Wood Roof Sheathing & Underlayment Requirements

Wood Roof Sheathing & Underlayment Requirements

- POST a QUESTION or COMMENT about the requirement for sheathing & underlayment (felt) beneath wood shingles or shakes

Wood roof sheathing & felt requirements:

This article discusses the requirements & specifications for roof sheathing (nailers or plywood or OSB) and underlayment (roofing felt) or interlayment (between shingle courses) for wood shingle & wood shake roofs.

This article series discusses best practices in the selection and installation of residential roofing. Our page top photo shows a wood shingle roof on the historic Mesier Homestead in Wappingers Falls, NY.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

- Daniel Friedman, Publisher/Editor/Author - See WHO ARE WE?

Sheathing or Nail-Base Specification for Wood Shingle & Shake Roofs

Adapted/paraphrased with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , chapter on BEST ROOFING PRACTICES:

Other than selecting a durable wood, the most important factor in determining a wood roof’s longevity is its ability to dry out from both top and bottom when wet.

While this was a natural feature of traditional installations over spaced sheathing, new methods and products are required for installation over solid sheathing.

[Click to enlarge any image]

The two main approaches are:

- Create a system of spaced sheathing above the solid sheathing using vertical and horizontal battens; or

- Use a breathable underlayment applied over the sheathing.

Specifications for Spaced Sheathing or "Skip Sheathing" for Wood Shingle & Shake Roofs

The traditional way to lay wood

shakes and shingles on spaced sheathing was ideal for

wood roof longevity, but it has largely fallen by the wayside.

The traditional way to lay wood

shakes and shingles on spaced sheathing was ideal for

wood roof longevity, but it has largely fallen by the wayside.

Spaced sheathing is especially beneficial in warm, high-moisture climates, since the gaps in the substrate allow the shakes or shingles to dry out from both sides.

Installing wood shingles or shakes over skip sheathing is not recommended in areas of windblown snow and not always permitted structurally.

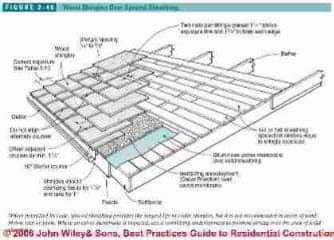

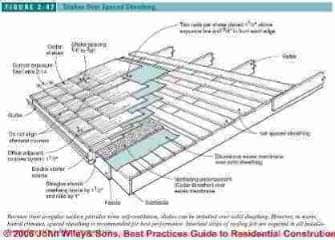

Where allowed, spaced sheathing typically uses nominal 1x4s for shingles or 1x6s for shakes.

Building Codes for roofing reqiure a minimum 1x4, and the spaces between battens should not exceed 3 1/2 inches (Figure 2-46 - wood shingles over spaced sheathing, and Figure 2-47 wood shakes installed over wood sheathing are illustrated below).

[Click any table or image for an enlarged version with more detail.]

The boards are spaced on centers equal to the weather exposure of the shakes or shingles, and they are lined up so the nailing falls in the center of each board. In areas where the average daily temperature in January is 25°F or less, solid sheathing is required on the lower section of the roof to support an eaves membrane.

The eaves membrane should extend into the house 24 inches past the interior face of the outside wall.

Figure 2-47, wood shakes over spaced sheathing is shown below.

Solid Sheathing Required for Wood Roofs in High Wind Areas

This is required in areas of high wind or seismic activity and wherever else a solid roof diaphragm is required by code. Solid sheathing is also recommended in areas subject to windblown snow.

Because of their irregular surface, rustic-style shakes are partially self-ventilating and may perform adequately on solid sheathing in relatively dry climates.

Pressure-treated shingles or shakes can also be installed over solid sheathing. Shingles or smooth-surface (taper-sawn) shakes, however, are more prone to moisture buildup over solid sheathing, so a batten system or a ventilating underlayment is recommended, as described below.

Watch out: having inspected quite a few wood shingle roofs, we find that wood shingle roofs nailed directly to solid plywood or OSB sheathing (that is with no ventilation, battens, etc), while a permitted practice, produces much shorter wood shingle life, sometimes showing severe deterioration: splits, curls, cracks, lost shingle fragments, in as few as four years after new construction - Ed.

