equipment,, roofing underlayment, and building exteriors.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for this article. All rights and contents are ©Journal of Light Construction and may not be reproduced in any form.

- Asphalt Roofing Residential Manual from ARMA the Asphalt Roofing Manufacturers Association Website https://www.asphaltroofing.org/product/residential-asphalt-roofing-manual/ ,

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.