Battens Over Solid Sheathing Improve Wood Roof Venting

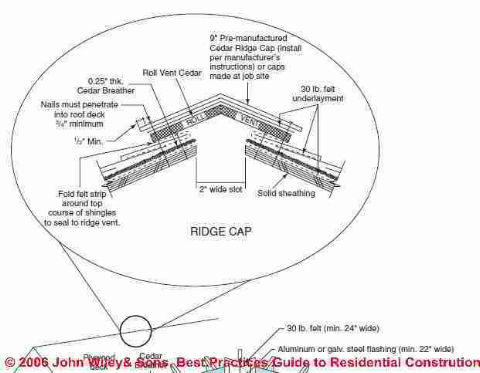

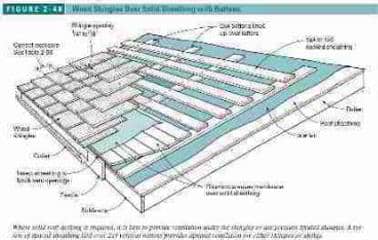

This provides the full benefit of spaced sheathing on top of a solid roof deck. After laying down No. 30 felt underlayment, install vertical 2x battens lined up with the rafters beneath for solid nailing. Next, place horizontal 1x4 or 1x6 battens (see “Spaced Sheathing,” above) and nail into the vertical battens (Figure 2-48 below).

At the upper and lower edges of the roof, use insect screening or matrix-style roof vent material to block the entry of insects and other pests. Shake and shingle installation proceeds as for spaced sheathing.

Wood Shake or Shingle Roof Installation Specifications: Felt Interlay or Felt Underlayment

Underlayment Specifications for Wood Shingle & Shake Roofs

Wood Roof Shingles: Over solid sheathing, use minimum No. 30 felt lapped at least 3 inches horizontally and 6 inches at end laps. Over spaced sheathing, no underlayment is used except at the eaves if eaves flashing is required.

Wood Roof Shakes: Over solid or spaced sheathing, use 18-inchwide “interlayment” strips of No. 30 felt installed between shakes, as described below (Shake Installation, below).

Wood Roof Interlayment Detailed Requirements

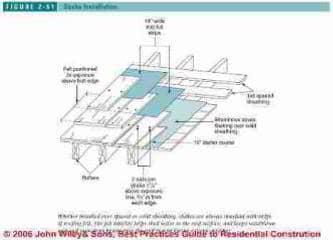

Whether installed over spaced or solid sheathing, shakes should always be interlaid with 18-inch-wide strips of No. 30 roofing felt. The felt strips acts as baffles to keep windblown snow and other debris from penetrating the roof system during extreme weather.

The felt “interlayment” also helps shed water to the surface of the roof. It is important to locate each felt strip above the butt of the shake it is placed on by a distance equal to twice the weather exposure (Figure 2-51).

Placed higher, the felt strips will be ineffective. Placed too low, they will be visible in the keyways and will wick up water, leading to premature failure of the shakes. In addition, follow these guidelines:

- For the starter course, use either a single layer of shakes or two layers separated by a strip of felt interlayment (installed up from the eaves by a distance equal to the weather exposure). Fifteen-inch shakes are available for the bottom layer of a double starter course Each shake gets two nails about 3/4 inch in from each end and 1 1/2 inches above the butt line of the overlaying shake.

- The first course should overhang the fascia by 1 1/2 inches.

- All courses should overhang the rake trim by about 1 inch.

- Leave a gap between adjacent shakes of 3/8 to 5/8 inch for expansion when wet.

- Offset joints in successive courses by at least 1 1/2 inches

Ventilating Underlayments Used with Wood Shingle/Shake Roofs

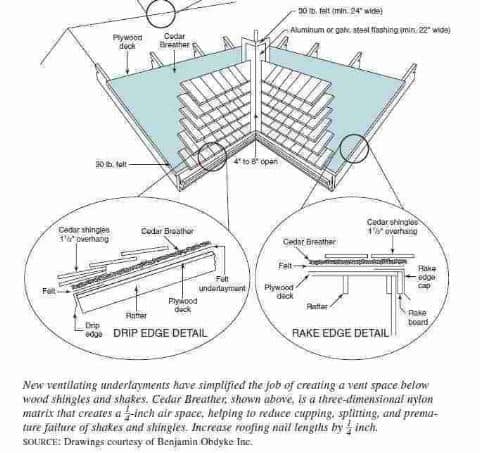

Many installers are shifting to a ventilating underlayment such as Cedar Breather (Benjamin Obdyke), which is easy to install and only adds about 10% to the cost of a wood roof. Cedar Breather is three-dimensional nylon matrix with dimples on the bottom and a smooth top surface.

It lays over the felt paper and is tacked in place. It creates a continuous air space below the roofing, helping the shingles to dry out more rapidly and evenly.

Although the air space is only about 1/4 inch, contractors report that it reduces cupping and splitting. And by speeding up drying time, the air space should also help reduce the growth of decay fungi.

However, ventilating underlayments are too new to draw conclusions about long-term performance. Installation details are shown in Figure 2-49. [Click any table or image for an enlarged version with more detail.]

[Click to enlarge any image]

Eaves Flashing Details for Wood Shingle & Shake Roofs

Apply eaves flashing to either spaced or solid sheathing in regions with an average daily temperature of less than 25°F (under the IRC) or in other areas prone to ice and snow buildup.

The eaves flashing should extend up the roof to a point 24 inches inside the building. Where eaves flashing is required with spaced sheathing, install solid sheathing along the bottom section of the roof to support the eaves flashing.

-- Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

Wood Roof Venting Underlayments

- Benjamin Obdyke www.benjaminobdyke.com Cedar Breather, a 3/8 -in.-thick matrix-type underlayment designed to provide ventilation and drainage space under wood roofing

More Information about Wood Shake & Shingle Roofing Materials, Methods, Standards

- Cedar Shake and Shingle Bureau www.cedarbureau.org

-- Adapted with permission from Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) .

...

Continue reading at WOOD ROOF SHINGLE PROPERTIES or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- SIDING WOOD SHINGLE INSTALLATION

- WOOD SHAKE & SHINGLE ROOFING - home

- WOOD ROOF COATINGS & FIRE RATINGS

- WOOD ROOF FLASHING DETAILS

- WOOD ROOF HIP & RIDGE DETAILS

- WOOD ROOF INSPECTION GUIDE

- WOOD ROOF INSTALLATION SPECS

- WOOD ROOF LIFE EXPECTANCY

- WOOD ROOF MAINTENANCE

- WOOD ROOF MOSS & LICHENS

- WOOD ROOF SHAKES INSTALLATION

- WOOD ROOF SHEATHING, UNDERLAYMENT

- WOOD ROOF SHINGLE PROPERTIES

- WOOD ROOF WEAR / INSTALLATION DEFECTS

- WOOD SHINGLES, RE-ROOFING WITH

Suggested citation for this web page

WOOD ROOF SHEATHING, UNDERLAYMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING ROOFING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about sheathing, nailing, nailing battens, or skip sheathing for wood roofs.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

IF above you see "Comment Form is loading comments..." then COMMENT BOX - countable.ca / bawkbox.com IS NOT WORKING.

In any case you are welcome to send an email directly to us at InspectApedia.com at editor@inspectApedia.com

We'll reply to you directly. Please help us help you by noting, in your email, the URL of the InspectApedia page where you wanted to comment.

Citations & References

In addition to any citations in the article above, a full list is available on request.

- ARMA - Asphalt Roofing Manufacturer's Association - Asphalt Roofing Manufacturer's Association - https://www.asphaltroofing.org/

750 National Press Building, 529 14th Street, NW, Washington, DC 20045, Tel: 202 / 207-0917 - ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA, 19428-2959 USA The ASTM standards listed below can be purchased in fulltext directly from http://www.astm.org/

- Cedar Shake & Shingle Bureau, CSSB, U.S.: Sumas, WA 98295-1178, Tel: 604-820-7700, In Canada: Cedar Shake and Shingle Bureau #2 - 7101 Horne Street, Mission, BC V2V 7A2 Tel: (604) 820-7700, E-mail: info@cedarbureau.com , Web: http://www.cedarbureau.org/

- U.S. Forest Products Laboratory, US FPL, One Gifford Pinchot Drive, Madison, WI 53726, Tel: (608) 231-9200, Email: mailroom_forest_products_laboratory@fs.fed.us608-231-9200, website: http://www.fpl.fs.fed.us/

- NRCA - National Roofing Contractors Association - Website: www.nrca.net 10255 W. Higgins Road, Suite 600, Rosemont, IL 60018-5607, Tel: (847) 299-9070

- UL - Underwriters Laboratories - https://www.ul.com/

2600 N.W. Lake Rd.

Camas, WA 98607-8542

Tel: 1.877.854.3577 / Fax: 1.360.817.6278 E-mail: cec.us@us.ul.com - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Best Practices Guide to Residential Construction, by Steven Bliss. John Wiley & Sons, 2006. ISBN-10: 0471648361, ISBN-13: 978-0471648369, Hardcover: 320 pages, available from Amazon.com and also Wiley.com. See our book review of this publication.

- Decks and Porches, the JLC Guide to, Best Practices for Outdoor Spaces, Steve Bliss (Editor), The Journal of Light Construction, Williston VT, 2010 ISBN 10: 1-928580-42-4, ISBN 13: 978-1-928580-42-3, available from Amazon.com

- The Journal of Light Construction has generously given reprint permission to InspectAPedia.com for this article. All rights and contents are ©Journal of Light Construction and may not be reproduced in any form.

- Wood Shingle Roofs, Care and Maintenance of wood shingle and shake roofs, (EC), Stanley S. Niemiec (out of print)

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.